-

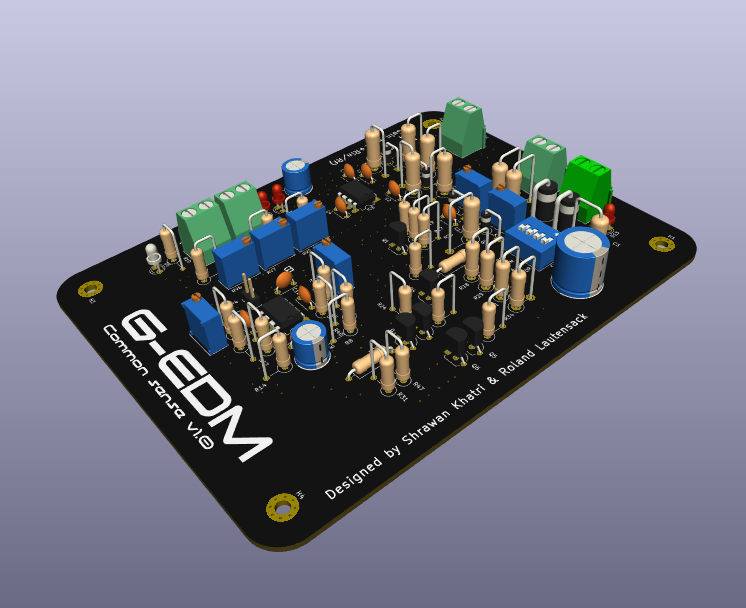

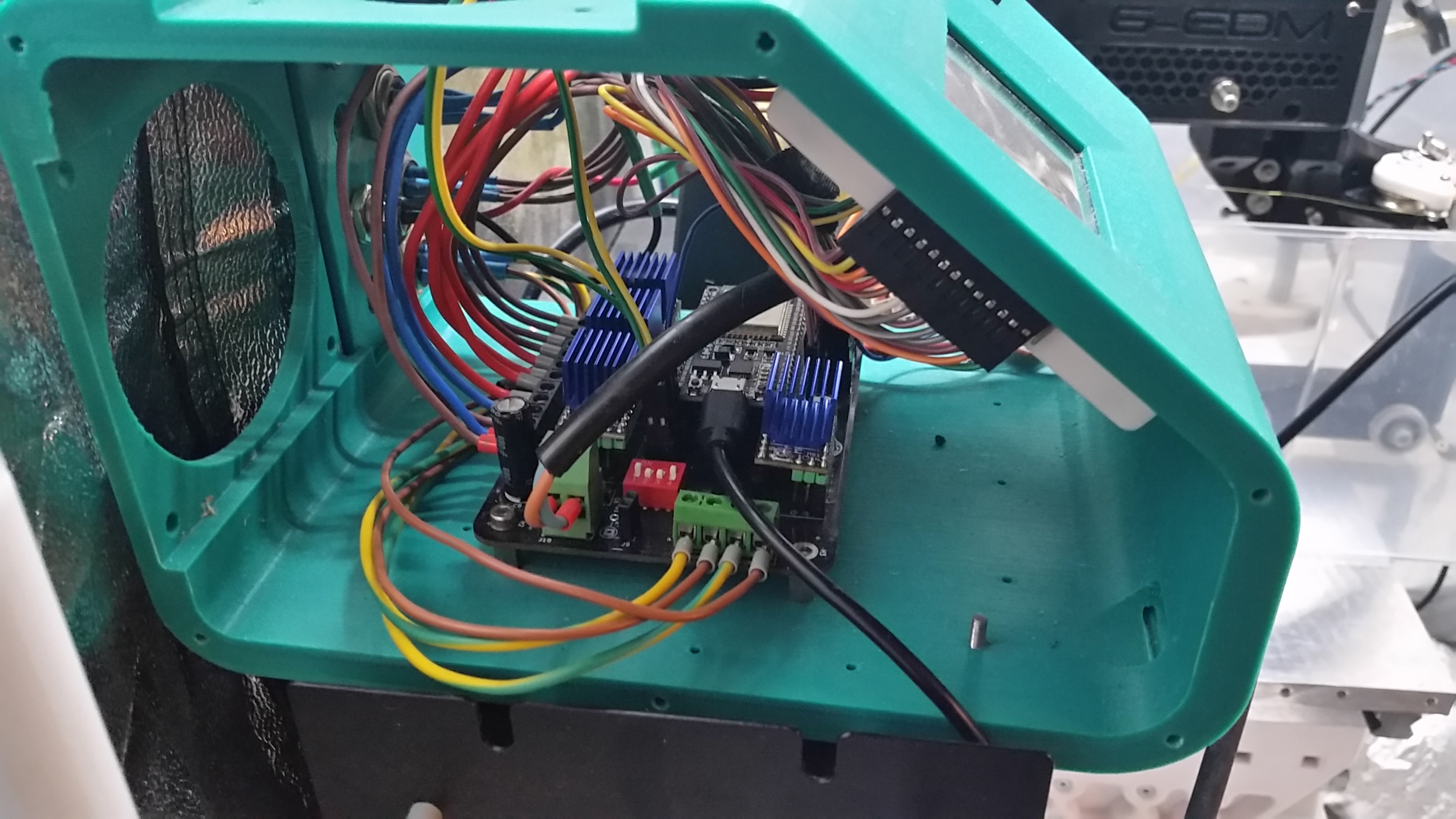

New PCBs, new sensing unit

03/08/2024 at 17:17 • 0 commentsThe new sensing unit finally evolved from a breadboard prototype to a nice and shiny PCB.

The feedback works nice and sensitive. It is able to capture the raw water contact too. and reacts to tiny single discharges.

I won't go into details about the parts but the board offers a fully isolated high side shunt current feedback. A linear optocoupler is used for isolation. The ESP is now fully disconnected from the pulseboard.

PS: Thanks to PCBway for the extra boards.

![]()

![]()

![]()

![]()

-

Repeatable results - GEDM vs 30mm steel

02/18/2024 at 04:07 • 0 commentsThings start to turn out very nice. Another cut on the 30mm block was successful. Some changes to the code doubled the speed of the cut.

