-

A Competition for Robotic Speedboats

10/24/2021 at 13:02 • 0 commentsIn this log, we present a competition for robotic speedboats. The competition's main purpose is to engage participants in mechanical design and autonomous control and system design. There are similar competitions to this one but they use less dynamic environments (i.e. on ground or in flat waters). These competitions ultimately have the same goals but all of them have a much higher budget cap, reducing the target audience.

The powertrain, hull size, and hydrofoiling should be regulated as they dramatically increase the cost of the platform and would offer advantages to teams with higher budget caps. Since this is a competition intended for learning, the hull design and waterjet design are free for each participating team to modify.

Challenges

There are two types of challenges in this competition, static and dynamic. Static challenges are challenges that can be completed without the boat running. This includes deliverables like a design report, and the cost optimization challenge. These challenges are intended to make participants go through a proper design process and think about how different designs can affect the performance of the platform. More points are awarded to a lower cost platform. The design report is used to encourage teams to explain the methodology behind their design and is judged based on depth of technical knowledge and completeness of the design process. The second type focuses on dynamic challenges. These are challenges that require the boat to run with full autonomy. These challenges include a drag race to dictate hull and jet efficiency via acceleration and top speed in a straight line. The drag race consists of a starting gate and a buoy located at a distance. Each boat is timed to evaluate how long the boat takes to reach the buoy and return to the starting gate. Then there is the sprint race which aims to evaluate performance of the boat over dynamic conditions, including pitch and yaw control and roll stability. For the sprint race each boat autonomously navigates itself around an unknown course with colour coded buoys that help with navigation. The final event is the endurance event where each boat is run over a long distance to test the robustness of the autonomous algorithm and the boat efficiency and robustness. An example layout of the competition course can be seen above.

Scoring

The scoring for individual challenges (S_ch) in the competition is calculated from the teams score in a challenge (S), the best performer for that challenge (T_s), and the maximum available points for that challenge (Max_ch), as reported in Table \ref{table2}. This formula can be seen in the equation below, where the final score associated with a challenge is calculated. The overall competition score for a team (S_total) is calculated from the formula seen below and is the sum of all the points from all challenges.

