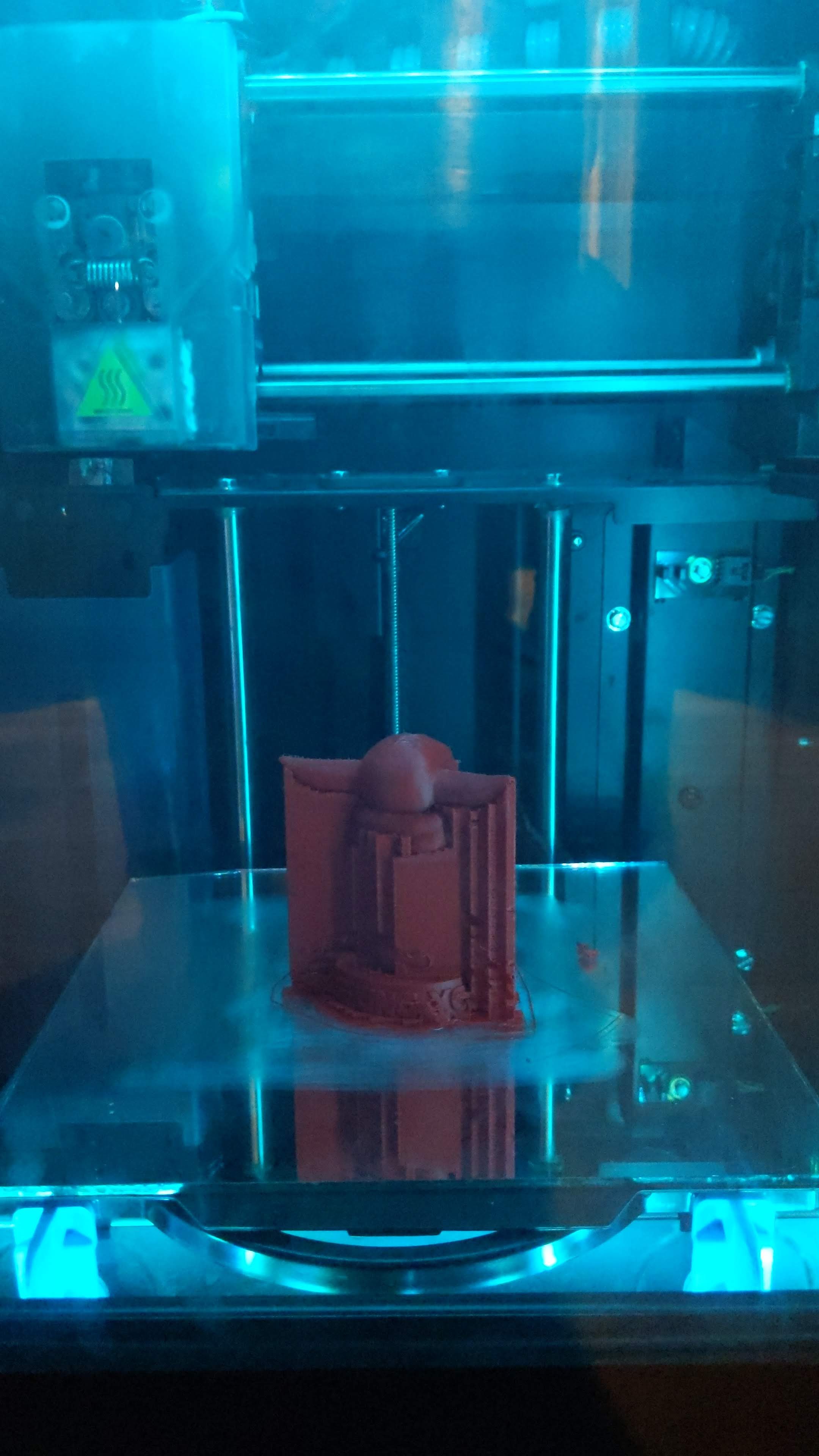

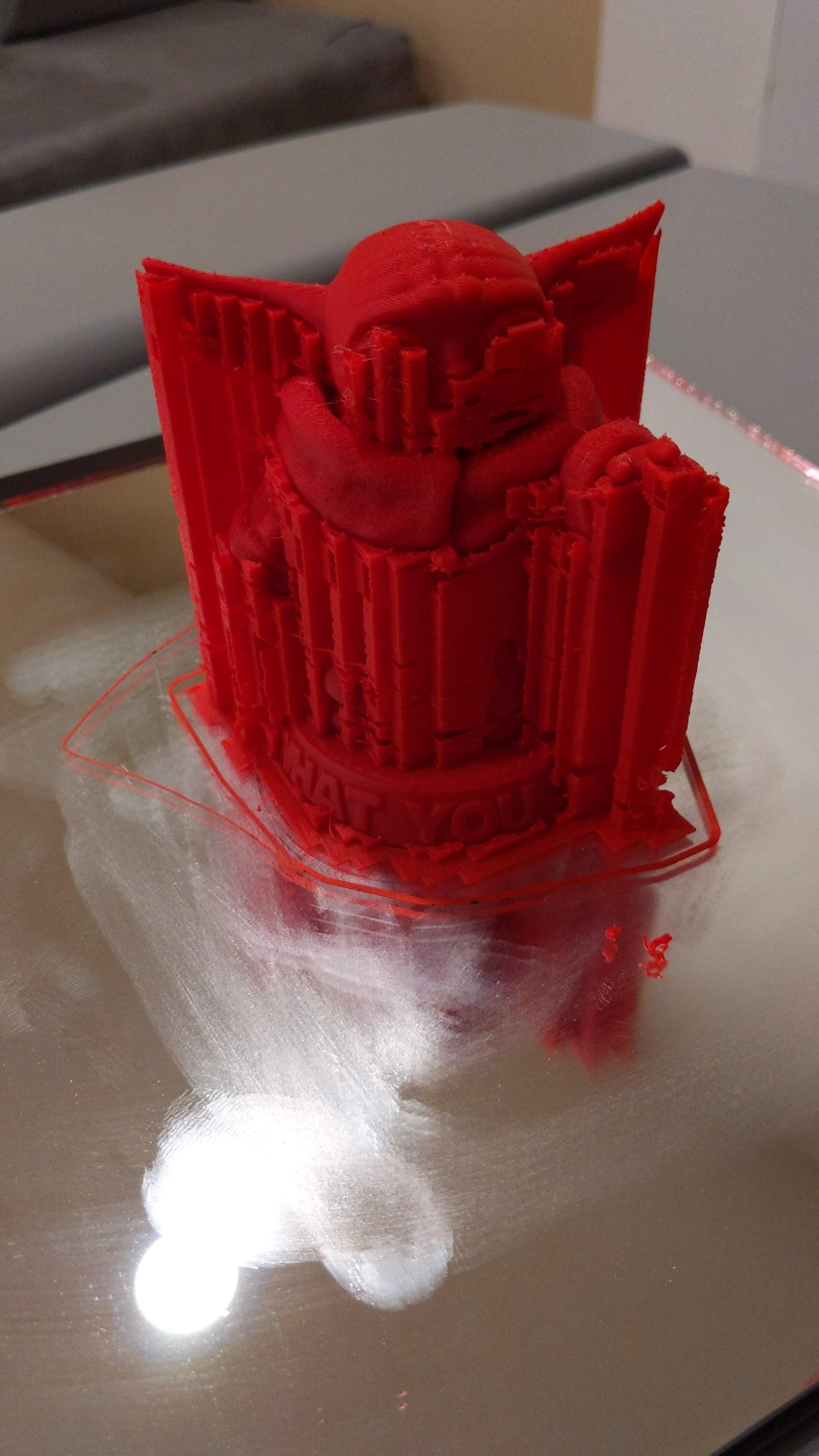

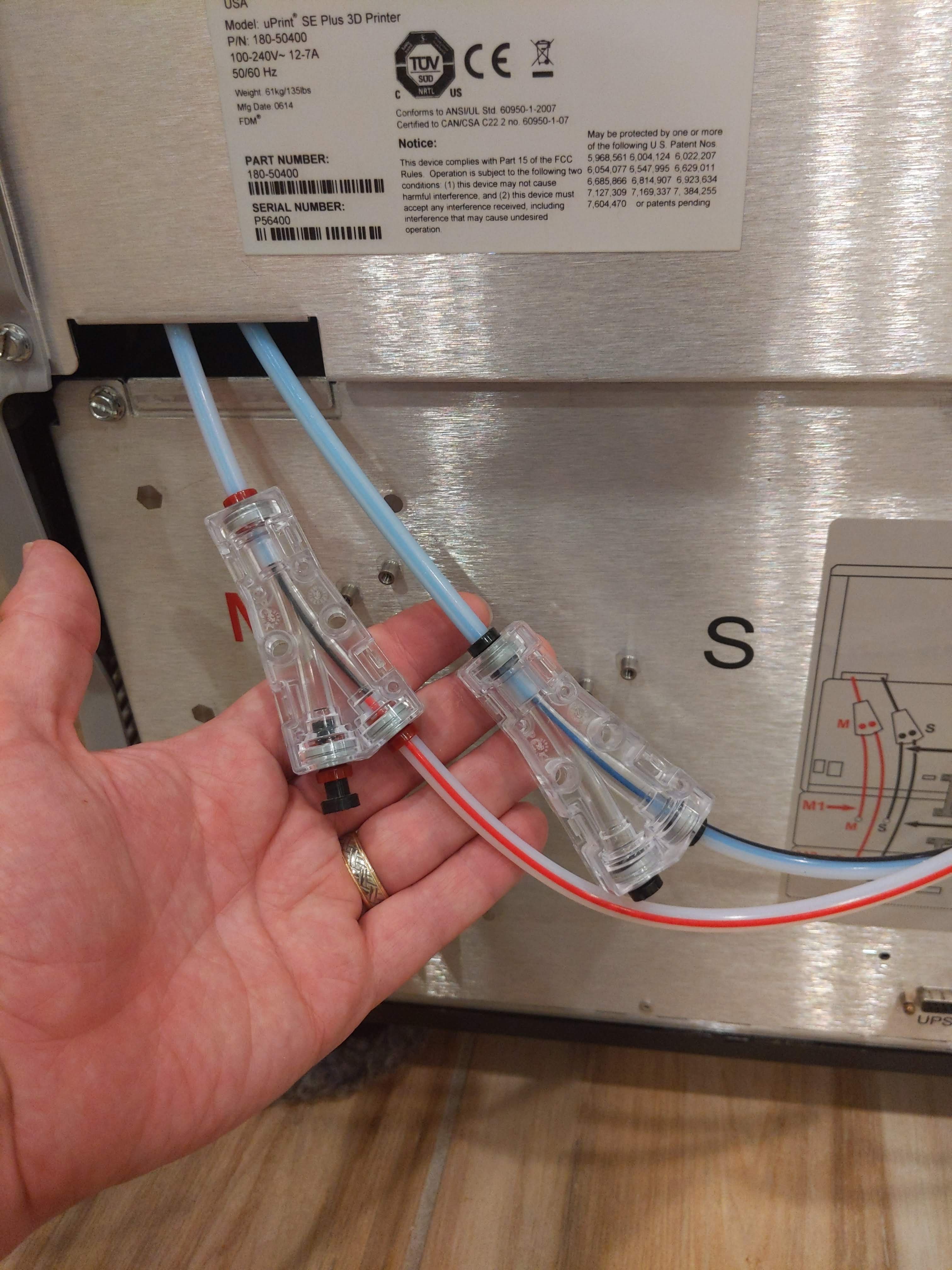

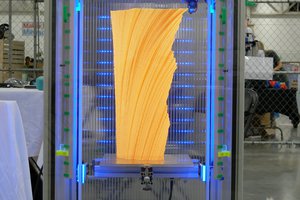

This project was started from 2 design requests. The first began as a request to take an old Stratasys Uprint 3D printer and reversibly retrofit it with a new control system (AJ Quick). Some hurdles were solved through the design of PCBs involving level shifters for communication with some of the existing electronics hardware. The second followed along when an old Stratasys Uprint SE plus was scrapped at work due to heat rotted Gates timing belts. (Jeremy) This printer is essentially a 3D printer in an oven with a CNC milled print head and survivalist step motors designed to function at higher temperatures. He acquired the printer and replaced the belts to get a functioning 3D printer. However, these systems use proprietary filaments with EEPROM encoders and heavily restricted slicing software to print models. The price of the filament is exorbitant for an at home tinkerer and maker (up to $300 for a roll of filament). While the community has developed ways to reprogram the EEPROMs the printer still had to be controlled by the proprietary slicer software. Not to mention that the Uprint SE plus EEPROMs pose additional challenges that may have been resolved by now. Others went another route to get these types of printers to function, yet usually the extruder ended up being replaced.