![]()

![]()

![]()

![]()

![]()

![]()

-

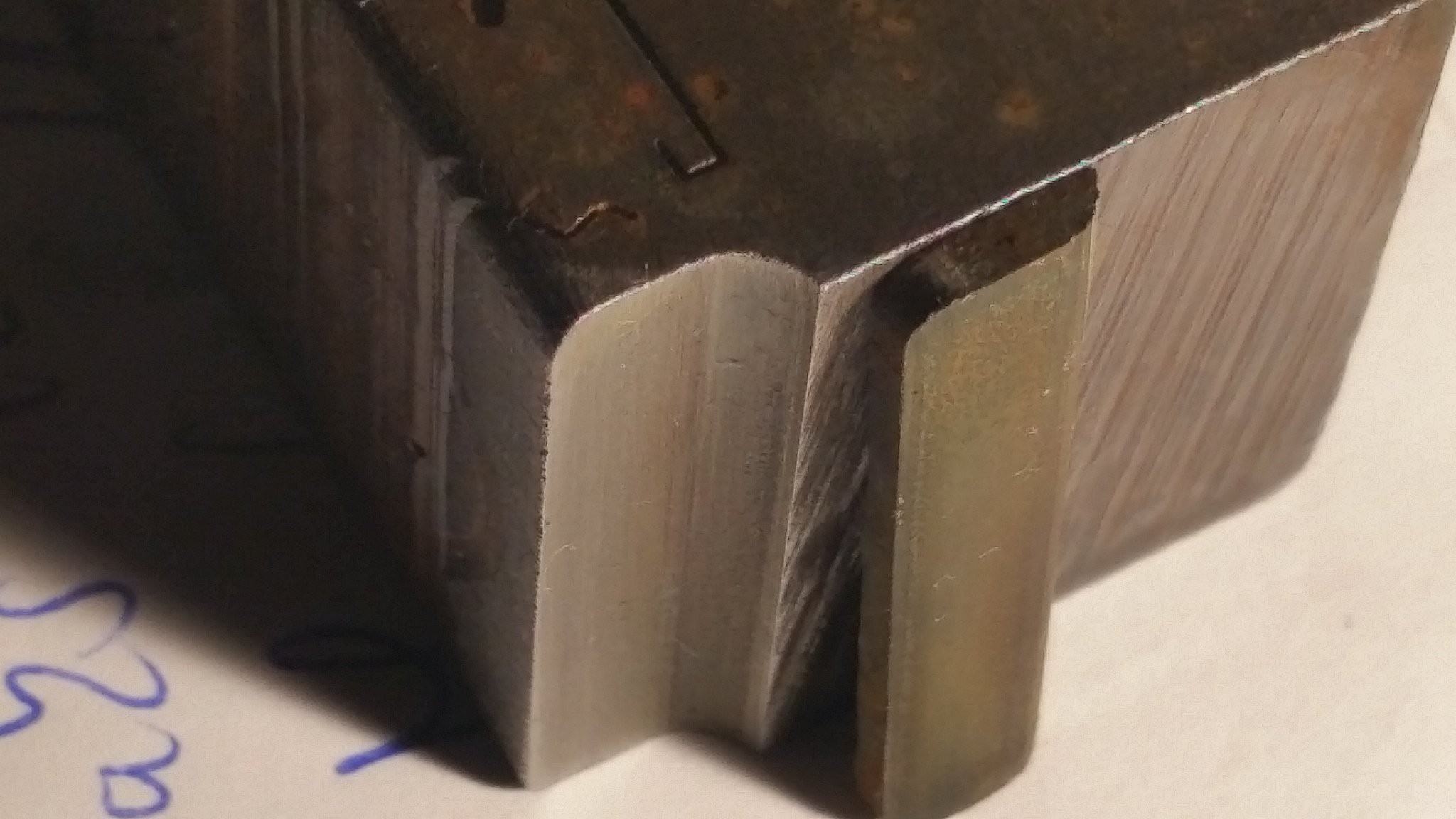

30mm steel against the GEDM - The final challenge

02/17/2024 at 06:41 • 0 commentsPS: Most of the other cuts on the block where testcuts. The one G would have finished but the process is too slow and I had to edit the code. Can't wait for the full cut to finish every time.

Points so far:

30mm Steel: 200

GEDM: 1

The finish is insane.

![]()

![]() The exit moment:

