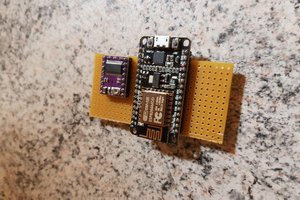

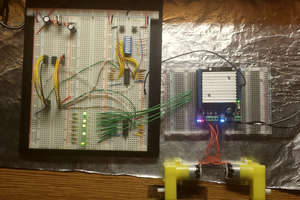

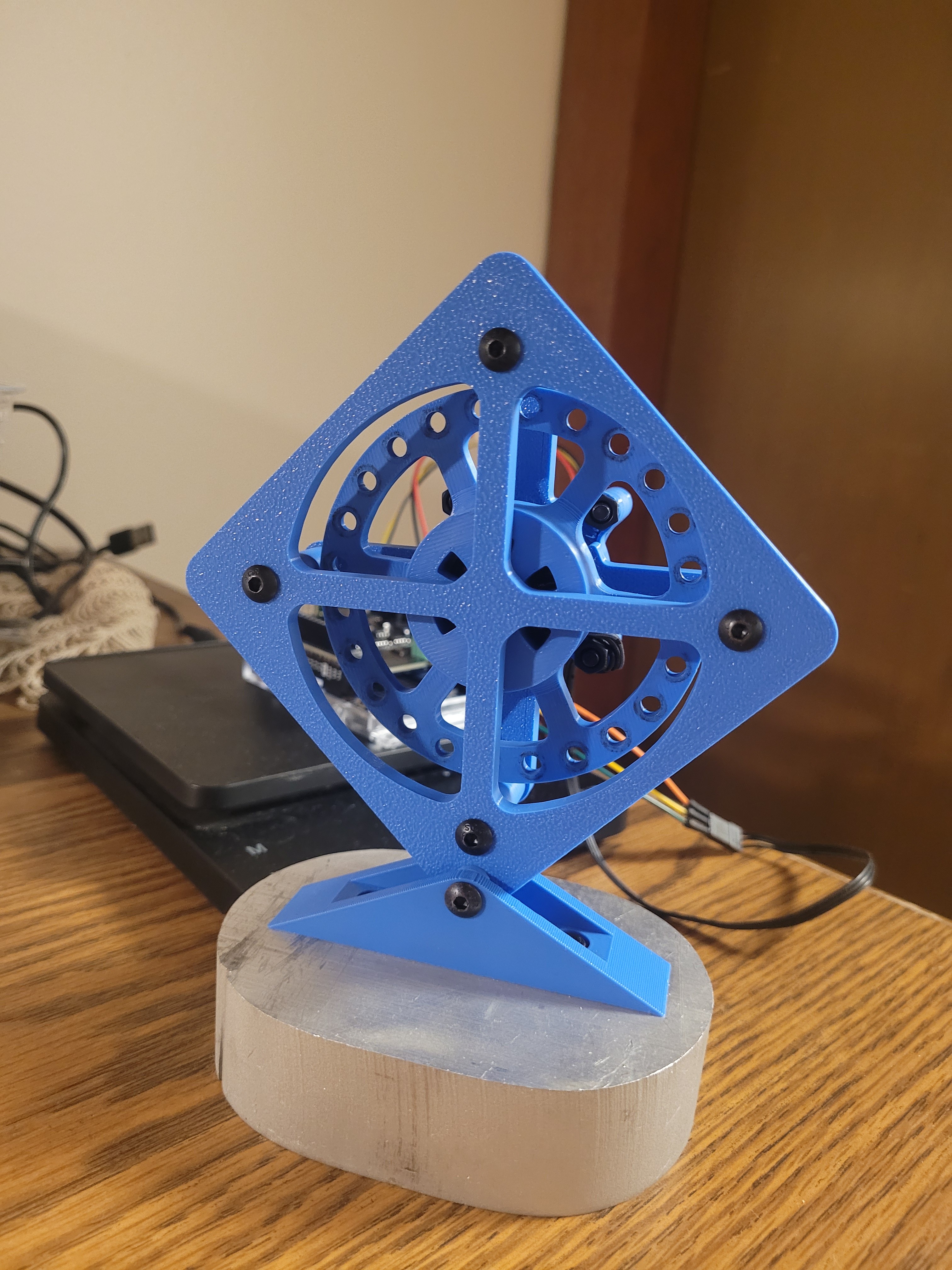

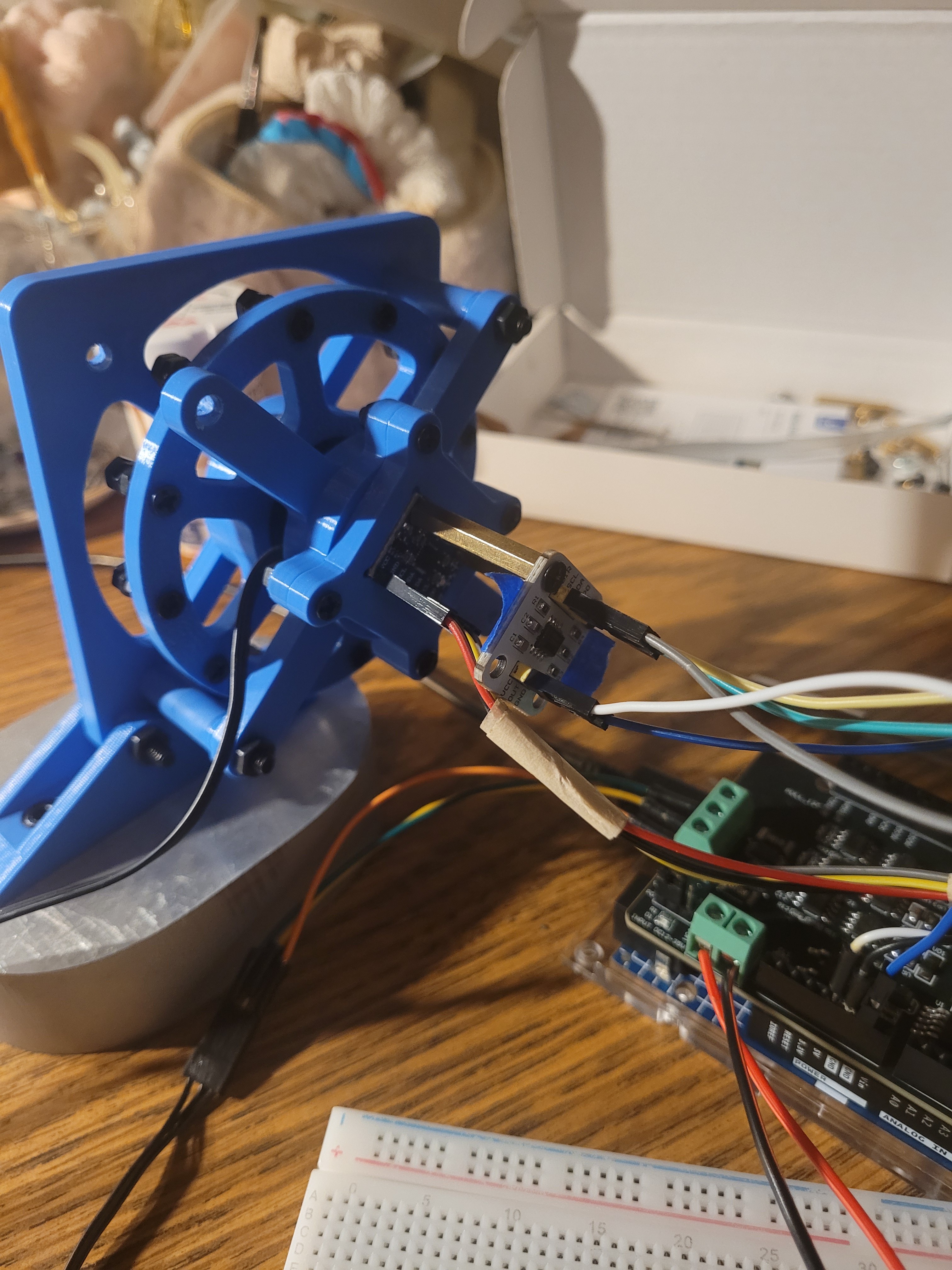

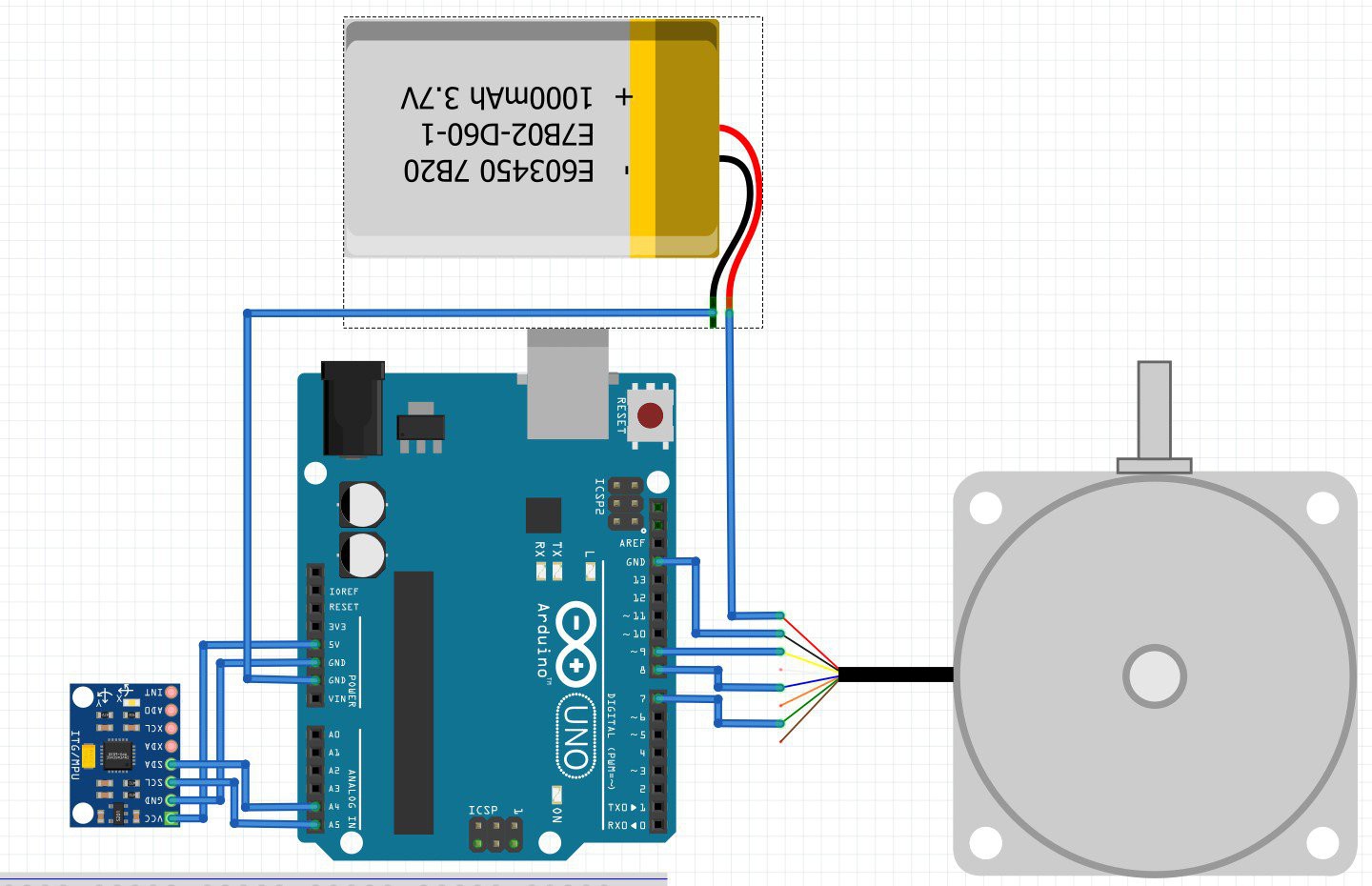

