-

Let's talk cost - time, rather

01/15/2022 at 15:08 • 0 commentsI want to take a moment and discuss what it means to make boards at home.

At first glance, it seems like a great idea and it certainly was when I started making boards at home. You get the parts quickly, at least that's the thought, and you can find bugs before you make a larger run with a board house if needed.

As far as prototyping goes, that's the end of it. However, the actual process of making a board on a home made or cheap CNC machine is very involved and can cost tens of hours - per board. I'll go into a little more detail why this is such a crazy high number in a bit. Today, you can just go to a company like jlcpcb.com and get your board made in a day and shipped in three if you are willing to pay $15 for shipping for your $2 PCB. But you get it in the color you want within a week, no questions asked. That's amazing and in my experience, these boards come out great! If you are willing to wait for the cheap shipping, it'll take about two to three weeks for your boards to arrive, which - given that I'll talk more about the tens of hours - still doesn't sound too bad.

What it takes...

- First of, it takes longer to design a double sided PCB for home manufacturing.

It does, because vias and traces need to be larger and thicker than they would for a manufactured board. It easily translates one way (to the board house) but rarely the other (to the home cnc mill). - Small vias with tiny holes are difficult to make at home simply because you have to manually solder top and bottom of the via with a snippet of wire or a very tiny rivet. If the hole is too small, that won't work. For that reason, my vias are 2mm in diameter with 0.8-0.9mm holes. That's huge compared to what I would do when designing for manufacturing.

- Since the regular home pcb workshop does not have the ability to galvanize boards at home and create the through-hole plating, all vias have to be hand solders or riveted AND none of the connections to pin headers can be connected from both sides! Because there is no through-hole plating! That means, all connection on my boards to any of the pin headers are exclusively connected on the bottom side of the PCB. Often, that means a lot of extra vias just to connect the trace at the bottom even though I have a trace right in front of the pin at the top - and there is usually no space for an additional, large via.

- Traces need to be thick to allow for error. I have managed to get my trace size down to 0.3 mm for short sections. Like for example when I need to get a trace in between two pins of 2.54mm pin-header. I go from 0.8mm down to 0.3mm, go through the two pins, and immediately go back to 0.8mm. I do that because I have seen traces break either after the milling was done or cut into pieces due to the last remaining play and backlash in the system. Bigger traces need larger spaces.

- The same is true for the space in between traces and vias, called clearance. My clearance in the design rule checks is set to 0.26mm as that's the setting in FlatCAM for my router bit. If I go with a lower clearance, I run into shorts because the traces aren't separated after milling.

- Double sided PCBs must be aligned perfectly on the cnc mill. The slightest misalignment has the potential to destroy precious vias and pin-header connections. I had multiple instances where a skew in my machine caused traces to break that use a through-hole of a pin header to go from one side of the pin header to the other, on the same side of the PCB. This happens because I mill the top side first, then flip the PCB over to mill the bottom side and then drill the holes on the bottom side. If the PCB is not aligned perfectly, the drilled holes look great on the bottom side but are offset on the top side -> disaster as this cuts the rest-ring in half cutting the connection.

- My personal machine has a small skew. That's because the machine was lasercut on my cheap laser cutter. It's minor but it's there. Aligning top and bottom side perfectly is therefore impossible without a correction in software. This is a one-time setup but it took me many hours to calibrate all this.

- After I had a good alignment, I was still faced with the occasional misalignment because I just didn't get the PCB exactly into the position and orientation it needs to be in to be perfect. It's just a matter of probability whether it works or not and you will only be able to see the result of all your hard labor once the board is already drilled and cut out. At that point, there is no turning back to fix things. It's already done.

- PCBs are never flat. I usually spend a few minutes or more to bend my PCBs with my hands to flatten them, fit check the PCB on the mill bed, do it again and again until it doesn't wobble anymore. I also added a vacuum table to suck the board flat to the bed which helped a great deal.

Still, despite all that work, I have to autolevel the PCB. That means attaching a probe and running a program that measures the deformation of the board in Z across the entire board. Setup and execution takes another 10 minutes and then you can only hope it's setup and measured properly. You will hopefully be able to tell once the first trace is being engraved.

Once the top side is done, you have to do it again for the bottom side. That also means, order of operation is very important as drilling the through-holes on the top side of the board will make autoleveling the bottom side impossible as the probe will eventually hit a drilled hole and mess things up badly. Drill holes last! - Tool change takes time. I use multiple tools to make one board. At the very minimum, I need a V-shaped engraving bit and the cutout tool which is a 1mm cylindrical mill-bit with a diamond pattern. All my mill bits are carbide coated to last longer and are made for fiber glass PCBs - unlike the Bantam Tools which are specialized to mill FR1 pressed paper boards. They won't last on FR4. Setting up a tool means touching the spindle and applying a force and torque to it. That can potentially change the orientation of the spindle which can lead to top and bottom not being aligned afterwards as the end-mill tool position might change a little bit. Then, the tool needs to be leveled to Z=0mm as an additional step. Each time a tool change is performed, leveling must happen or the board is ruined. There is almost no margin for error here and forgetting a step might ruin the board or the machine - like forgetting to remove the z-axis probe wire from the endmill before starting the cnc milling job.

Some jobs can require multiple tool changes. Not only for top and bottom milling as well as board cut-outs but also multiple different hole diameters. Each diameter needs a different drill bit which then also needs to be leveled to Z=0. It's not needed to autolevel the entire board each time but Z=0 must be found and ideally always in the same location on the board. If there is a hole now, you have to change the probing location and that might introduce errors due to the autolevel function. But at the drilling stage, that's alright - at the milling stage, not so much. - Last but not least, the workflow is complex and parts of it are easily forgotten when not practiced every day or at least regularly! At the moment, I use my mill every day but that's not normal. I haven't used it in a year and if I hadn't documented all my steps here on my project page, I would never have been able to set this back up again in the amount of time it ended up taking me. I also experience that I discover new issues and new things I want to implement each time I use the machine and the software packages. That means extra time spend just to make one board. The workflow usually involves adding an alignment coordinate system to the board in (KI)CAD, then GERBER export, then DRILL file export, then FlatCAM import for top, bottom, cutout, drill, modifying the cutout to have tabs, generating the gcode for all these and for top and bottom jobs differently due to the skew compensation and then doing all the steps needed to mill the board with cnc-gcode-controller as mentioned above - which has broken more than one endmill due to quirks when connecting to GRBL at random.

Having said all that, I designed four boards in the past four weeks and contemplated having them manufactured to not deal with all this stuff. Then I spend FOUR attempts making the first of the four boards, spending days getting everything up and running, only to end up with a board that works on the bottom half - that was the moment I discovered the skew in my machine.

The next three boards, after all this training, took much less time and I wasn't staring at the machine to check for errors all day long anymore. However, a large double sided PCB (80x100mm) takes about 3-5h start to finish, from GERBER export to the board on the table. Then you still have to do all the vias which is another hour depending on your strategy and workflow. So let's say 6h to get a board on a well oiled machine with a really well practiced workflow. Man, I wish I would have just ordered those boards!

Single sided boards are a whole different question as those are easy. Run the mill, run the cutout, run the drill. Done. No additional work needed since no vias need to be soldered. That's easily done in an hour. Double sided is hard and requires full concentration to get right. Not something I have time for every time and my patience to make these boards at home is shrinking given that ordering these boards (all four of them) in quantity of five EACH including shipping would have set me back only $55....

- First of, it takes longer to design a double sided PCB for home manufacturing.

-

Adding a vacuum table - the best upgrade!

01/14/2022 at 23:04 • 3 commentsThere are upgrades and there are upgrades.

Sometimes, an upgrade is a small thing. An LED here, a new line of code that improves things there... this is a major major livability improvement that I wasn't expecting to work this well:

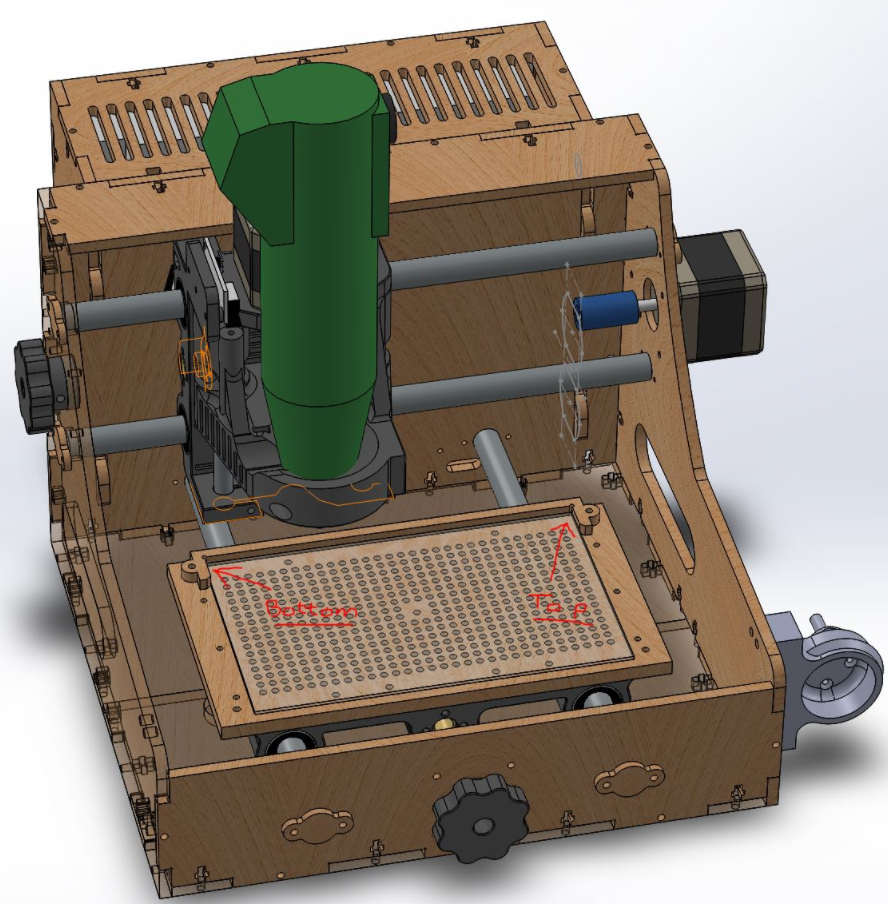

I added a vacuum table to my mill. It's rather unbelievable that not every PCB mill has one.