-

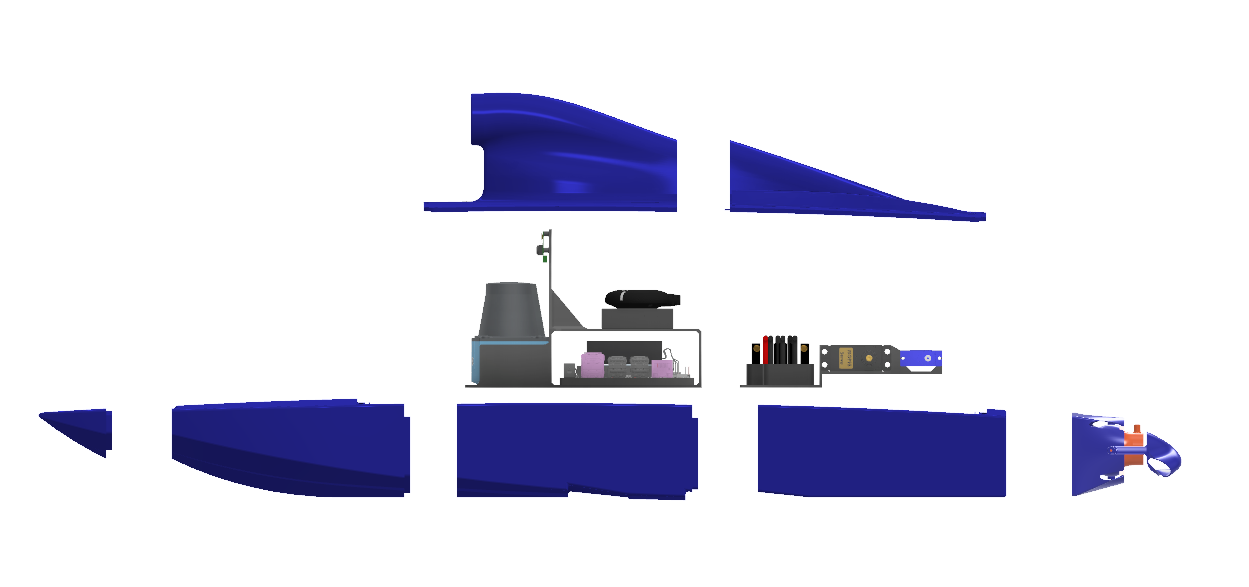

Control / Sensing Hardware & Cost of Components

10/22/2021 at 17:45 • 0 commentsTo enable autonomous control of the platform we equip the platform with various sensors. In particular, the platform uses a 2D LiDAR (SICK TM510 LiDAR) and a monocular camera (Raspberry Pi Camera). These two sensors allow for detection of objects and landmarks in the environment. The two are used in conjunction with one another to increase the robustness of the computer vision system as neither LiDAR or RGB imaging offer great performance in dynamic environments with reflections like water. There are also two on-board IMUs, a GPS, and a magnetometer (provided by a Pixhawk 4 and Pixhawk 4 GPS Module) that provide the estimated pose of the platform. These sensors can also be used for active stabilization to further increase stability and reduce the chance of capsizing.

A dedicated on-board computer (Nvidia Jetson Nano) can be used to collect and process all of the sensor data and generate movement commands for the on-board flight controller (Pixhawk 4), which interacts with all of the actuators on-board the speedboat. A block diagram presenting the interactions between the propulsion, control and sensing components can be found in Fig. \ref{hardware}.

The main propulsion power of the boat comes from two waterjets powered directly by brushless DC motors. These motors are controlled by electronic speed controllers (ESC) that receive a PWM signal from the on-board flight controller. Both systems are water-cooled from an outlet on the jet housing. Four servo motors control steering of each waterjet and the forward/reverse motion via reversing buckets. Actuators are powered by lithium-polymer batteries.

The costs of all components are presented in the table above. The Jetson Xavier NX and Sick LiDAR were not included due to cheaper alternatives that serve the same purpose with similar ability. The motors and ESC do not need to be as powerful with less than 50\% of their power being used.