The exit moment: -

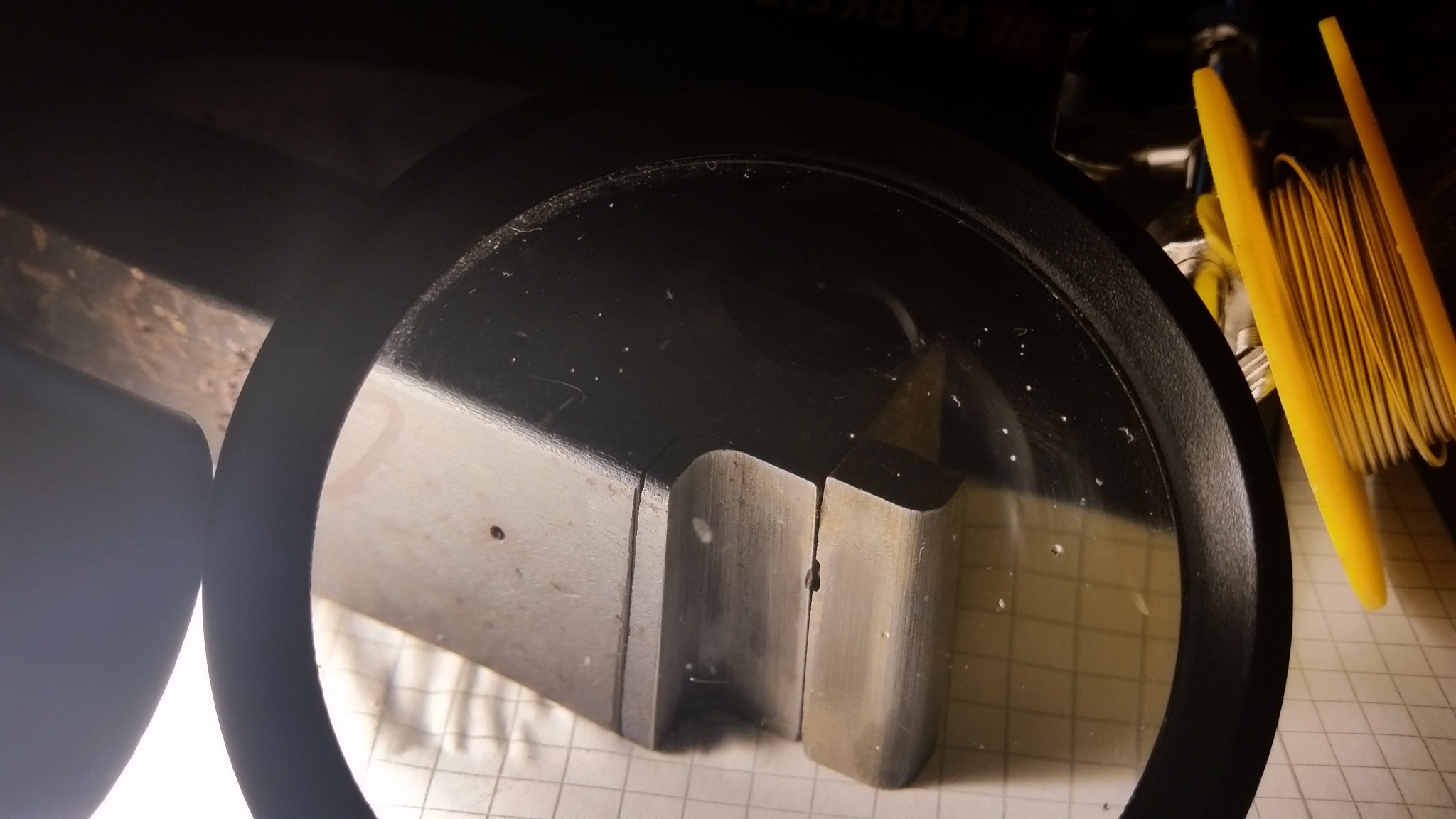

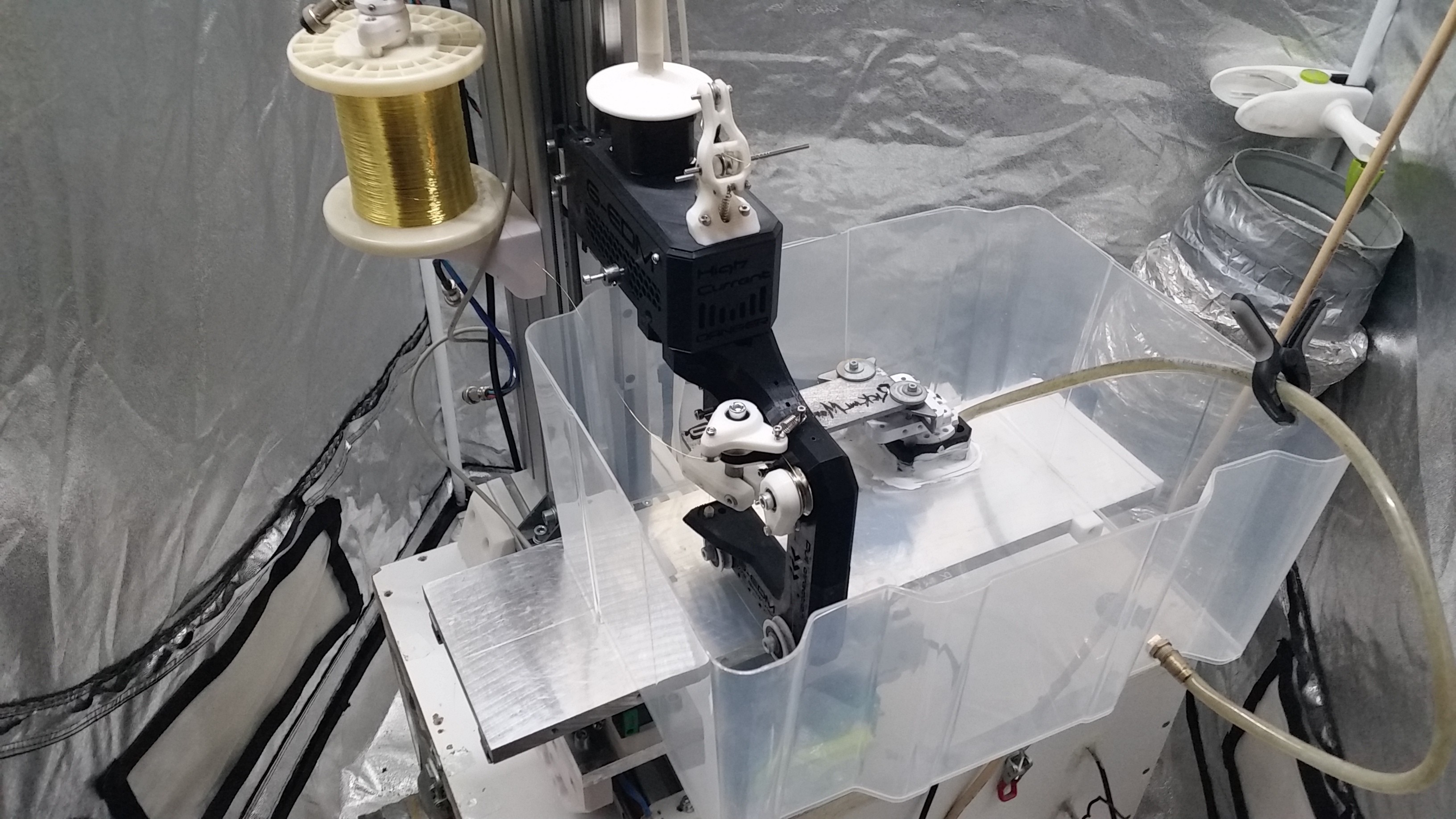