The Issue:

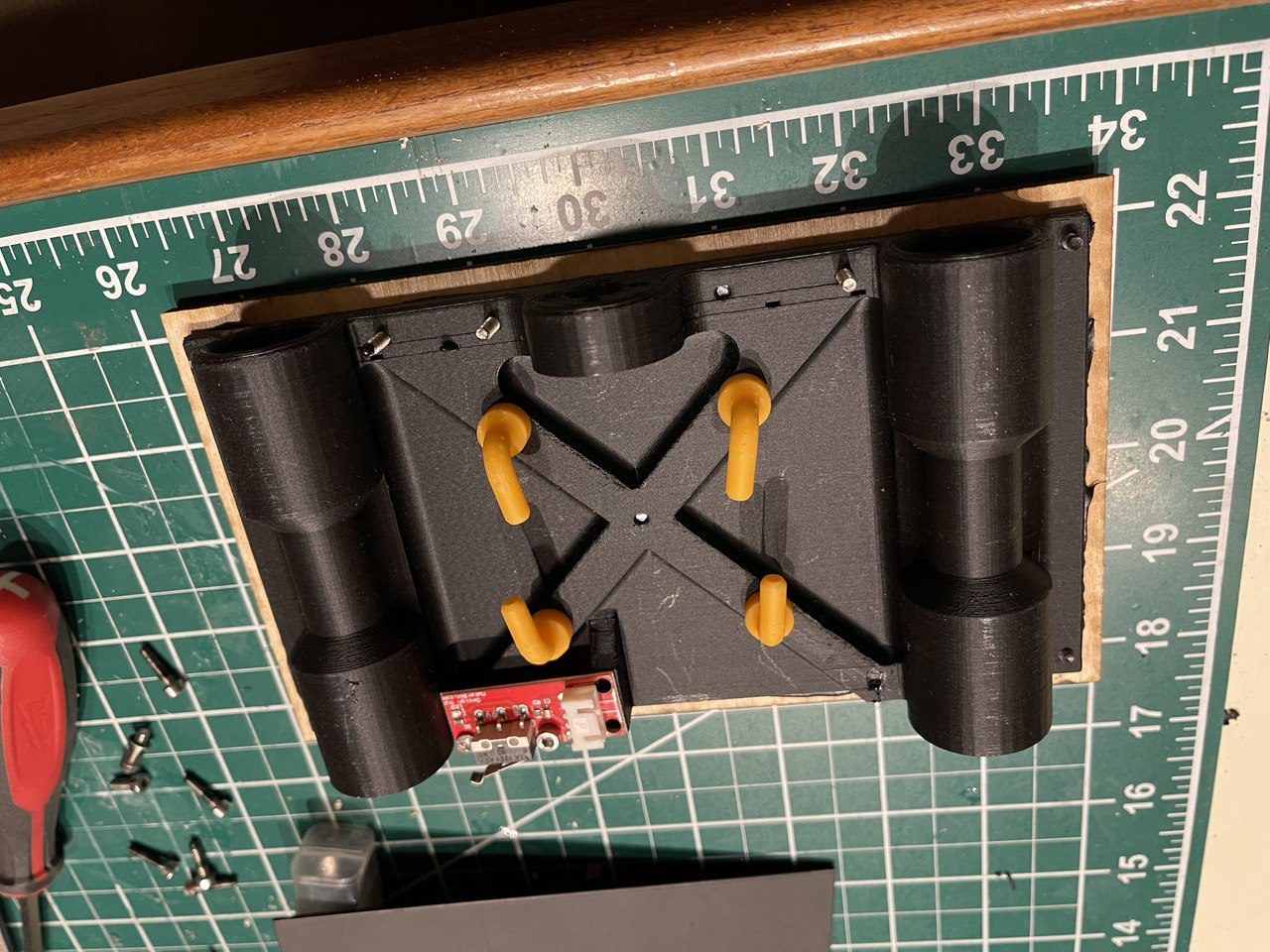

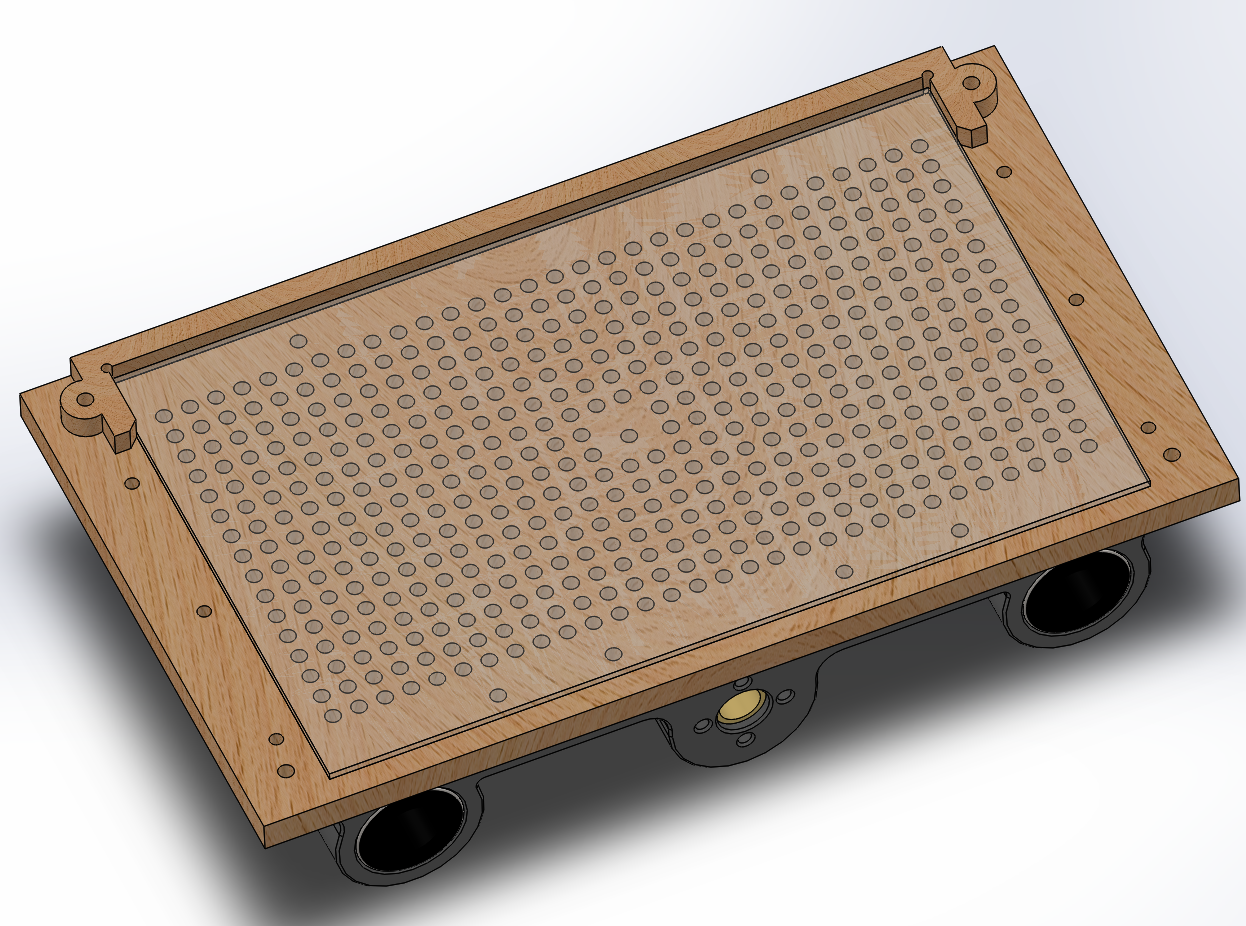

Boards aren't flat. They never are. The CNC bed isn't flat either. You can make it flat but that costs a lot of time and potentially frustration depending on the material of the bed. My bed is laser cut plywood and I can cut it on my laser cutter. The carrier is 3D printed and I can print it on my 3d printer.

When placing a PCB onto the bed, it must be secured somehow such that it doesn't wonder off. Clamping it down might lead to warping since I press the material into the plywood, or worst, clamp it from the side. Then the PCB can be a bit warped and despite my best efforts, I was never able to get it 100% flat without spending 30 minutes on pushing and bending and rolling the PCB until I couldn't see and flex anymore when pressing onto the board with my finger. An insane piece of work that, if not done absolutely right, can ruin an hour long cnc job.

The Solution:

In the original version of the bed, I already had ribs to avoid warping during the print and to make the part a bit stronger since these ribs would add material to the perimeter. One night, I thought to myself: "Vacuum doesn't need much airflow, why not just make the ribs into tiny stand-offs and laser cut holes into the bed?" Well? Seriously, why not? All vacuum needs is a volume and a way to create suction, like using a vacuum cleaner. I have one that I never liked because the head is so ill-designed that it doesn't clean at all. However, when the hose is used by itself, it's remarkably powerful for a $50 part.

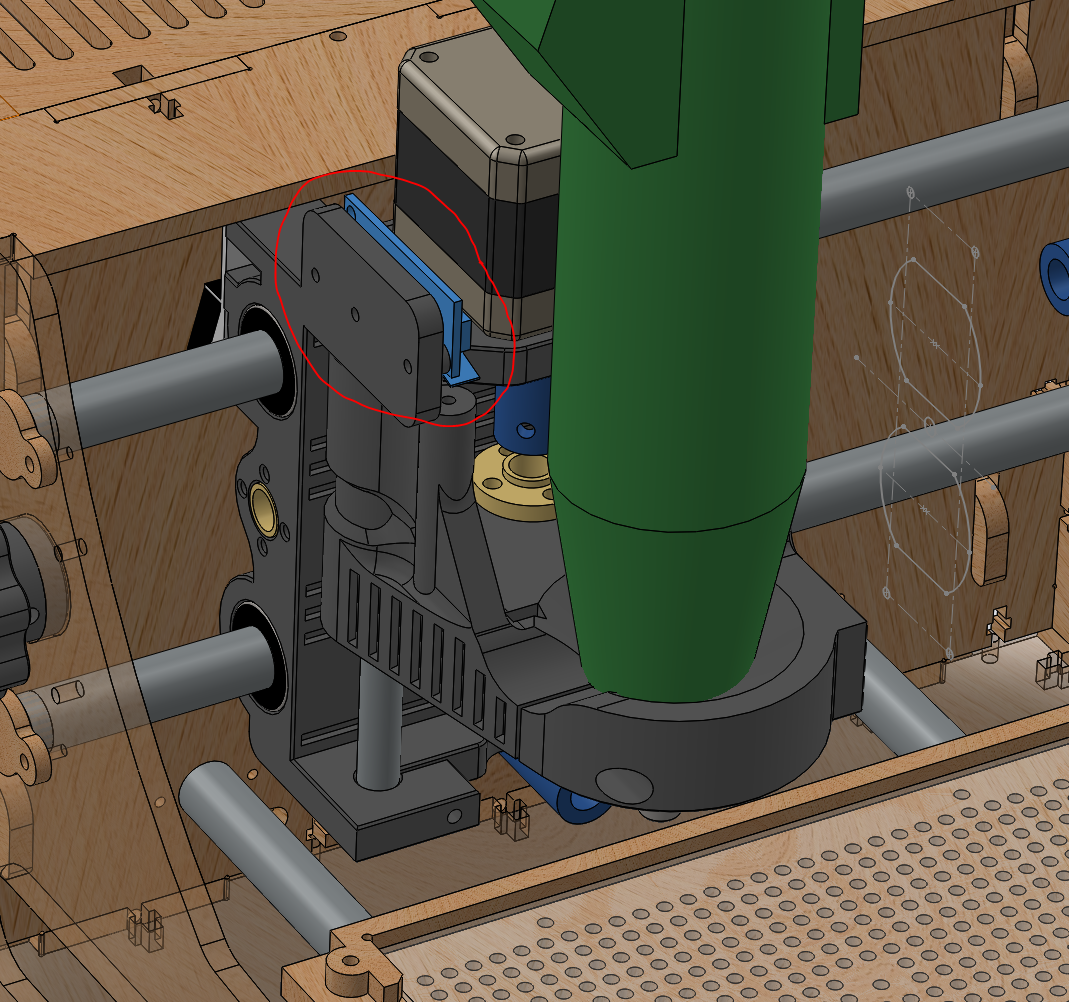

One morning, I decided to get to work and redesign the X-axis carrier to allow sucking the air out from underneath the bed.