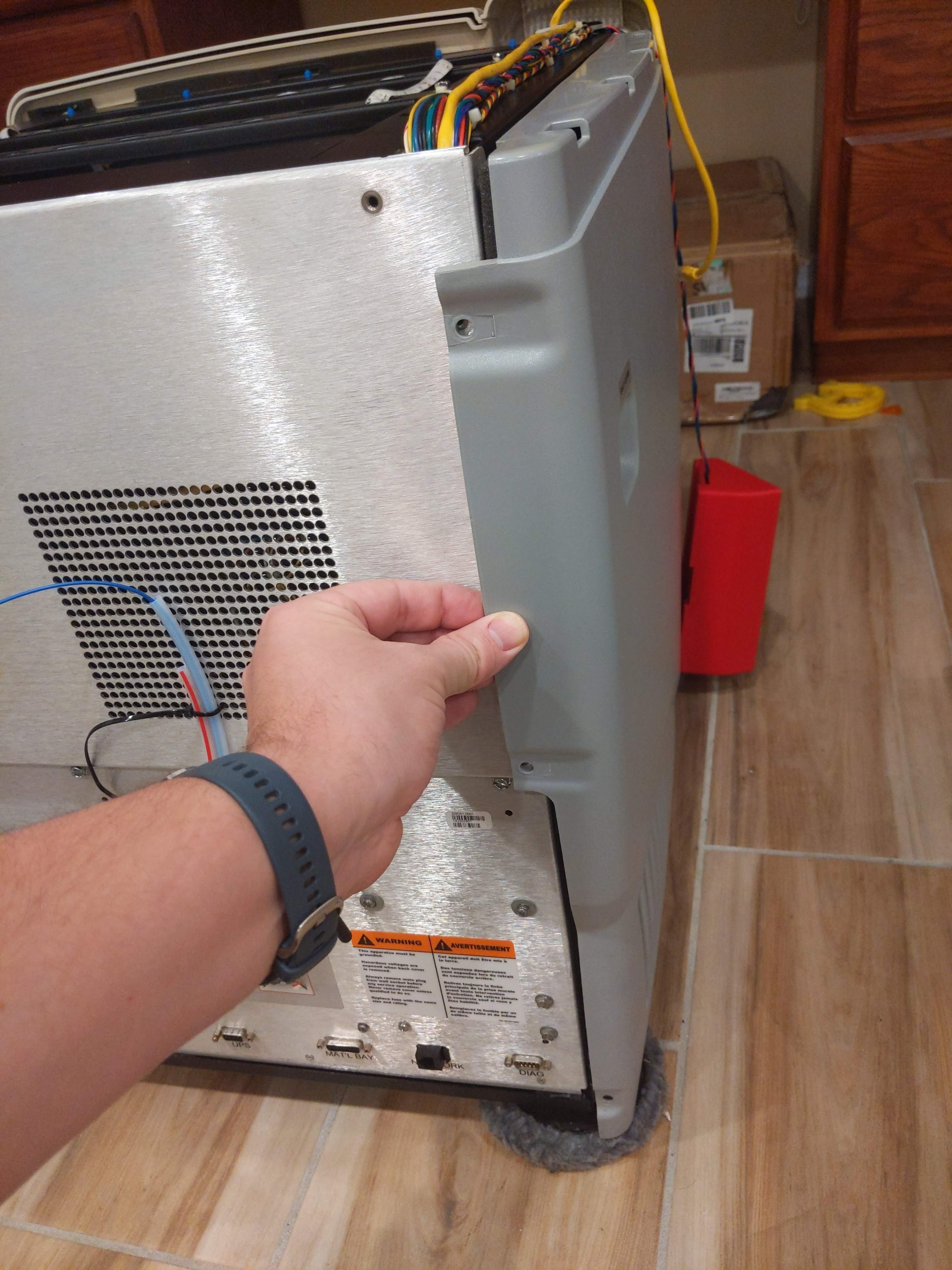

Thus the challenge began to find a way with commercially available and preferably open source hardware to take over the controls of this powerful dinosaur of a printer without removing any of the hardware. AJ Quick's work on wiring pinout diagrams would prove helpful in figuring out what connections needed to be made where to enable full control of the printer. Between the time of AJ's initial work and the acquisition of the Uprint by Jeremy, updated open source 3D printer control and expansion boards were made by Duet3D that allowed for 5V signaling and PWM output getting rid of the need for level shifters.

