-

[R - T] Screen, NanoDLP and the Photon M3

04/23/2022 at 06:04 • 0 commentsIt seems that NanoDLP is the resin equivalent to Marlin or Klipper for FDM. Apparently, I can just use Marlin for motion control, as stated in this relevant subreddit. I'd need 5 if I'm having resin applicators on both sides. Alternatively, I may have to sacrifice one of them for a layer washer / UV cure light.

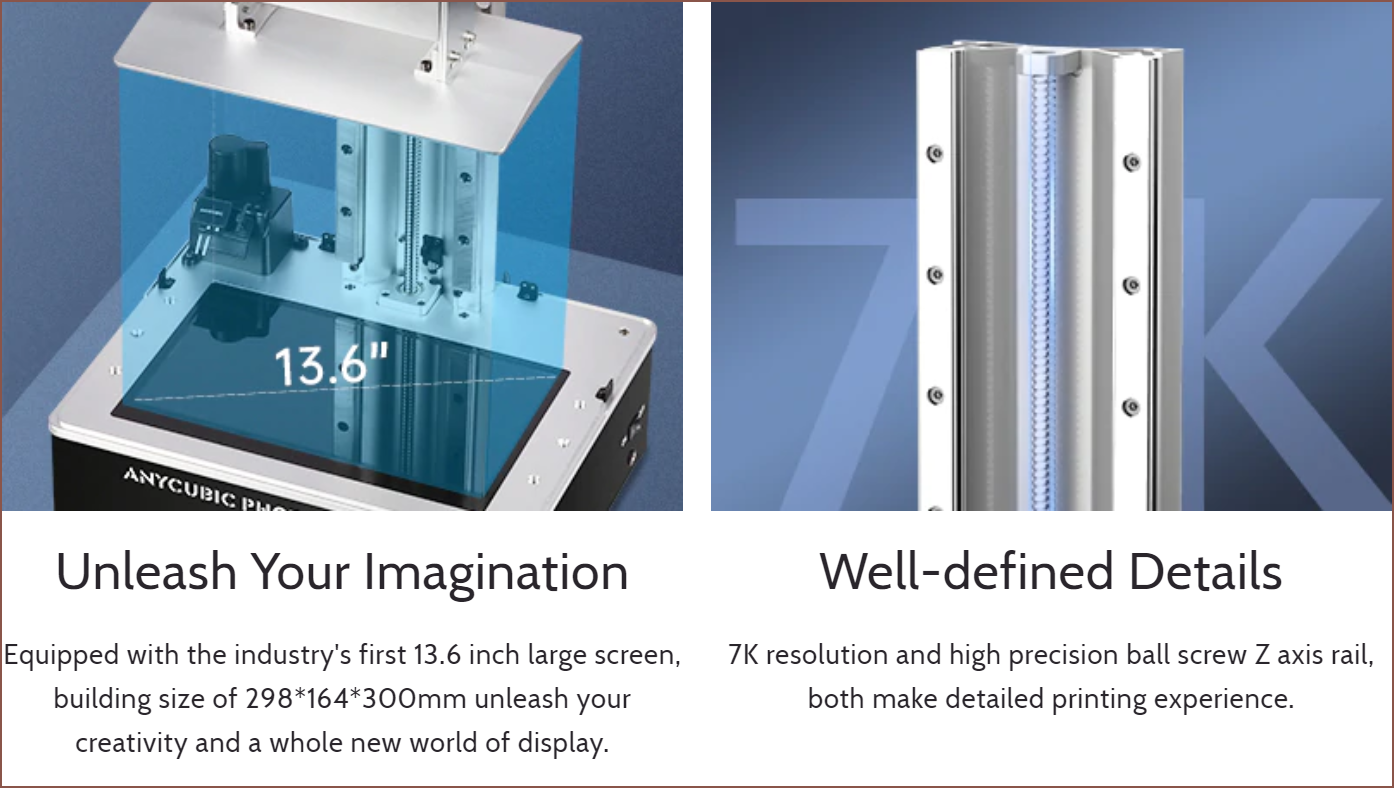

As for the screen, I'd like to go with monochromatic (or DLP if that's an option). Either the CanDoTheTaskApp succeeds or fails, so for me, the valid options are 13.6 inches or larger, or a cheap and small screen around 6 inches. Anything in the middle will needlessly affect the CostApp and SpaceApp while not fufilling the CanDoTheTaskApp.

