-

BJR_LOG_18 Project Complete

11/09/2025 at 21:29 • 0 commentsThe BJR_019 is now complete!

Thank you for coming along for the design and development of the BJR!

I learned a lot about coding, prototyping, sensors, and control systems during this project.You can find the full source code of the project in this repository: https://github.com/EverydayDynamics/bjr

Here is a picture of the finished product:

![]()

The coated 3d printed parts came out beautiful!

My worry was that the black vinyl on top of the touchscreen would hinder it's effectiveness, but no issues found whatsoever.

Please enjoy this short video showcasing the robot in operation!

Let me know if you would like me to show how any of it's parts work, or what project I should do next.

I'm thinking about something with machine learning in it.

Cheers!

-

BJR_LOG_17 Software Overview

08/22/2025 at 09:39 • 0 commentsRunning the BJR on Rust

Inside the BJR_019 lives an STM32F4 microcontroller, orchestrating motion control, sensing, and communication. Every line of firmware on that chip and the supporting software that interacts with it was written in Rust.

The decision was deliberate. I believe the Rust ecosystem is mature enough to get more widespread in the embedded community. With this project I wanted to test my assumptions.

![]()

Impressions of using Rust in embedded systems

Debugging bare-metal embedded systems is always harder. Crashes rarely announce themselves with helpful stack traces. Most often, things just stop working.

With Rust, many memory-related bugs are caught before they ever touch the hardware. The compiler enforces safety rules that can feel annoyingly strict at times. In retrospective those same rules have saved me from introducing hard-to-find bugs.

Using a different language doesn't make bugs magically disappear, but even if it fails, debugging has been much simpler.

Took a little while until I got used to the HAL's design patterns, but once I got a hold of it, I could apply it to all the other projects in rust. It also gave birth to my own higher level abstraction (BAL, the Board Abstraction Layer) that I'll introduce in a later log.

What's included?

The BJR_019 project isn’t just firmware. Alongside the embedded code, I wrote a telemetry visualization tool, also in Rust.

![]()

This small visualizer enabled me to chisel out control related issues with minimal data processing. I could see what's happening to the robot in real time.

Because both the firmware and the visualization software shared the same language, I could rapidly iterate on the communication protocol. Adding a new telemetry field was as simple as tweaking a few lines in one package That tight integration was a huge win for speed.

Programming and communicating with the BJR_019

One of the standout parts of this journey has been using probe-rs. an incredible toolkit for embedded Rust. With a single-line installation, I gained:

- A flashing tool

- A debugger

- A communication bridge using RTT

If you're unfamiliar with Segger's Real Time Transfer (RTT) feature, you're in for a treat! Check it out here.

Calling

cargo embed --bin bjr_app --releaseWill do a couple of things:

- Build and flash the specified program

- Opens 3 RTT channels:

- The log outputs from the device

- the terminal interface for sending commands

- a binary stream of telemetry data, piped into a web socket. the telemetry visualizer connects to this socket and displays the measurement data real time.

To configure this, I added a simple Embed.toml file:

[default.general] chip = "STM32F446RETx" [default.rtt] enabled = true up_channels = [ { channel = 0, mode = "NoBlockSkip", format = "String" }, { channel = 1, mode = "NoBlockSkip", format = "String"}, { channel = 2, mode = "NoBlockSkip", format = "BinaryLE", socket = "127.0.0.1:8080" }, ] tabs = [ { up_channel = 0, name = "Log" }, { up_channel = 1, name = "Terminal" }, ]You set it once and forget it.

Why This Matters

For me, rapid iteration is the name of the game. The faster I can flash, debug, and visualize, the faster I can tune the robot and push it forward.

Rust, combined with probe-rs, RTT and the visualizer, gave me a workflow that was fast, productive and genuinely enjoyable. It reduced friction, allowing me to focus less on plumbing and more on experimenting with the robot itself.