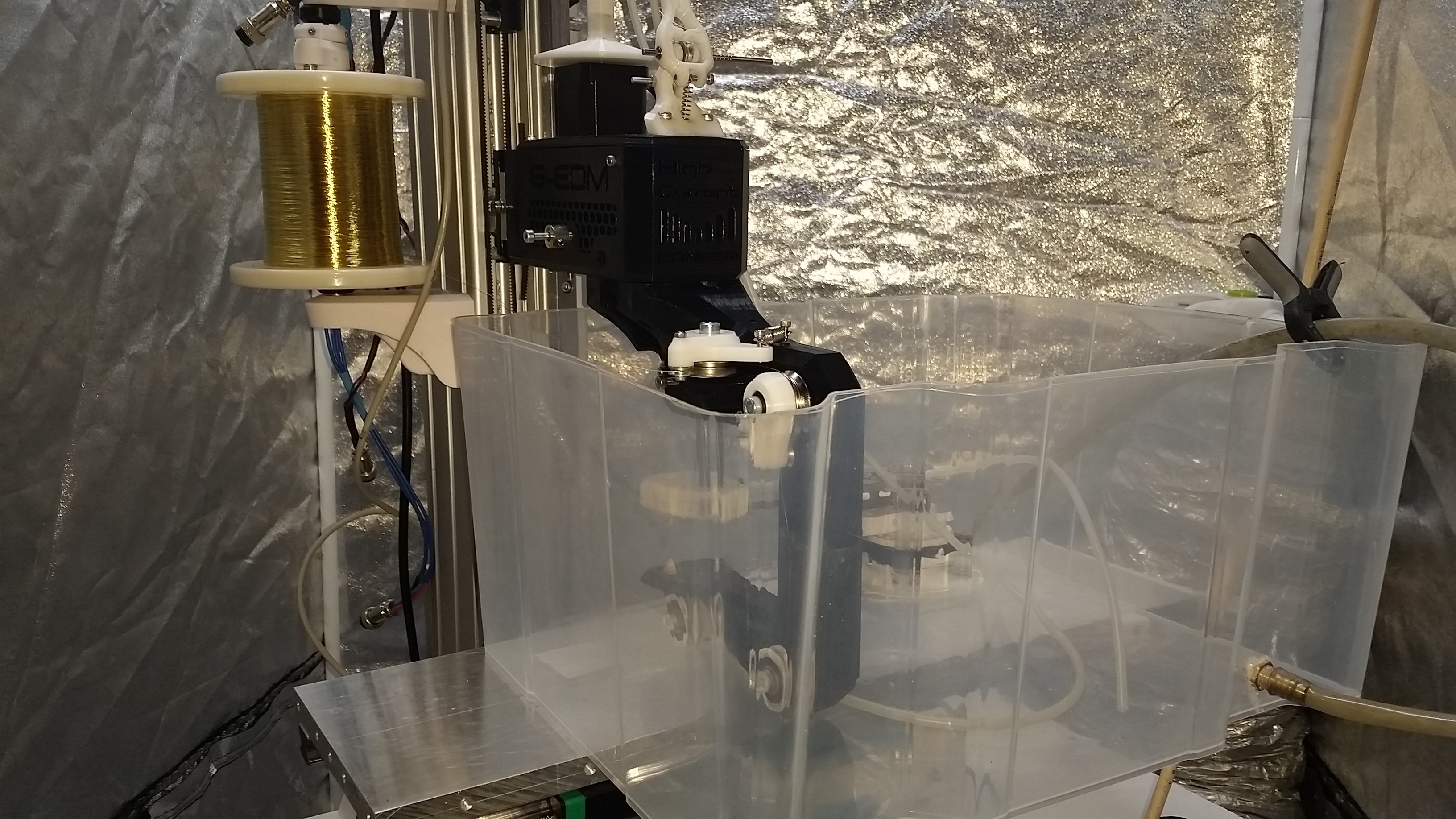

New water reservoir

01/21/2024 at 00:55 • 0 comments![]()

![]()