The pre-sale price might not last, but at the moment it looks like the Anycubic Photon M3 Max is £656 (Listing 1, Listing 2) delivered to UK, which actually sounds pretty nice. I can also see that Anycubic is using their own slicer in the listing, suggesting that there's no need for ChiTu's software. Prometheus and SUMAOPAI also seem to be using the same screen. The reason why I like the 13.6" screen is that the X axis is almost 300mm. Pixel pitch is 46um.

The front of the Suspense will likely be orientated the same way as the aformentioned printers so that parts like the build plate can be used and without modification.

Strongly considering moving this project to ongoing but I'm waiting to see if my initial hype will die down.

-

[T] Technology Naming?

04/21/2022 at 11:46 • 2 commentsSo, Viscious Lithography Manufacturing is a trademarked process name, meaning that I or someone else needs to think of possible alternative names for this process. I'd like to avoid a Honda / Lego / Disney like situation.

Names I've thought of:

- [Film / Suspended] Lithography Printing

- [Film / Suspended] MSLA

- Suspended Film Additive Manufacturing

- Suspended Masked (Stereo)Lithoghraphy

- Suspended Film Stereolithography

As you might be able to tell, I'm biased towards "suspended" and an abbreviation that begins with S. Since the plastic film on rollers is the main thing that differentiates the current form of VLM from top down or bottom up MSLA, I think something MSLA related makes the most sense.

Alternatively, there's no reason why the same method can't be used for laser or DLP light sources, so "Masked" wouldn't apply to them.

Suspended Liquid Stereolithography has a nice look to it, but there's already an additive manufacturing "SLS", and someone might figure out a way of using powders and a laser instead of UV resin and a UV source to build a part, perhaps though static electricity or a slightly sticky film. Considering that SLS and DMLS are similar processes but use different materials, the same naming convention may apply with this naming situation too.

I'll continue to think about it.

-

[R] Compatible with advanced FDM strategies

04/21/2022 at 11:25 • 0 commentsI've just seen this video which shows all the cool things that can be done in FDM.

And I realised that the VLM process could allow for the same benefits for UV resin printing! This further puts it a step up from other additive manufacturing methods.

Now if we could just inkjet some colour on white resin covered film before it's sent to the screen to be cured, that would be, like, Futuristic Additive Manufacturing Bingo!

-

[T] Modding an existing printer?

04/20/2022 at 12:36 • 0 commentsLooking at all the MSLA printers on the market, it seems that, hardware wise, everything is already there. The real concern is controlling the additional motors and print process. It's not like the Z axis and all the other motors need to be precisely timed within microseconds, so it sounds plausible that 2 controllers could be used: the first one as part of the doner printer that deals with the z axis motor and the LCD, and the second one for all the additional features needed.

From research, it seems that anything with ChiTuBox's controller and features a 4K or larger display will need an SDK, for which I'd have to apply for. I'm skimming over the free use agreement but I don't have high hopes by attempting to go down this route.

-

[R - T] Screen Choices

04/18/2022 at 23:00 • 0 commentsThe decision is simple:

- Large screen

- [+] Larger parts

- [+] Less need for a larger "version 2"

- [-] Screen more expensive

- [-] Larger footprint

- [-] More cleaning fluid needed for the same part

- Smaller screen

- [+] Cheaper to build printer / replace screen if it breaks

- [-] May hide issues that would be experienced when scaling up

where the benefits of one option are the drawbacks of the other.

So I thought about the fact that the AvailabilityApp could ruin my entire run, so I instead started looking for possible electronics candidates, starting by avoiding ChiTuBox printers. I discovered the Creality Halot, thought it was a good research session and went to bed.

