-

Fun Experiment with New PCB

08/07/2021 at 19:37 • 0 comments![]()

You can find the assembly Instruction and more details on my Instructables page

![]()

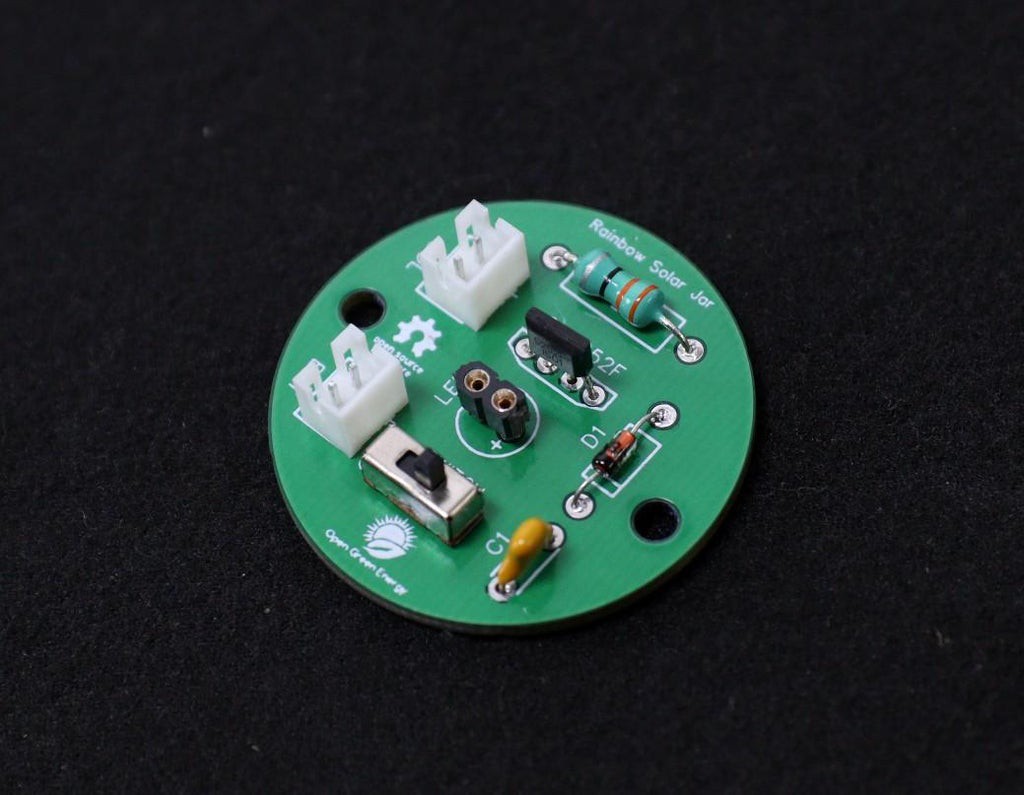

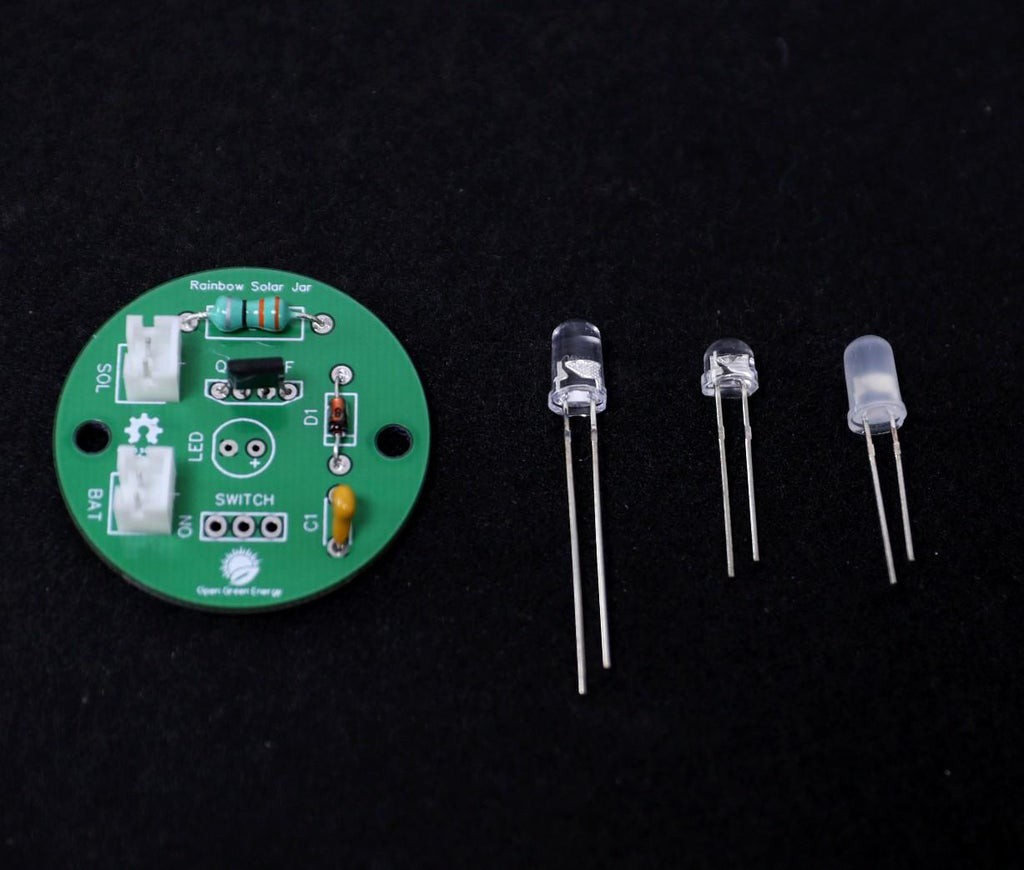

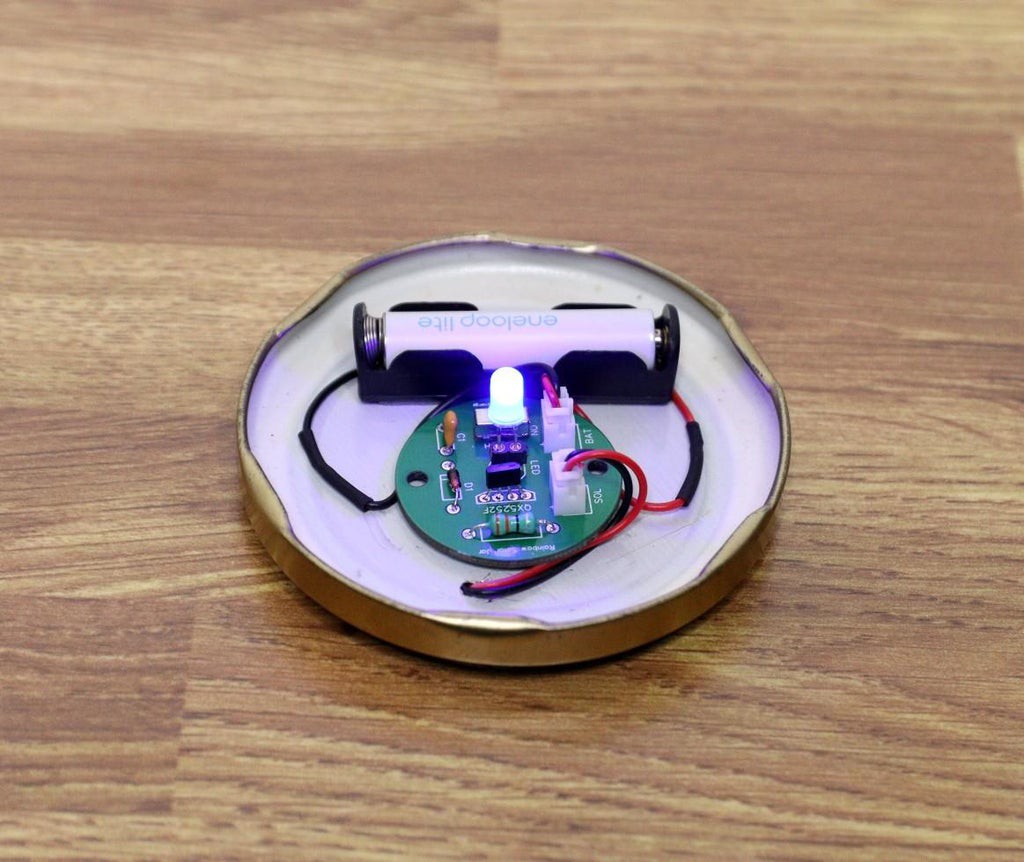

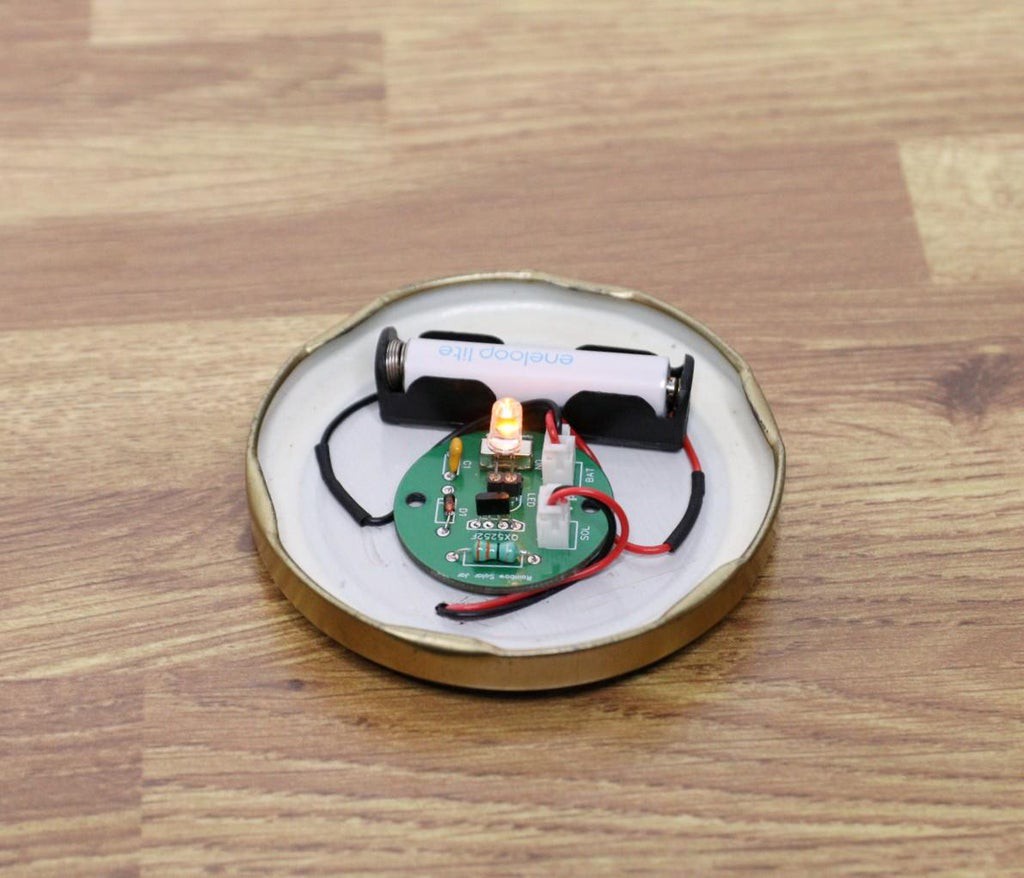

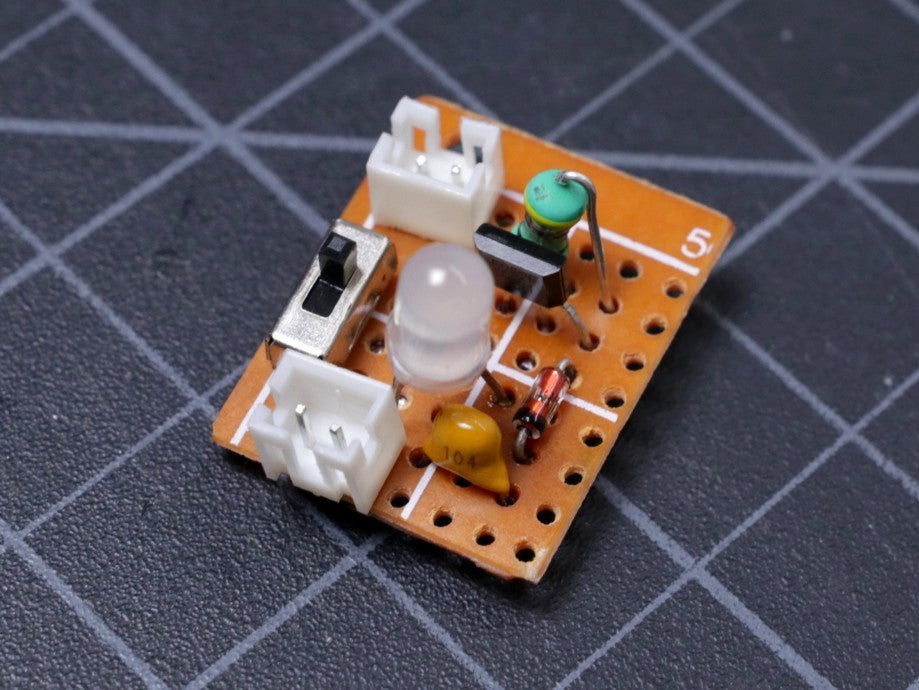

We can solder a 5mm LED onto the PCB directly. But to test a different kind of LED, here I have