-

BJR_LOG_016 Flight Case

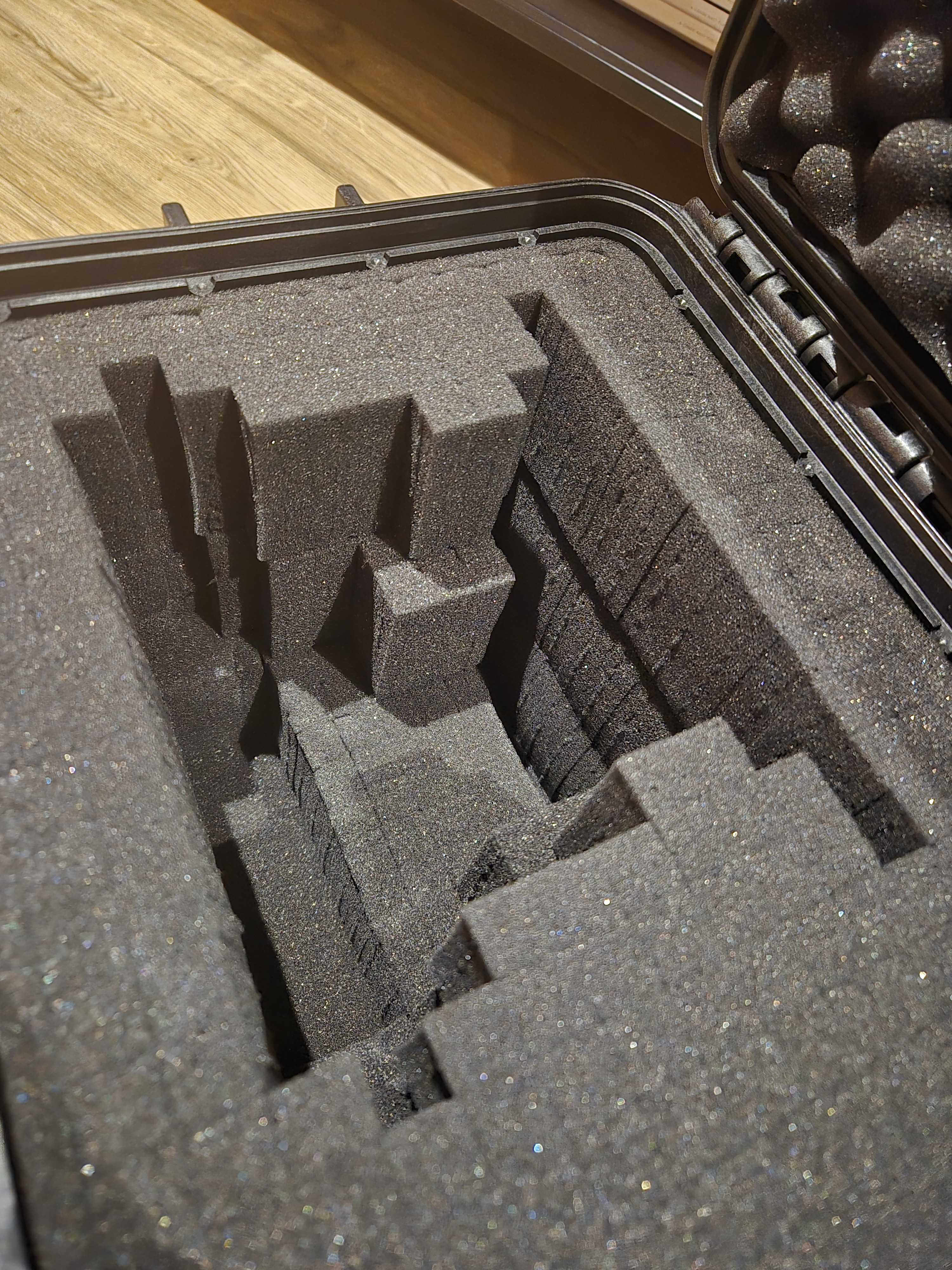

08/19/2025 at 22:57 • 0 commentsThe BJR just received a flight case!

It's probably an overkill, but I've been working on this project for a long time, so I wanted to make the investment to be able to transport it without having to fear for it's safety.

The case came with multiple layers of pre cut foam cells. All I needed to do was to break away the thin bit of foam holding the chunks together, and that left me with a cavity that fits the robot perfectly.

![]()

![]()

The box is the MAX400 case. It's a tad bit bigger than what I needed, but better this way, so I can ship the accessories alongside with it.

These flight cases are no joke, it's rated for IP67, and various military standards as well.

If you find yourself having to transport your project, I can highly recommend a flight case. If not for else, the coolness factor is through the roof if you rock up to the function with one of these. -

BJR_LOG_015 Dry Transfer Decals

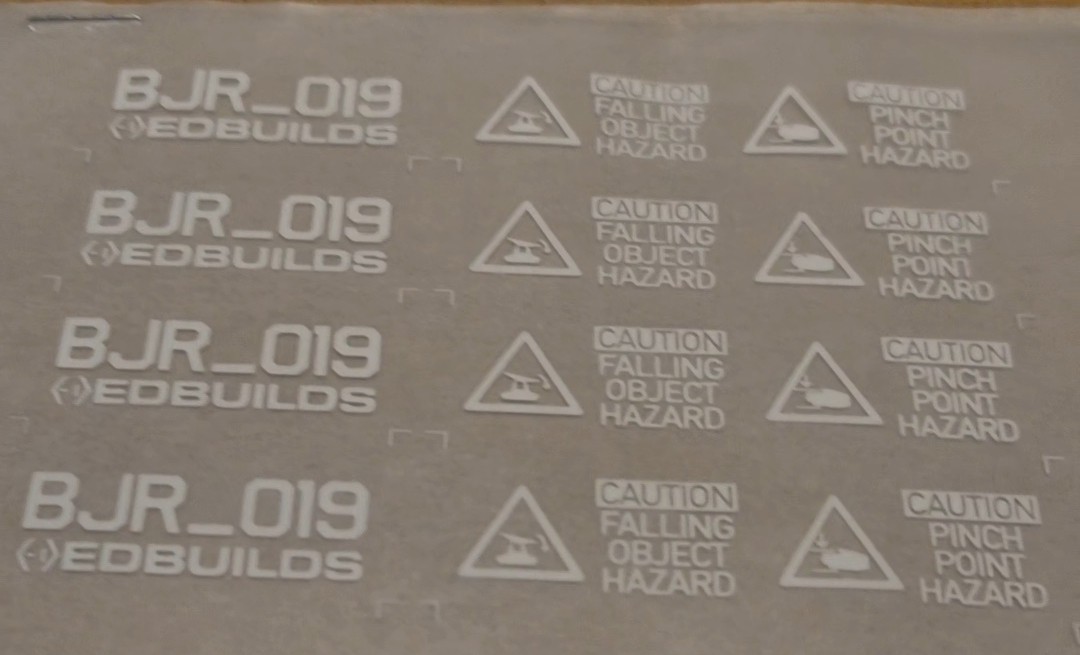

08/18/2025 at 21:25 • 0 commentsSome Dry transfer decals have arrived today!