Then I had the idea of searching for DIY MSLA projects. I originally dismissed it, thinking "printers are so cheap these days that there probably wouldn't be anyone trying to make their own these days.", but it only takes a few minutes to check. It didn't take long to find the Prometheus MSLA and I immediately saw the YouTube link. I thought the size of the vat in their most recent video looked like a nice size, and so I went into the discord. There, I find out that they're planning to use a new Anycubic printer called the Photon M3 Max, which has a great sounding screen and build volume.

![]()

My only concern is the CostApp. Anycubic's offering costs more than a monitor stand. I already knew that was going to be iffy and thus the reason the project was shelved on arrival. The SpaceApp was also a factor.

Long story short, I'll be making design decisions with the Prometheus project in mind, assuming that the software part of the equation (excluding slicer) theoretically allows a solution for this project.

- Large screen

-

Initial Thoughts 2022 Colourized

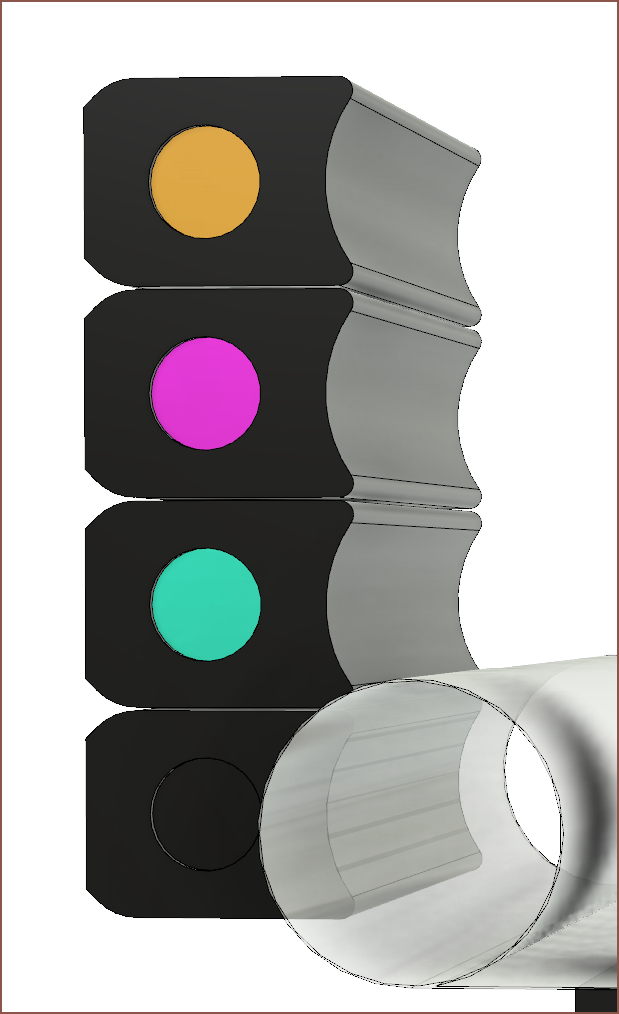

04/18/2022 at 15:07 • 0 comments![]()