soldered a two-pin female header. By using this, I can easily swap between different kinds of LEDs one by another.

In the next few steps, I will test with the following LEDs:

1. Strawhat LED

2. Colour Changing RGB LED

3. Candle Flickering LED

4. Fairy String Light

![]()

![]()

![]()

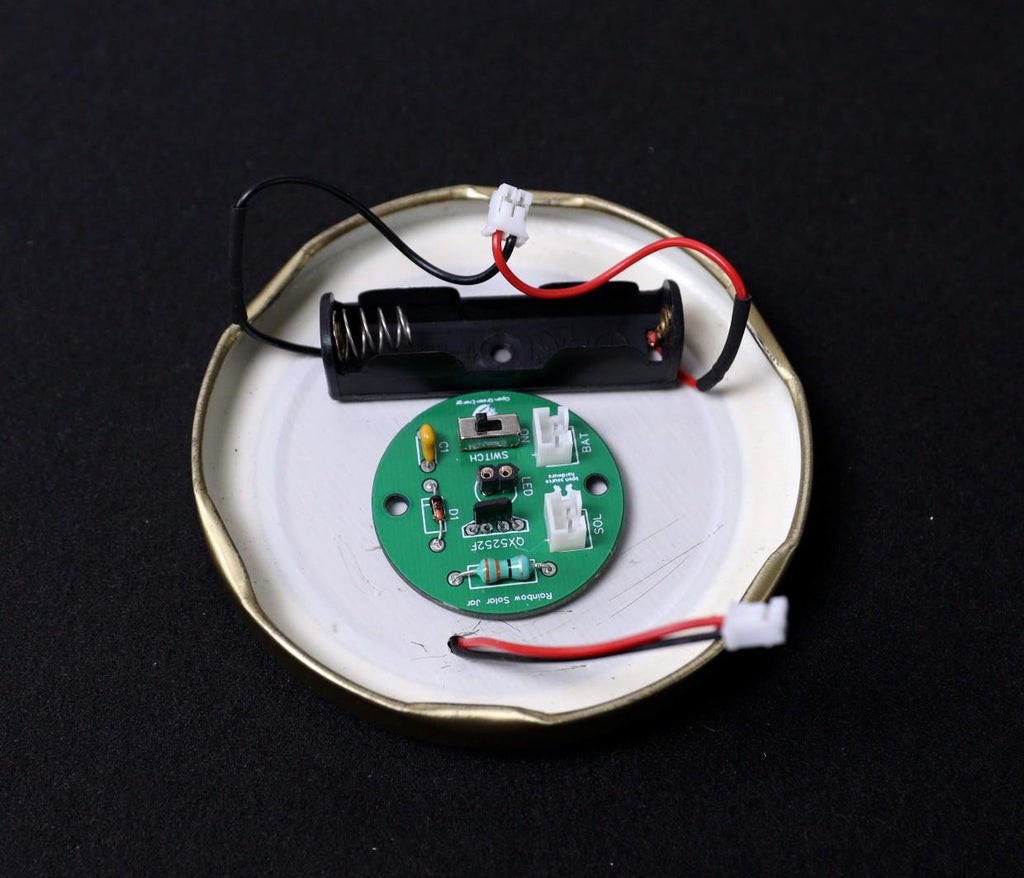

Now slide the solar lamp switch to ON position and then place the Jar in the bright sunlight.

The solar cell will charge the battery.

