-

Custom motors!

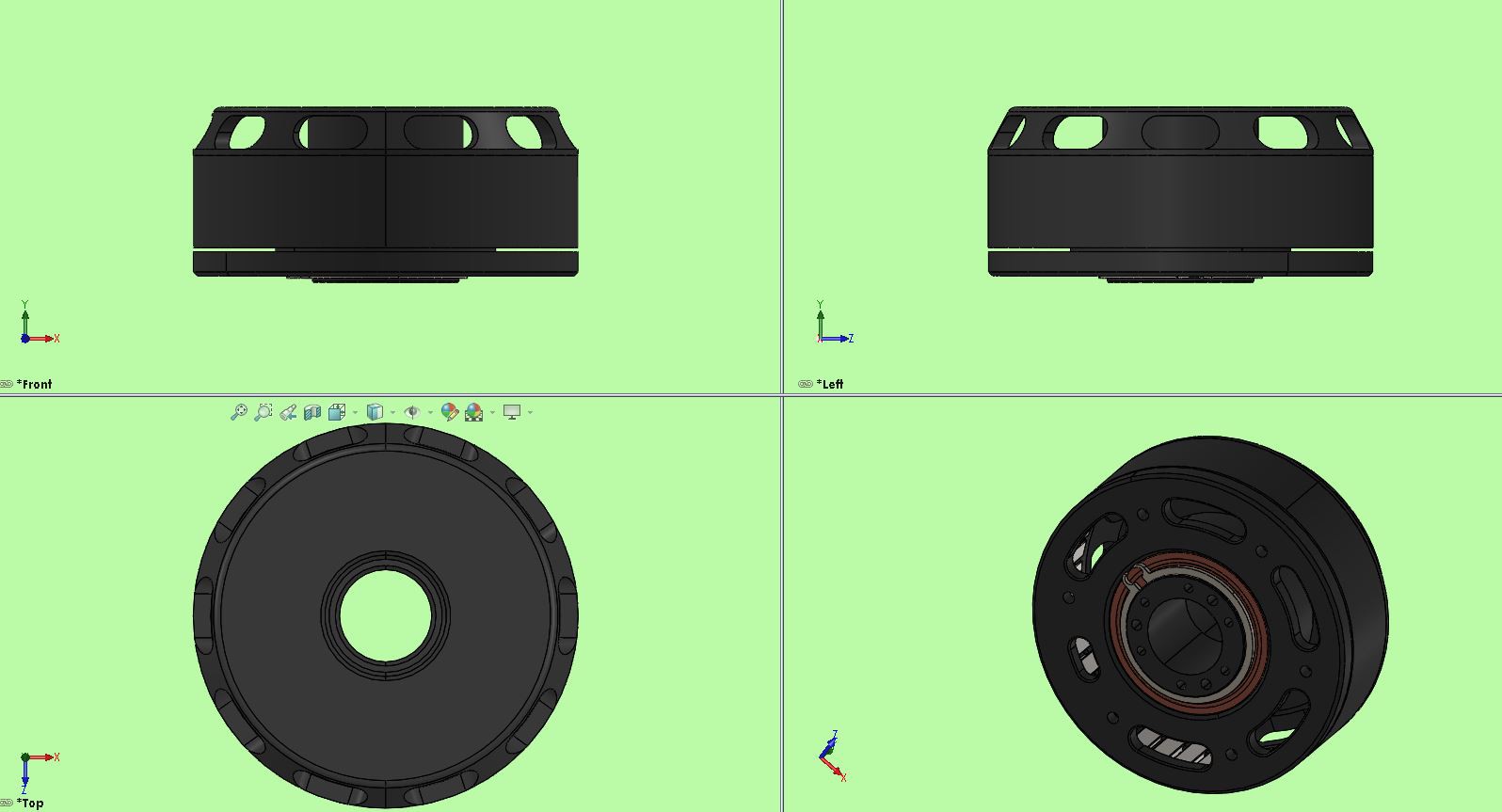

10/27/2018 at 19:52 • 1 commentPlaced an order for my first batch of custom Open HD 8318 motors.

-

Flexspline Racheting

10/03/2018 at 07:27 • 1 commentI thought this would be worth publishing a log about.

While preforming a load test I found that the flexspline will start to rachet if too much reverse torque is applied. I find this interesting, I was under the impression that the first mode of failure with this version of the flexspline would be the teeth shearing off.