![]()

What are these?

These are sort of stickers that will act as decoration and warning signs. on the robot. I chose these instead of Vinyl or water transfer, as it adds the least amount of height to the surface. (Or as I was told, I still need to test it.) I want the decals to have a low profile, so on the plate it wouldn't disrupt the movement of the ball.

The markings show:

- the corners of the active area

- The diameter of the "Circling" mode

- A cross in the center for the "Center hold" mode

- The triangles show the "Point-to-Point" mode locations.I added the hazard labels after doing a quick risk assessment. these are the main risks that I see when anyone interacts with the robot:

- The universal joint could pinch the skin on someone's finger

- The ball could fall off from the platform, onto someones foot.![]()

And of course, Can't forget the name and iteration of the project:

![]()

Let me know what you think of these designs! I'll post soon about how they look on the robot.

-

BJR_LOG_14 Stable control

08/26/2024 at 19:49 • 0 commentsSorry for the radio silence, in the past couple months I've been busy with getting the software ready.

I will write a couple logs about the software later, but for now, please enjoy this demonstration of the control system:

It's jittery, it's wobbly, it's loud, it's noisy, it's inaccurate, but at least it's stable!

Currently it's a simple PD controller, but more on that in a follow up log.I'm so happy with this milestone, but we are far from being done.

- The control needs to be polished up

- The Base PCB needs to be designed, as it's all on breadboard now.

- The signature middle cable need to be selected

- The Cladding would need a little more work

After that, we might have a viable MVP!

Looking forward for the next steps, stay tuned for updates by following this project.

Please give it a like as well, to keep me encouraged to continue -

BJR_LOG_13 Resistive plate PCB

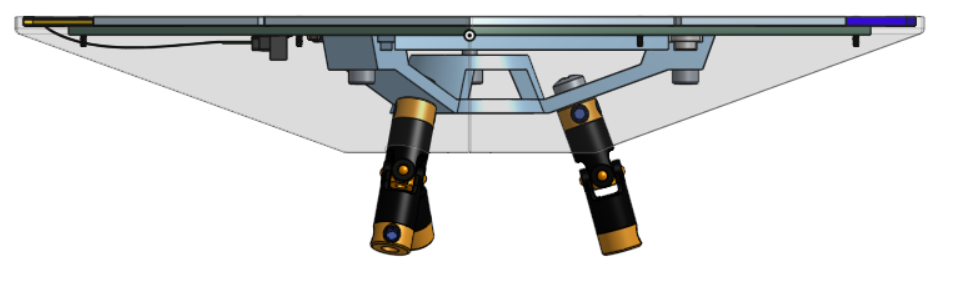

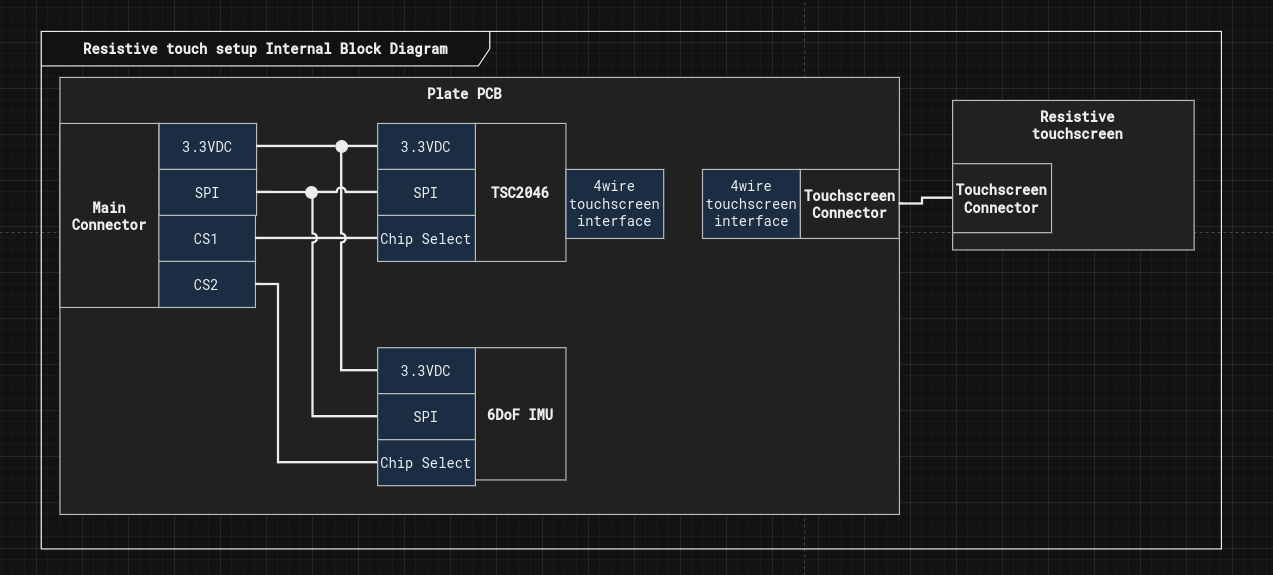

06/12/2024 at 14:12 • 0 commentsIntroduction

In this log we will take a look at the resistive plate PCB, see it's functionality, where it sits in the assembly, and how it was assembled. Lastly I'll go over the lessons learned.