1. Strawhat LED :

![]()

![]()

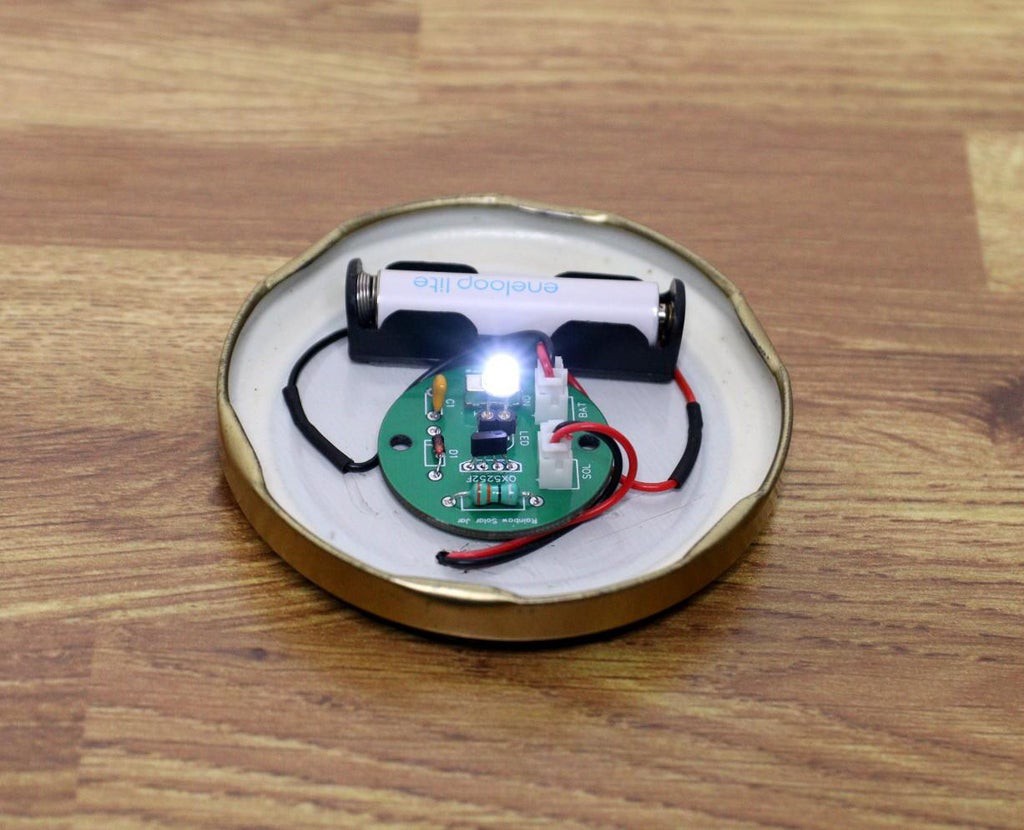

For a quick test, insert the LED into the female header.

Then slide the solar light switch to the ON position and cover the solar cell with your hand. The light should be turned ON.

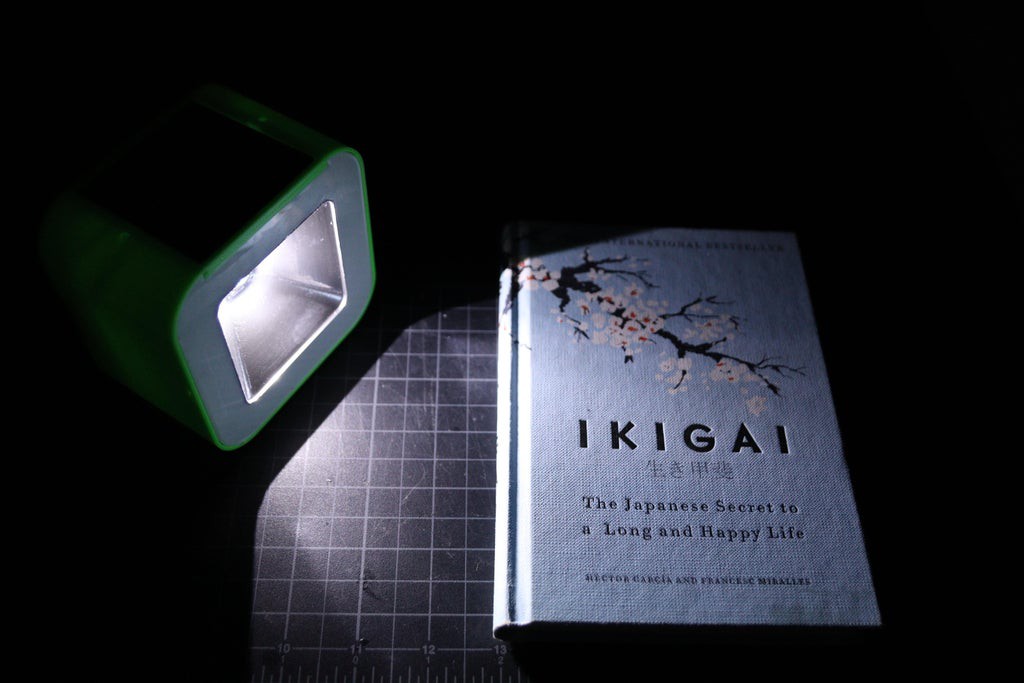

Here I have used the 5mm Strawhat LED. The output of the lamp resembles a flashlight.

2. Colour Changing RGB LED:

![]()

![]()

![]()

You can use your creativity to produce various attractive effects on the lamp.

I have filled the jar with acrylic pebbles to get the glittering effect.

![]()

![]()

![]()

![]()

Here I have a two-pin RGB LED. Insert the LED into the female header.

Then close the glass jar lid and enjoy the slow and fast color-changing rainbow effect.

The acrylic pebble scattered the light in different directions which looks very attractive.

3. Candle Flickering LED:

![]()

![]()

![]()

Insert a candle flickering LED into the female header in the PCB.

Close the lid, and see the flickering effect.

Then I have added the acrylic pebbles, to get the more attractive light effect.

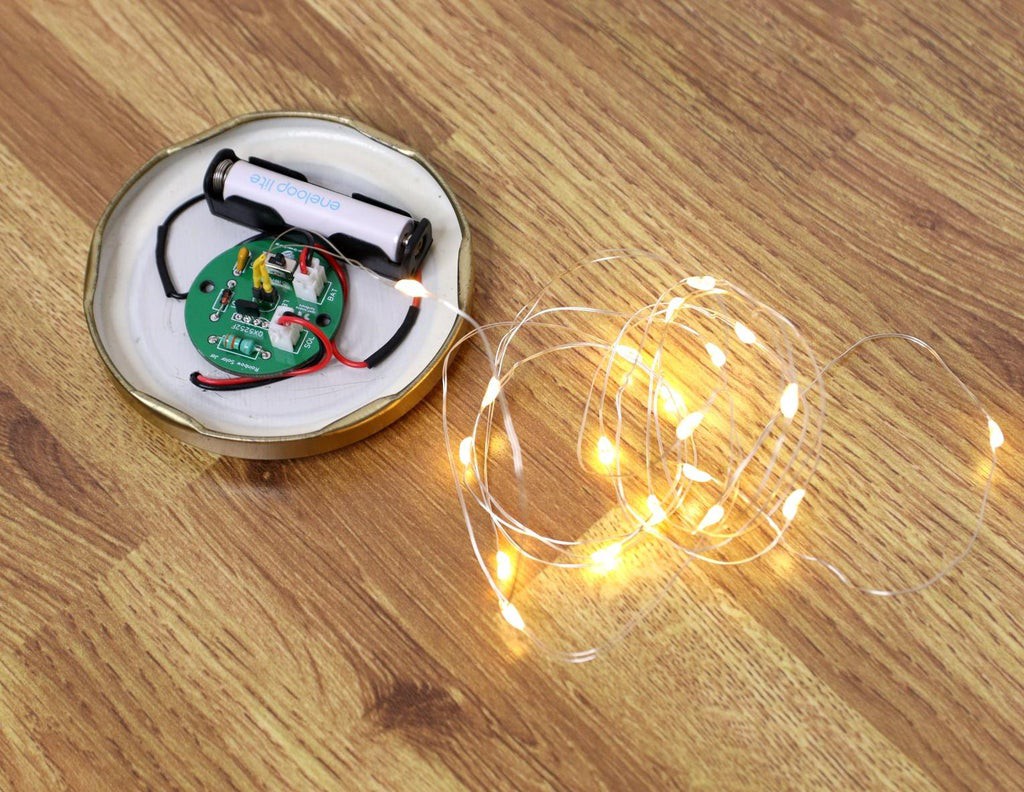

4. Fairy String Light :

![]()

![]()

Initially, I was not sure, whether the PCB will support a fairy string light or not. But when I tested it, I was really amazed that it works with charm. But I will recommend you not use too long a string, because it may exceed the current handling capability of the IC QX5252F.