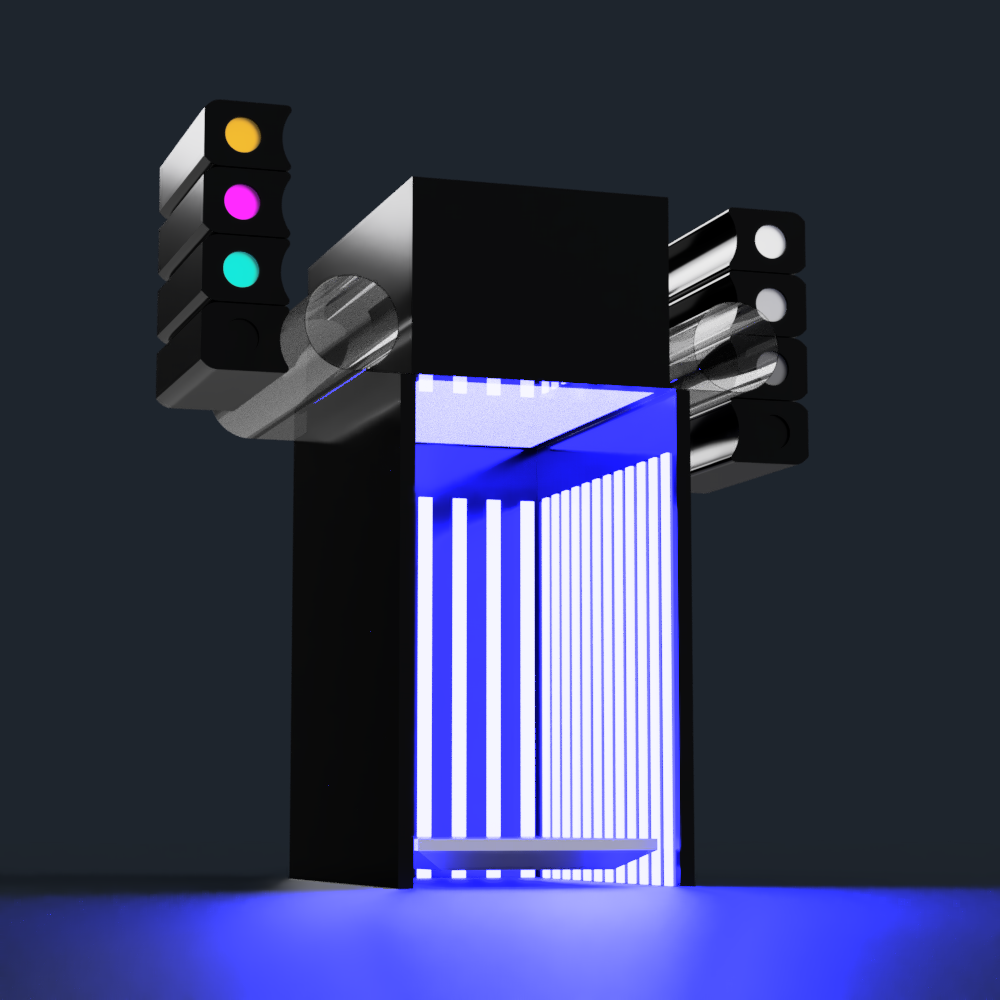

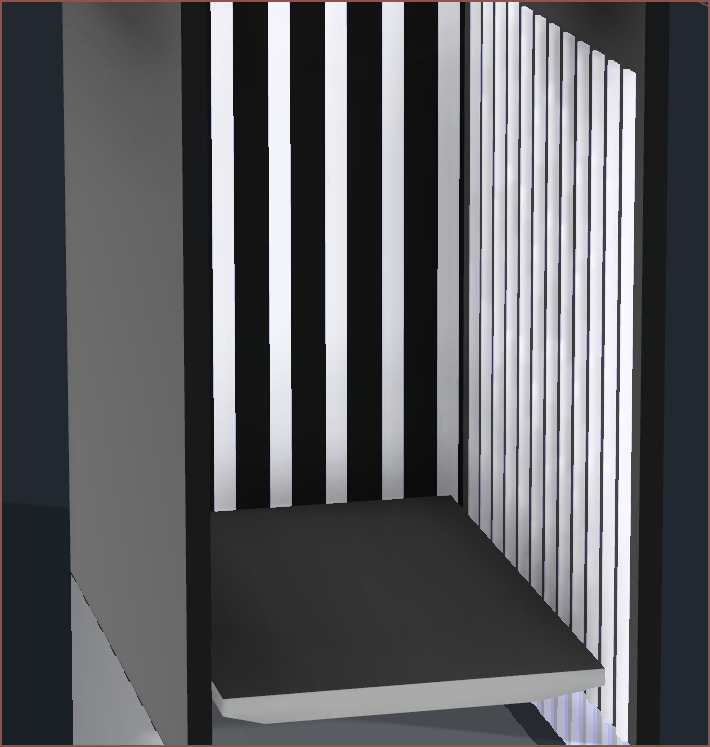

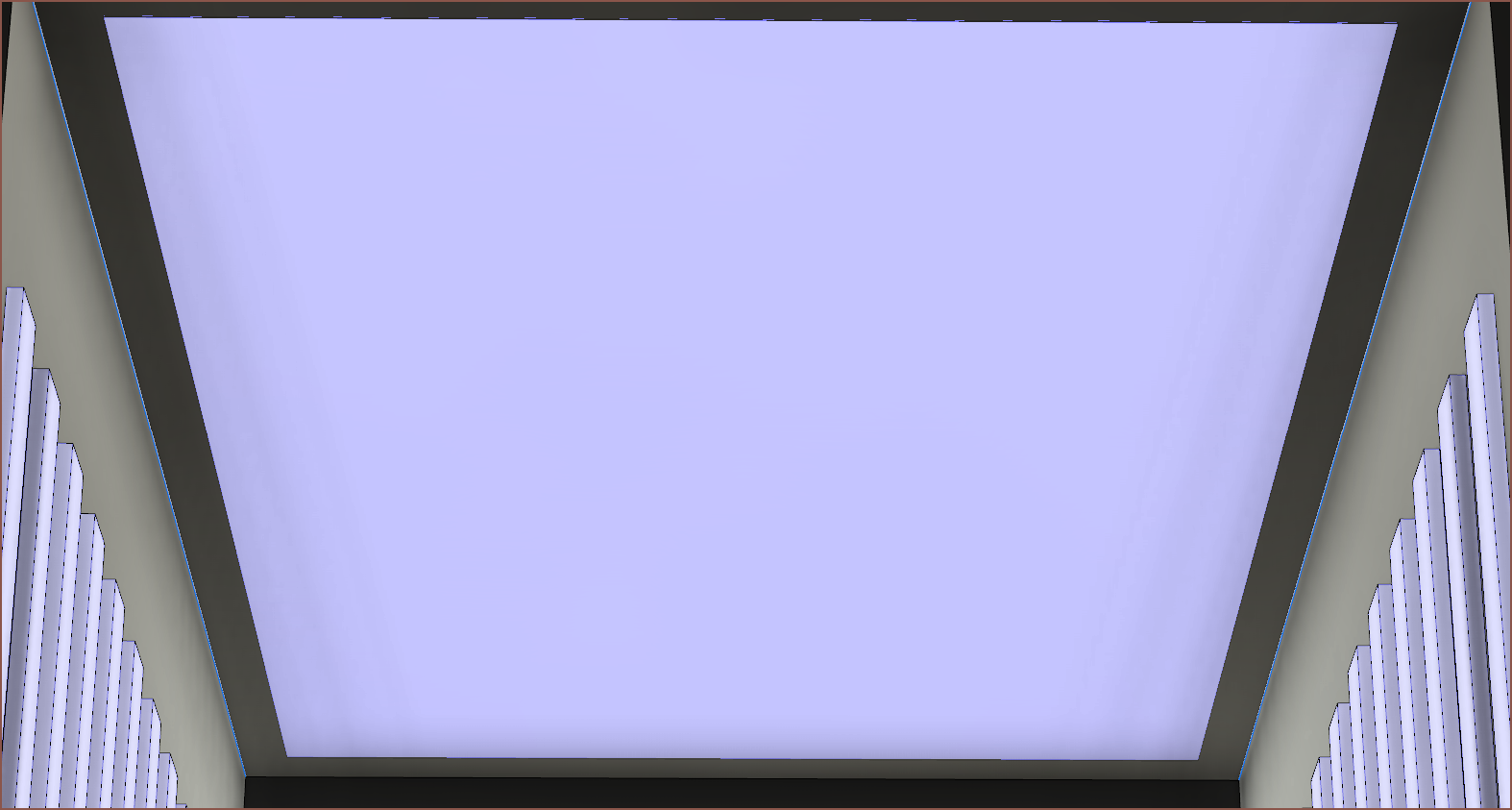

I've just made a minimum viable 3D model to better explain my previous project log.

- I intend for the printer to also have a built in wash and cure station.