-

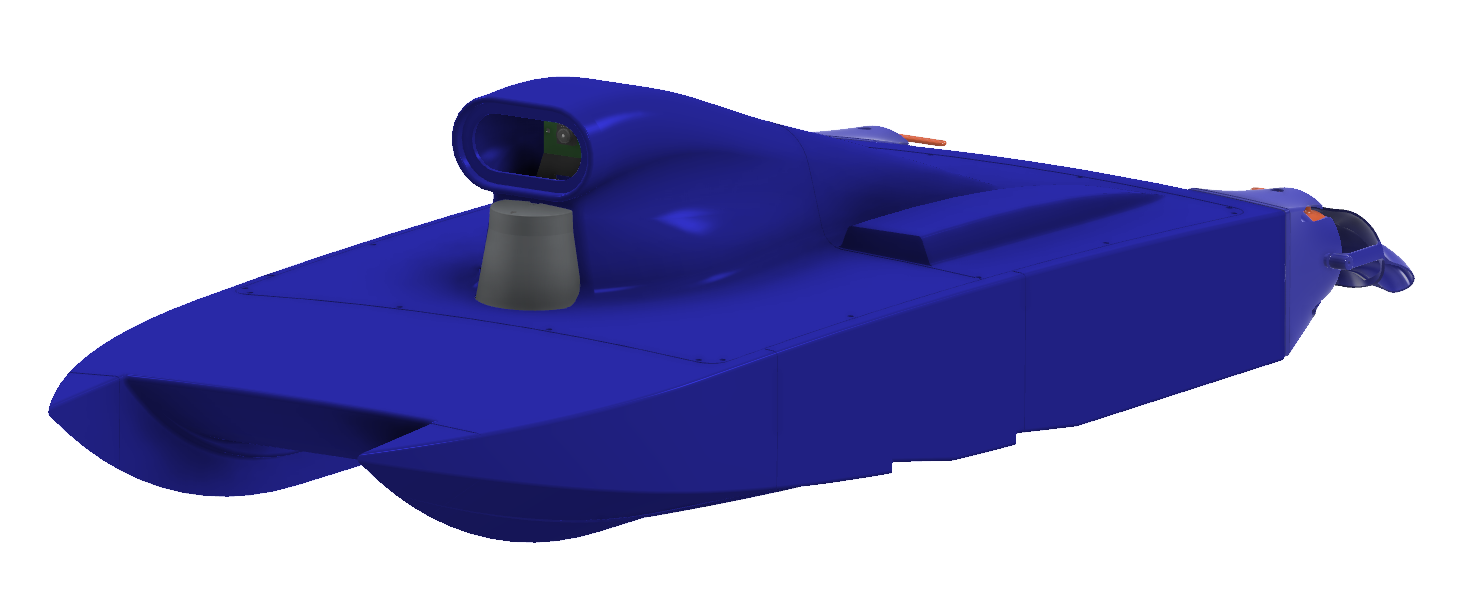

Catamaran Design

10/18/2021 at 15:28 • 0 commentsWhen considering the form of the hull there are two main criteria to consider; speed and stability. Two major components of efficiency of a boat hull are the wetted surface area and the wave making abilities of the hull. Minimising both of these resistance components allows for more efficient operation of the boat platform, including higher top speed and better acceleration. When considering displacement hulls (hulls that are displaced in the water when travelling at speed), the monohull typically has a higher wetted surface area than a catamaran.

However, to reduce the wetted surface area of a hull dramatically, a planing or hydrofoiling hull can be used. These hulls allow the boat hull to rise above the water when traveling at speed. In this work, a planing hull was determined to offer superior performance to displacement hulls, and it was simpler to design than a hydrofoiling hull. The stability of a vessel is inherently determined by its size and weight distribution. As the weight and placement of components in the hull are usually already determined, the size and dimensions of the hull determine how stable the vessel is on the water. A longer boat will have greater stability in pitch and a wider boat will have greater stability in roll. The most unstable axis on the majority of boats is the roll angle. This is particularly prevalent when a boat is hit side-on by waves. Having a wider hull will again help with this issue. For this reason, a catamaran was chosen due to its superior roll stability characteristics. The hull beam of this platform is 250 mm wide, this is due to manufacturing restrictions due to the 3D printer bed size and was also deemed to be stable enough for a platform of this size. The mass of the vessel should be as close as possible to the water line and lower down than the centre of buoyancy to create a statically stable craft. The weight distribution of the catamaran needs to be even (avoiding majority of weight in one hull) so as to maximise stability, hence why the battery and all electronics are mounted centrally in the boat. One of the advantages of a planing catamaran is the reduction in the wetted surface area. As seen in the figure below}, the wetted surface area can be further reduced at speed by employing a stepped hull which further reduces contact with the water while planing. Also, it is evident that spray rails help lift the boat at speeds where the boat is unable to plane and narrow hull beams are utilised to reduce the wetted surface area. A reduced area tunnel is also used on the catamaran to increase the pressure gradient in that section, effectively creating a suspension of air in the tunnel of the catamaran so as to reduce damage and vibration when the hull slams against uneven water. The jet intakes were fitted with grates to reduce the chances of injuries that could be caused by the impeller blade.

This autonomous boat platform is intended to be easily reproducible by students with reasonable knowledge of mechanical assembly. For this reason, the boat was designed in a way that it wouldn't be too big or complex for anyone to manufacture. Both composite manufacturing and 3D printing are easily accessible and achievable by most students.

Composite manufacturing offers superior strength, rigidity, and waterproofing compared to 3D printing. This is due to composite materials often employing high tensile strength and light weight fibres combined with a resin matrix to produce a high strength, lightweight part. Boat hulls are often made from fibreglass as it offers enough strength for loading on water and is lightweight. Mechanically, composite boat hulls are superior to 3D printed ones but there are a few disadvantages of this manufacturing technique to consider. Composite manufacturing requires moulds to form the shape of the hull. The moulds can be quite expensive if they require the use of a CNC machine. 3D printed moulds could cause mechanical locking due to the surface finish of a 3D printed part but this issue could be negated with preparation of the surface before manufacturing. 3D printed moulds often fail under vacuum and high temperatures. Other costs of manufacturing for composites that need to be considered are the consumable components needed (vacuum bags, breather, release film, and mould release), the materials used, and a vacuum pump (if needed).

The autonomous boat platform designed for this competition was designed to fit onto a 250 mm x 210 mm x 210 mm 3D printer bed, a common size for FDM 3D printers. Four separate components have to be printed and later glued together with high performance resin (HPR). This process results in a faster and cheaper alternative to composite manufacturing as it does not require any moulds, consumables, or specialist tools. Due to PLA being able to absorb water and swell, a sealant of some kind is recommended for the 3D prints.

-

Updated Waterjet Design

10/18/2021 at 15:24 • 1 comment

The initial jet design worked as intended but the nozzle and impeller were not optimized yet. The picture below shows a cross sectional view of the final jet design with an exploded view of each component below it.