First I cut the fairy string light from the battery box. Then stripped out the insulation from the terminal wires.

Then insert it into the female header to connect the LED. Place the string light inside the Jar and it's done.

You can make a few similar jars and place them in your garden or lawn. Now enjoy your new solar jar.

-

Testing

08/07/2021 at 19:09 • 0 comments![]()

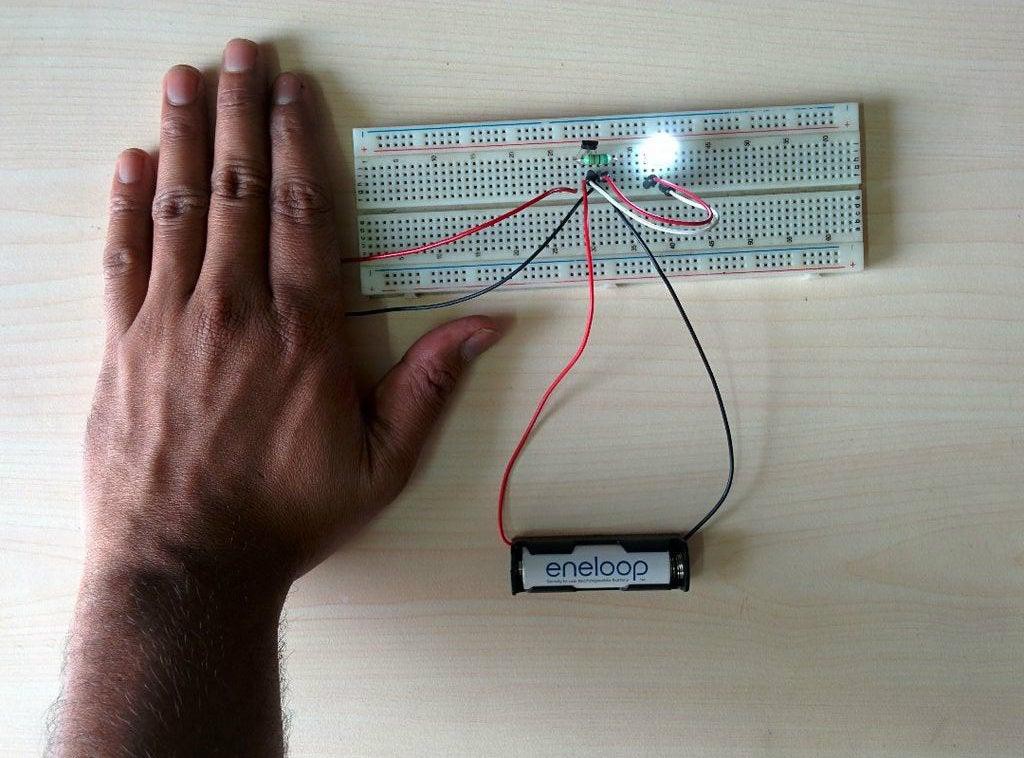

![]()

![]()

![]()

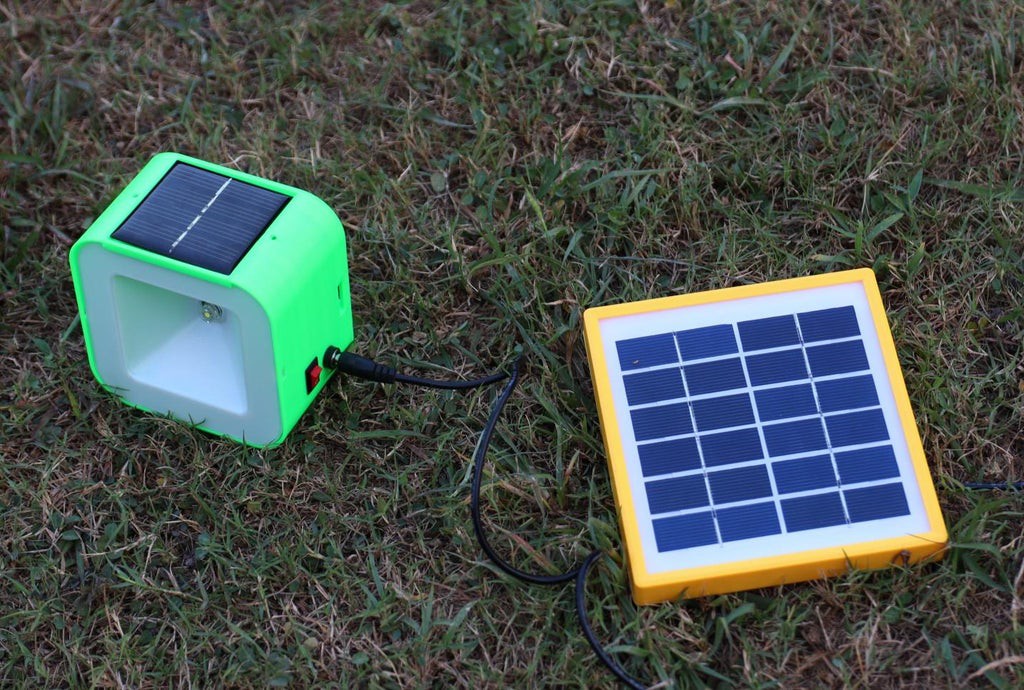

To test the lamp, cover the solar panel with your palm, the LED should glow. If the LED lights up, then the circuit is working perfectly.

Before using the lamp, it is recommended to charge the battery in bright sunlight.

You can place the lamp outside or you can keep the lamp inside and use an external solar panel (4 to 5V) to charge the lamp.

Hope my solar light bulb will give light to many rural people around the globe.