Resistive plate PCB

This pcb serves 4 main functions:

1. It controls the resistive touchscreen through the TSC2046 chip

2. It serves as a strucutral support that holds the resistive touchscreen, and the adjacent elements.

3. Anchors the middle hub, which serves as the holding point of the universal joints

4. It houses a 6DoF IMU as well, to be able to tell which angle does the plate sit relative to the gravity vector.

CAD view of the resistive plate pcb

here you can see how the PCB contributes to the top assembly. (the green hexagonal part)

![]()

![]()

PCB assembly

The chosen IMU (LSM6DS3TR-C) had a leadless package, and a very fine pitch. I didn't feel comfortable soldering it by hand, so I tried out for the first time stencil soldering. At the end it turned out better than I expected it would, however I did have to touch up the connectors by hand. I recorded the process, so please enjoy this short video of the process:

Let me know in the comments if I should improve the soldering process.

Lessons learned

- The PCB manufacturer quotes the PCB based on size, so using the PCB as a large structural element might not been the best choice. In the future it's best to keep the PCB as small as possible, and use other material for support.

- The threaded anchors rip the copper off easily from the PCB, so I had to glue them in position, which helped at the end. It's a good lesson again not to use PCBs for structural support.

Summary

Over all the resistive plate PCB will be an important part of the build, and now I have a working prototype of it.