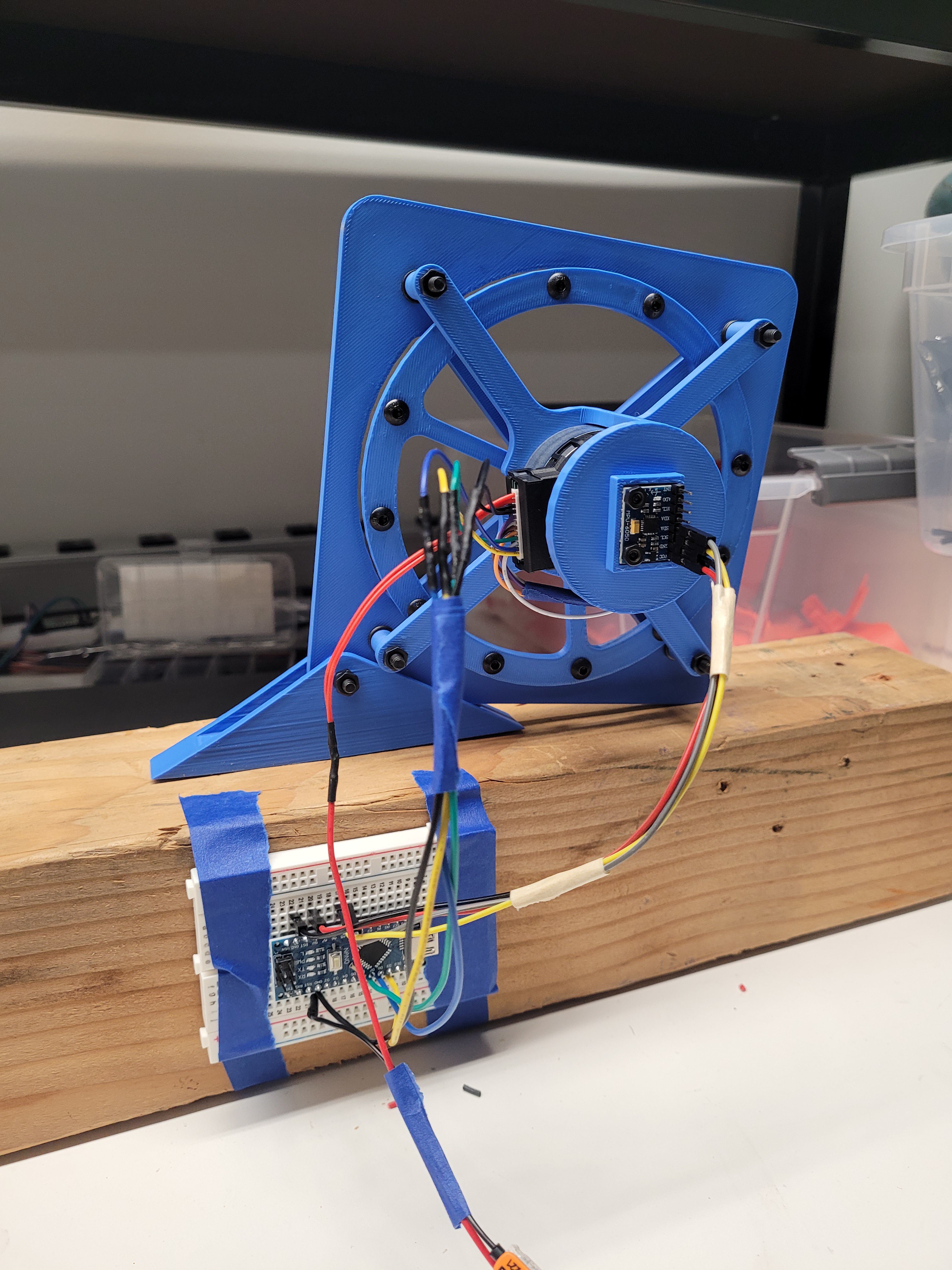

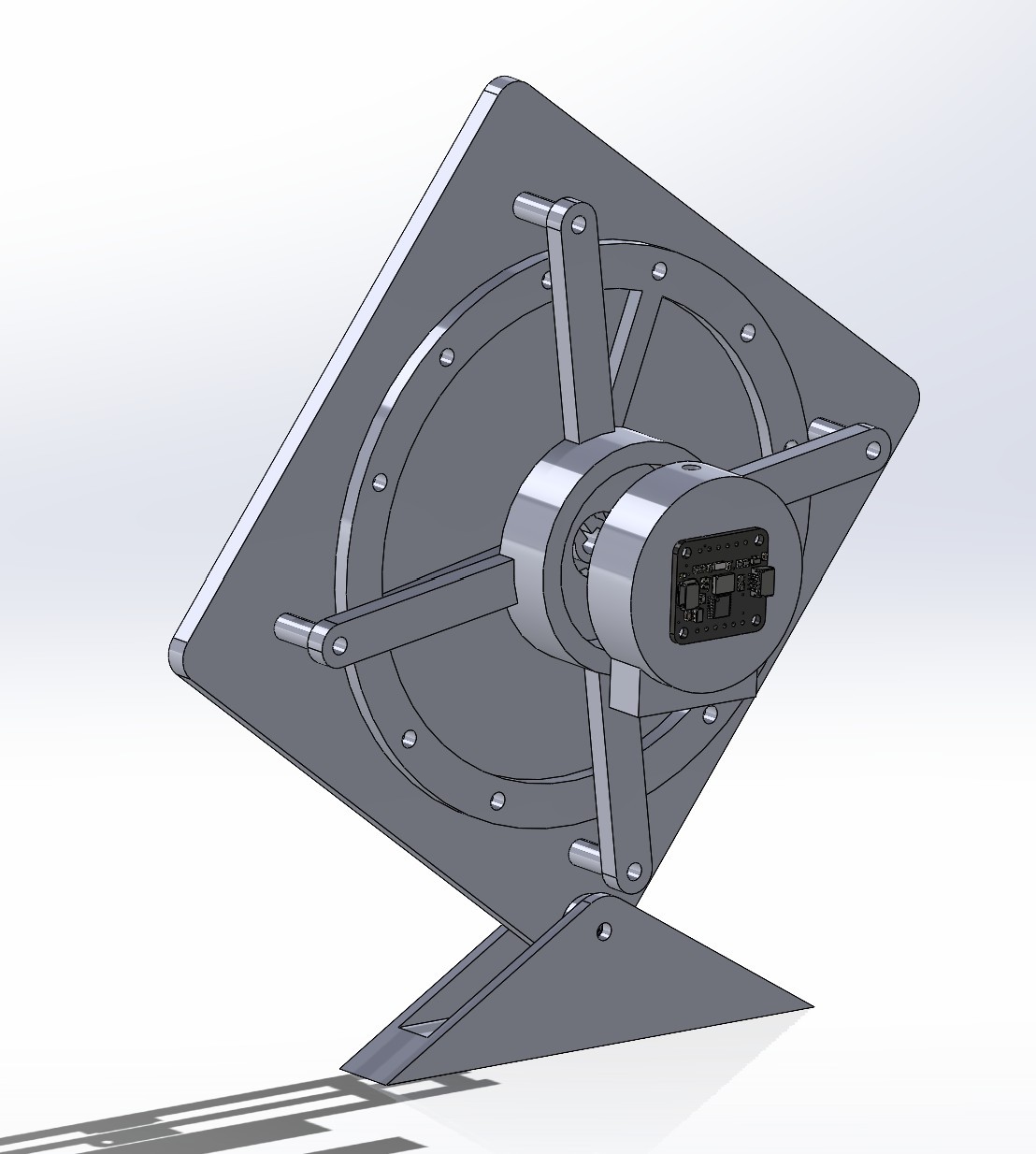

This project attempts to prototype a self balancing cube using reaction wheels. We are in the process of prototyping and testing a 1 DoF test bed that uses only one reaction wheel to balance. We use an IMU to calculate the tilt angle from 0° (upright) and estimate motor speed. We experiment with the reaction wheel's size and weight to provide enough torque to lift the entire platform. When the platform leans to one side, the reaction wheel spins in the opposite direction to self-balance.

Reaction Wheel Self Balancing Cube

This project attempts to prototype a self balancing cube using three reaction wheels

Dami Kim

Dami Kim

Rob Englebright

Rob Englebright