-

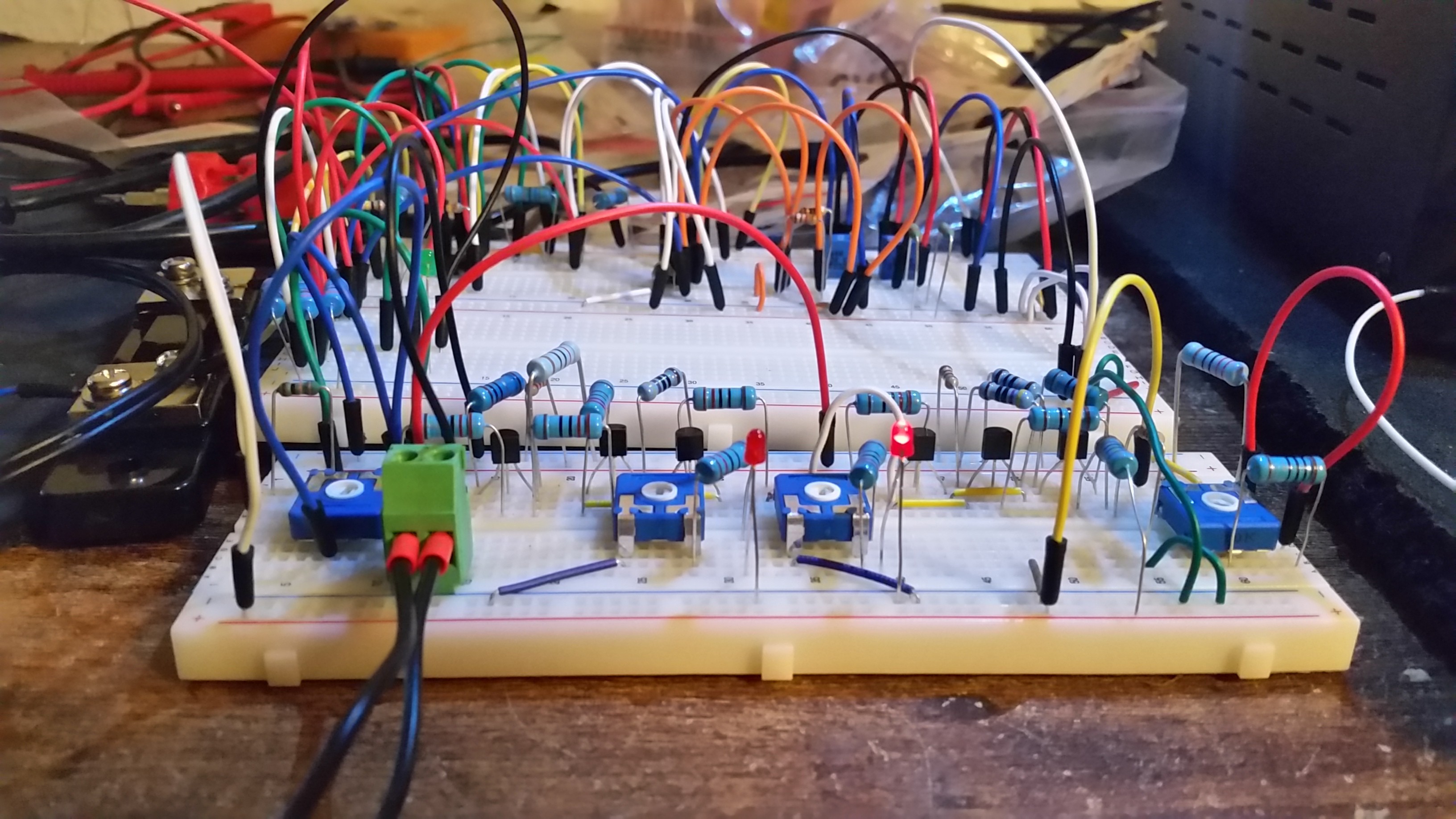

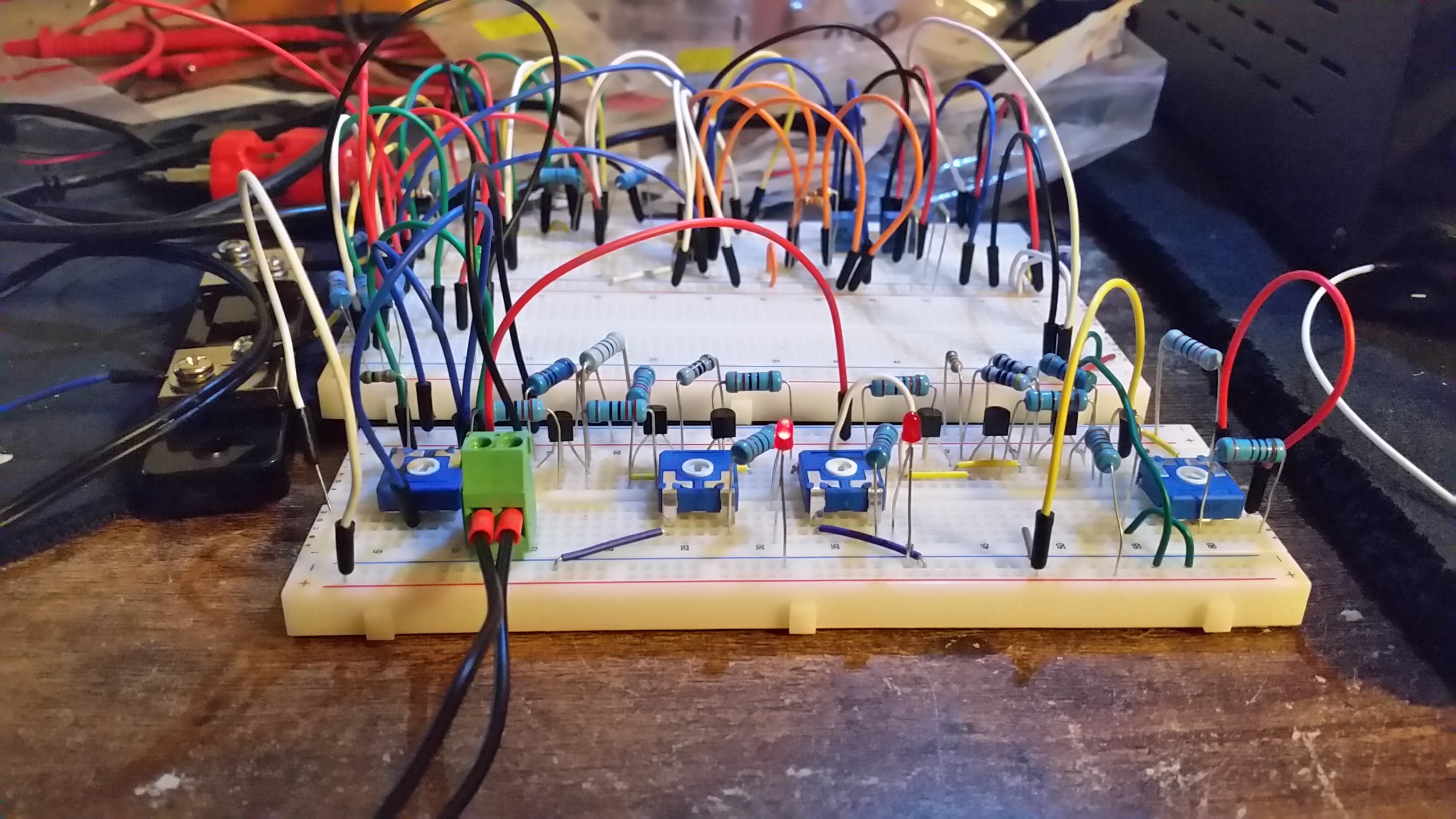

Common sense v1.0 extension

11/27/2023 at 03:42 • 0 commentsCurrently the GEDM uses a simple voltage divider network on the spark PSU as only source of feedback. This only works with a current controlled PSU and it is not perfect.

So it was time to get into real gap sensing or at least something that is able to sense the current that runs through the electrode.

Wasn't easy to get some usable results but the circuit designed for sensing seems to work on the breadboard.

It provides analog feedback and two digital feedbacks with variable setpoints.

This is not a replacement part for anything. The current pulseboard is powerful and works acceptable well. In combination with this extension it should be possible to get very accurate control over the EDM process even with a linear PSU.

The circuit was designed with the help from Shrawan Khatri

![]()

![]()

![]()

![]()

-

Custom single axis sinker EDM running on GRBL makes big progress

10/15/2023 at 21:56 • 0 commentsThe first custom machine running on G-RBL starts to produce some very stable burns.

It wasn't easy to get it running and the code had many changes that will be part of the next release. I'm impressed with this build.