ImpellerThe impeller has a number of key features, these being the number of blades, blade pitch, hub diameter, and the overall length. These measurements are best determined from experimental testing due to their performance being very dependent on the other features of the waterjet system. Therefore the design was made with the ability to easily change these features and test them. The impeller is printed with a D-slot that fits onto the key of the shaft.

Increasing the number of blades reduces the amount of flow separation on the blades, which increases the amount of torque transmitted to the flow therefore, increasing thrust. Efficiency also improves due to more of the flow being in contact with a blade which reduces turbulence in the flow. However, after a point, efficiency decreases as friction of the blade surface increases to the point where it outweighs the benefits previously mentioned. Increasing the size of hub diameters increases pump efficiency at lower mass flow rates by the majority of the work done on the flow being centripetal. It also increases the inter-row meridional velocity, which leads to more axial flow downstream. With a smaller hub diameter it is more efficient at higher flow rates, increasing the throat area which reduces the frictional losses. With changes to pitch the flow rate of the system increases, but it requires more torque from the motor, and therefore greater current draw. If not balanced correctly, it leads to a decrease in efficiency, so the ideal pitch is found from testing with the specific motor and nozzle design.

Nozzle

The design of the nozzle has two key features, the guide vane design and the reduction in area from the impeller to the outlet.

The guide vanes (stator) have the purpose of converting rotational flow to axial so as to improve the performance of the waterjet and increase flow rate. Guide vanes can vary in length and number. The number of vanes is best determined by the number of impeller blades as the two can have adverse effects such as resonance. In terms of reduction area, the greater the reduction the greater the change in velocity and pressure and therefore the increase in thrust. However, motor limitations lead to the flow rate and efficiency decreasing therefore there is a balance between impeller pitch and nozzle reduction.

Waterjets provide a force in line with the inlet which allows the hull to be propelled forwards, however, for it to turn the thrust needs to be vectored. This is done using the thrust vector shown in with a rotating section that is controlled by a servo. It has 60 degrees of rotation, with 30 degrees in each direction, allowing the hull to rotate. Waterjets aren't capable of running in reverse, therefore a reversing bucket was designed. This redirects the thrust so as to allow the platform to reverse but also steer with the bucket redirecting flows at a 45 degree angle. It also forces the water down at a 45 degree angle to prevent the buckets pulling the boat down.

Testing

A single waterjet setup identical to that on the boat was run with varying impeller designs and nozzle sizes at a fixed throttle input. This means that the theoretical RPM is the same due to the same PWM signal being sent to the motor, however the actual RPM varies due to the varying torque required. All measurements were taken from static testing therefore when the boat is moving the values will vary due to inlet velocity ratios. The important parts to consider from testing is the efficiency and thrust which is based on the current draw and the force measurements recorded using a load cell. With simple changes such as number of blades, blade pitch, nozzle diameter and hub size the results vary significantly. Analysing the first figure it is clear that the best result was a 4 blade, 40 mm pitch impeller with a 30 mm nozzle diameter which produced 4.5 kg of thrust at an efficiency of 38%. Looking at the second figure this impeller and nozzle combo performs very poorly which highlights the trade off between thrust and waterjet velocity. In terms of boat performance the trade off results in a balance between acceleration and top speed. A combination that offers a good balance is the 3 blade, 40 mm pitch impeller with a 25 mm nozzle. Further optimisation can be done to produce more efficient waterjets with a better balance therefore offering an opportunity for users to vary the waterjet design themselves and increase performance.

-

Monohull Design

10/13/2021 at 14:22 • 0 commentsIt was the easiest to design and implement as it was only one hull and therefore only required one jet propulsion system}. The boat was capable of rolling as the vectoring nozzle rotated which reduced the turn radius of the boat making it very maneuverable. However due to its roll it produces an unsteady surface for the camera and LiDAR which results in unusable footage and LiDAR data. Therefore it was used to validate that a 3D printed hull would be durable, buoyant and waterproof enough. It also allowed for testing of propulsion systems on open water in dynamic testing rather than just stationery.

Construction

The monohull boat is printed from PLA on a larger than standard printer in two 400mm long sections that were then bonded together using epoxy. Due to the size of the printer a 0.5mm layer height was used which resulted in a rather rough finish but it would for the hull. The inlet for the jet housing was printed separately as it needed to have a much smoother surface finish. It also was done separately so we could iterate through different inlets on the boat. Custom laser cut gaskets were used to seal it however, they didn’t work where it joined with the back of the boat. This was due to the high pressures created from the impeller. Therefore it was just siliconed in.