-

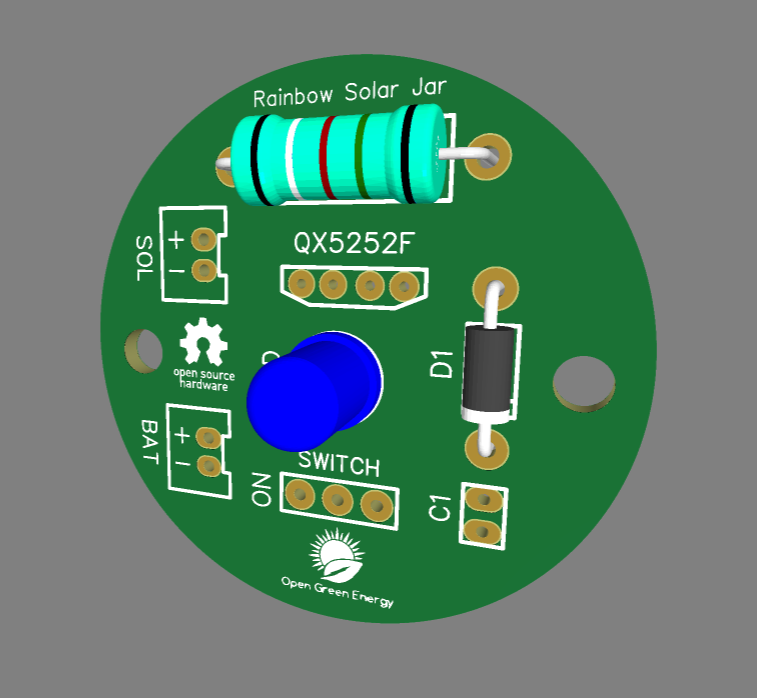

PCB Design With Color Changing LED

08/01/2021 at 06:59 • 0 comments -

Driving a Color Changing LED

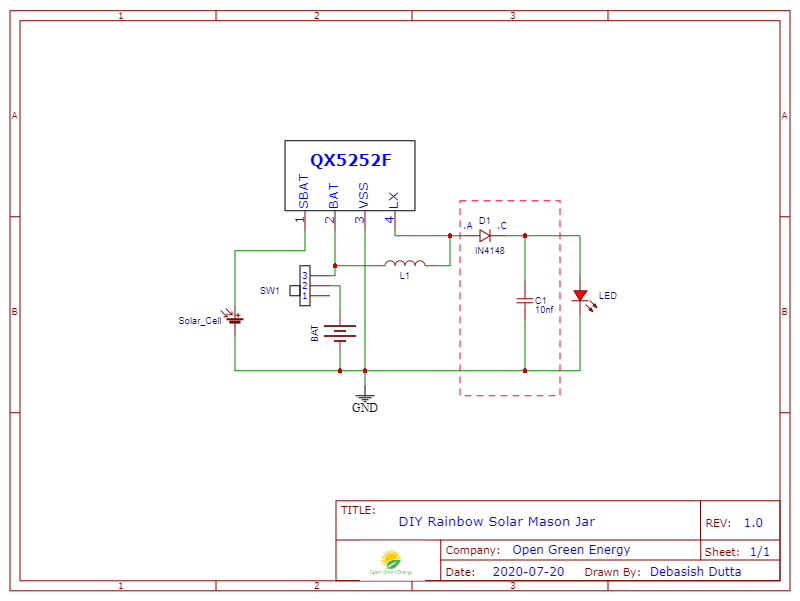

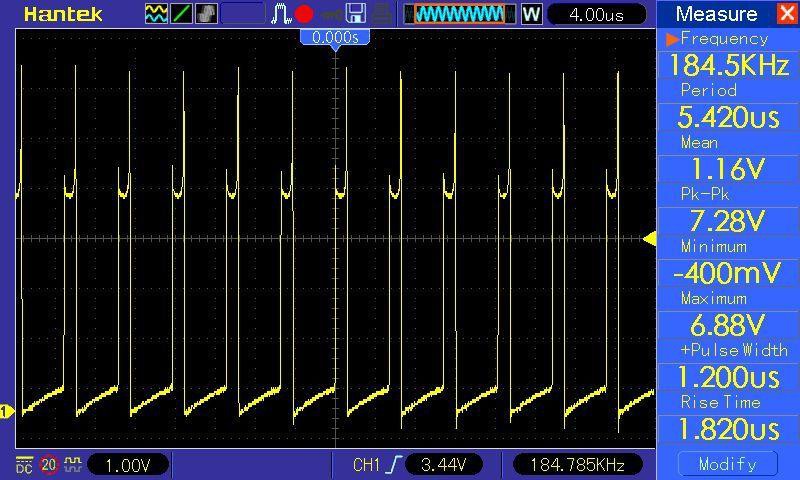

07/31/2021 at 19:39 • 0 comments![]()

![]()

In the reference circuit diagram, the configuration is powerful enough to drive a white LED. But if you connect an RGB LED, instead of white you will notice that the RGB LED lights up however it doesn’t cycle through red green blue color.

The circuit is not working because the output from the circuit is not a steady DC output rather it is a high-frequency pulsating signal. In my breadboard prototype with only one LED, the configuration oscillates near 184.5KHz (see the image).

How to fix this Issue?

To fix this you need to add a buffer circuit at the output.

The buffer circuit is just a diode ( 1N4148 ) and a capacitor (10nF ) at the output before connecting the LED. The diode keeps the capacitor charged when the pulsating signal goes to 0 volts.

After adding the buffer circuit, you can notice that the RGB LED cycles through all 7 colors. Now you connect the oscilloscope at the LED terminal, the output is DC current with a little amount of ripple signal which is adequate for driving the RGB LED.

-

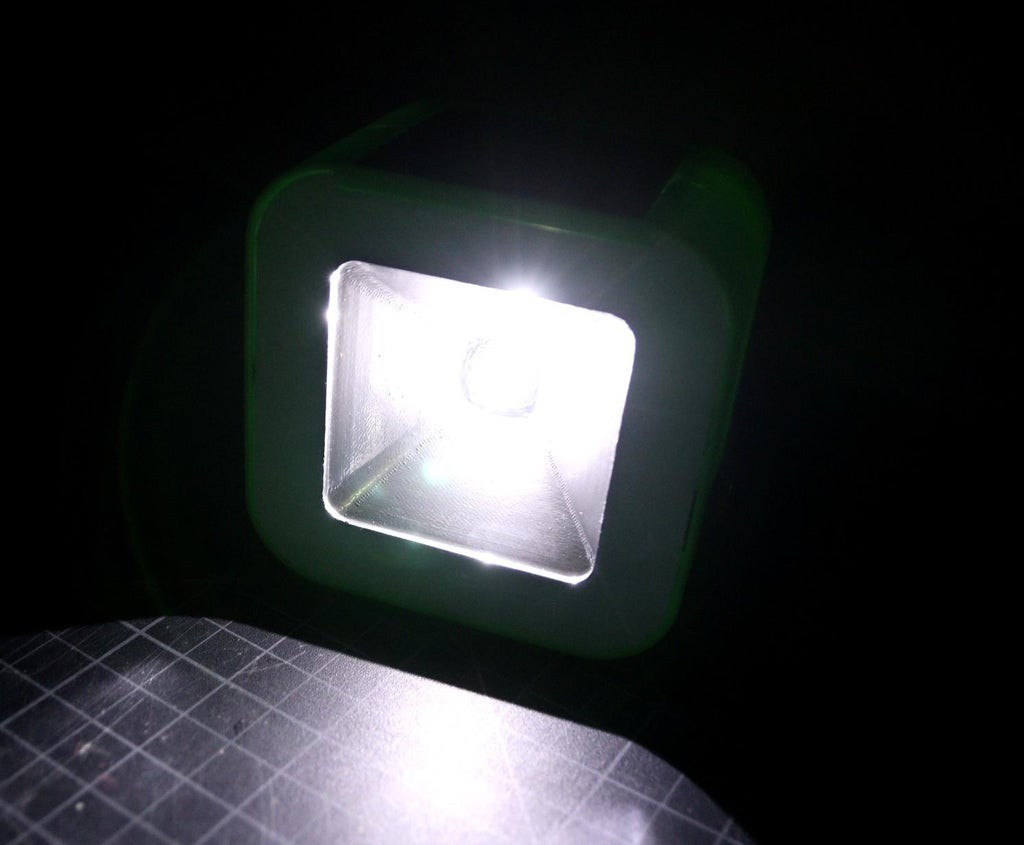

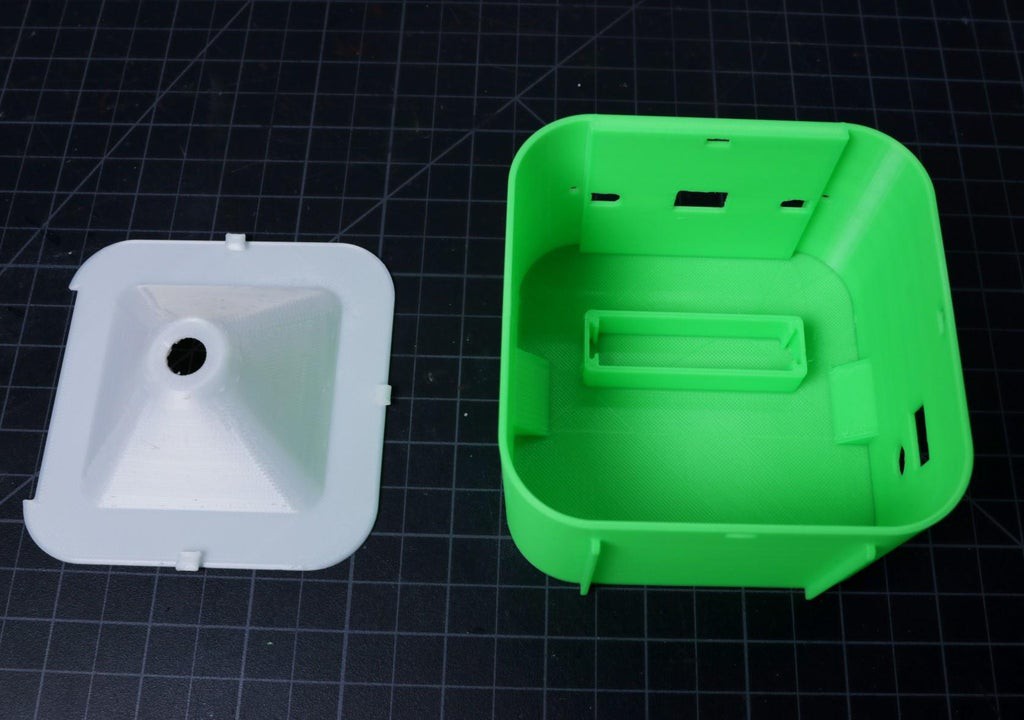

Printing the Enclosure

07/31/2021 at 19:31 • 0 comments![]()

![]()

I have used my Creality CR-10 Mini printer and 1.75 mm Green and White PLA filaments to print the parts. It took me about 5 hours to print the main body and around 2 hours to print the front reflector.

