Following Dylan's lead, here's the recipe:

Preparation time: 5 minutes, plus printer time (an hour each in my case)

Ingredients:

1x Threaded rod: Material, size, pitch and length to taste.

1x Nut for threaded rod

1x Cup magnet with mounting hole, size to taste

1x 3D printed base

1x 3D printed nut holder

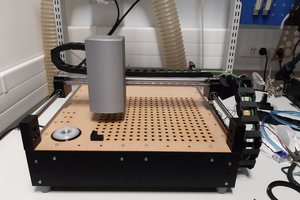

Step 1: Print the base part

Step 2: Print the nut holder part

Step 3: Insert the threaded rod into the base

Step 4: Screw the magnet onto the base

Step 5: Insert the nut into the nut holder

Step 6: Spin the nut+holder onto the threaded rod

Done!

I got the cup magnets off Amazon (arrived in 12 hours): cat number B09ZX7SXMF "MAGXCENE Strong Magnets with Holes" in 16 mm size.

The printed parts are modeled in Fusion 360, and printed in PLA. I used a 0.3 mm nozzle and 0.1 mm layers. It's helpful to chase the threads with a tap (1/4-20 in my case), and ream the hole for the magnet screw to size with a twist drill (2mm or 3/32 work for the mystery screws I got with the magnets).

They work splendidly, though they do grab the plate a lot more aggressively than the ceramic magnets I used in the previous iteration, and I'll have to get used to that.

Timo Birnschein

Timo Birnschein

Dylan Radcliffe

Dylan Radcliffe

Miroslav Zuzelka

Miroslav Zuzelka

Henry York

Henry York

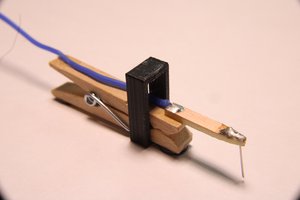

Your suggestions are all great but I didn't read your reply in time, so I went the most convoluted way of designing a M6 nut with a larger hex head and printing that instead... yes, I can be that dumb! :)

Anyway, I think it turned out great!

Here's a picture of the clamp holding a 5x7 stripboard: https://i.imgur.com/GsMY5dS.jpeg

It should work ok with bigger boards too, now I just need some magnets.

Thanks for posting the project!