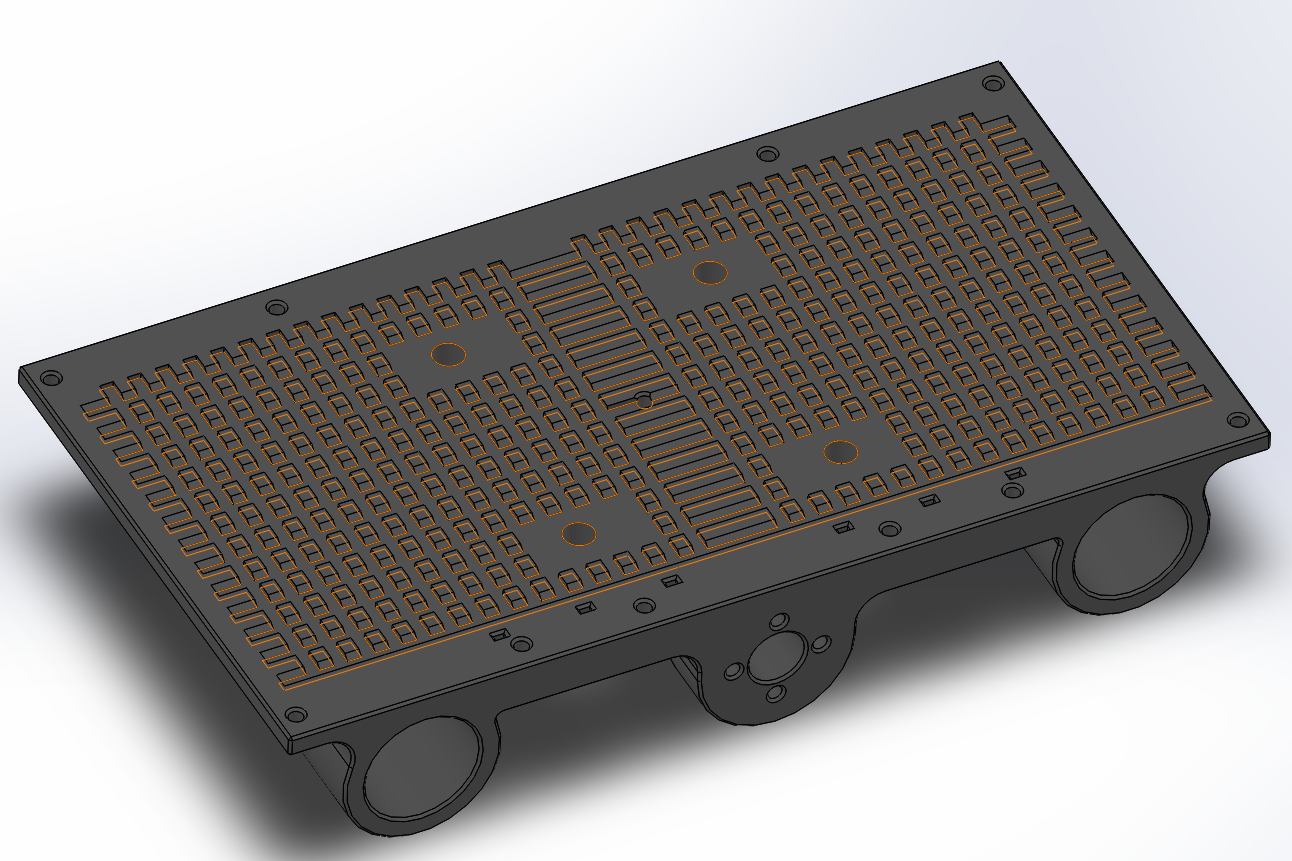

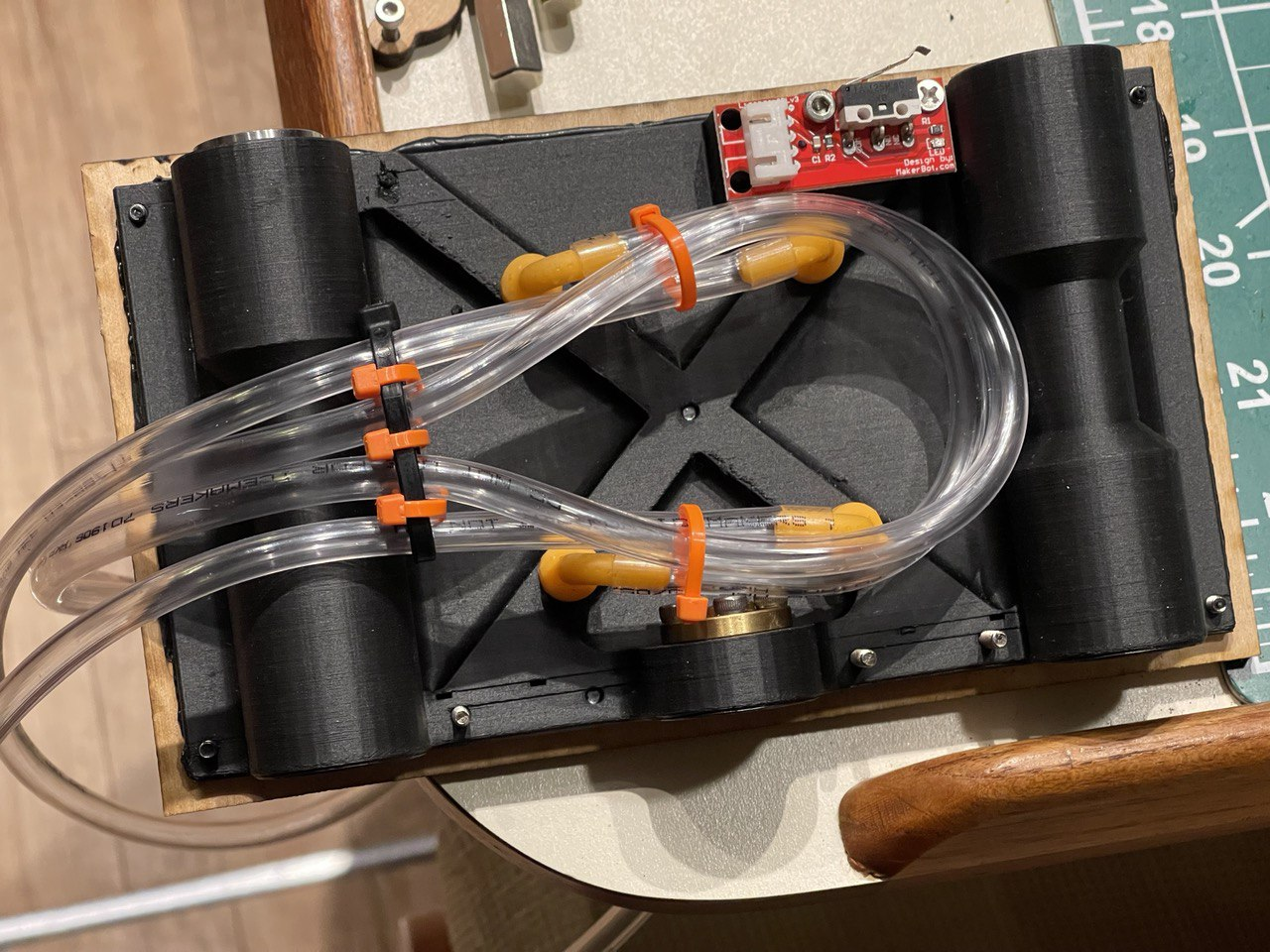

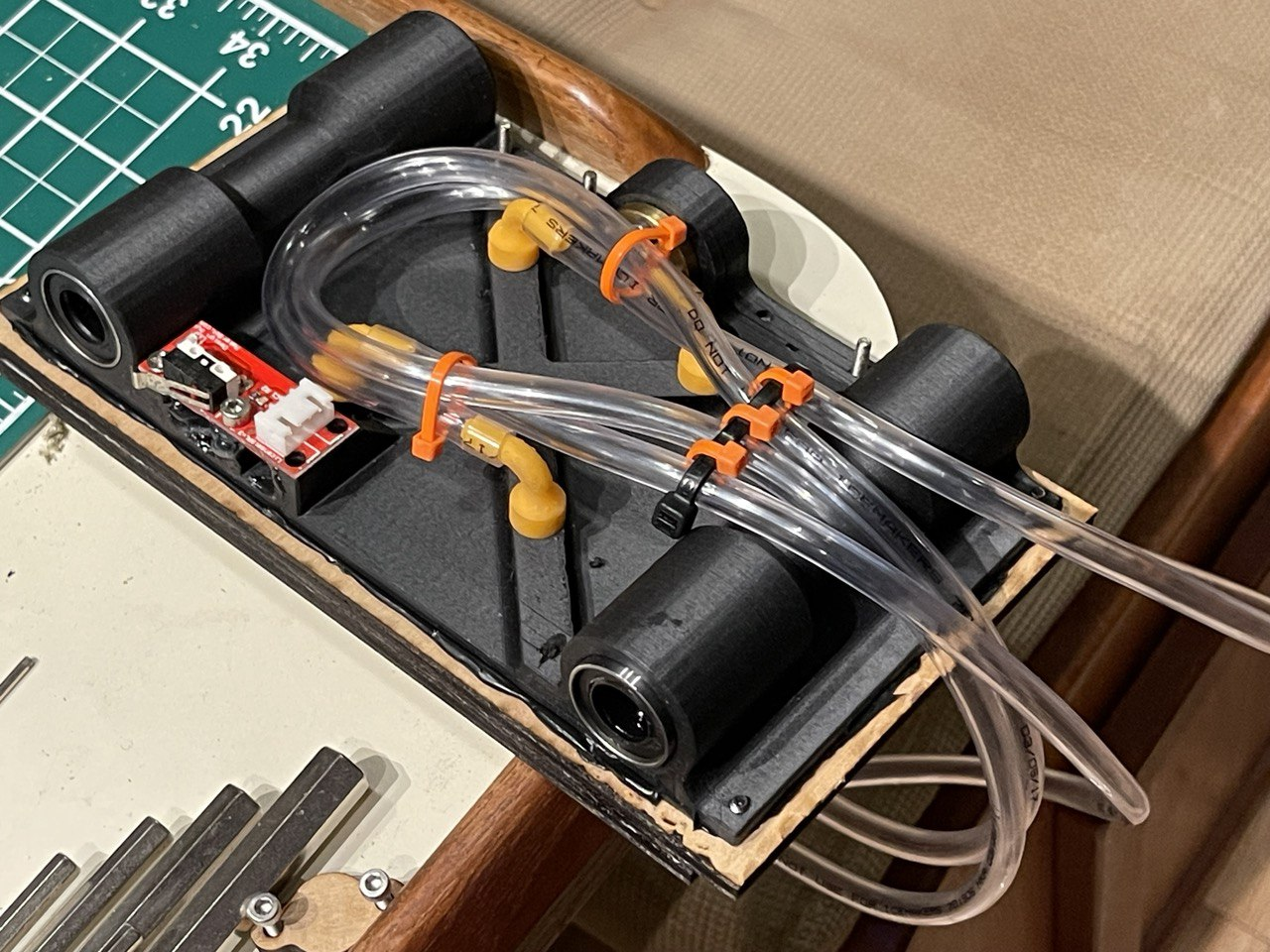

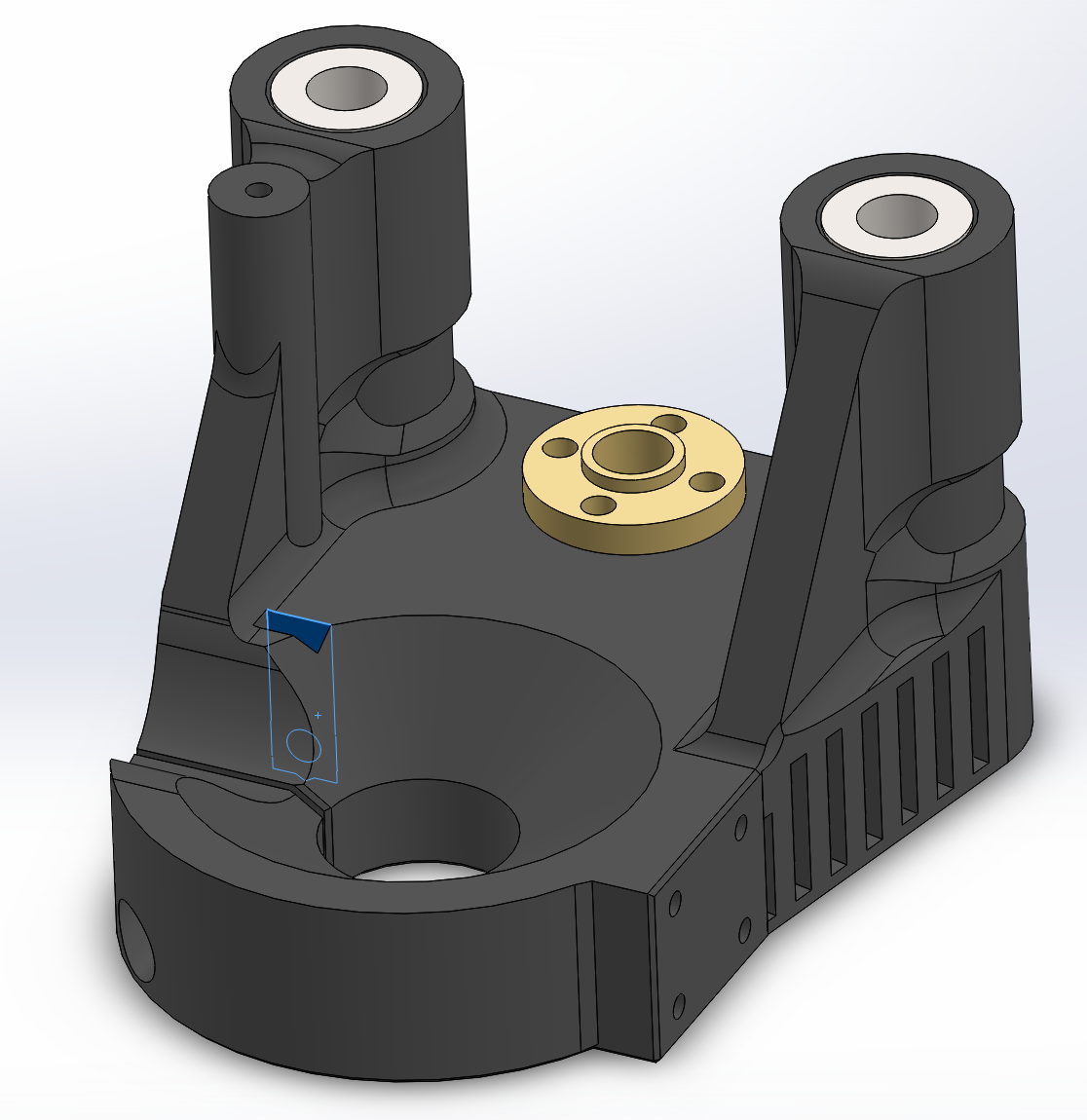

This is a rather large 3D-printed part (remember, the entire mill only needed three large 3D printed parts as everything is fully integrated). In addition to the field of little standoffs, I added four holes for the air to be sucked out.

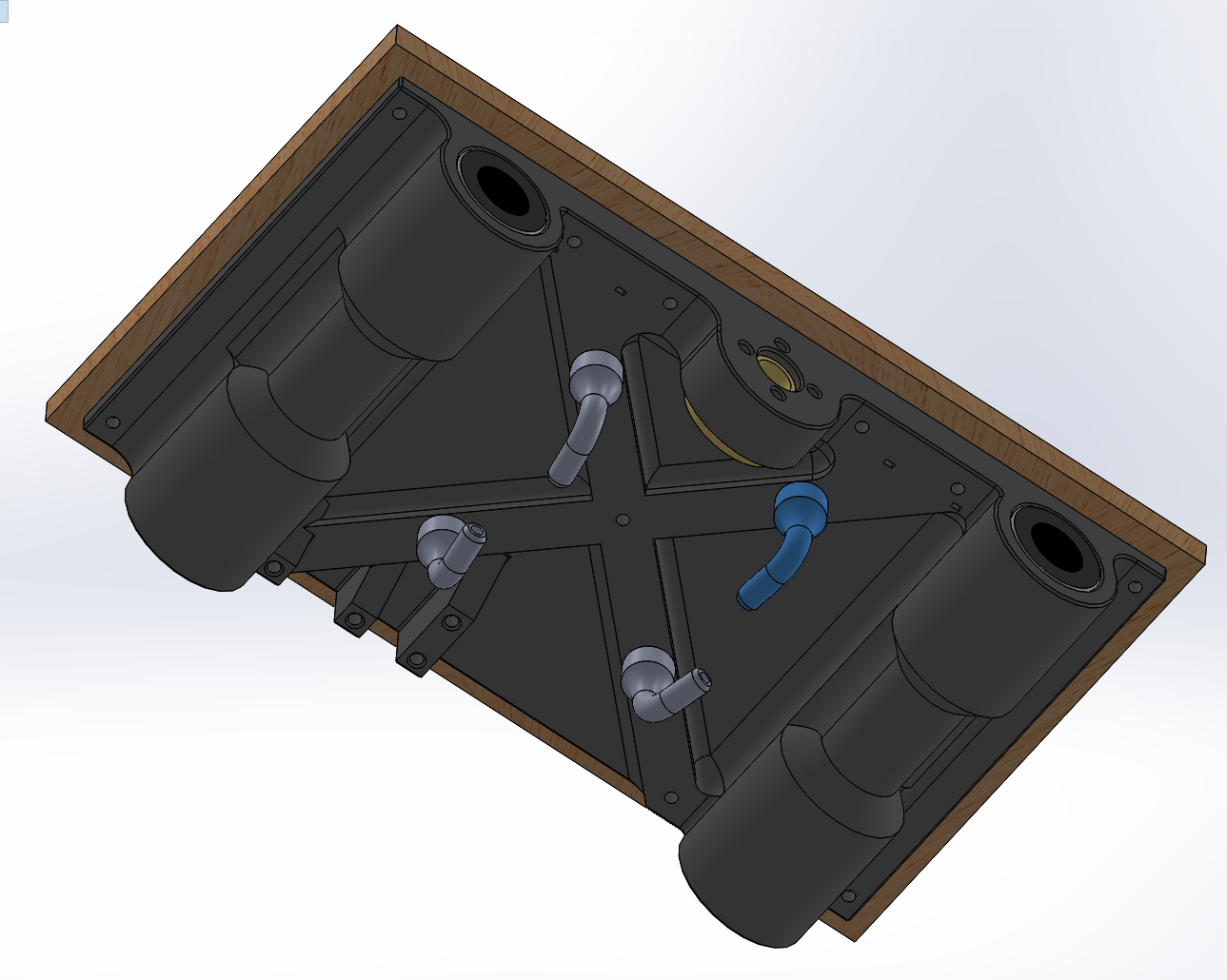

On the underside, I added attachments for clear tubing. I think mine are just 1/4" tubes that I slide onto the 90 degree angles. These are resin printed instead of purchased and even with standard resin, surprisingly strong.