-

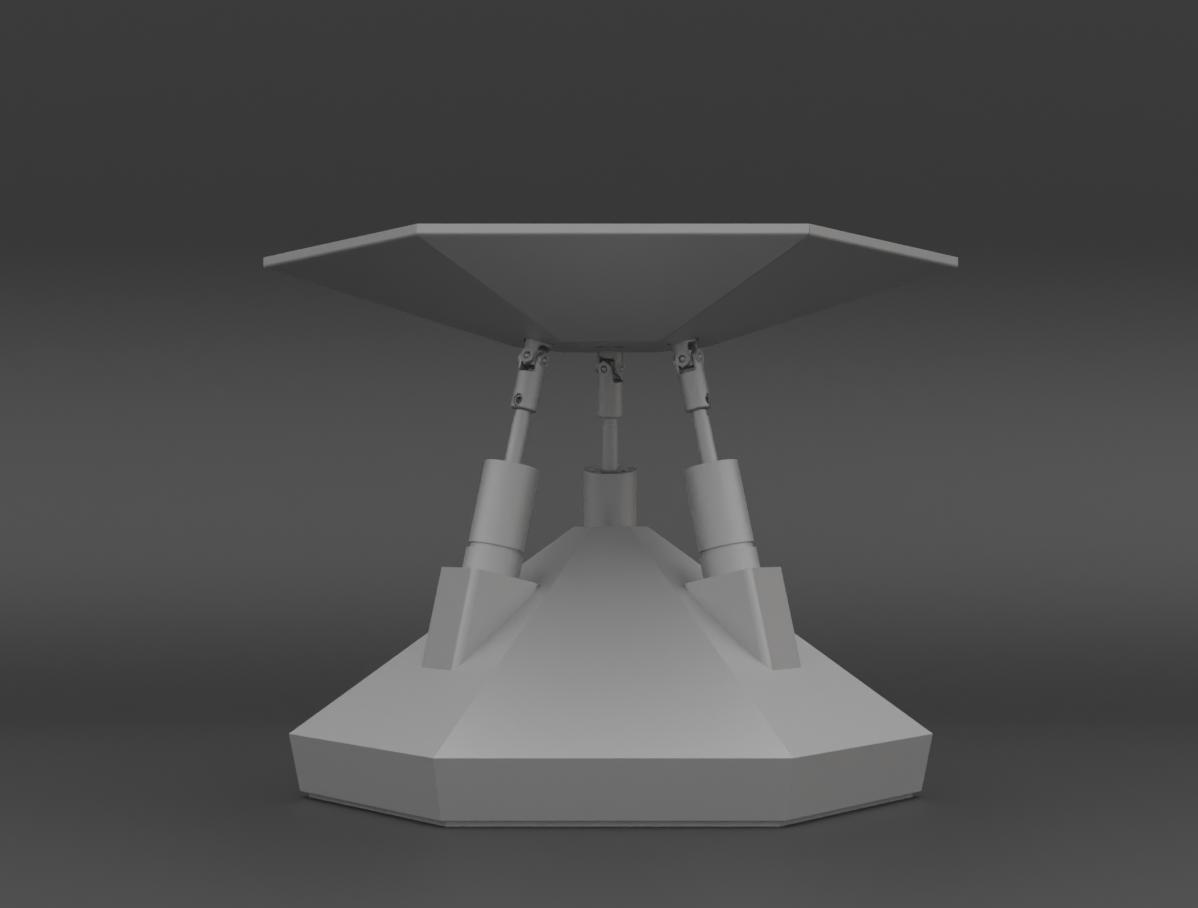

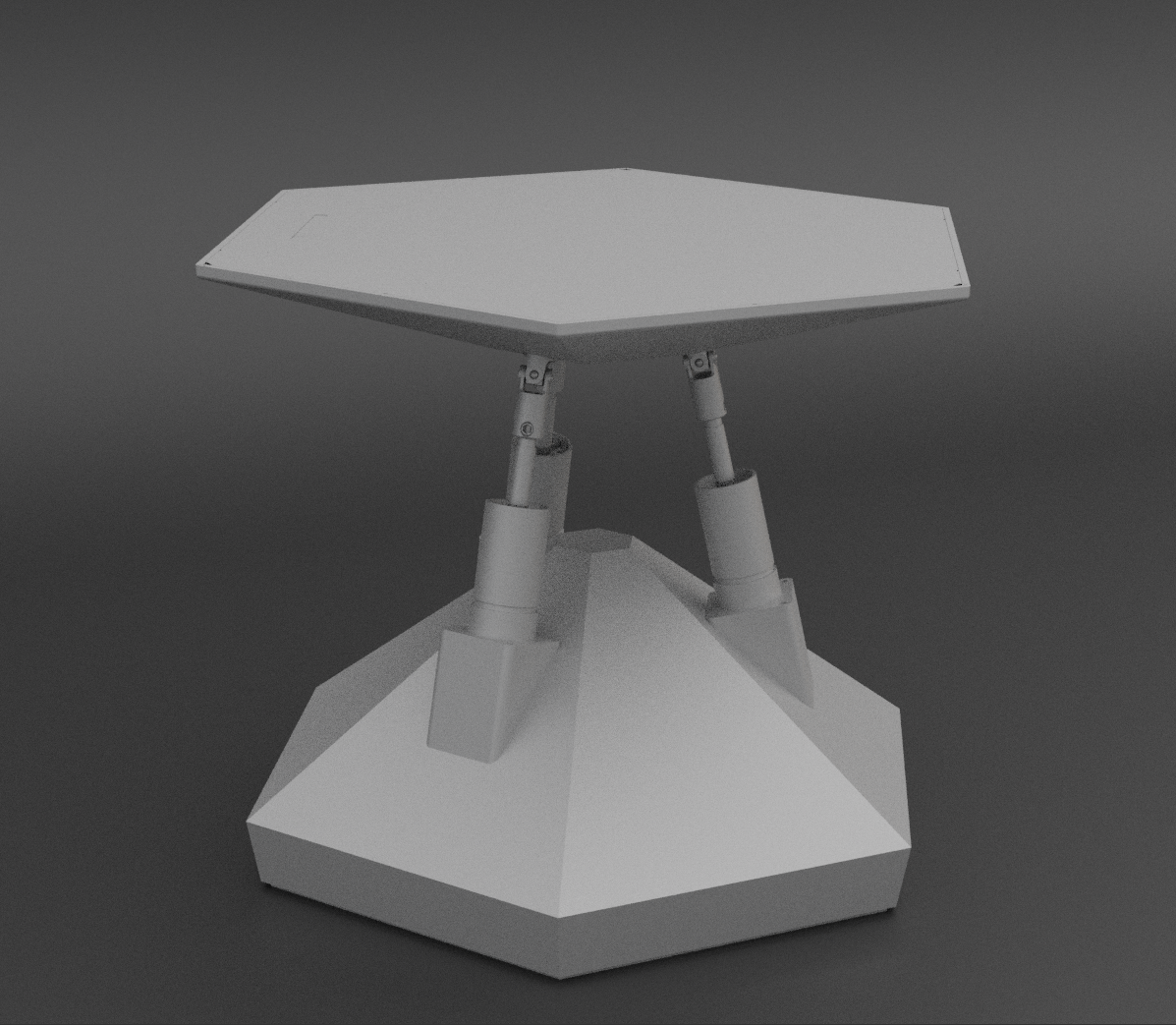

BJR_LOG_12 New renders

05/18/2024 at 20:59 • 0 commentsI've made a couple more renders, that elaborates more on the visual identity I envisioned for the project.

Please take a look, and tell me what you think:![]()

The bottom and the top parts are geometric and very clean looking in terms of visual aesthetics. In the meantime the middle layer is unapologeticly exposed, celebrating the raw robotics. It exposes the universal joints, the pistons and a striking cable that flexes as the plates moves around.

The renders were done in Blender by exporting the model from onshape. Here are a couple more setups:

![]()

![]()

There are still a lot to be designed here, the cable is just a placeholder and the bottom shell is to be detailed further, but this would be the general outline.

Tell me what's your idea to improve the visual identity here. -

BJR_LOG_11 Reviving the project

05/09/2024 at 20:14 • 0 commentsIntroduction

The last log has been a couple months ago, In the meantime I moved houses and now that I'm settled in, let's get this project off the ground again. In this log I'll introduce an alternative design that uses resistive touch sensing instead of capacitive or inductive sensing.

The reason for the change

In the earlier logs it looked like the inductive sensing would be a suitable candidate for this project, so why is it changing? you might ask.

It's true, however it takes a fair amount of design, prototyping, coding to make it into a feature that can accurately detect the ball's location. There are many other subsystems that I need to prove out. If I spend so long to get this tech off the ground, the rest of the subsystems will stay at risk.

In the industry the metric for how mature a technology is is called the Technology readiness level.

