At DEF CON 27, I released my first badge addon - a nametag that keeps your name upright no matter its orientation. See here: #GAT Nametag DC27 Addon

At DEF CON 29, I needed some code for the Whiskey Pirates badge. I ported the nametag code to a new platform and added more RGBLEDs, resulting in the WP DC29 minibadge. See here: https://hackaday.com/2021/08/06/hands-on-whiskey-pirates-dc29-hardware-badge-blings-with-risc-v/

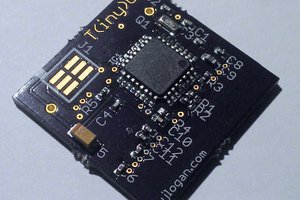

For Supercon 8, I am revisiting this nametag. Porting to yet another MCU, the nametag has become smaller yet still eye-catching and readable.

Original features:

- Shows your name (of course)

- Select from several fonts

(will include instructions on converting and adding new fonts at SC8) - Letters in the name are always upright no matter the addon orientation

- Alternate rendering modes such as static, wiggling letters, or demoscene waves

- Has 12x configurable RGBLEDs to show off and attract attention

- Full on-board menu system to edit your name, choose fonts, and configure other settings

- Does all this while remaining (somewhat) power-efficient: low-power RGBLED programs, no movement auto power off, etc.

New features for Supercon 8 (WIP):

- I2C slave support; set arbitrary text or operate menus from the host nadhe

- Infrared communication to sync virtual contact cards

- USB support, to edit contact card or read synced contact cards

- BLE support...maybe?

- Games like 'snek' might finally be completed???

Current status:

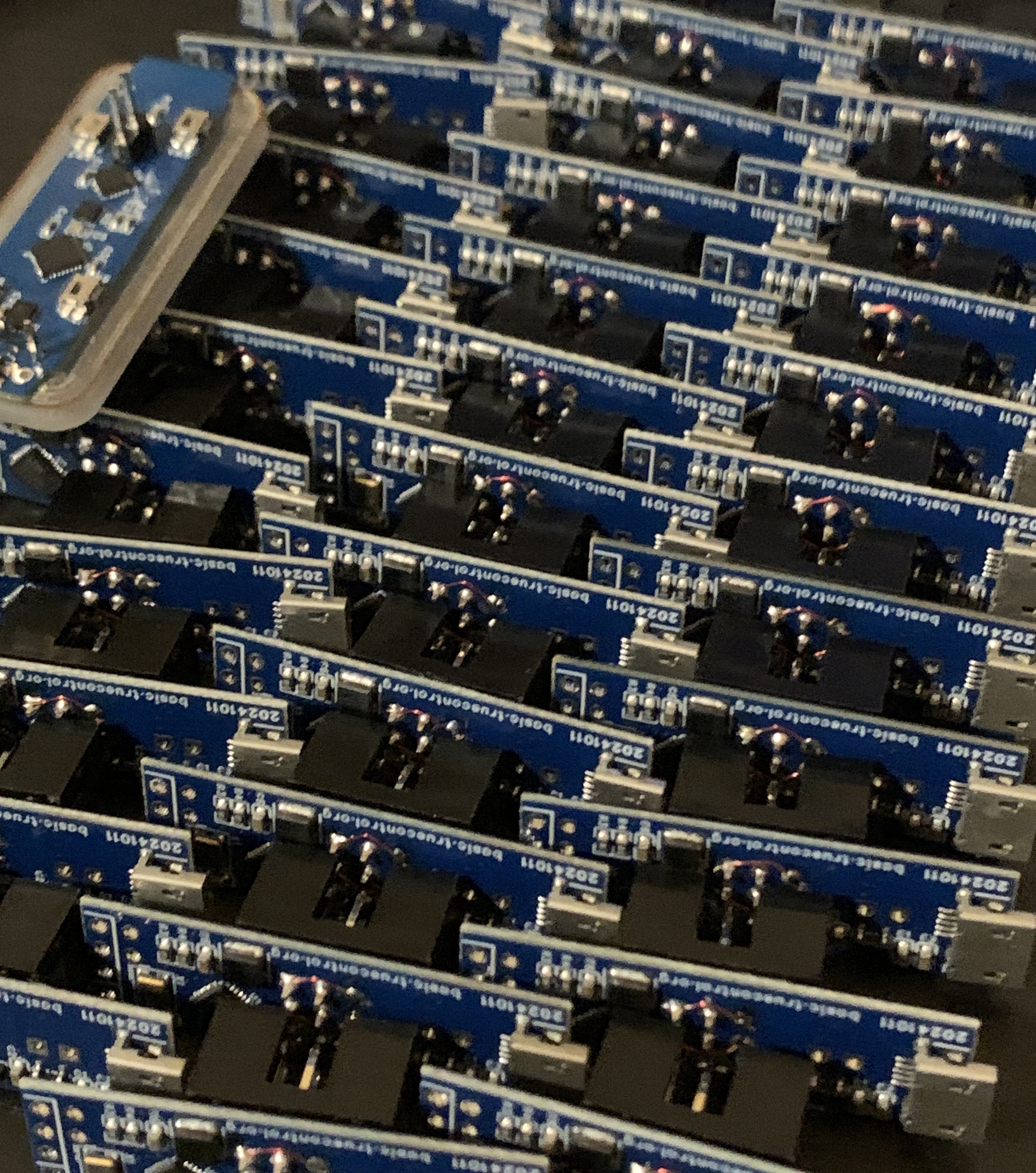

Boards have arrived. Made a major mistake which will require rework of every board. It is my hope that I have around 80 of these ready for Supercon 8.