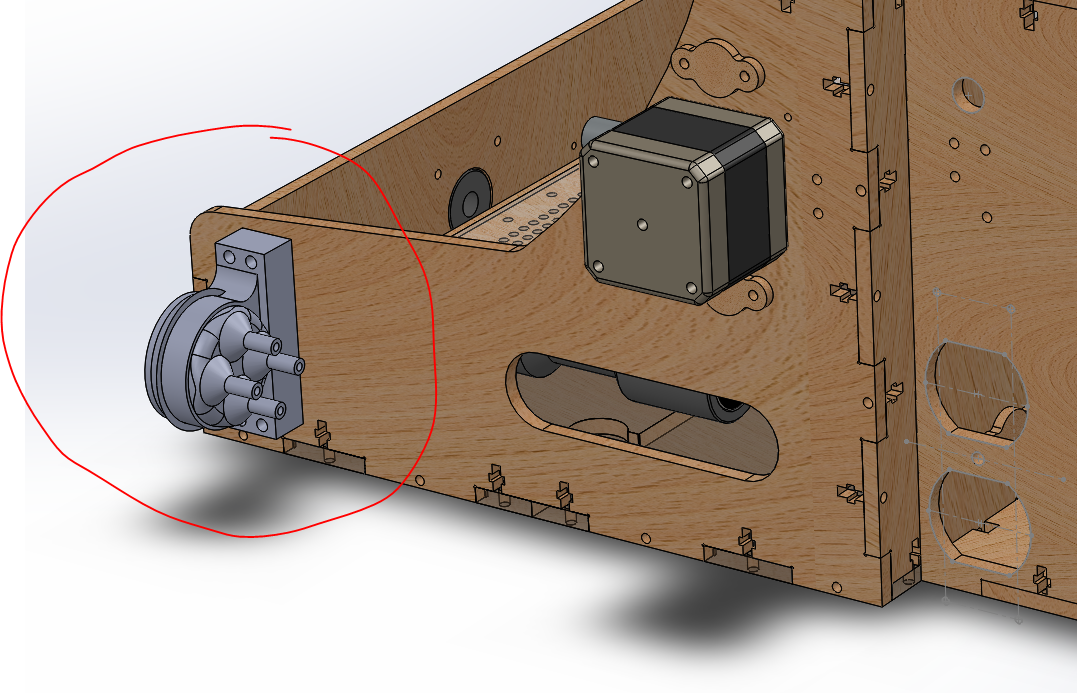

The clear tubing then goes to my vacuum adapter that's mounted to the side of the mill:

Here, I can just slide on my vacuum cleaner hose and everything is connected. It was a bit challenging to organize the clear tubing underneath the X-axis but with the help of various cable ties I was able to the the X-axis to move back and forth without additional resistance.

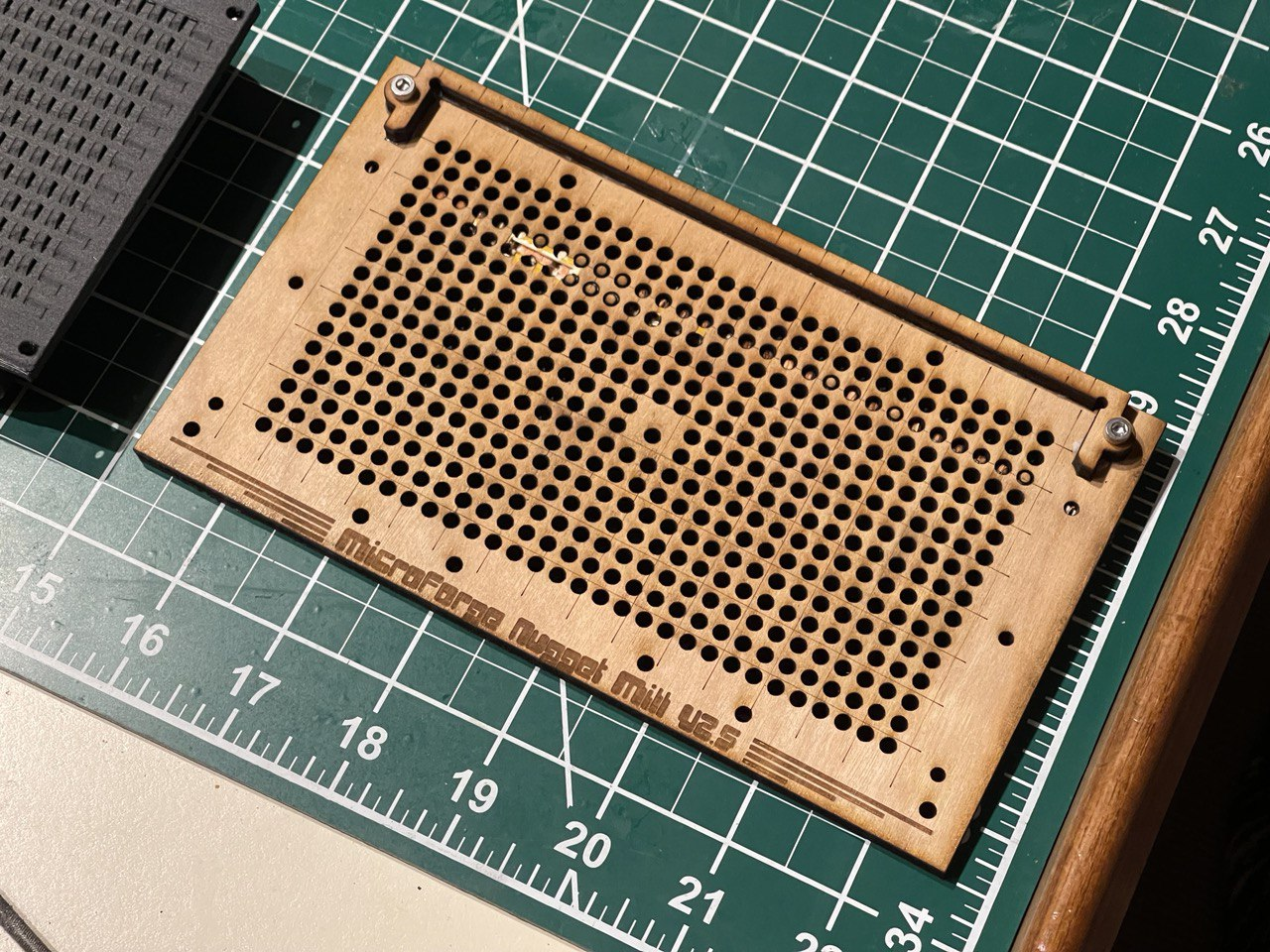

On the top, I added a new bed. This time, it was perforated with lots and lots of holes. My laser cutter lens was dirty and the cuts barely went through but I made it work and, spoiler alert, it works amazingly well!