To help mitigate the roll of the boat on the camera footage a simple 2 axis gimbal was designed however due to the speed of the boat the cheap servos didn’t work well enough.

Testing

Pool testing

Pond Testing

-

Initial Waterjet Design and Lessons Learned

10/11/2021 at 13:24 • 0 commentsPropellers are the most commonly used propulsion systems on unmanned surface vehicles. This is due to the simplicity of their design and implementation, however, they offer no protection to their surroundings. A simple duct can be added to protect the blade tips while offering some protection to users, but it doesn't reduce the chances of entanglement. Therefore it was decided that waterjets would be the ideal solution as they are inherently safe, allow for operation in shallow waters, reduce the risk of entanglement with ocean algae, and provide a range of design optimization options. The design is based on an axial flow pump and it follows a standard pump curve. It is made up of a number of features, these being the inlet passage, impeller, nozzle, and thrust vectoring components. Additional features are added such as an o-ring to reduce pressure loss and bearings to reduce friction are also used. Within these there are more features that can be modified to vary pump performance to suit the user or task requirements.

Inlets

Jet design began with different inlets as this is the major difference between propeller and jet propulsion. A range of designs are shown below with it progressing from left to right. The initial design had a very small opening and sharp edges which resulted in turbulence due to the flow separation. The later designs improved the transition between the water and the inlet which allowed the flow to stay attached.

The inlet length and inlet angle have been optimised to reduce the overall inlet swirl and wall cavitation. This was done by having an inlet angle of 30-35 degrees which still leaves room for mounting a range of motor sizes. After the inlet angle, enough length is needed to house an impeller while still ensuring a very close fit to improve pressure differences.

Impellers

A range of impeller designs were tested, initially they started off unrealistic but became closer to that of full size commercial impeller designs which resulted in faster priming and greater thrust.

Nozzles

The idea of the nozzle is to redirect the rotating flow to axial to increase the jet exit velocity. Progression can be seen from left to right, with the initial being 4 simple guide vanes. The designed one has 7 guide vanes with slight curvature to them and a thrust vector mounts internally. A reversing bucket was also added to allow the platform to reverse.

Testing

This was the initial test set up, the only shaft we had at the time was not rigid so it led to a number of issues as RPM increased. However it served as a solid starting point.

The design above is one of the later designs, probably around 5/6th iteration and was made to a diameter of 30mm rather than the previous 40mm. It used a fixed shaft and provided water cooling to the motor via the jet inlet.

A load cell was used for testing as this would measure the thrust output of the jet. Current clamps were used on the battery side to measure the current draw.

This testing was rather rudimentary but provided a key difference between the potential output of the 40mm jet vs the 30mm jet. The majority of the difference is due to the fixed hub size due to the size of the bearing in the nozzle and shaft diameter. Therefore continuing on we stuck with the 40mm jet as we saw there were great optimizations to be found.

-

Importance of Autonomous Speedboats and Related Work

10/11/2021 at 13:13 • 0 commentsWith the majority of the world consisting of waterways and open ocean it is important that they are well researched, monitored, and protected. Several companies and research groups have focused on the development of unmanned marine vehicles that rely on classic or renewable energy sources (e.g., wind powered) and that can monitor the oceans autonomously. This has allowed, among others, tracking of sea life and assessing the impacts of climate change. In New Zealand and the Pacific Ocean in general, autonomous boats are becoming a key part of maritime units that monitor unmarked vessels and ensure marine laws are upheld. These boats can operate 24/7 and can be placed in dangerous situations without endangering human lives. Rivers throughout New Zealand have also been degrading in water quality due to farmland runoff and rubbish dumping. The NZ Police and Department of Conservation have attempted to enforce regulations but there are too many waterways for them to look over and monitor. Therefore, having autonomous boats that can independently monitor these rivers is of paramount importance.

Another potential application of autonomous boats and speedboats is searching for survivors and providing life saving vests or other inflating devices to people stranded out at sea due to capsized or damaged vessels. Autonomous speed boats will be able to reach the survivors faster as they can be docked at solar powered buoys or lighthouses and can be deployed as soon as a call is received. For such applications to be successfully demonstrated more research needs to be done into such autonomous platforms. When developing autonomous systems, consideration for the system to be safe to operate and to not damage its environment or harm any bystanders is crucial. Therefore in autonomous boats it is common to find the use of various sails for propulsion such as [1], [2]. The safety benefits of these solutions are quickly outweighed by significant disadvantages, such as the fact that their control is relying on external, environmental conditions. An alternative solution that is safe, yet allows for total control, is a waterjet powered propulsion system that protects the impeller in an appropriate housing, reducing any chance of entanglement. This has been explored by [3] and other commercially available solutions.