Resistive touchscreen technology

In BJR_LOG_03 I've introduced the resistive touchscreen, but just for a recap, here is how it operates:

In a resistive touch screen, there are 2 conductive films separated by a thin layer of air gap. Once something applies pressure to the top film, the contact is made by the 2 conductive surfaces. opposing edges of the films are connected to electrodes, so if a voltage is applied across them, with the contact point it forms a voltage divider. The voltage can be measured and from there the touch location can be interpreted.

![]()

The reason why I chose this over the other technologies is it's ease of use. Resistive touchscreens are available on Mouser, they are relatively cheap, and there is a wide support for controlling them. I chose the TSC2046 IC for control.

TSC2046 Rust driver

I chose rust as the main programming language for this project, simply because I enjoy writing firmware in this language. I published a driver for the TSC2046 chip on crates.io. If you ever happen to need it.

Mechanical assembly

Now that the plate is not a single pcb, but rather a combination of multiple elements, I needed to redesign a little the top part of the robot. While I was at it, I thought I would give it a little personality as well.

Summary

The development continues with a resistive touchscreen as the ball detection device.

-

BJR_LOG_10 Designing the inductive sensor

01/30/2024 at 18:22 • 0 commentsIntroduction

In the last log, we tried using Capacitive sensing to sense the ball, but that ultimately failed.

In this log, we are going to explore an inductive sensing method to detect the ball's position on the plate.Inductive proximity sensing

There are multiple ways to exploit inductance for proximity sensing. In this article, we will focus on the resonant sensing principle.

The sensing inductive coil and a capacitor are connected in parallel to form an LC tank circuit. The inherent resonant frequency of this circuit can be calculated as

As a conductive target approaches the inductive coil, eddy currents form on the surface of the conductive target. The magnetic field of these eddy currents resists the current of the inductive coil, which reduces the inductance of the system and increases the resonant sensing frequency.

Here is an example LC circuit with 2H of inductance

![]()

And the same example but with half the inductance

![]()

You can see that the frequency of resonance has changed and this is the property that we will measure in this experiment. You can find out more about the principle of operation in this

For testing, I'm using the TI LDC1614 high-resolution inductance to digital converter.