Due to unforseen emergency commitments, this addon was designed much later than originally planned. The design started in the second week of October and was finalized and sent for production on the third week. Several issues have been found during the assembly process.

If somehow this addon wins the Supercon 8 addon contest, I propose and can make the following changes to improve use / feel, product reliability, and reduce assembly steps and manual intervention. Most of these changes are trivial.

- Part overlap, pinout, and other errors will be fixed

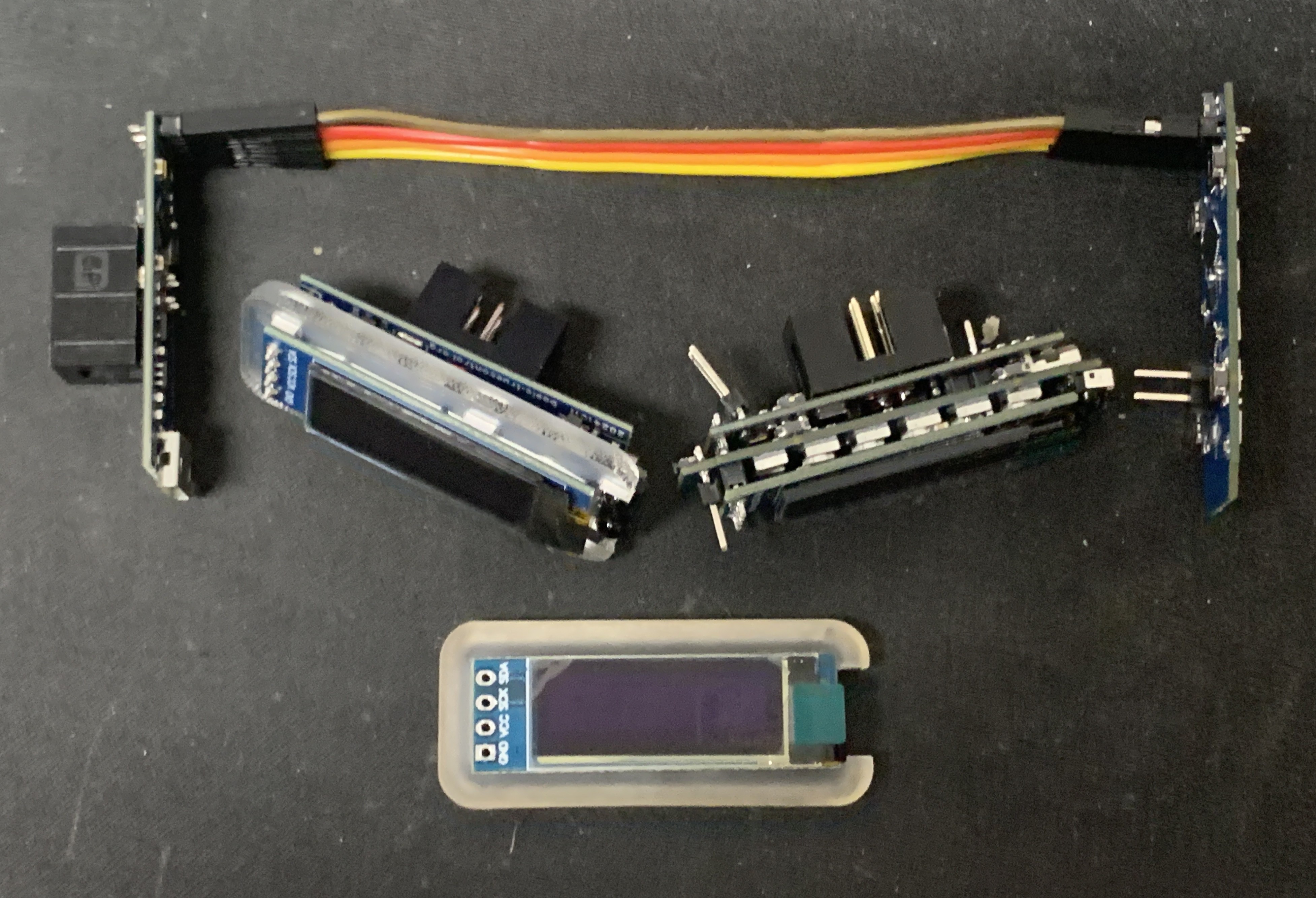

- Following changes should reduce manual soldering to: addon header, OLED hot bar, and board-to-board interconnects without need for spacers or a hard requirement for jigs, trimming headers, etc.

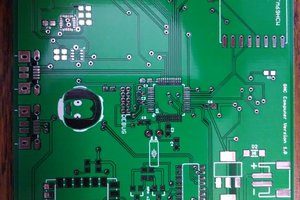

- Bottom PCB changes:

- Will be made slightly larger as it doesn't affect the visual design

- The menu operation buttons will move to the bottom PCB

- The menu operation buttons may be larger for easier use

- Prototype-related pads and components will be removed (debugger pins will stay)

- Will use Type-C instead of micro-b

- Top PCB changes:

- Will use different IrDA part that can be machine placed

- OLED changes:

- Will custom design board for better front look, faster machine assembly

- Custom board will slightly reduce power consumption

- Diffuser changes:

- Will ensure proper fitment

- Cutout holes will be changed for new OLED board

- Code changes:

- At a minimum, further power optimization

- Will try to clean stuff up to be easier to understand

Piotr Esden-Tempski

Piotr Esden-Tempski

This project is likely seriously underappreciated. After seeing it in person and being fortunate to trade for one, it's incredible what is all packed in and how well it is done. Lots to learn from this.