After I put everything together, I turned the vacuum cleaner on for the first time and was amazed that I was barely able to move the PCB with my fingers. I can probably pull on the board with 20N before the board starts to slide. That's a lot for a 0.2mm V-endmill. All holes that are not covered by the PCB that I'm using can simply be covered using either just paper or packaging tape or a matching piece of wood! As long as all holes are covered, the suction force is great!

During this upgrade process I also decided to revamp the Y-axis as well as the Z-axis. The Y-axis had a few broken plastic clips and wasn't really save to use anymore. The Z-axis desperately needed an endstop switch:

I also finally added a slot for a 4mm nut such that I can tighten down the Proxxon MicroMot properly without ripping the threads in the 3D printed plastic.

This works so well that for top and bottom side milling, I don't even need to add any clamps at all! That's insane. All I do is bending the PCB to a reasonably flat shape, place it on the bed in the top right corner for TOP milling or the top right corner for BOTTOM milling and activate the vacuum cleaner! Flat and fixed! It's important to note that milling the outlines is risky and the through-holes need to be drilled last! Otherwise too much air can be sucked through the board and the vacuum doesn't hold anymore.

One last item I added was a piece of folded packaging tape as a fence for all the particles such that they don't spray all over my spindle drives.

-

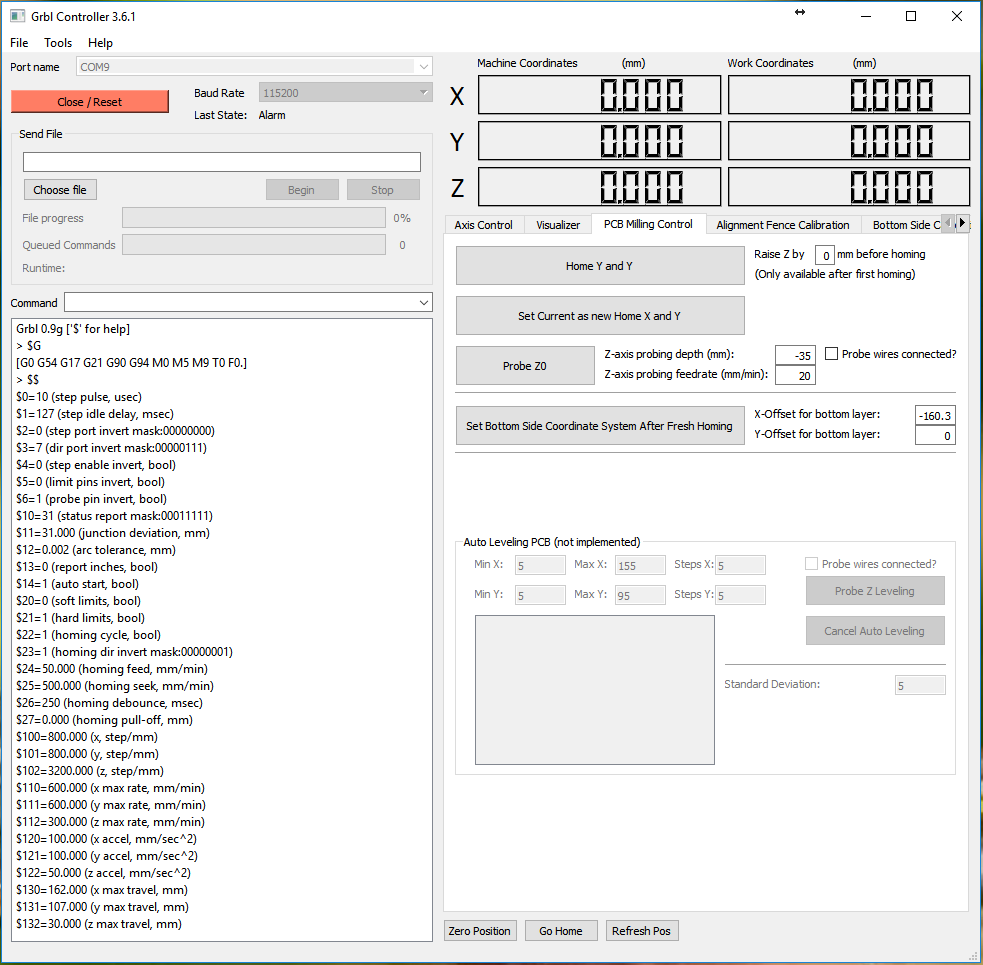

Updating cnc_gcode_controller and FlatCAM

01/13/2022 at 15:10 • 1 commentcnc_gcode_controller is an amazing open source project. As far as I'm aware, it has the only open source auto level feature that properly works by probing the board, creating a height map of it, and then splitting all the gcode commands up into snippets to linear interpolating them in the Z-Axis to match the the actual PCB or bed shape. When it works, it's fantastic!

However, GRBL1.1 changed a few things around and, of course, it didn't work anymore.

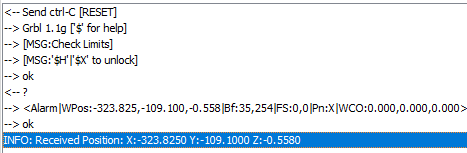

First of, GRBL1.1 uses a separate probe pin on the Arduino and the previously used Z-MIN/MAX pins won't do it anymore. The probe pin is now also reported with a 'P' instead of a 'Z' when asked what endstops are hit using '?'.

In the above example right after power up, the X axis endstop is reported shown in the |Pn:X| section.

Then, when the probe pin is hit, the command to let cnc_gcode_controller or any other gcode sender know where this was, is also different so cnc_gcode_controller didn't interpret it properly. I went ahead and created some issues around it on github and the original author (Patrick) quickly reacted and fixed the issues I described. THANK YOU!

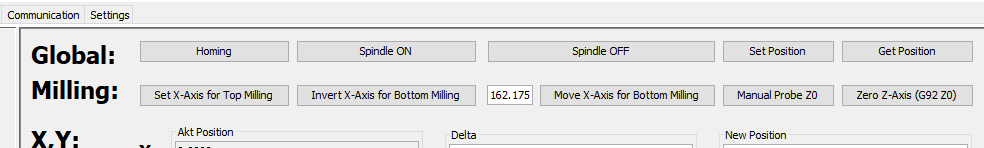

In addition, I decided to add a few buttons to the software to make my workflow a bit easier.

The Advanced Controls panel now contains a second row of buttons underneath "Global" specifically for "Milling".

These buttons allow me to easily invert the X-axis and move the tool over to the other side of the bed to a calibrated location to create perfectly aligned double sided boards without the need for any alignment pins. Just flip the board over, align the same corner of the PCB used for the top side and align it with the bottom side on the bed, done.

The Skew-Problem

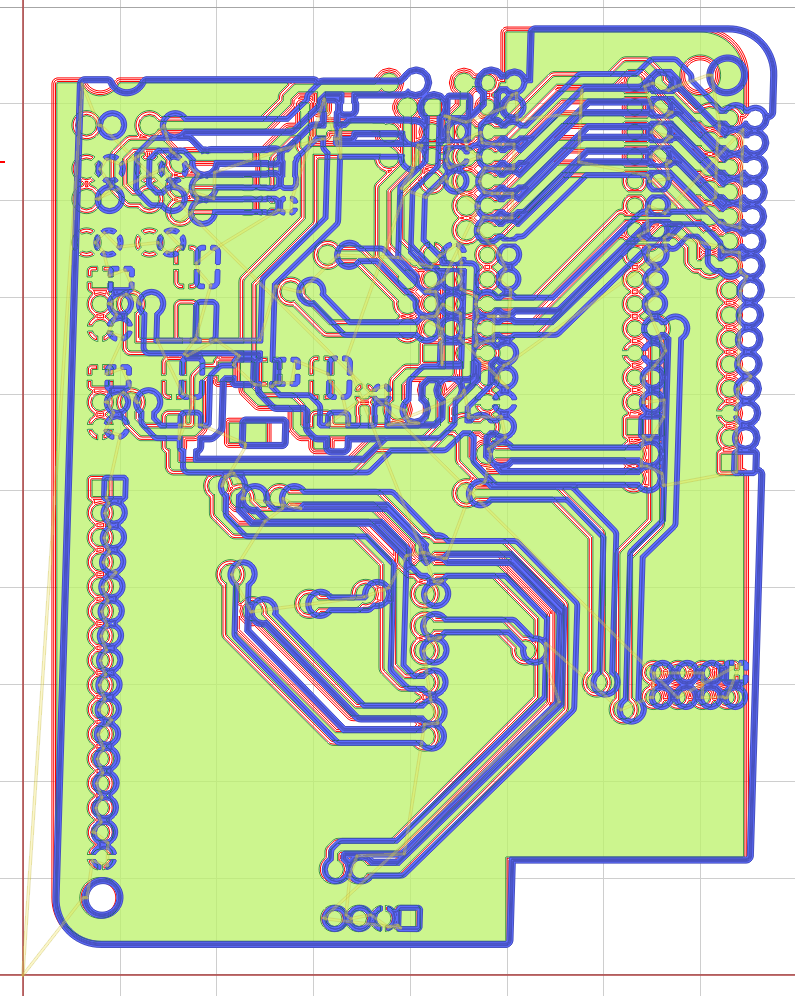

After calibrating the machine offset for top and bottom milling perfectly after many trials of milling and drilling test patterns, my mill appeared to work perfectly. As long as you only want to mill at the very bottom of the bed. Turns out, the machine is skewed. It has a parallel shift along the Y-axis resulting in parallelograms rather than squares. The lower 10mm of the board look great while the upper 75mm go more and more out of alignment with the bottom side of the PCB. All consequently drilled holes on the bottom side are therefore misaligned with the vias on the top side. Extremely annoying and in this case breaking the layout as some connections are broken now.

At first, I was confused about this but it occurred to me that I used my $350 Chinese K40 laser to make the PCB mill which most certainly is not 100% square looking at the way it's put together. It's sturdy but there is a different between something being ridged and something being well aligned and calibrated. So the cnc is skewed because the base plate of the cnc is skewed which in turn is skewed because the laser cutter is skewed. hmmmm...

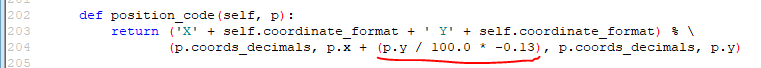

How can I fix this? Turns out it's very easy to do in software.

My first thought was to write a python script to ingest the gcode and translate every X-Coordinate based on it's corresponding Y-Coordinate. However, that's a lot of work and it felt like a waste of time for the number of boards I make a year.

I found a much more elegant way to do this: In the grbl1.1 preprocessor of FlatCAM, I added an equation that just adds an offset to the X-coordinate based on Y. I just need to flip the sign for the other side of the PCB so I created a second preprocessor script that does just that. Problem solved :)

I then presented this idea to the developer of FlatCAM which is my favorite PCB CAM software of all time. He liked the idea as it turned out his personal machine also has a skew, so he went ahead and implemented a variant of it into his software!

In my version, I created two different preprocessors for GRBL1.1. One for top side milling and one for bottom side milling. This works well for me as I only need to change one thing in FlatCAM during the creation of the CNC commands to correct for top and bottom skew. The issue my setup poses is that flipping the board over means the skew technically inverts as well. So I either have to have a checkbox or a flag of some sort to select top or bottom or I’d have to change the skew in the configuration settings every time. Selecting a different preprocessor seemed easier to me, for now.