- Ideally, I'd like to be able to cure from the top without the use of the LCD panel to increase longevity.

- With the screen oriented this way, I can install more LEDs on the walls

- This also means that the film's unsupported span is shorter than if it were oriented the same way as the vast majority of MSLA printers.

- The same LED pattern will be on the front window, but more sparse to increase visibility

- A drawback is that the hardware responsible for resin application will have to be longer

- The same LED pattern will be on the front window, but more sparse to increase visibility

- The whole print area will be as "watertight" as needed so that the part can be washed

- Ideally, the print will be washed as it prints.

- this might need some kind of sensor to know if any liquids may have splashed onto the resin-covered screen

- the print likely has to be washed when the material is switched

- Ideally, the print will be washed as it prints.

- The resin is held inside modules which also have the hardware that applies and retrieves resin from the rollers

![]()

- The modules are on a gantry that will move away from the roller and then move up or down to switch to a new one before pressing against the roller again.

- An RGB LED is an idea for the coloured dot; the benefit is that it can be dynamically changed easily. However, it would need a power source when the module is stored away. Maybe a 3V coin cell is enough for this. Alternatively, there could be a window/cutout so that the inserted bottle of resin is visible.

- For the render, I've installed CMYK on the left and White, Transparent, Support, Black on the right

- The washing fluid will be at the base of the printer, under the max Z location.

- A current design concern is that the washing system and/or the curing LEDs might not be able to get to every part of the print.

- A circular bed instead of a rectangular one could fix this.

- It might be beneficial to see how dishwashers clean their contents.

Also, I'm computing a mental simulation and I come to the conclusion VLM technology removes the need to have drainage holes (assuming that the layer height is thin enough for the screen to fully cure the resin), further getting towards the convenience of FDM. It might be required to first print the layer, wash the layer and then cure the inside offset of the layer so that any trace amounts of resin that would be in the part will be cured.

Other than the resin applicators, this solution doesn't seem that much more complex than a toner printer + dishwasher. Additionally, I haven't done extensive research but I'd like to believe that a hobbyist (chemist) would have a much easier time creating the resin blend (especially since viscosity is less of a constraint) and just being able to use it in the printer, rather than creating polymer pellets and then presicely extruding it through a filament extruder for use in an FDM printer, opening up the possiblility of a maker both designing a custom part and custom material to make it out of.

- I intend for the printer to also have a built in wash and cure station.

-

Initial thoughts and ideas

04/16/2022 at 20:59 • 2 comments- I thought of the name SecSavr Suspense because the resin looked like it was suspended in air the first time I saw the demonstration video, and because it sounds mysterious.

- The door of the machine will lock like a washing machine when printing.

- I'd prefer it if the build volume is a cuboid, but if the build plate needs to be rotated for curing and space is a concern, it might have to be cylindrical.

- Washing while printing might be possible, especially considering that the topmost layer would have to be cleaned so that other colours / materials can be used.

- The plastic film could also act as a splashguard for the overhead screen.

- I'd like the resevoirs to be the resin bottles themselves so that changing colours is as easy as the J55.

- I'm thinking of a vertical "magazine" of resin-to-film applicators on each side that would have n amounts of colours.

- There would be 2 axes: one to line up the colour to the roller of the film, and one to move the applicator /cartridge on or off of the roller.

- The target for n would be 4 and above, thus 8 total.

- CMYK, White, Transparent, Soluable is 7.

- Desigining for a bigger screen would be more useful, but that would increase cost and size.

- Having it so that the shortest side of the screen is at the front and back of the machine would likely have benefits over the longest side, as seen with most resin printers on the market today.

- One would be that the unsuported span of film would be shorter, but the disadvantage is that the length that the applicator would have to cover would have to increase, increasing the chance of resin application defects.

- Another would be the increase in wall surface area that can be covered by the curing LEDs and still have a visible window at the front. It's not that the window will have 0 LEDs, it's that it's possible it would have less so that the part was still visible from outside.

Liquid Laminate Lithography 3D Printer [gd0105]

The best of resin with the best of filament; is such a 3D printer possible?

kelvinA

kelvinA