I'll be working on a fix for this issue over the next few days. A few ideas in mind have are:

- Use a less ductile TPU (I have various types on hand)

- Change the tooth profile

- Print the teeth and one boundary layer (in Cura slicer "wall line") in nylon and leave the structure of the flexspline printed in TPU

I've also been given a suggestion by Gabrael Levine, the designer of OpenTorque Actuator, to alter the wave generator geometry to keep a preload on the flexspline. I shall see what works best and include it in the next Open HD revision.

-

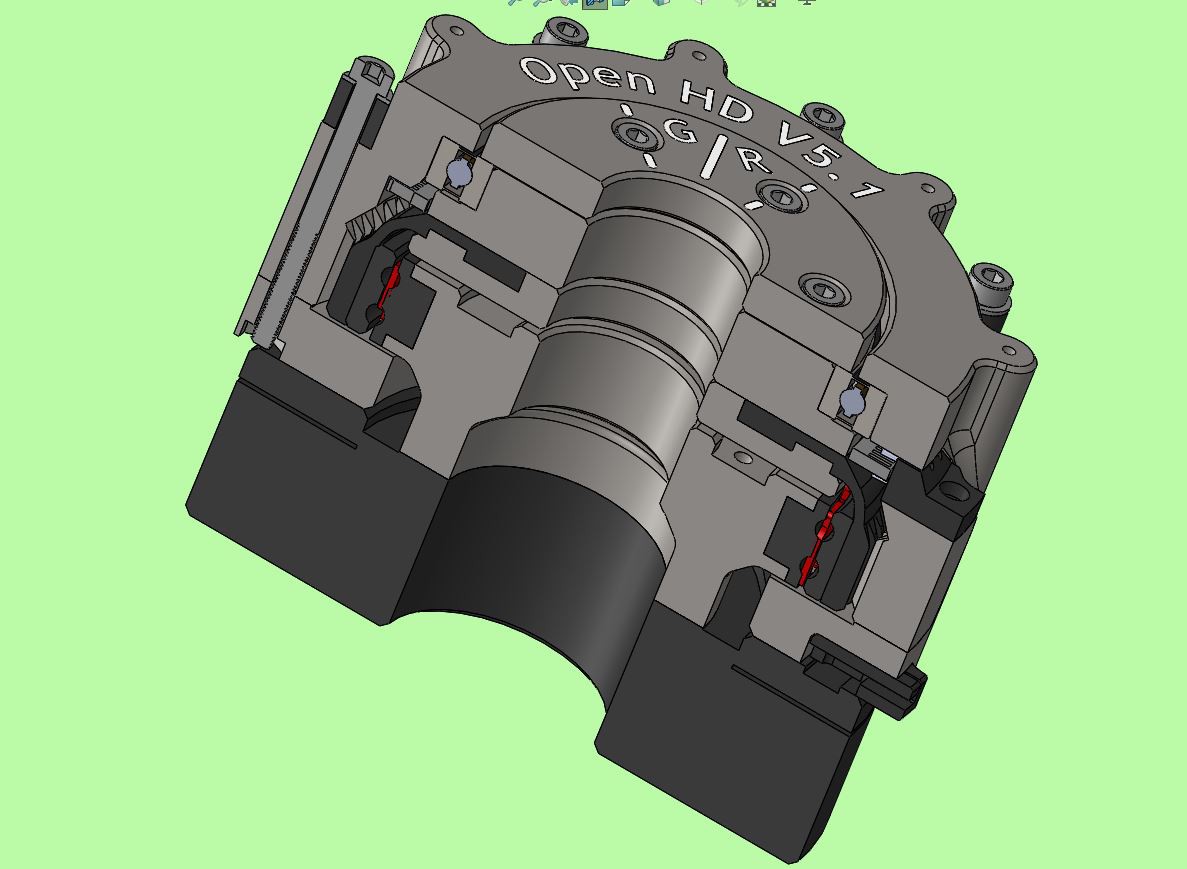

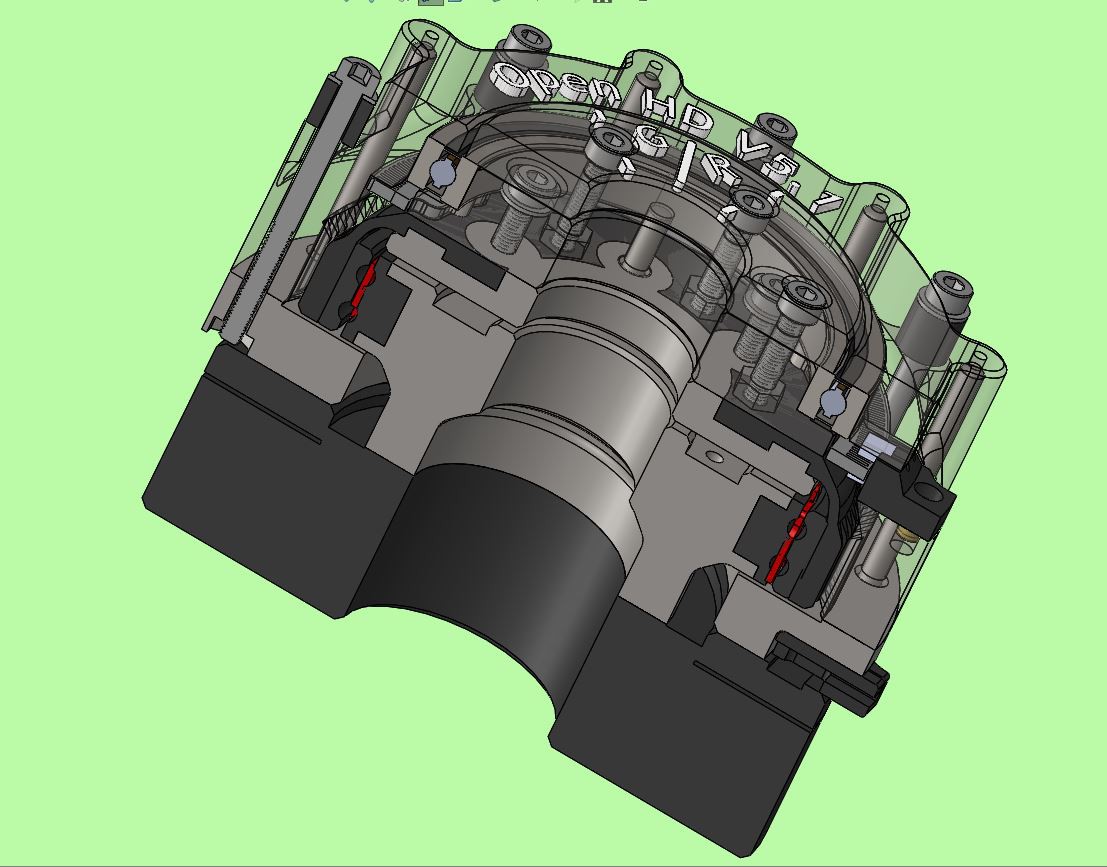

V 5.1

09/17/2018 at 01:47 • 6 commentsV 5.1 is a general refinement sweep

That brings a revised wave generator, fixed spline, and output shaft assembly. There are now 3mm dowel pins of various lengths (40mm, 14mm, 8mm) placed throughout the fixed spline as well as output shaft assembly for precise mating and added structural support.

![]()

Changes to the wave generator were primarily processes focused to make their manufacturing simpler to automate. List of component changes:

- Raceway refinement / re tolerancing on both inner and outer races

- Precision fix so that all component heights are formatted in exact print layer height units

- Ball cage re tolerancing and added a snap-off sacrificial adhesion feature to the bottom layer

- Added 22mm through hole to all output shaft components for slip ring connector