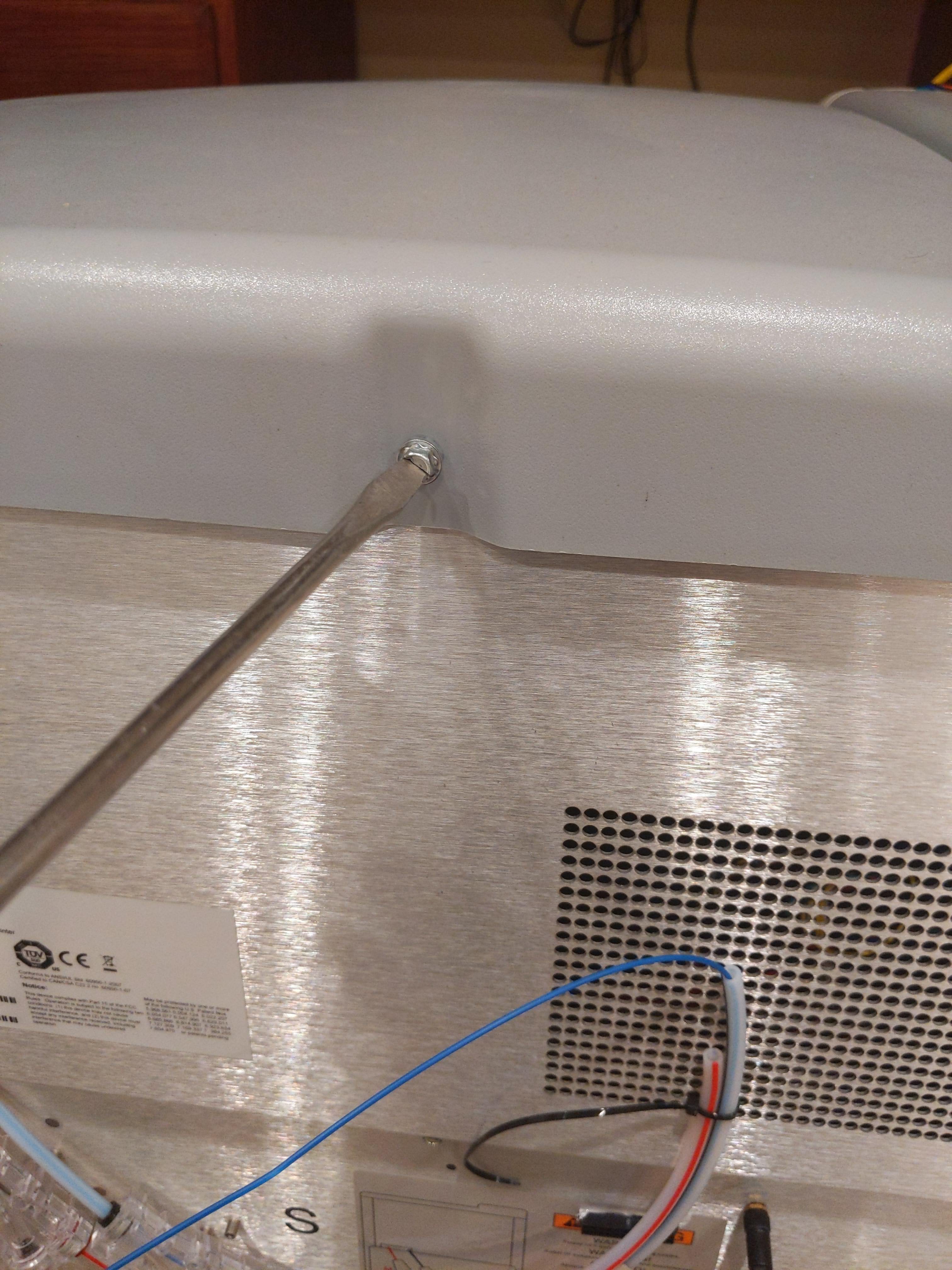

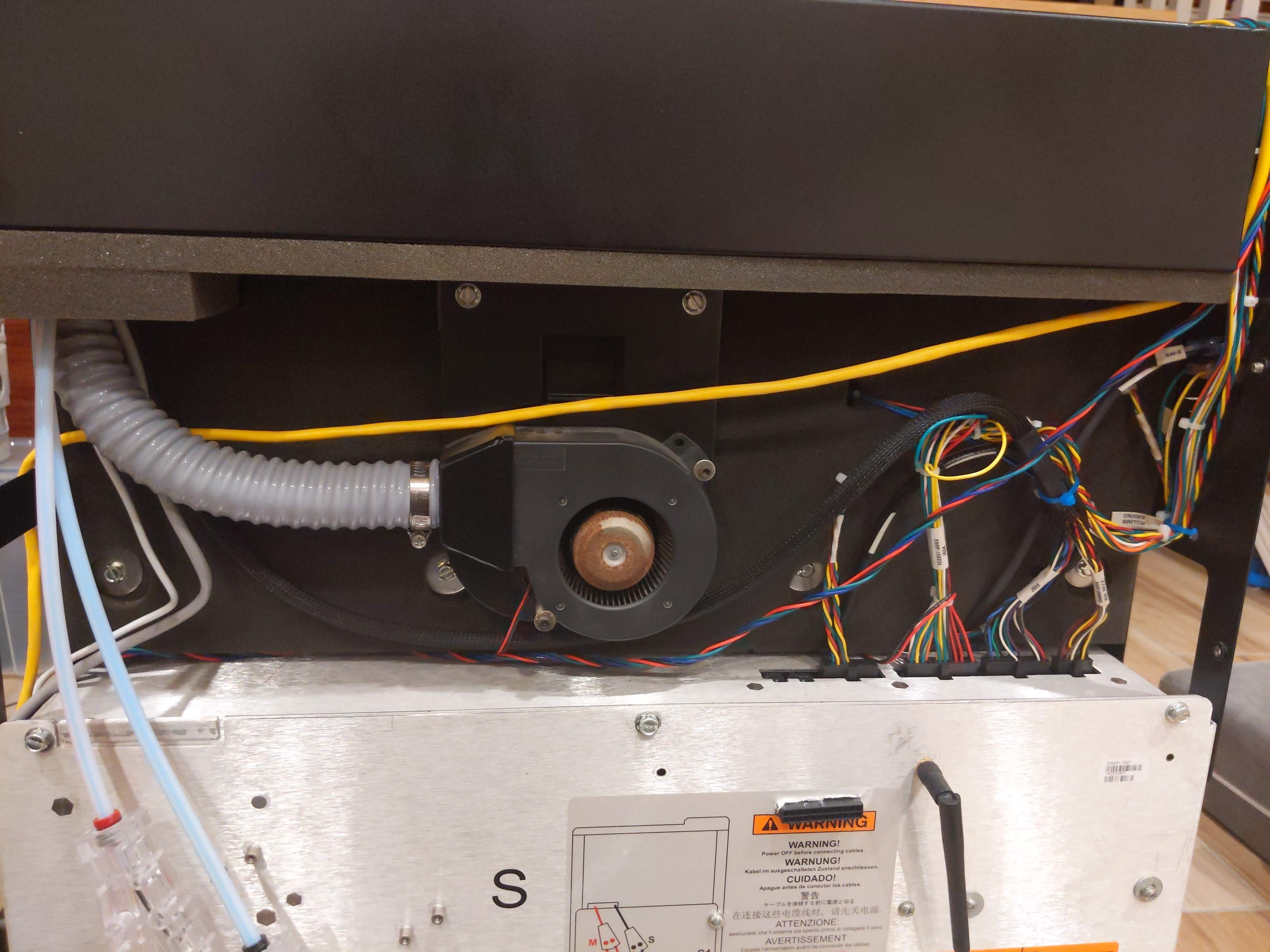

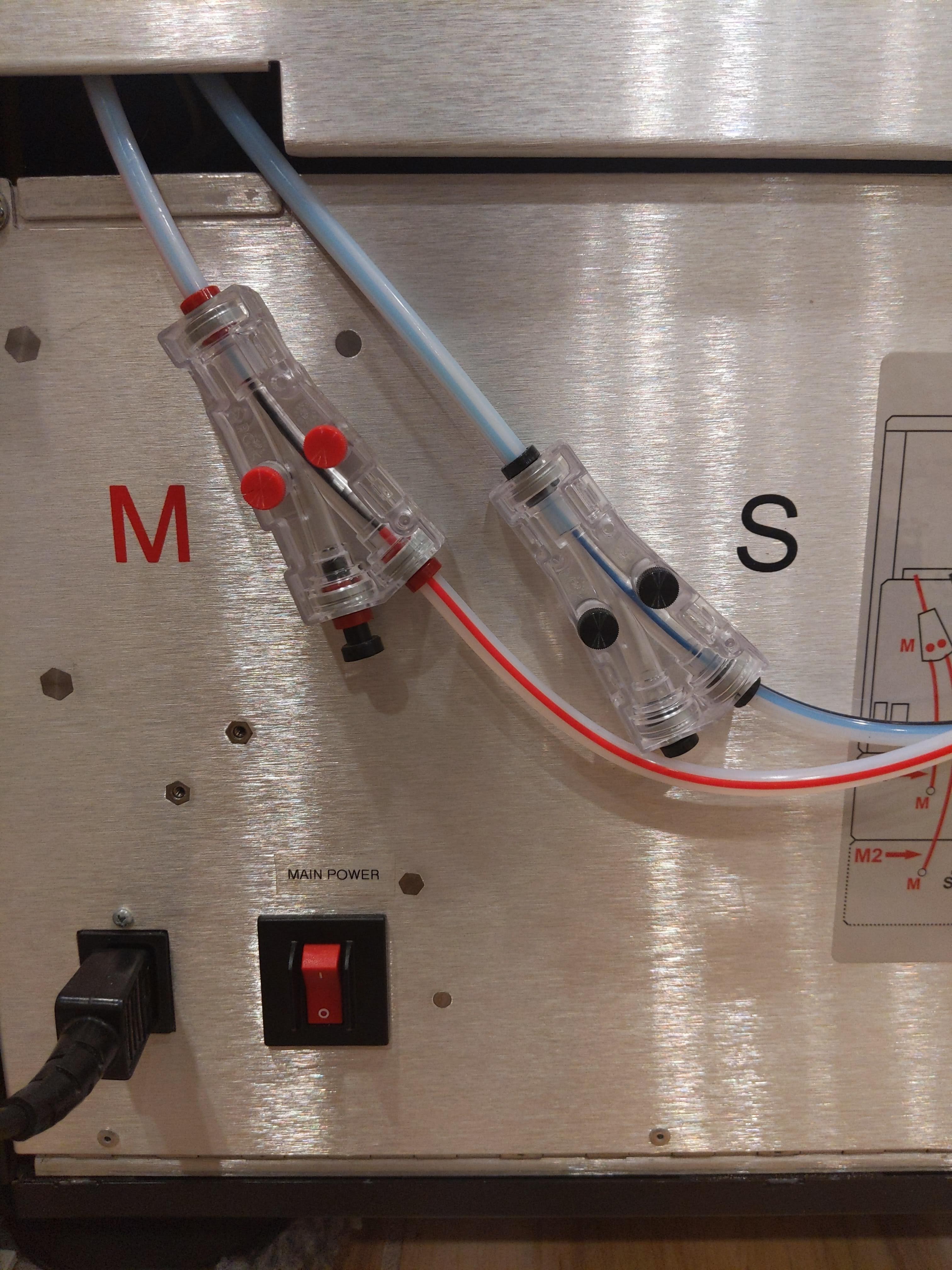

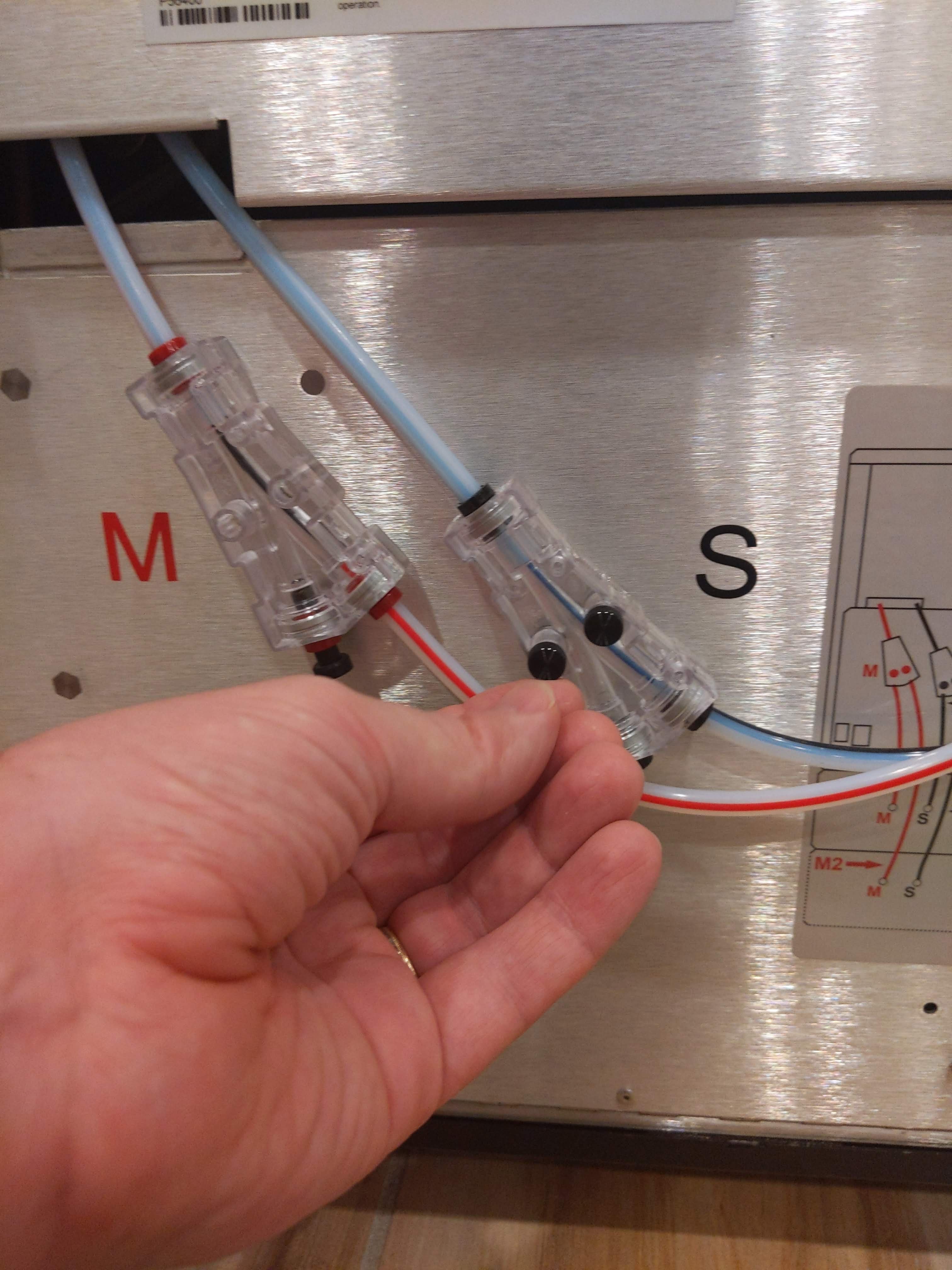

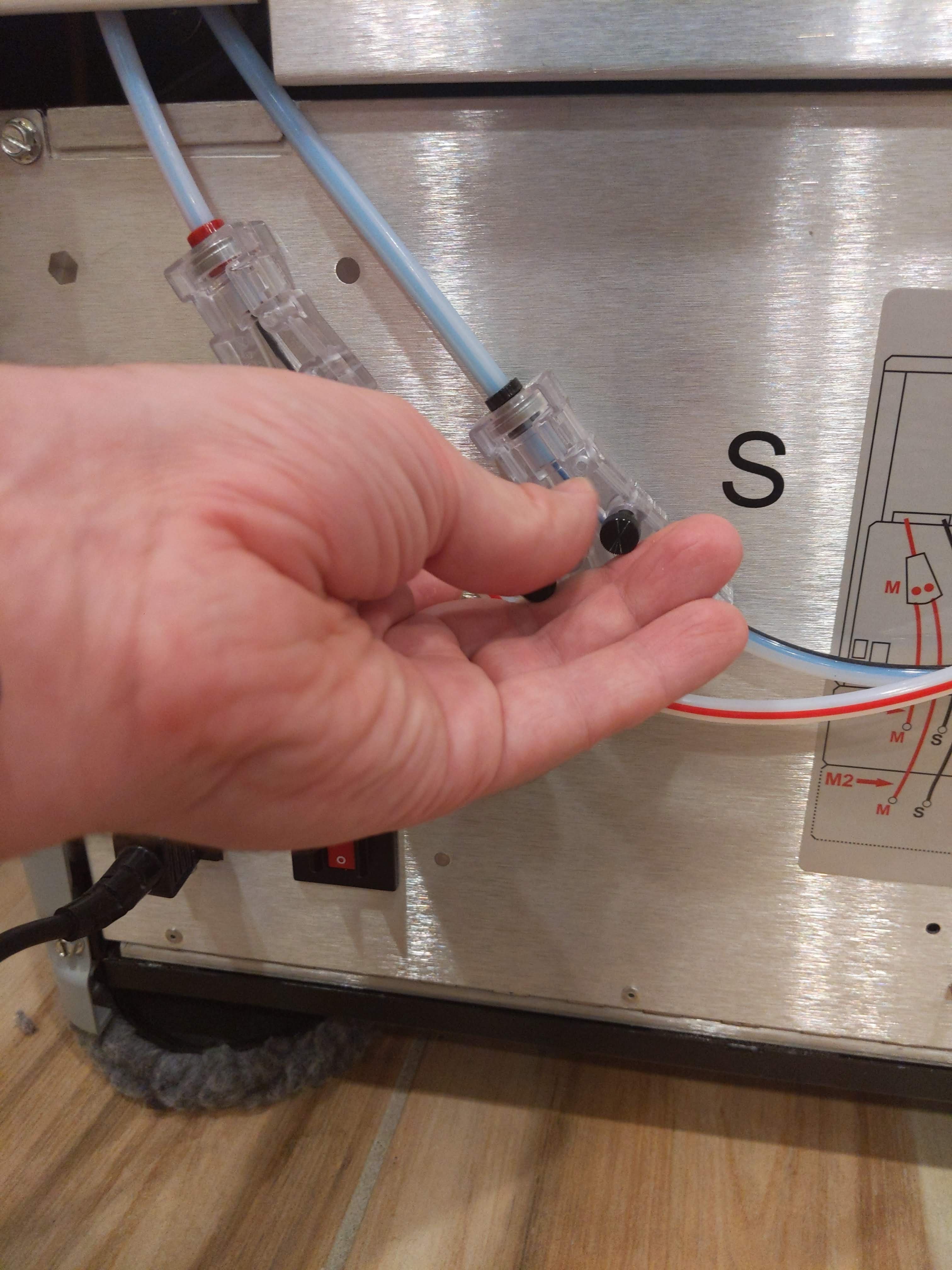

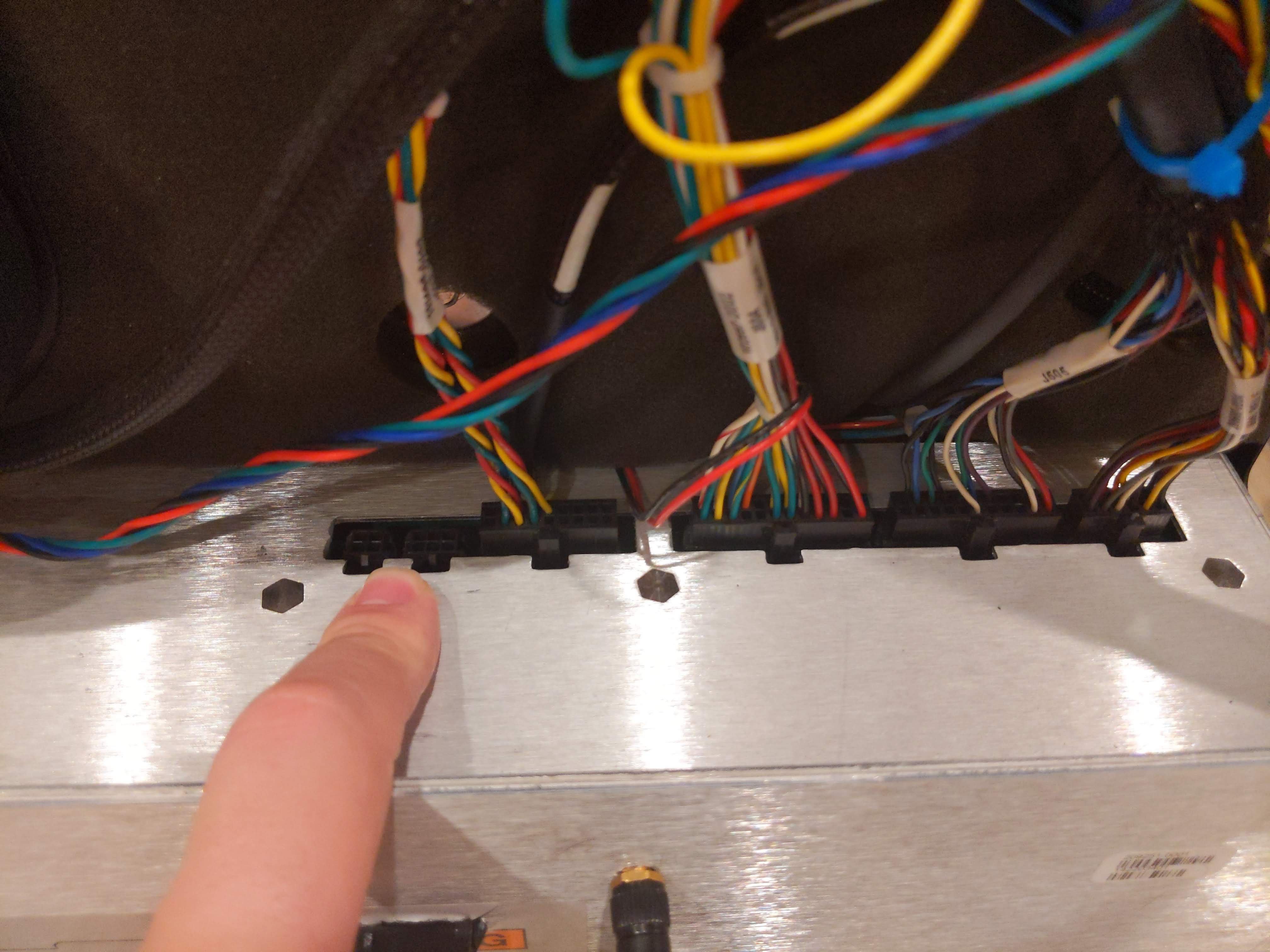

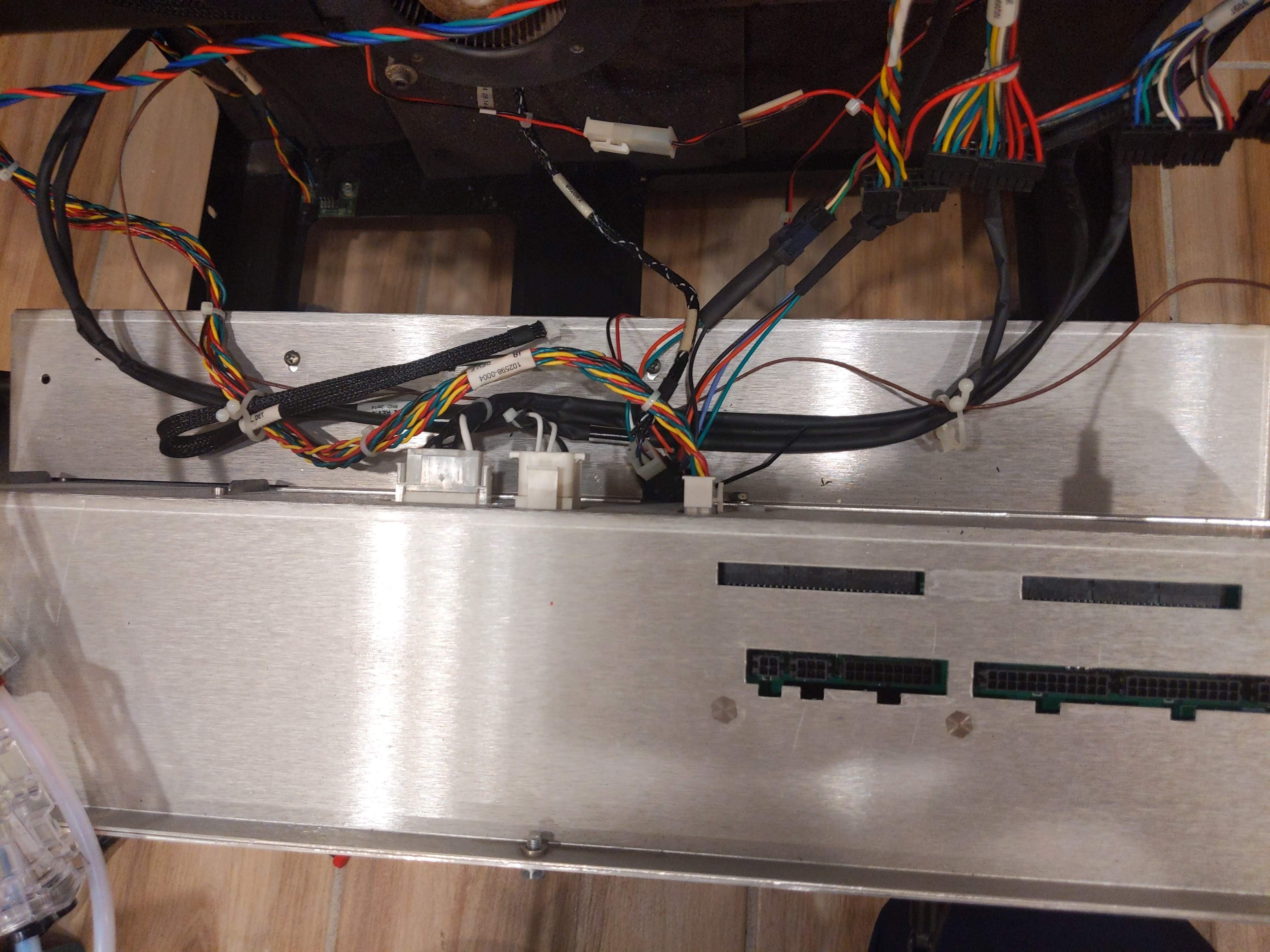

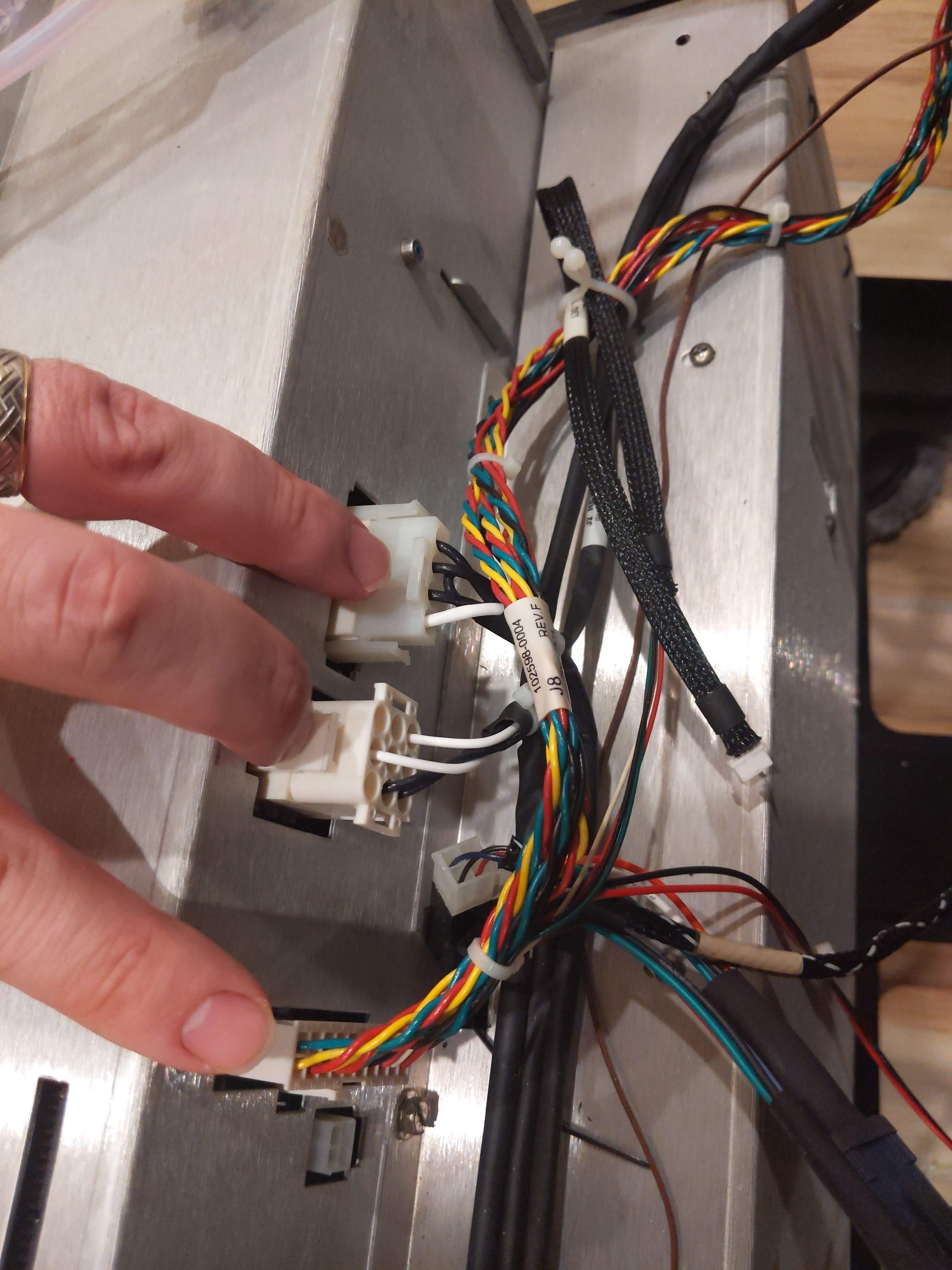

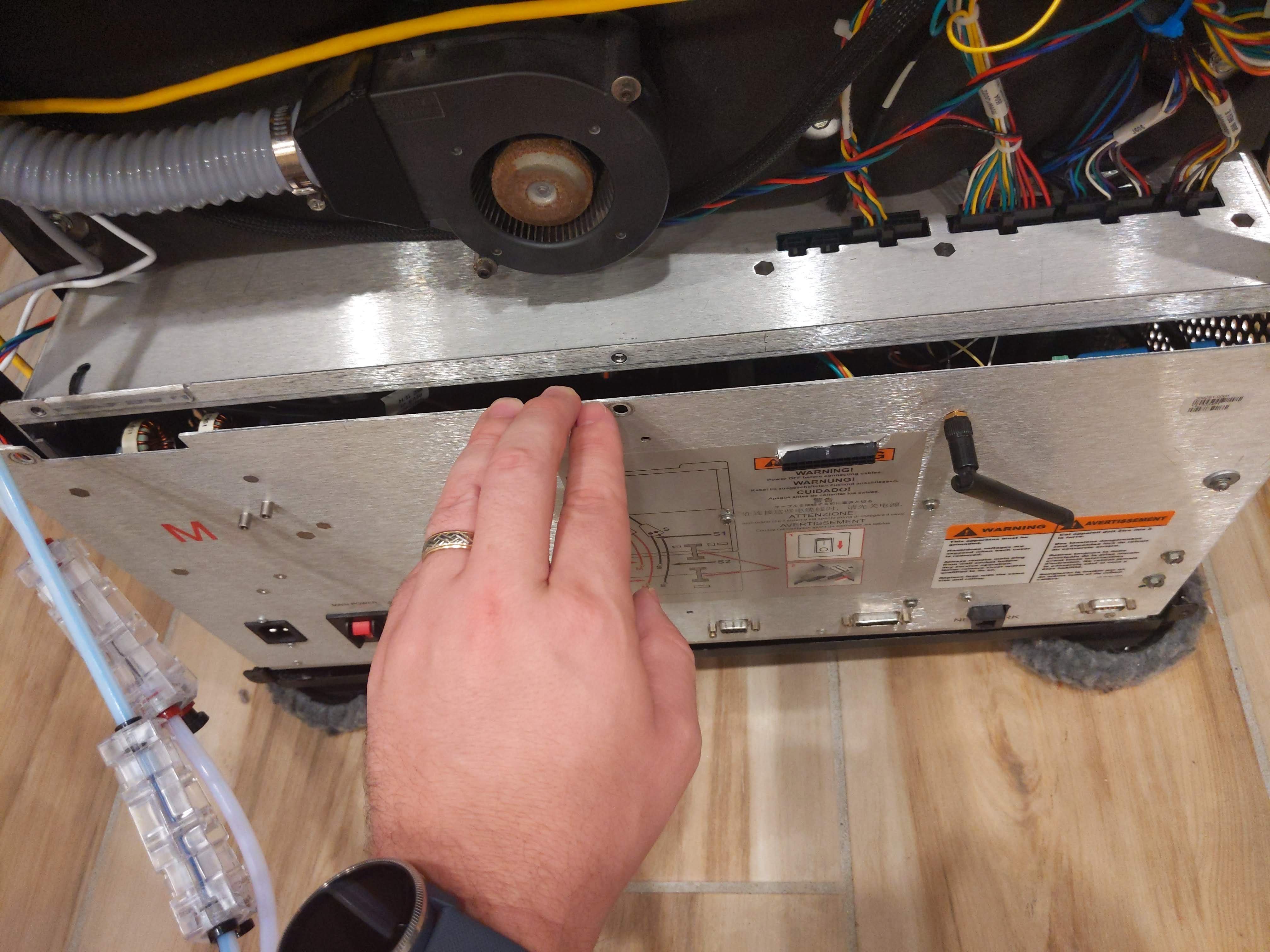

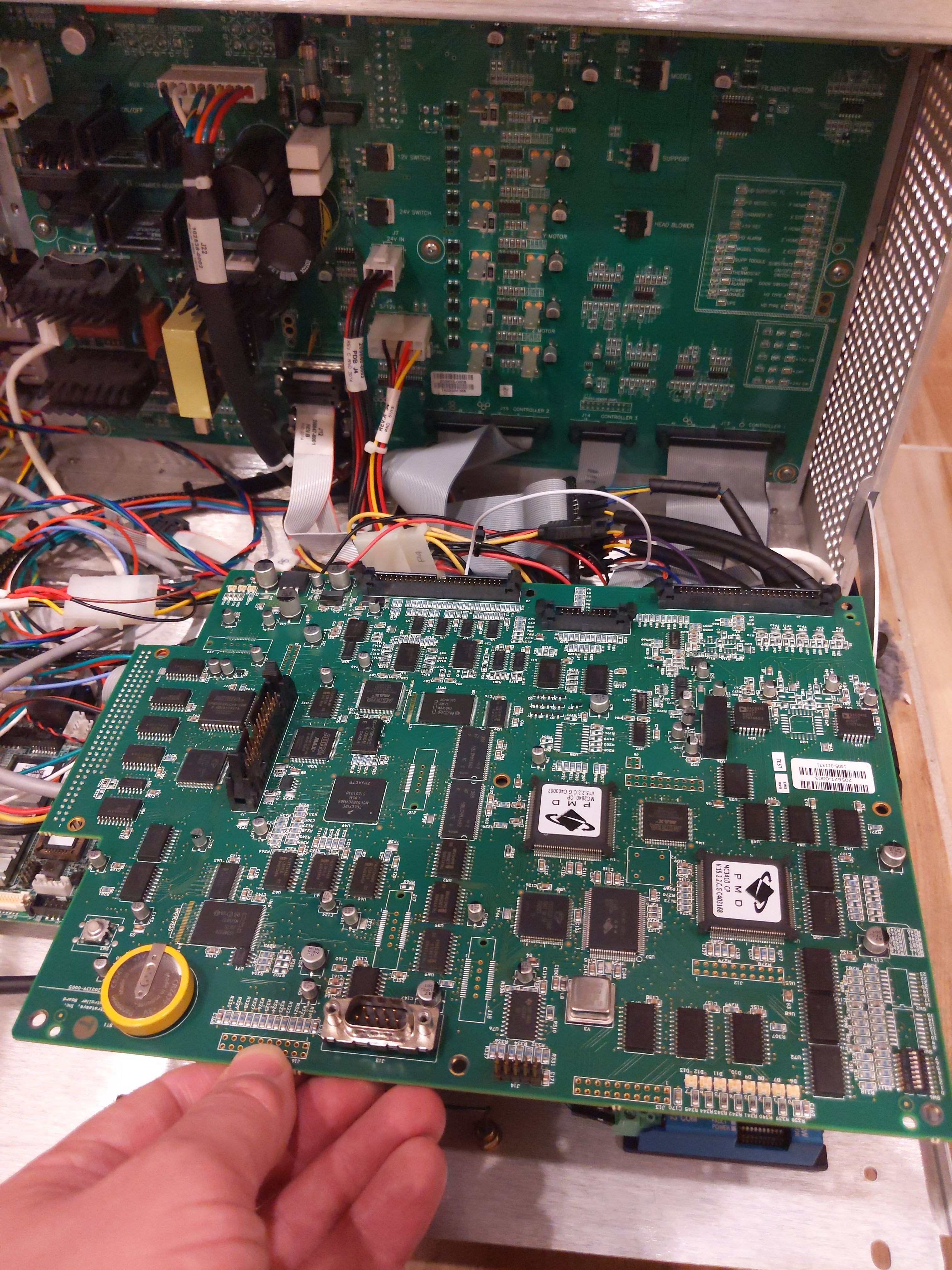

A Duet 2 WIFI and DueX5 expansion board were purchased. These two boards were mounted on the inside of the