Detecting 2d position with inductive sensing

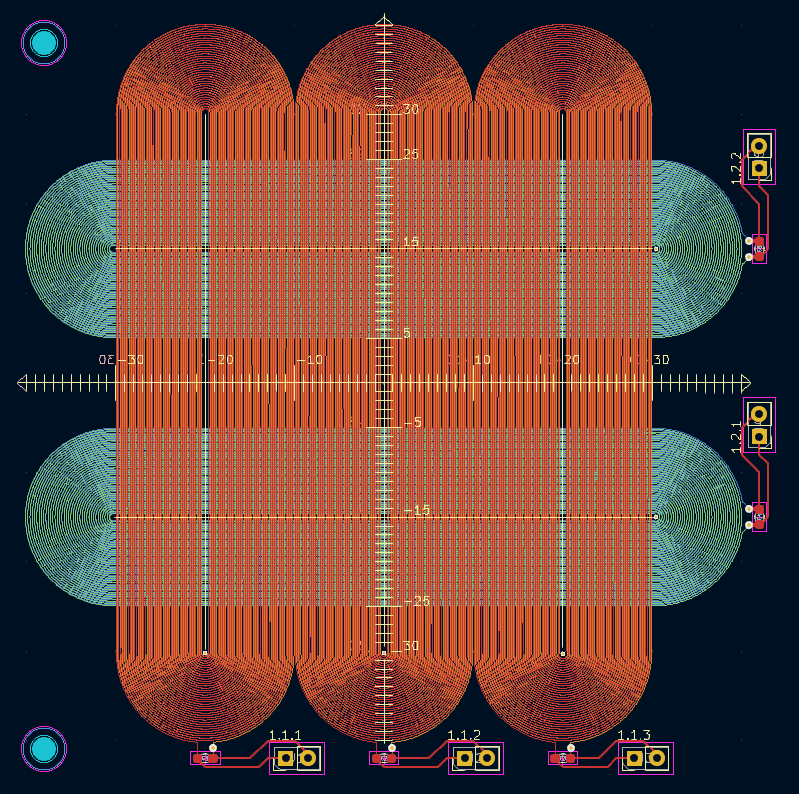

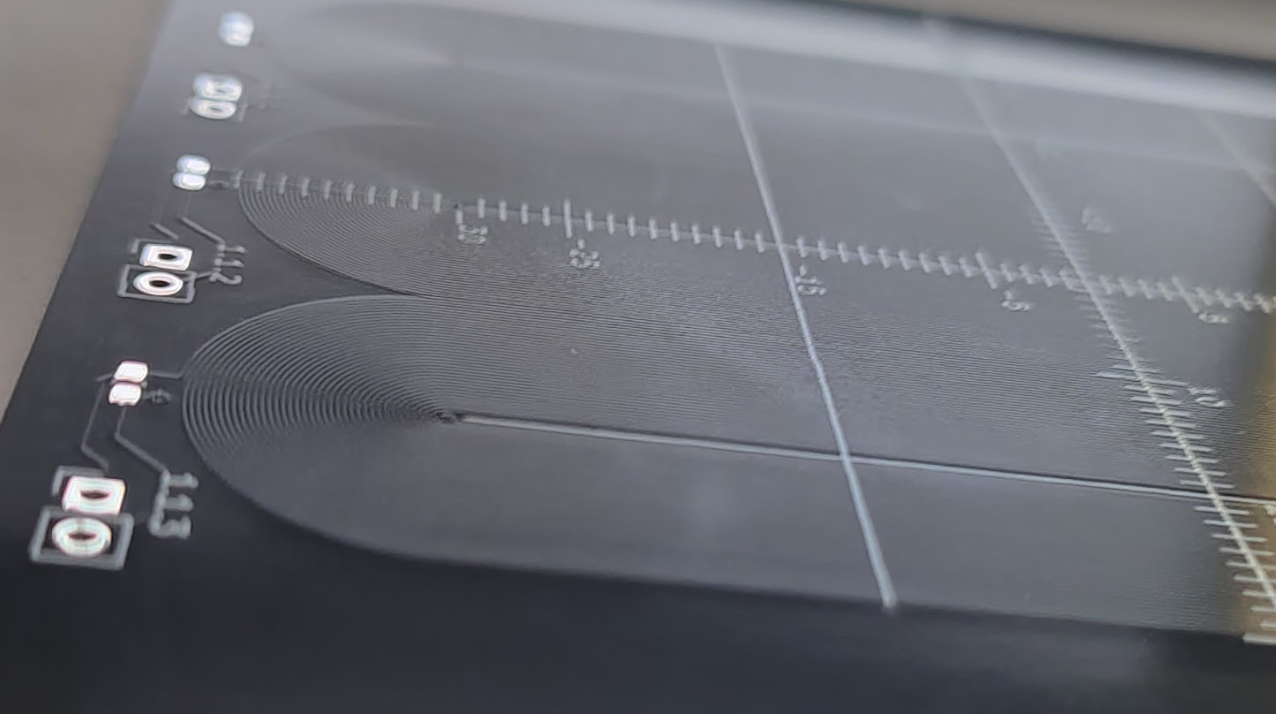

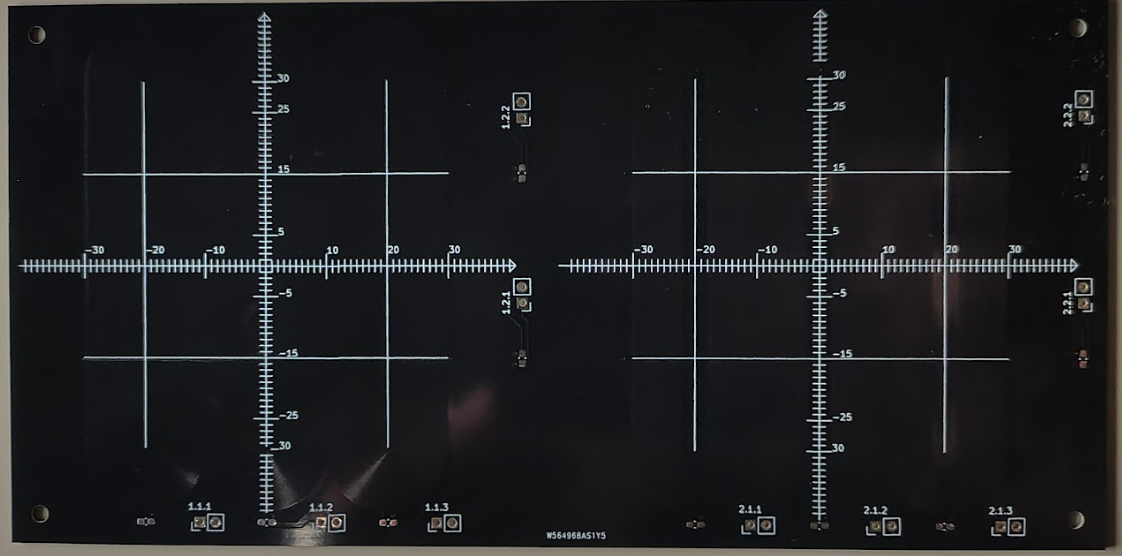

The way I chose to construct the sensing elements is by lining up multiple sensing coils next to each other. The sensing elements are spiral tracks printed on a PCB. They've been elongated into a "Horse race track" shape, so that they would be sensitive to the ball's movement only in one axis. Later tests confirmed that moving the ball alongside the racetrack doesn't influence the measurement to a significant degree.

Multiple of these tracks have been put next to each other and interlaced in different directions on a 4 layer pcb, so that we have sensing resolution in both the X and Y directions.

The final test pattern looks like a weaving pattern:

This way the vertical racetracks detect the X position by observing which coil has changed it's inductance the most. Hopefully to sub mm accuracy. Same applies to the horizontal racetracks.

Designing the PCB

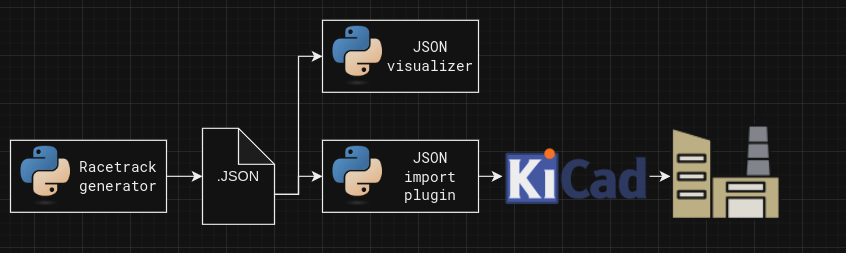

The issue with these racetracks is that there is no built in feature in KiCad (Open source electronics design software) to lay spirals out. Doing it by hand would be a grudgingly long job. Instead I opted of automating the process through python scripting.