Just to show what this code does, here is an exaggeration:

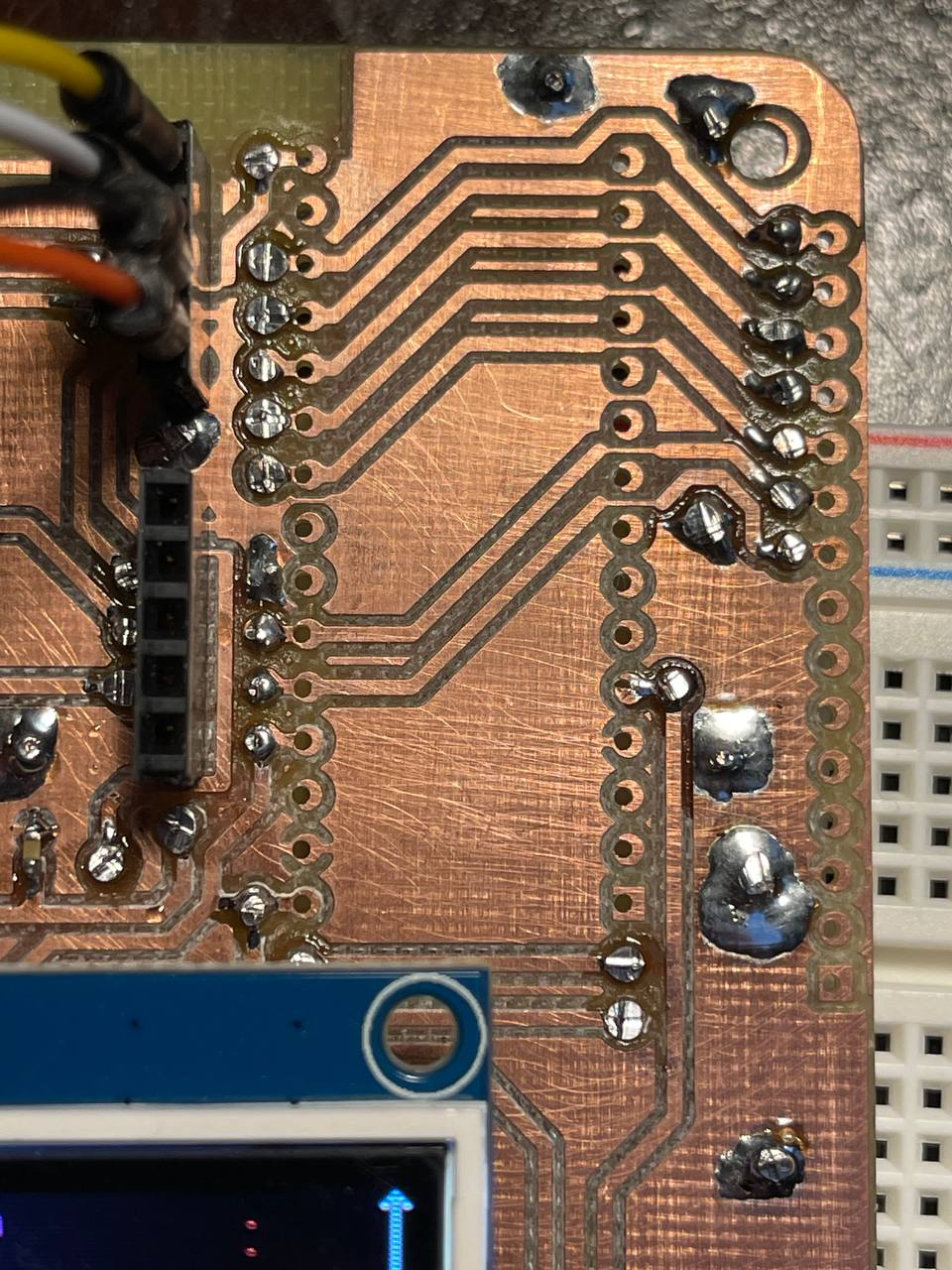

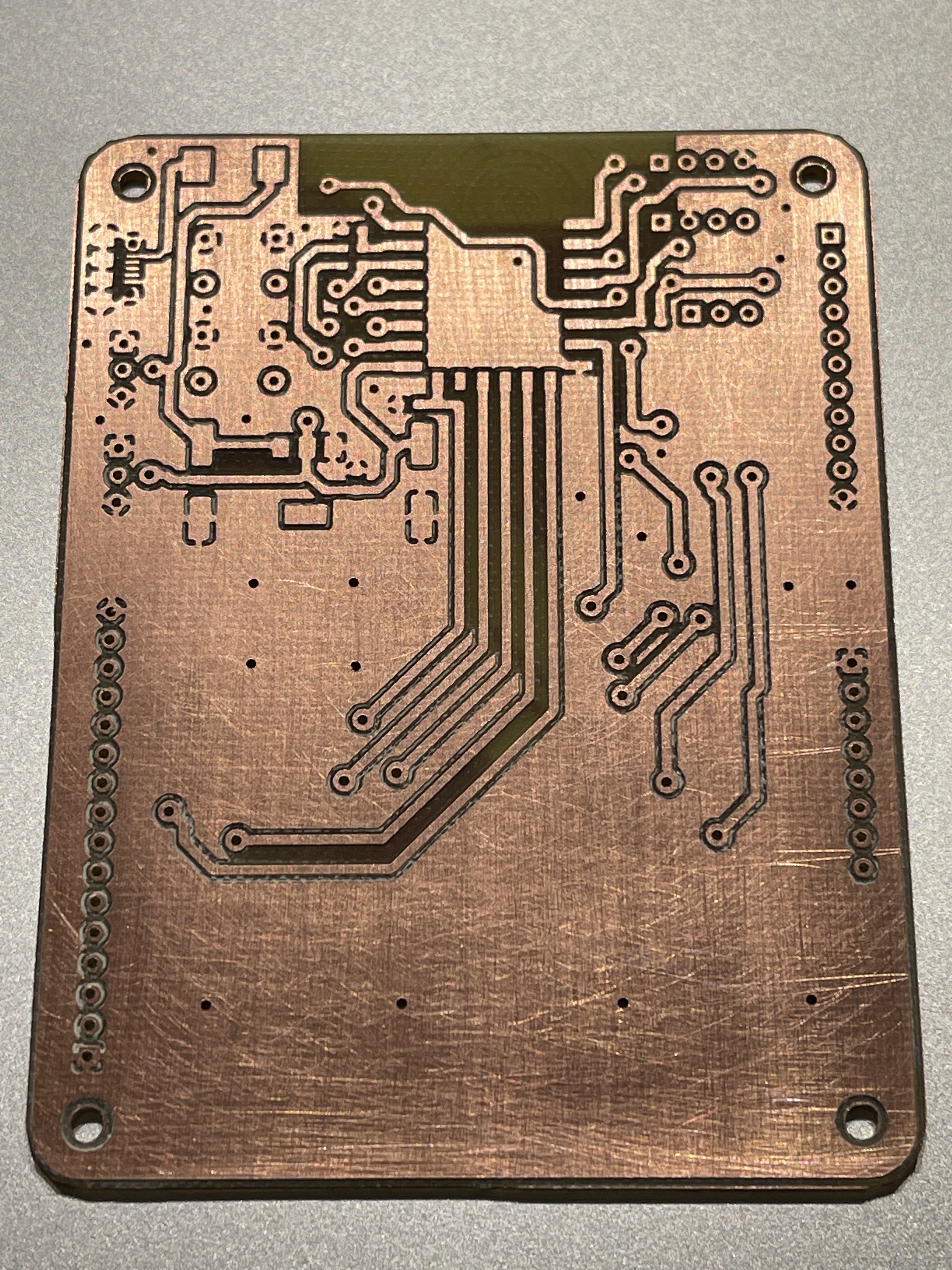

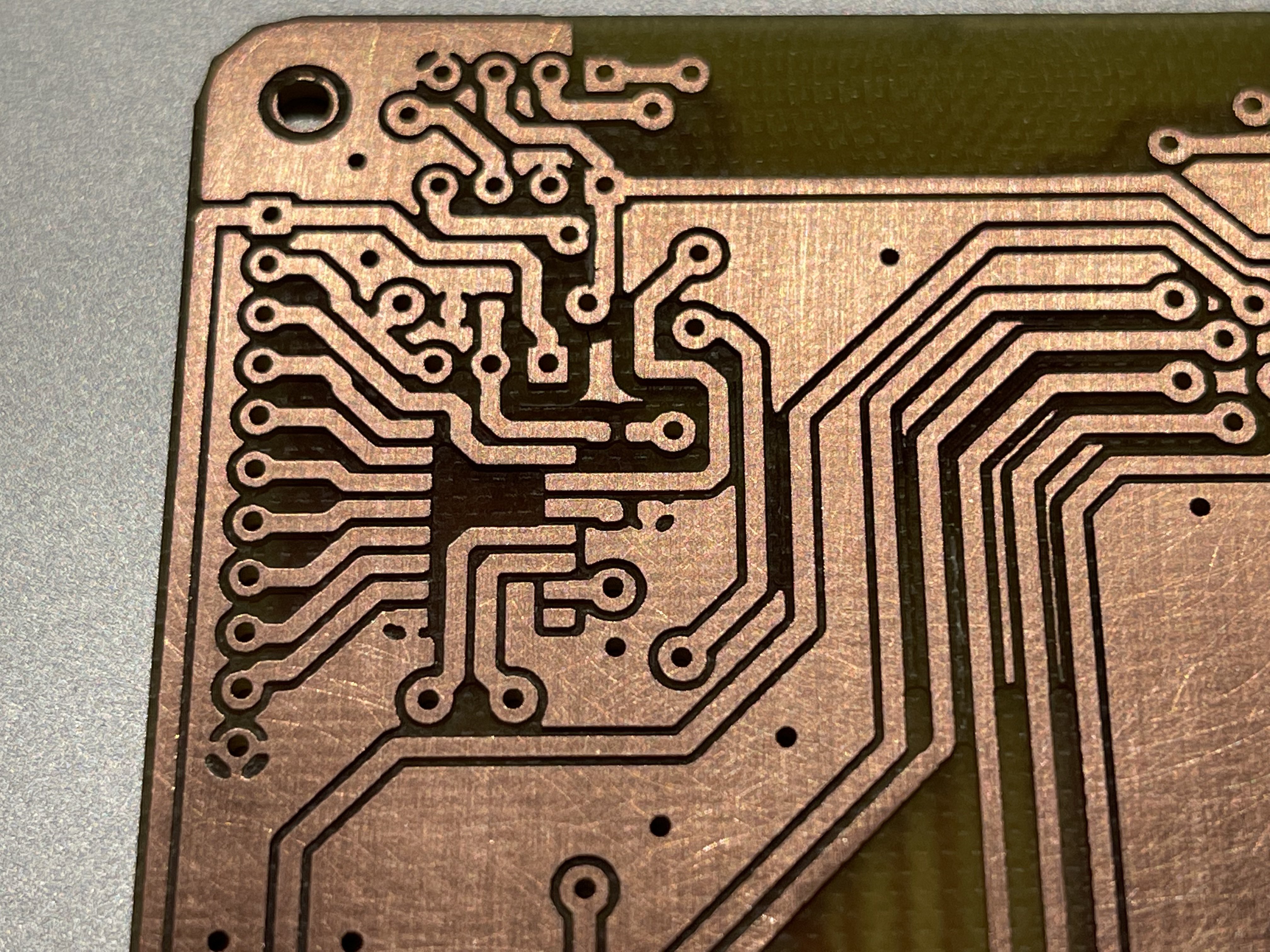

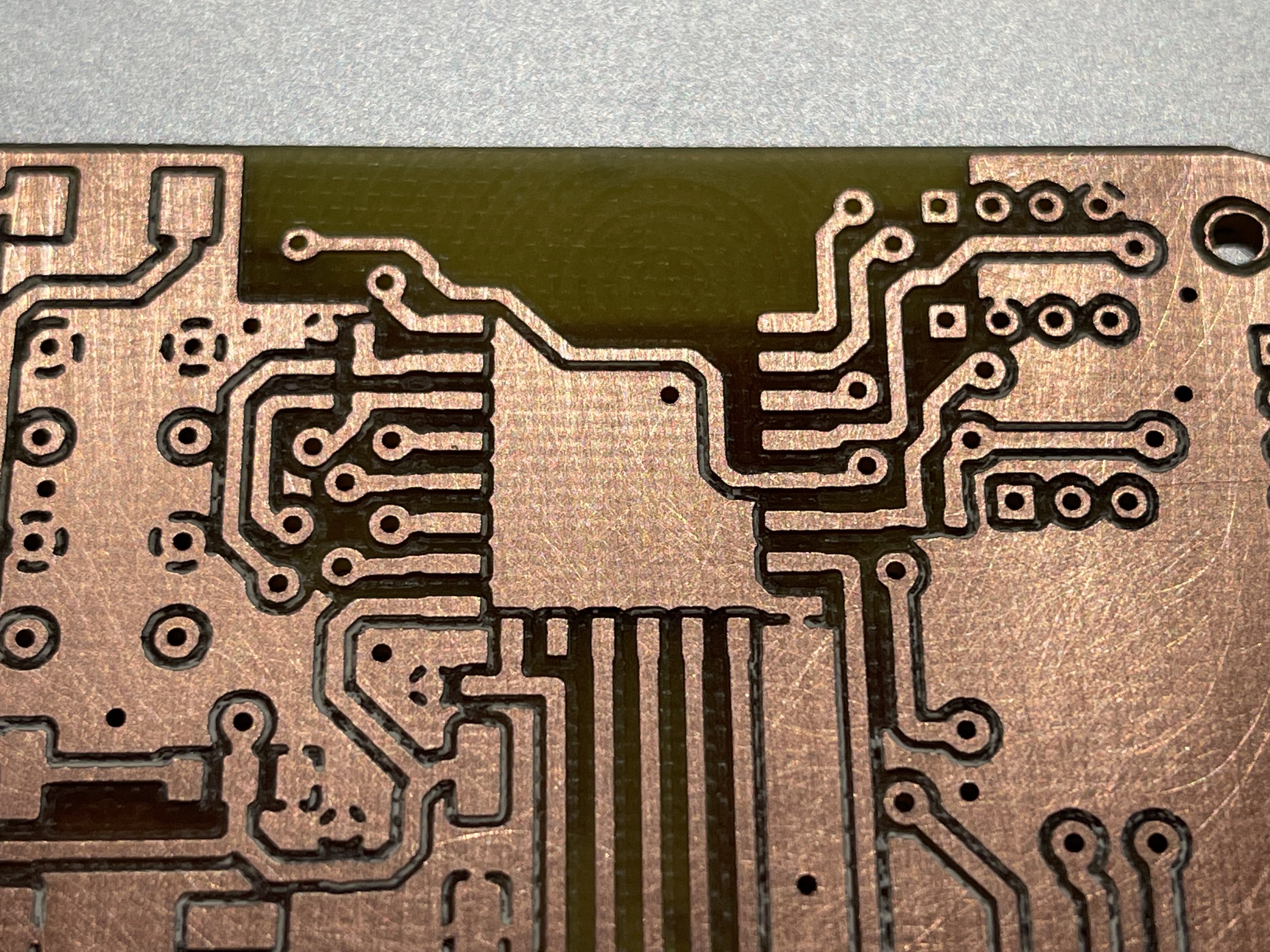

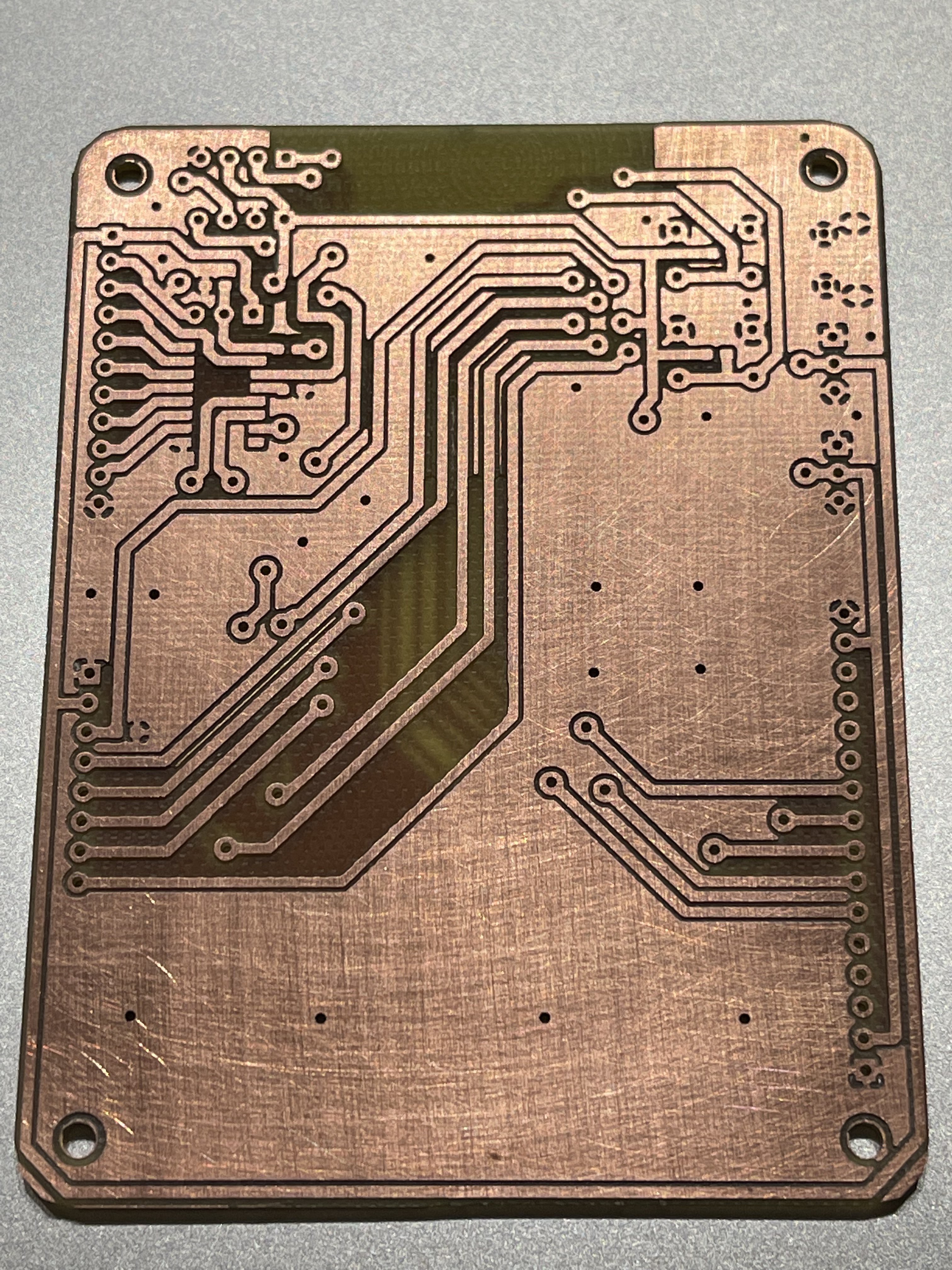

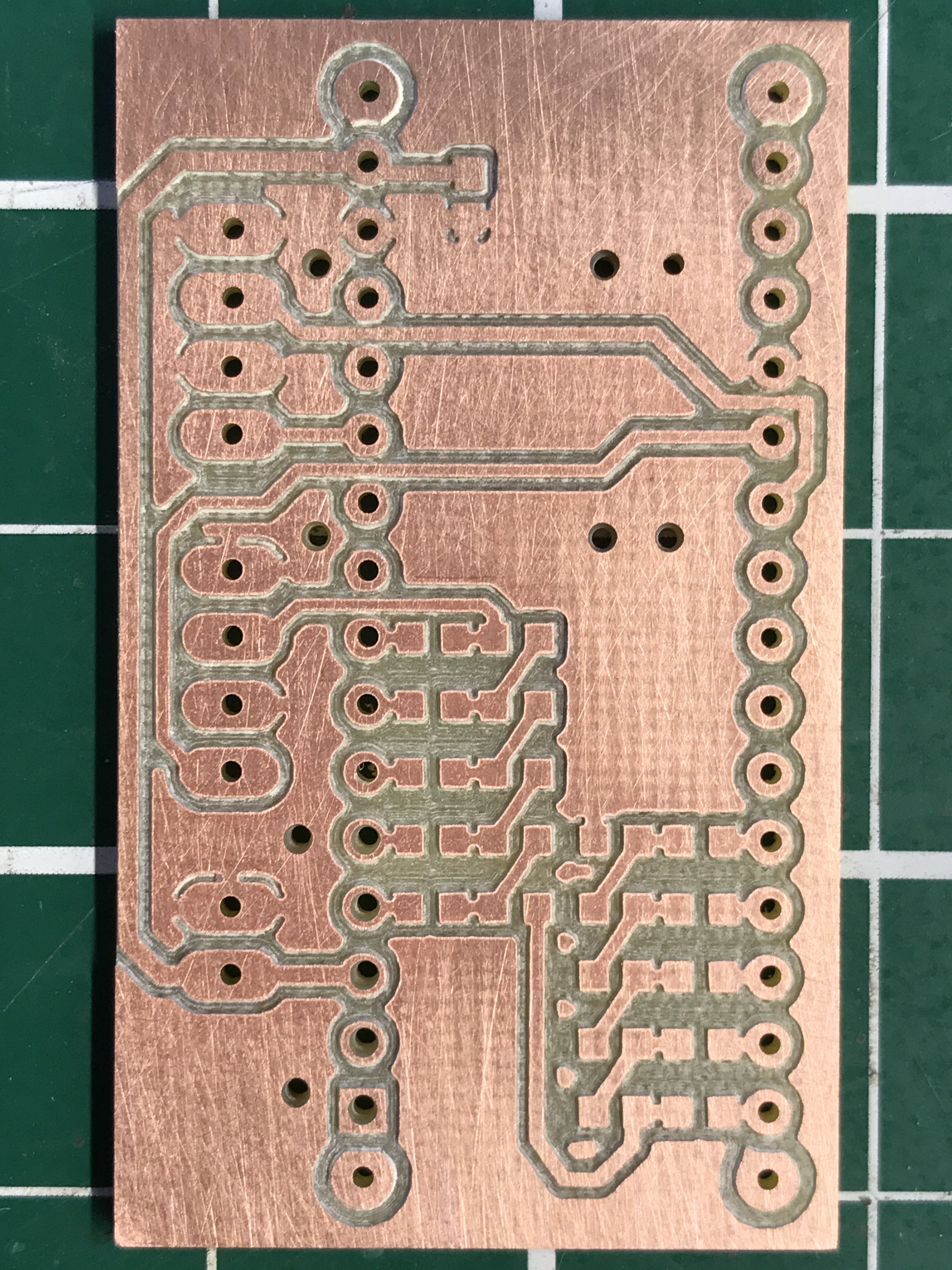

Another large amount of calibration mills and drills later, I ended up with near perfection from a $200 mill that was made on a $350 laser (plus some upgrades). That is pretty nice in my book and at the moment at least I could not be happier with the results!

![]()

![]()

![]()

![]()

![]()

As can be seen, top and bottom alignment is near perfect and does not need to improve at this point. I’m going to experiment with thinner traces and smaller vias now as the reliability has gone up so much with all these changes and I can dare to try this again :-)

-

GRBL Mega 1.1g - Tough Transition

12/17/2021 at 15:40 • 0 commentsThis morning, I spend 2.5h figuring out why the homing cycle on my mill doesn't wouldn't work after I upgraded to the latest GRBL mega. I couldn't find out where I had stored my original grbl version for this mill but it was rather old, like 0.9g and had quite a few bugs that I wasn't keen on carrying forward.

So this morning, after much consideration, I jumped right into it, cloned the repository and tried to reverse engineer the changes I had done for the old CycloneGRBL, or whatever I used back then, to work. Turns out the changes were rather minimal and what bit me in the end was a missing pullback for homing.