electronics cabinet on the Uprint using the standoffs from the previous control board. These boards enabled control of all signaling and X, Y, Z motor control. Yet, the extruder motor is not driven by a heavy stepper motor. It is driven by a DC servo motor. The Duet 2 WIFI allows for external motor drivers to by controlled through Step Dir outputs. A GeckoDrive G320X was also purchased. Following the pinout diagrams slowly the Uprint was taken control of like a slowly creeping mind controlling disease. First the X, Y, and Z strepper motors were directly taken control of by the Duet 2 WIFI board and tested making sure to connect the correct wires to each phase of the steeper motor (Phase A and Phase B determined by a continuity check on the existing Molex connectors coming from the motors to the I/I board and the back of the PDB board). Wires were run through the housing and connected to the Duet 2 WIFI using proper crimps for the connectors. The steps/mm was then calibrated by using a digital caliper. Then the optical endstop outputs from the PDB were fed into the Duet and range of motion was constrained for X, Y, and Z and motor directions were resolved using AJ's pinout diagrams as a guide.

Safety alarm outputs were wired from the Uprint to the DueX5 expansion board to shut down the heaters when any of the head, chamber, or head thermostat alarms are triggered. This was then programmed in the Duet Web Control Software to shut down the heaters and motors while leaving the cooling fans operational to prevent overheating and thermal runaway. There are 2 power enable relays in the PDB of the Uprint one controls power to the 120V DC power supply and one controls the motor power (in our case only the extruder motor due to the bypassing of the PDB for the X, Y, and Z motors). These relays were wired to the DueX5 PWM outputs. Additionally signaling to the door lock was also connected to prevent opening the door and letting out the...

Read more » Jeremy

Jeremy

Mark Rehorst

Mark Rehorst

Kernal BT

Kernal BT

E/S Pronk

E/S Pronk

Hi, Jeremy are you still working on this project?