Changes to the fixed spline consisted only of two component changes and some slight procces refinement.

- Added ~2mm to OD to allow for the addition of 3x40mm dowel pins

- Added features for mounting fasteners to the body

Changes to the (upper) output shaft assembly

- Added 22mm through hole for slip ring connector

- Reduced total number of fastening and mounting screws in the upper assembly to from eight m3 to six m3, and in the lower assembly from eight m3 to three m3 as to allow for the addition of indexing and structural dowel pins

- Added Indexing 3x8mm dowel pins to the assembly for precision mounting of the encoder wheel

- Slightly reduced the resolution of the encoder wheel to fix precision error in printing

- Switched the rigid component of the flex spline from being printed in polycarbonate to ABS due to PC cracking repeatedly (TPU and ABS components of the flex spline are printed as a single part)

Integration of the still unfinished encoder head also came with the V 5.1. Currently the encoder head is using a transmissive photointerrupter (link). I will be switching to a Broadcom reflective sensor in the future, but for now I have some stock of the EE-SX1108 and they work fine as a placeholder till then.

-

Integrated Motor Running

08/11/2018 at 00:40 • 0 comments -

Open back operation

08/11/2018 at 00:37 • 0 comments

Open HD

A high torque, high precision, Strain Wave Gear (harmonic drive) based 3D printable closed loop servo actuator for use in robotic arms

Sam Armstrong

Sam Armstrong