My settings are:

1. Print Speed: 60 mm/s

2. Layer Height: 0.2mm ( 0.3 also works well)

3. Fill Density: 25>#/p###

4. Extruder Temperature: 200 deg C

5. Bed Temp: 60 deg C

-

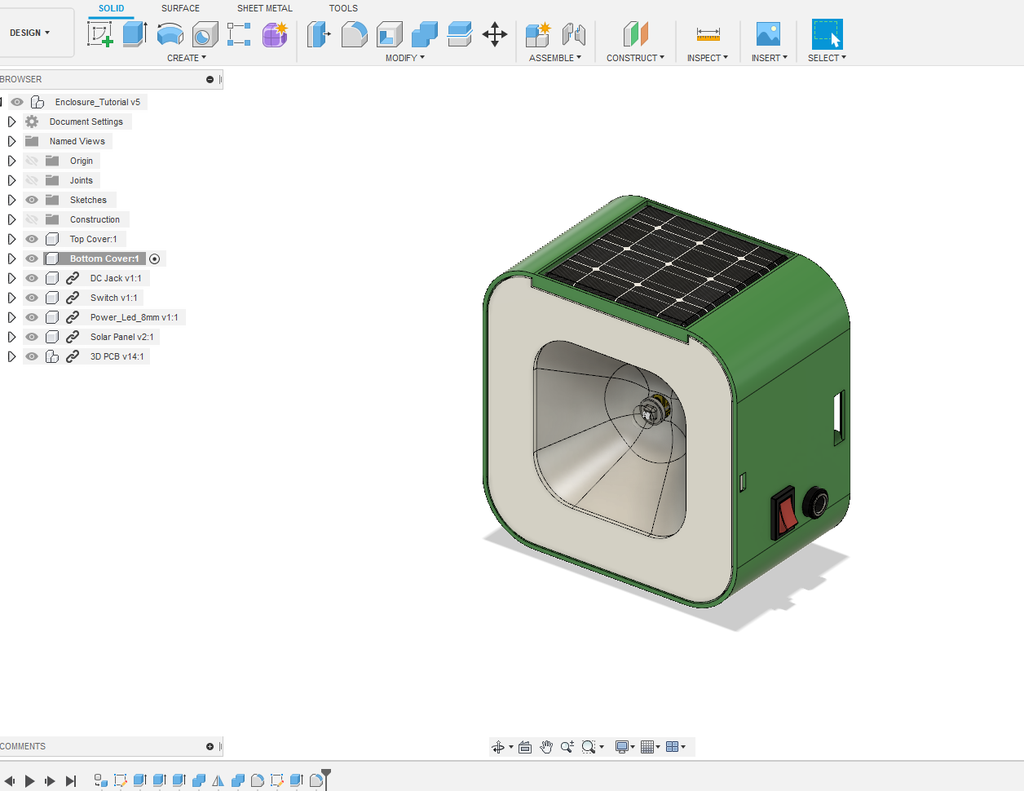

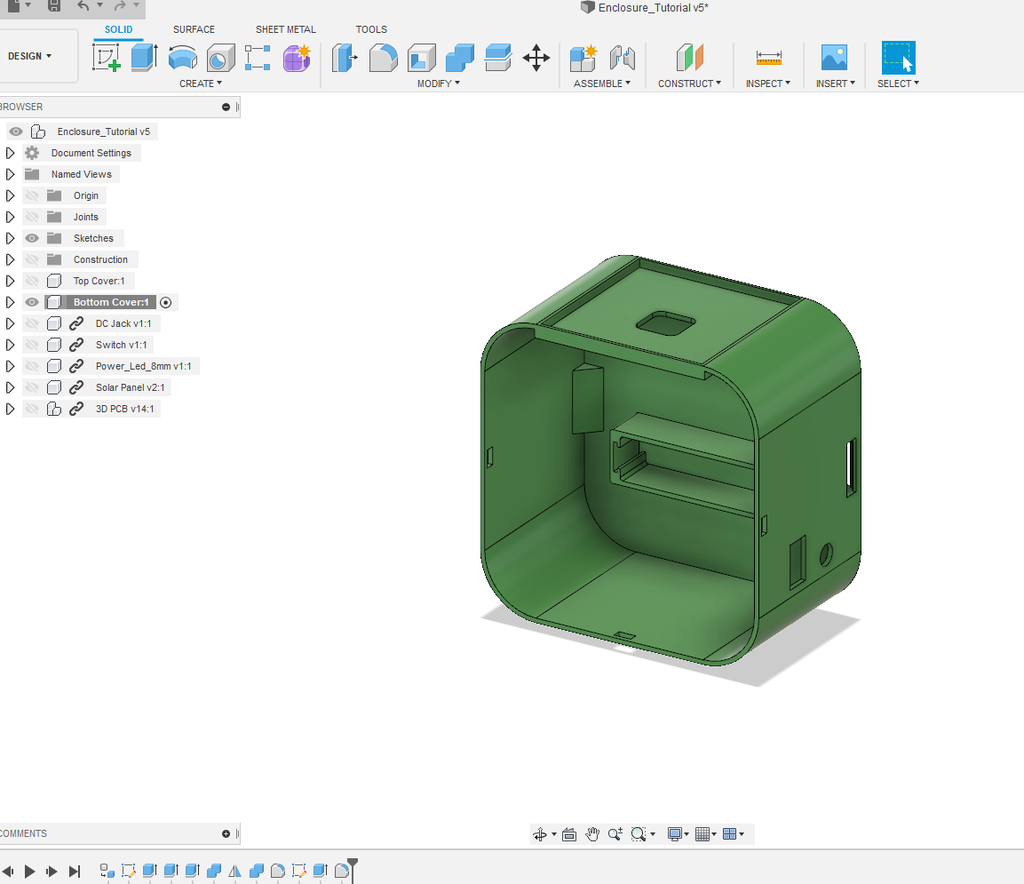

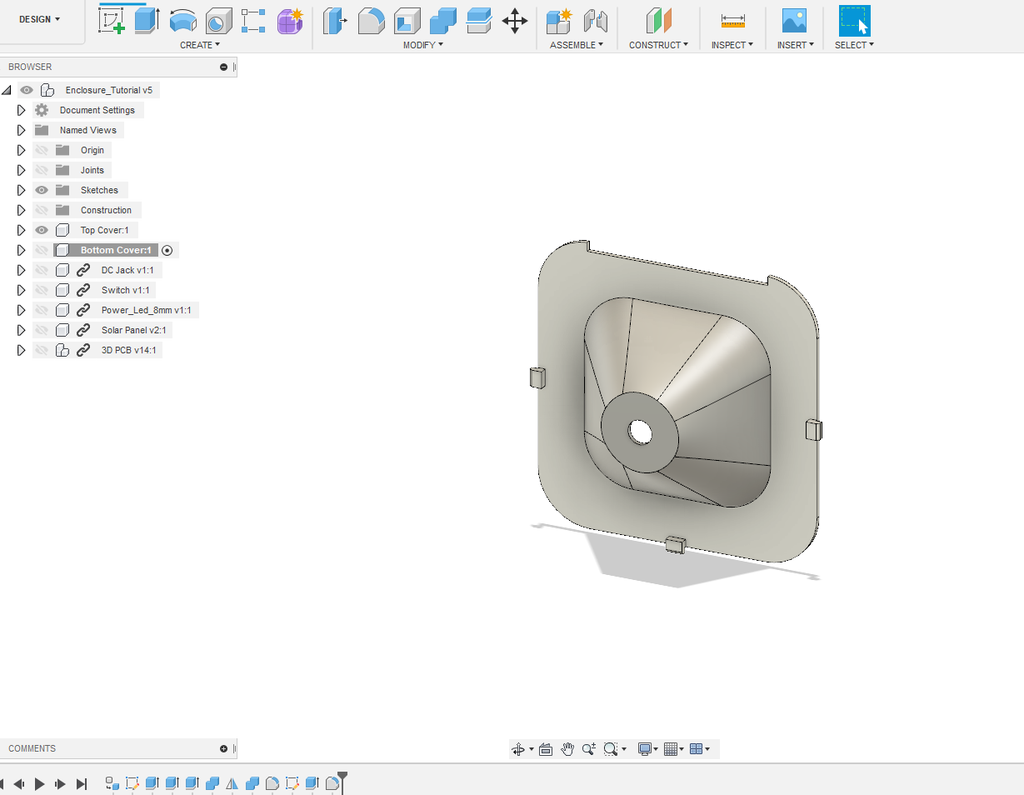

3D Printed Enclosure Design

07/31/2021 at 19:30 • 0 comments![]()

![]()

![]()

To give a nice commercial product look, my friend " VARUN" has designed this enclosure for this project. He used Autodesk Fusion 360 to design the enclosure.