An important question is how can we speed up innovation in the field of autonomous boats? A solution that has proven to work in other fields is through competitions. Humans have an innate desire to compare themselves to one another, making competitions an effective tool for encouraging students to participate in furthering research and development of systems. Competitions have been traced through all cultures which proves their effectiveness and importance in education [4]. Data presented in [5] has shown that students who took a test before and after participating in RoboFest (an autonomous robotics contest) ended up with higher scores in a STEM assessment afterwards.Regarding boat competitions, a strategy used by the RobotX competition is that all teams are required to use a platform that is supplied by the organisers for the competition. This ensures that all contestants will have consistent hardware and will only be limited by their sensing and perception (software) capabilities. The supplied monohull boat platform is roughly 5 m long and 2.5 m wide which requires a boat trailer to move it around and take it to the testing site [6]. Moreover, the cost of additional components is well over $5,000 USD. RoboBoat is a similar autonomous boat competition that has taken a more open approach as teams must propose solutions that respect the imposed length, weight and power constraints [7]. These custom built vessels are still expensive, costing at least $3,000 USD to build a competitive platform. The only low-cost platform that could be used for such competitions, is the micro Unmanned Surface Vehicle (USV) platform that was proposed in [8]. This platform has been designed to operate in indoor laboratory environments. It is built using 3D printed and off-the-shelf electronic components, it is very small (23 cm long), inexpensive (costs 320 USD per unit for 10 vessels), and an excellent platform for algorithm validation in an indoor environment.

Unfortunately, to the best of our knowledge, in the field of autonomous boats there is no open-source platform with a cost <1,000 USD that can offer multiple engineering challenges related to mechanical design, autonomy, perception, and control like the Mushr platform does in the field of car racing platforms [9].

This project focuses on the development of open-source, low-cost, waterjet-powered robotic speed boat platforms for both education and research.

References

[1] J. C. Alves and N. A. Cruz, “Fast - an autonomous sailing platform for oceanographic missions,” in OCEANS 2008. IEEE, 2008, pp. 1–7.

[2] R. Stelzer and K. Jafarmadar, “The robotic sailing boat ASV roboatasa maritime research platform,” in Proceedings of 22nd international HISWA symposium, 2012.

[3] Q. Xiaowei, R. Guang, Y. Jin, and Z. Aiping, “The simulation for autonomous navigation of water-jet-propelled unmanned surface vehicle,” in2011 Third International Conference on Measuring Technology and Mechatronics Automation, vol. 3. IEEE, 2011, pp. 945–948.

[4] T. Verhoeff, “The role of competitions in education, “Future world: Educating for the 21st century, pp. 1–10, 1997.

[5] C. C. Chung, C. Cartwright, and M. Cole, “Assessing the impact of an autonomous robotics competition for stem education, “Journal of STEM Education: Innovations and Research, vol. 15, no. 2, 2014.

[6] J. Park, M. Kang, T. Kim, S. Kwon, J. Han, J. Wang, S. Yoon, B. Yoo, S. Hong, Y. Shim, J. Park, and J. Kim, “Development of an Unmanned Surface Vehicle System for the 2014 Maritime RobotX Challenge, ”Journal of Field Robotics, vol. 34, no. 4, pp. 644–665, 2017.

[7] C. August and D. Beach, “Rules and Task Descriptions RoboBoat2020 Rules and Task Descriptions,” pp. 1–24, 2020.

[8] C. Gregory and A. Vardy, “microUSV: A low-cost platform for indoor marine swarm robotics research,” HardwareX, vol. 7, p. e00105, 2020.

[9] S. S. Srinivasa, P. Lancaster, J. Michalove, M. Schmittle, C. Sum-mers, M. Rockett, J. R. Smith, S. Choudhury, C. Mavrogiannis, and F. Sadeghi, “Mushr: A low-cost, open-source robotic race car for education and research,” arXiv preprint arXiv:1908.08031, 2019.

Low-Cost, Waterjet-Powered Robotic Speedboats

This project focuses on the development of open-source, low-cost, waterjet-powered robotic speedboats for education and research

New Dexterity

New Dexterity