KiCad's python scripting API is a bit difficult to use due to lack of official documentation, so I opted to offload the racetrack making into a dedicated python script, that outputs a JSON file which contains the details for all the tracks that it needs to contain. The plugin I wrote for this job takes in that json file, and imports all the primitives into KiCad. I wrote a visualizer, that enabled me to iterate on the generator without spamming KiCad with failed tracks.

Here are the results:

Testing the Sensitivity

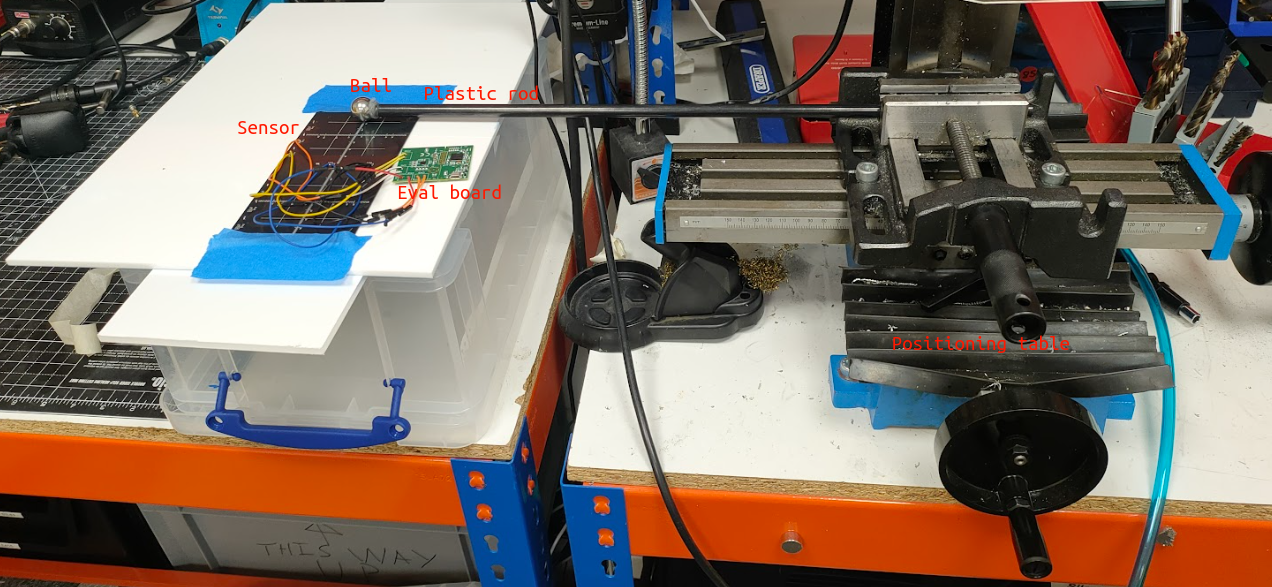

The big question about this side route is if we are going to be able to make enough change in the measured inductance that we can measure it well enough? Given that we have pcb coils, interviewing traces, and spherical target, instead of a flat one.

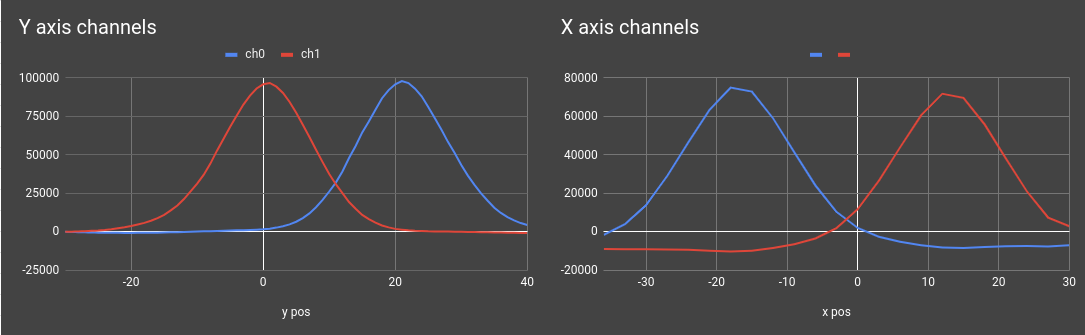

To test this I used the LDC1614EVM evaluation board and mounted the ball on a plastic rod, so it wouldn't interfere with the measurements. The plastic rod was fastened to an X-Y positioning table, that let me set the ball's position with sub mm accuracy.After painstakingly taking a measurement at every single millimetre and manually recording the measured value, here is what we got:

The results are promising. We are seeing a 100000 counts maximum activation on the Y axis channels, and around 75000 counts maximum activation on the X axis. With this level of resolution, i'm happy to continue exploring in this direction

Summary

In this log we've introduced inductive sensing as a potential alternative to capacitive sensing and I designed a PCB to test the theory out. So far the results look good, so in the next logs we will look into manufacturing the new plate.

Tamas Feher

Tamas Feher