The enclosure has two parts:

1. Main Body

2. Front Cover

The Main Body is basically designed to fit all the components including the battery. The front cover is to covers up the main body and serves as a reflector to spread the light from the LED.

Download the.STL files from Thingiverse.

-

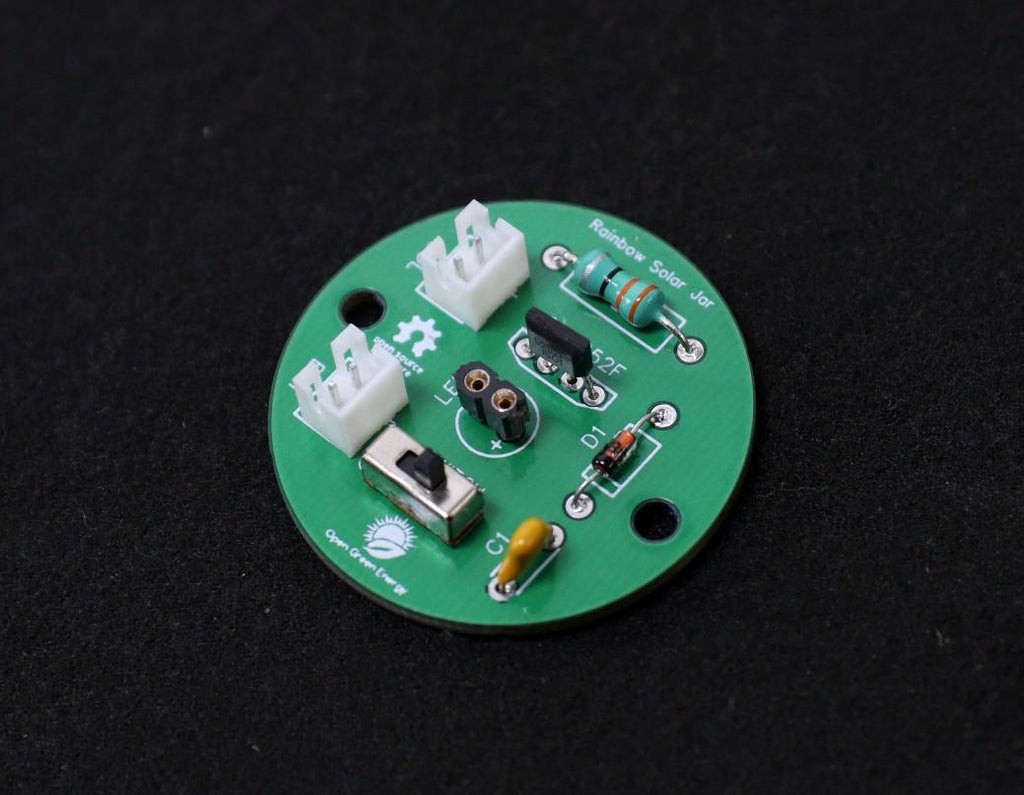

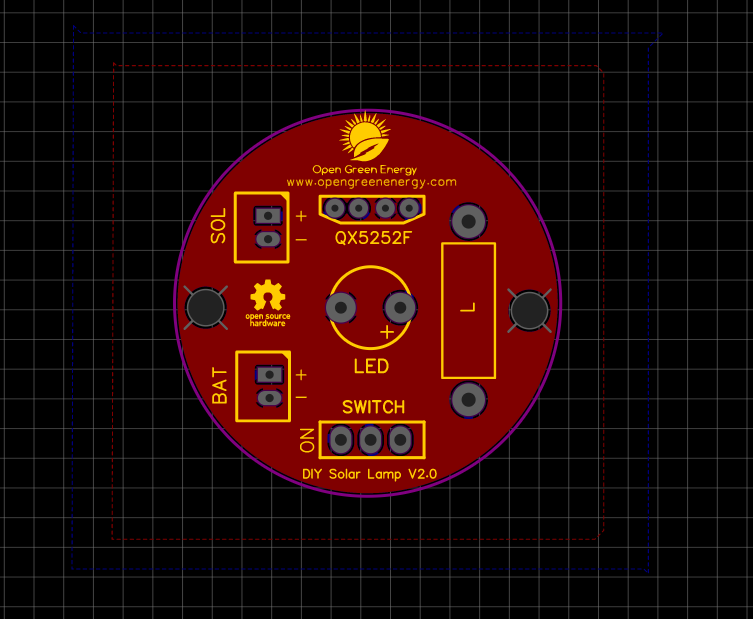

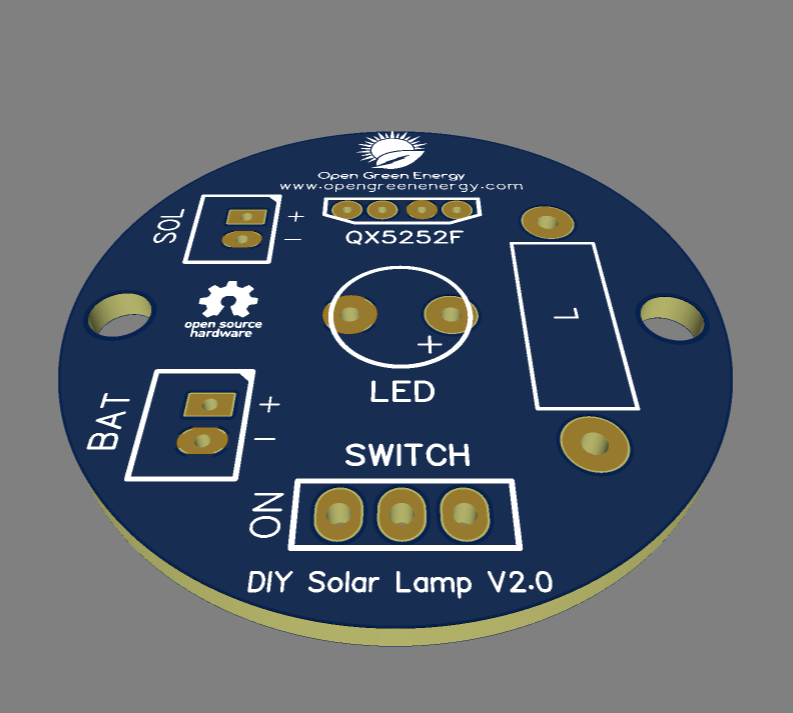

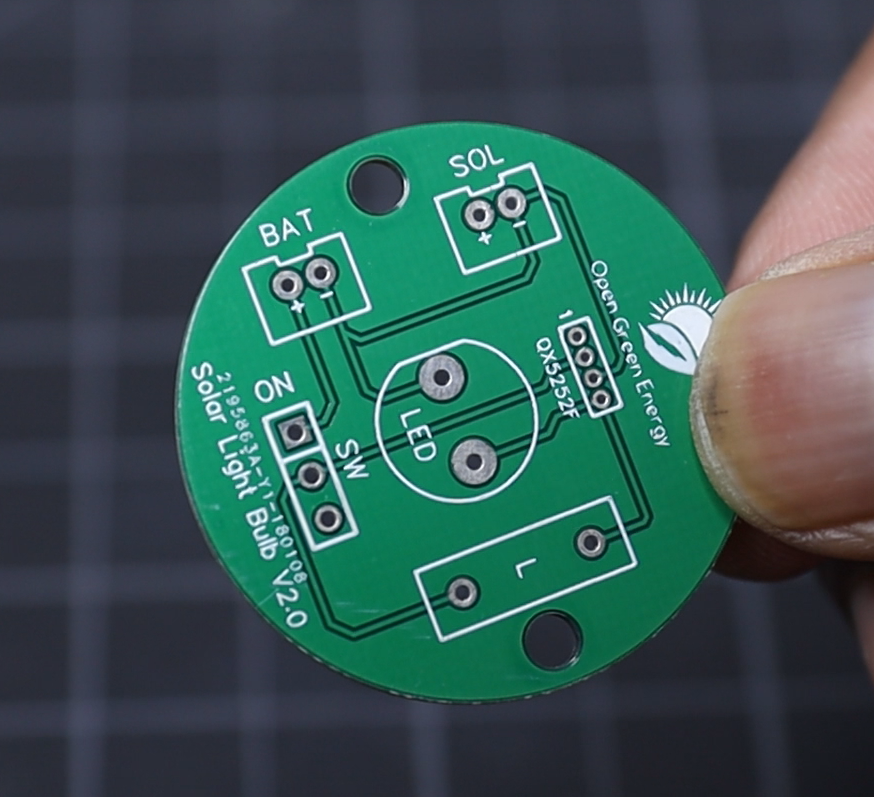

PCB Design

07/31/2021 at 19:26 • 0 comments -

Output Waveform and Observation

07/31/2021 at 18:53 • 0 comments![]()