It uses a TB6600 driver ( don't use them! Don't look at them! Maybe pretend those things don't exist at all! ) the step resolution is 346 steps per mm. So it is hard to get a stable burn at all as a single step can be enough to go from the lower setpoint range to a short circuit.

The pulse circuit is a little different from what is used in the G-EDM. It is currently a power resistor based circuit and the feedback signal doesn't measure the voltage drop on the PSU but the spark gab voltage.

It even uses high precision cutter-mud as dielectric.

-

Next cut - Wire EDM a dragon head (images only)

10/08/2023 at 21:01 • 0 comments![]()

![]()

![]()

![]()

-

But what about the Powercore?

10/05/2023 at 04:53 • 0 commentsThis log will be a little about the Powercore from rack robotics. I've heard a lot about it and people keep contacting me about it.

After looking into it a little I came to the conclusion that it is outdated technology.

Back in the days most EDM spark generators used some kind of power resistor to limit the current. But this concept generates a huge amount of heat and is just wasted energy.

My first pulse generators used power resistors too until I changed to a switch mode power supply.

It is somehow sad that they seem to not provide a lot of information about the specs of this product. The available information claim that the switching frequency is about 2khz which would be very slow if this is the max speed. On the G-EDM the lowest frequency I use is about 5khz and my personal sweet spot frequency is between 10-30khz.

Since it is only a pulsegenerator without any motion controller yet there is not much I can say about it. There are no customer videos available. After selling a huge amount one should assume some videos to pop up that are not related to the team of the product. This may speak for itself. But I don't want to make it look bad. Without a motion controller even the best pulse generator is useless.

But there are good news too for the powercore fans. After watching the channel from rack robotics there seems to be a great interest in ESP32 Motionboards with TMC2209 drivers in the last days. That is super cool since that is exactly what the G-EDM uses. So I know it is a good choice.

I'm confident that they will be able to come up with the promised wire EDM build and maybe it will run exactly as good as the G-EDM. Wouldn't that be awesome?Stay charged