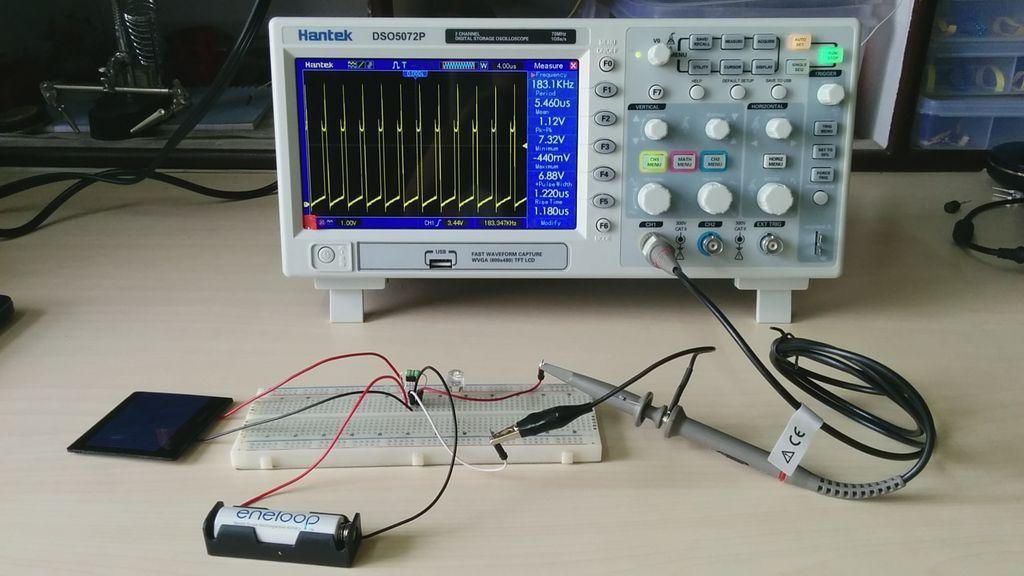

![]()

To check the performance of the circuit, remove the LED and hook up the oscilloscope probes.

You will observe that the output is not a steady DC voltage rather it fluctuates rapidly. In my case, the frequency is around 184.5 kHz. The peak to peak voltage is nearly 7.28 V and the average value is around 1.0 to 1.20V.

Note: If you try to measure the voltage by a normal multimeter, it will show near to your battery voltage.Because your meters only measure the average value of a fluctuating voltage.

-

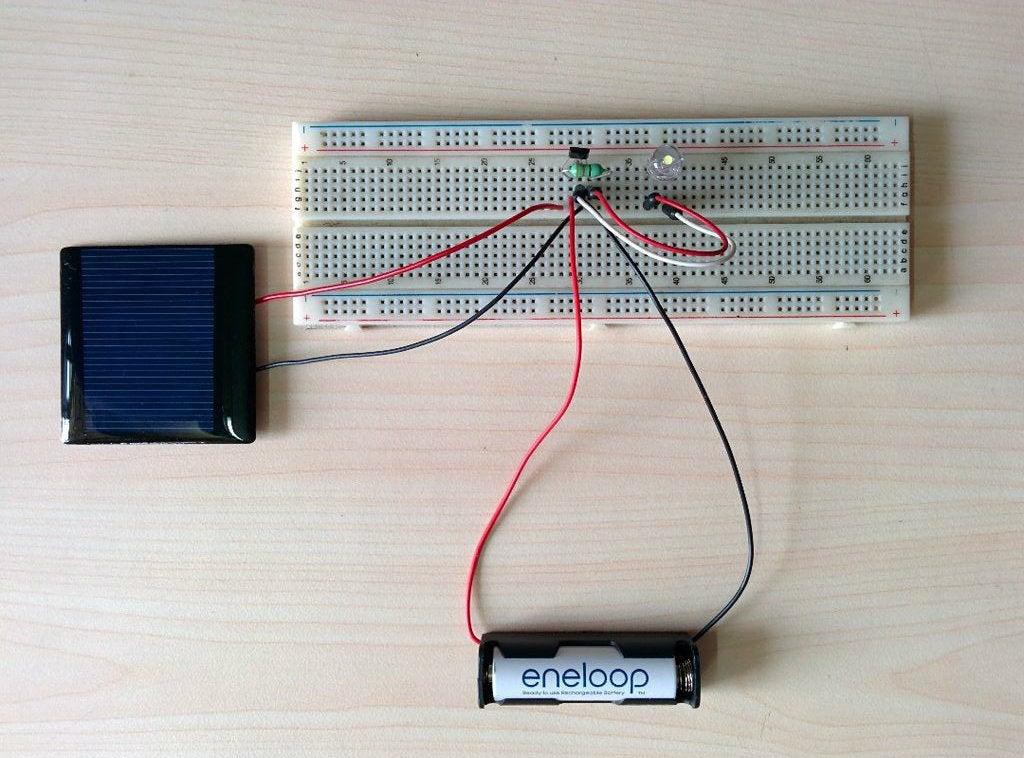

Breadboard Testing

07/31/2021 at 18:51 • 0 comments![]()

![]()

Before finalizing the circuit, It is always a good idea to prototype the circuit on a breadboard. This lets you check to make sure that all of your components are working perfectly.

Make the circuit on your bread bard as per the schematic. The LED should not glow if the circuit is correct. To simulate the dark condition, cover the solar panel with your palm. Now the LED should glow.

-

Controller Selection

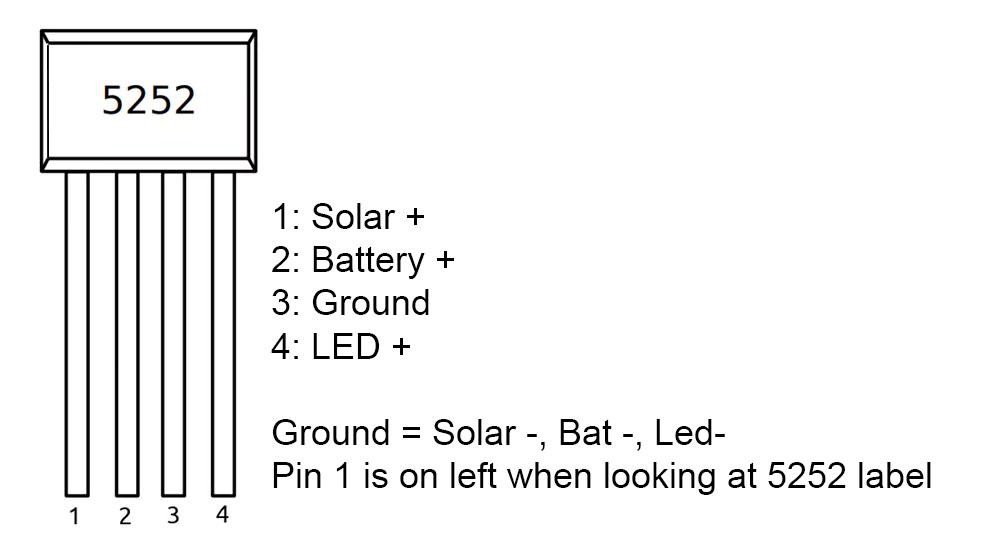

07/31/2021 at 18:47 • 0 comments![]()

The controller has two tasks

1. Charging the Battery:

Isolate the Solar Panel and Battery when the battery is fully charged and Isolate the load from the Battery when the battery voltage is low.

2. Driving the LED:

Capable to drive the selected LED ( ability to handle the required voltage and current ) i.e Boost the battery voltage ( 1.2V ) to LED operating voltage (3.2V) or higher

Here we will use a cheap QX5252F IC as a controller.

The main features are:

1.Suitable for a single AA NiMh/NiCd battery

2.Operating Voltage: 0.9V-1.5V

3.Output current: 3mA-300mA ( Our requirement is 93.7mA )

4.Integrated Schottky Diode

5.High Efficiency up to 84>#/p###

6.Low quiescent current: 17uA ( When the circuit is not working / standby )

7.Only an external inductor is required for making the Circuit

DIY SOLAR SOLAR LAMP

A low-cost solar lamp that can be used as a replacement for harmful kerosene lamps and a learning Kit for STEAM Education.

Open Green Energy

Open Green Energy