-

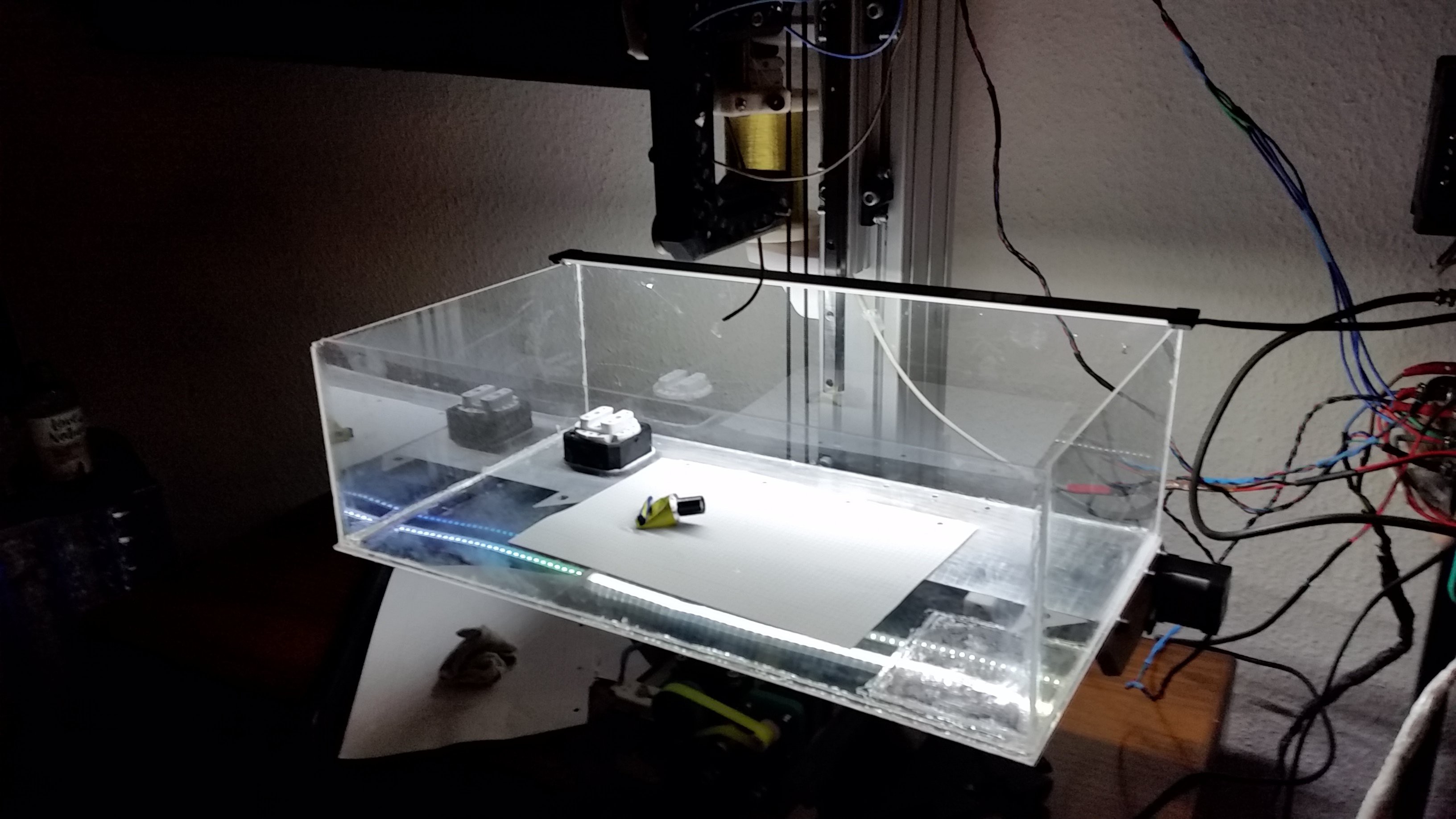

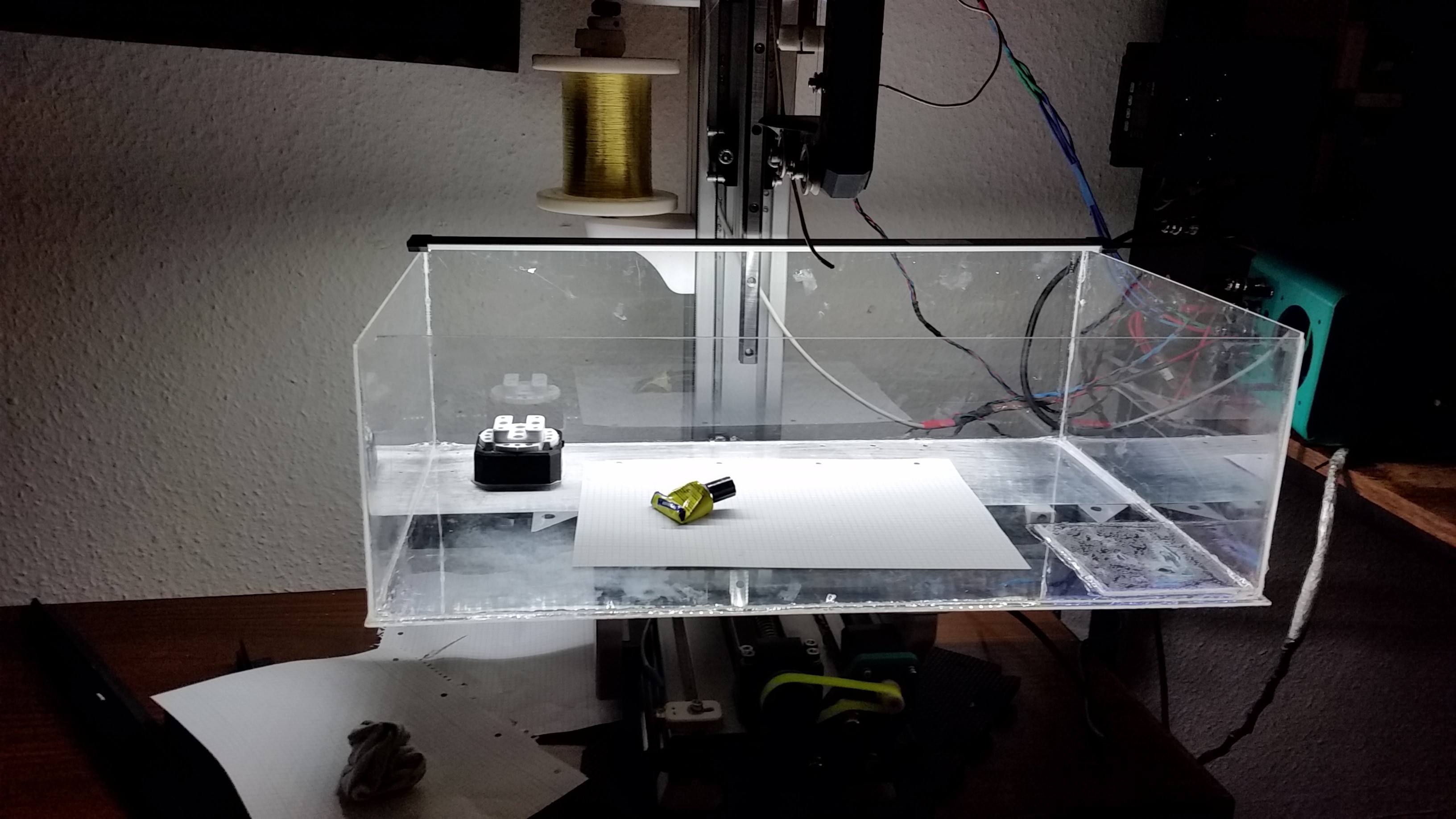

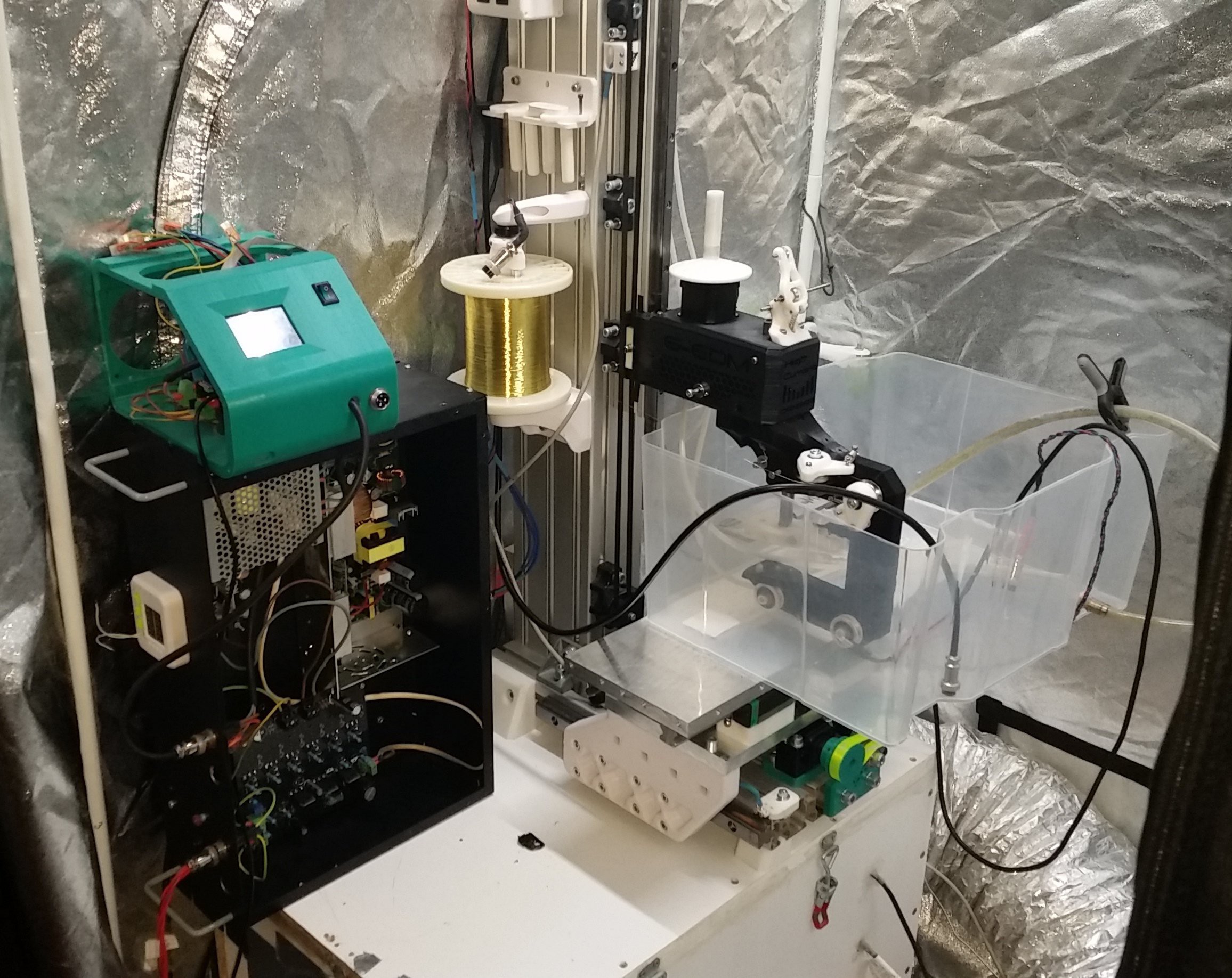

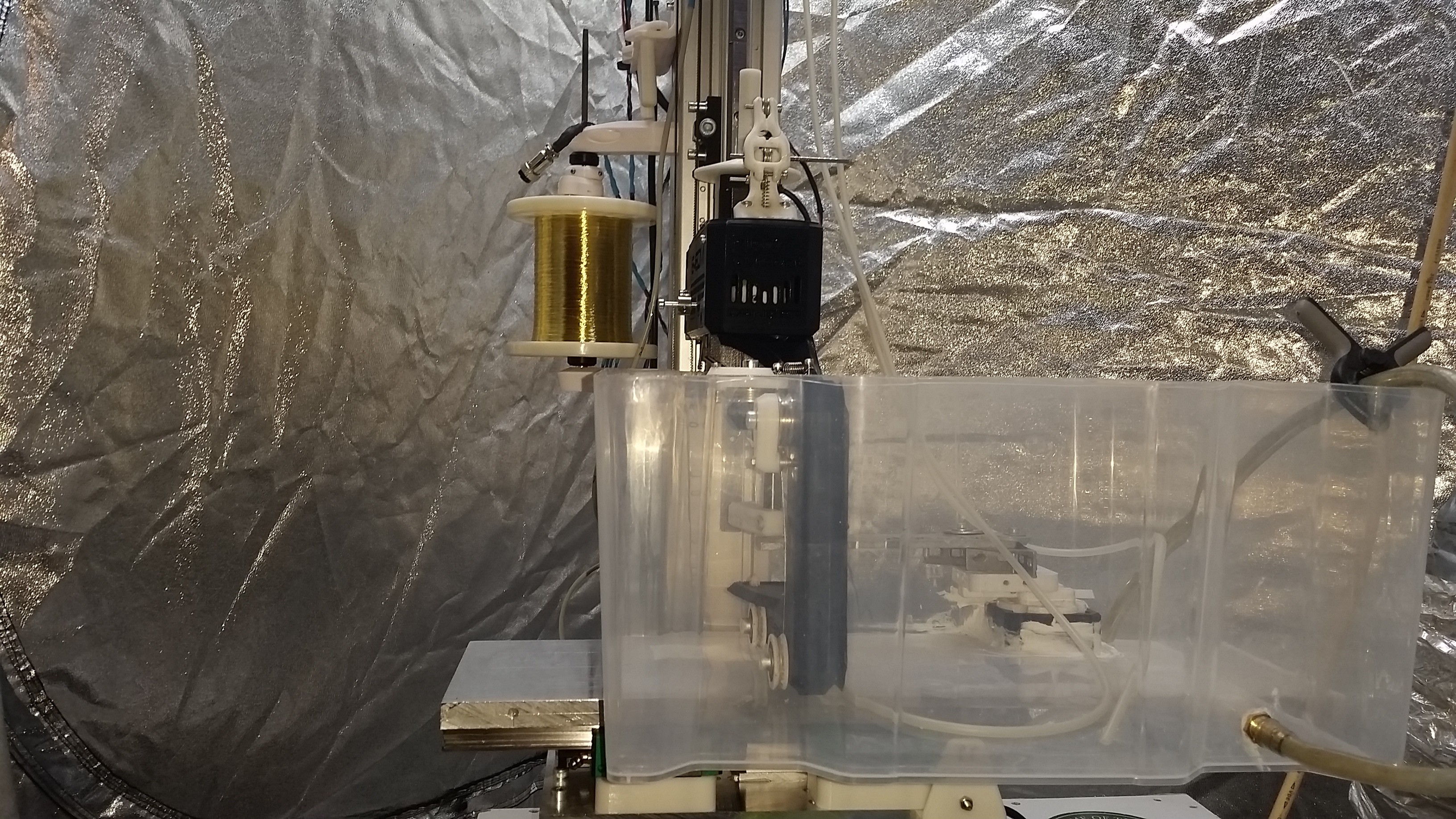

Safety first. EMI safe enclosure and air filter for safe EDM operation

10/04/2023 at 01:41 • 0 commentsI decided it is time for some safety measurements. While cutting every now and then some smoke bubbles emerge from the water. And sometimes one can smell metal after one of those bubbles burst.

I don't think this is something that should be inhaled and decided to move the whole build into a mylar tent with activated carbon air filtering. The mylar also helps reducing EMI noise which is a good thing.

It looks cool and will make a great setup for future videos with an even light distribution.

This is the naked G-EDM prototype:

![]()

![]()

![]()

![]()

![]()

-

The first custom single axis sinker EDM build running on G-RBL

10/02/2023 at 01:28 • 0 commentsThe first custom sinker EDM build running on G-RBL just emerged. It is a bare-bone build that doesn't use any G-EDM components except for the software.

It uses a custom stepper driver and a custom pulse generator running at about 100v.

Due to the different step resolution of this setup it will still need some finetuning.

Thumbs up!

G-EDM

The G-EDM is an electrical discharge machine that supports sinker EDM, EDM engraving, EDM drilling and Wire EDM operations. #Drahterodieren

gedm-dev

gedm-dev