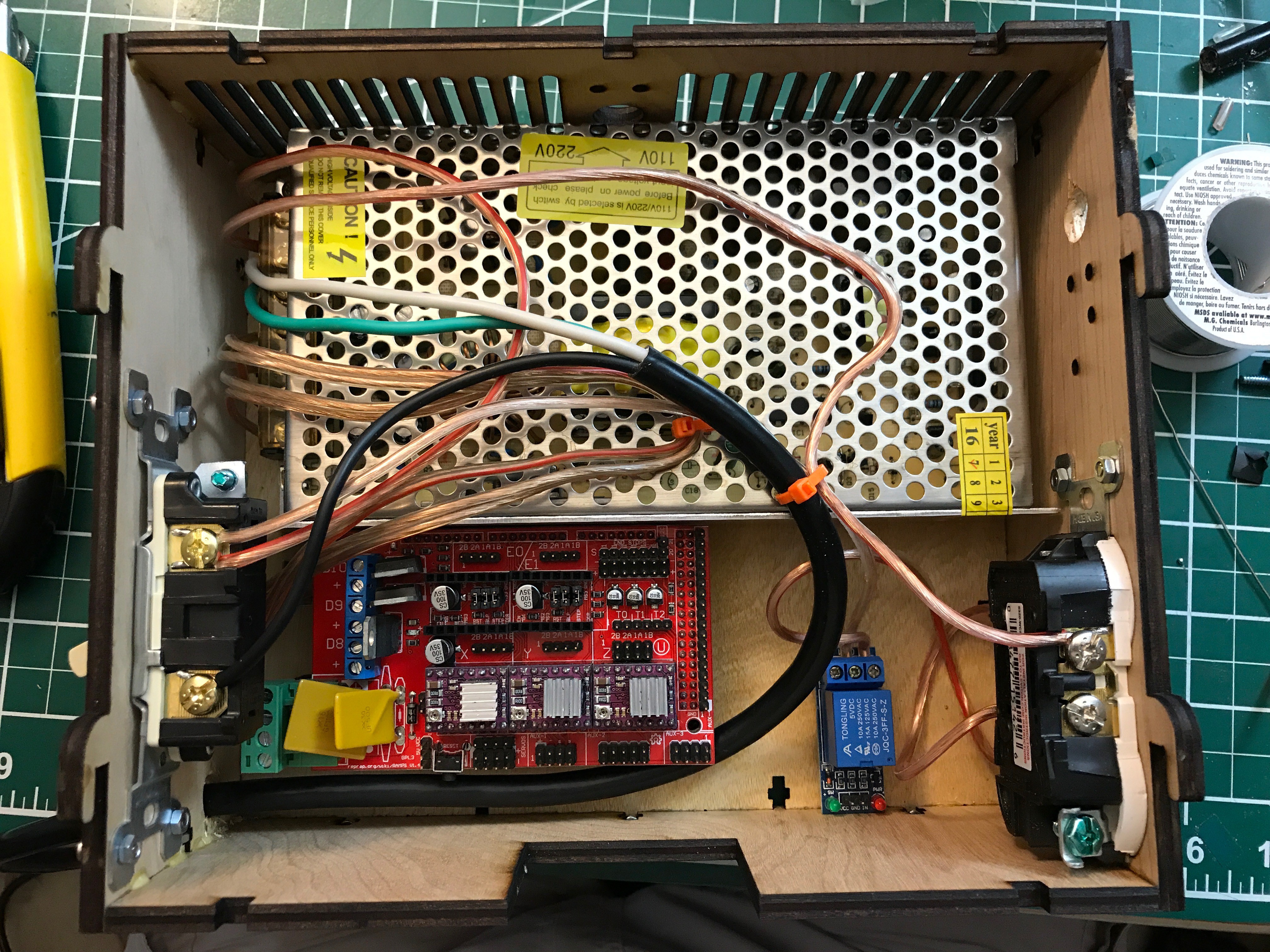

Since my mill uses an Arduino Mega256 with a RAMPS1.4 board, I needed to define the appropriate build flags in the config.h:

#define DEFAULTS_RAMPS_BOARD #define CPU_MAP_2560_RAMPS_BOARDThen I changed what the homing cycle looks like to reflect that I don't have a Z-axis endstop switch:

#ifdef DEFAULTS_RAMPS_BOARD #define HOMING_CYCLE_0 ((1<<X_AXIS)|(1<<Y_AXIS)) // Home X axis // #define HOMING_CYCLE_1 (1<<Y_AXIS) // Home Y axis // #define HOMING_CYCLE_2 (1<<Z_AXIS) // OPTIONAL: Home Z axis #else // #define HOMING_CYCLE_0 (1<<Z_AXIS) // REQUIRED: First move Z to clear workspace. // #define HOMING_CYCLE_1 ((1<<X_AXIS)|(1<<Y_AXIS)) // OPTIONAL: Then move X,Y at the same time. #define HOMING_CYCLE_0 (1<<X_AXIS) // REQUIRED: First move Z to clear workspace. #define HOMING_CYCLE_1 (1<<Y_AXIS) // OPTIONAL: Then move X,Y at the same time. // #define HOMING_CYCLE_2 // OPTIONAL: Uncomment and add axes mask to enable #endif // DEFAULTS_RAMPS_BOARDAnd for my specific setup, I'm running the SPINDLE_ENABLE_PIN on Digital Pin 9 for some historical reason, so I had to change the cpu_map.h in the appropriate place:

// Define spindle enable and spindle direction output pins. // #define SPINDLE_ENABLE_DDR DDRG // #define SPINDLE_ENABLE_PORT PORTG // #define SPINDLE_ENABLE_BIT 5 // MEGA2560 Digital Pin 4 - Ramps 1.4 Servo 4 Signal pin #define SPINDLE_ENABLE_DDR DDRH #define SPINDLE_ENABLE_PORT PORTH #define SPINDLE_ENABLE_BIT 6 // MEGA2560 Digital Pin 9After that, it was a matter of setting the correct configuration parameters using using the GRBL config that can be set at runtime (an amazing feature, btw. I wish Marlin would have something like that, too).

$0=10 $1=127 $2=0 $3=6 $4=0 $5=0 $6=1 $10=31 $11=31.000 $12=0.002 $13=0 $20=0 $21=1 $22=1 $23=0 $24=50.000 $25=1000.000 $26=250 $27=0.500 $30=0 $31=0 $32=0 $100=800.000 $101=800.000 $102=3200.000 $110=1800.000 $111=1800.000 $112=450.000 $120=30.000 $121=30.000 $122=10.000 $130=162.000 $131=107.000 $132=30.000

The important learning that cost me almost 2h of my life is $27=0.500. This defines the pull back distance after the homing switches have been hit during homing for the first time. I didn't want any pullback, I thought, and on my old setup this value was set to 0mm so I replicated that right after flashing without checking anything. However, GRBL 1.1 reacts differently from 0.9g as it REQUIRES a pullback distance to be defined to be able to home at all.

If the pullback distance is set to 0mm, it will go straight into an alarm state once the endstop was hit. In the end, it was a test like: "Yeah whatever, I'm running out of options...." shot in the dark. Target hit. Everything worked all of a sudden... dude.

What really bothers me, though, is that LaserGRBL still doesn't like the mill. I thought it doesn't like GRBL0.9g but it still won't connect to my mill. It's works fine with the laser cutter and apart from the lock state it wakes up in. But according to LaserGRBL, that's acceptable. Hm. I guess I have to continue to work on cnc-gcode-controller and make that software work for me with all it's quirks and bad performance gcode streamer.

-

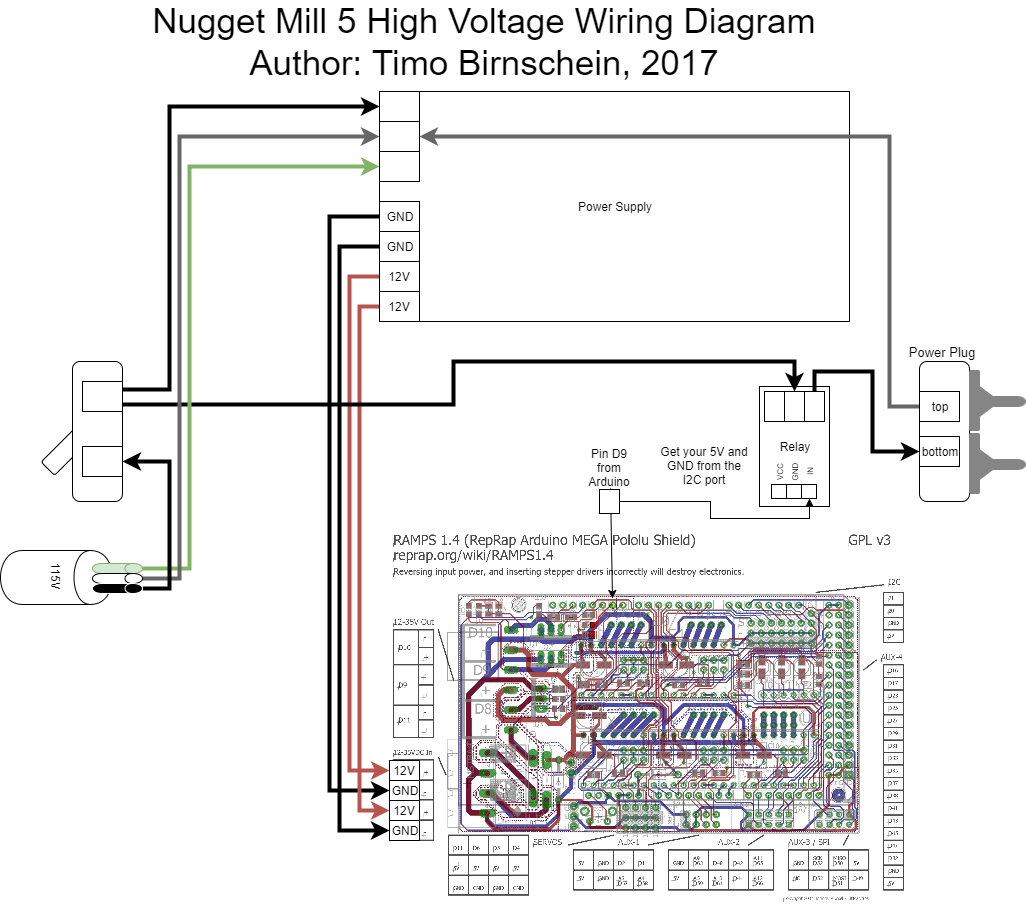

High Voltage Wiring Diagram

07/15/2017 at 22:00 • 0 commentswas asked to create a wiring diagram for the NuggetMill5, so here it is.

![]()

![]()

I left the basic stuff for stepper motors and endstops out because I already described it in my logs below.

Motors are standard. Just make sure they move in the right direction with my configuration. If not, please turn the plug around and it should be fine. I stole the 5Volts for the relay from the I2C port. I also needed to use the MIN EndStop inputs for the three endstops that are supported with this version of grbl instead of MAX as described for the original grbl. Please keep that in mind.

-

pcb-gcode bugfixes and github

07/08/2017 at 20:53 • 0 commentsI realized another bug when milling my first actual project on the mill:

pcb-gcode, even though many people seem to be using it and the documentation seems excellent, seems to have quite a lot of bugs that are easy to fix due to Eagles C-like scripting language.

The latest bug I found and hopefully just fixed is the issue that spotting holes during the etch step drills all the way to DRILL_DEPTH right after the first hole was spotted properly. Spot drilling is supposed to help a manual drill step by creating a center hole for the drill press to work with.

However, after the first proper spot drilling, the V-shaped engraver bit got punched into the PCB all the way to the drill depth (1.65 mm) which widened my holes quite a bit, shrinks the restring unnecessarily, it costs time, it wears out the engraving bit and it's generally... simply a bug! I don't yet understand why the first hole and all other holes are handled separately but I guess I will find out as soon as I work on my next project.

To make things a lot easier, I also created a github repository for pcb-gcode. I have no idea why the original author is not using github to distribute the software...

-

First actual project

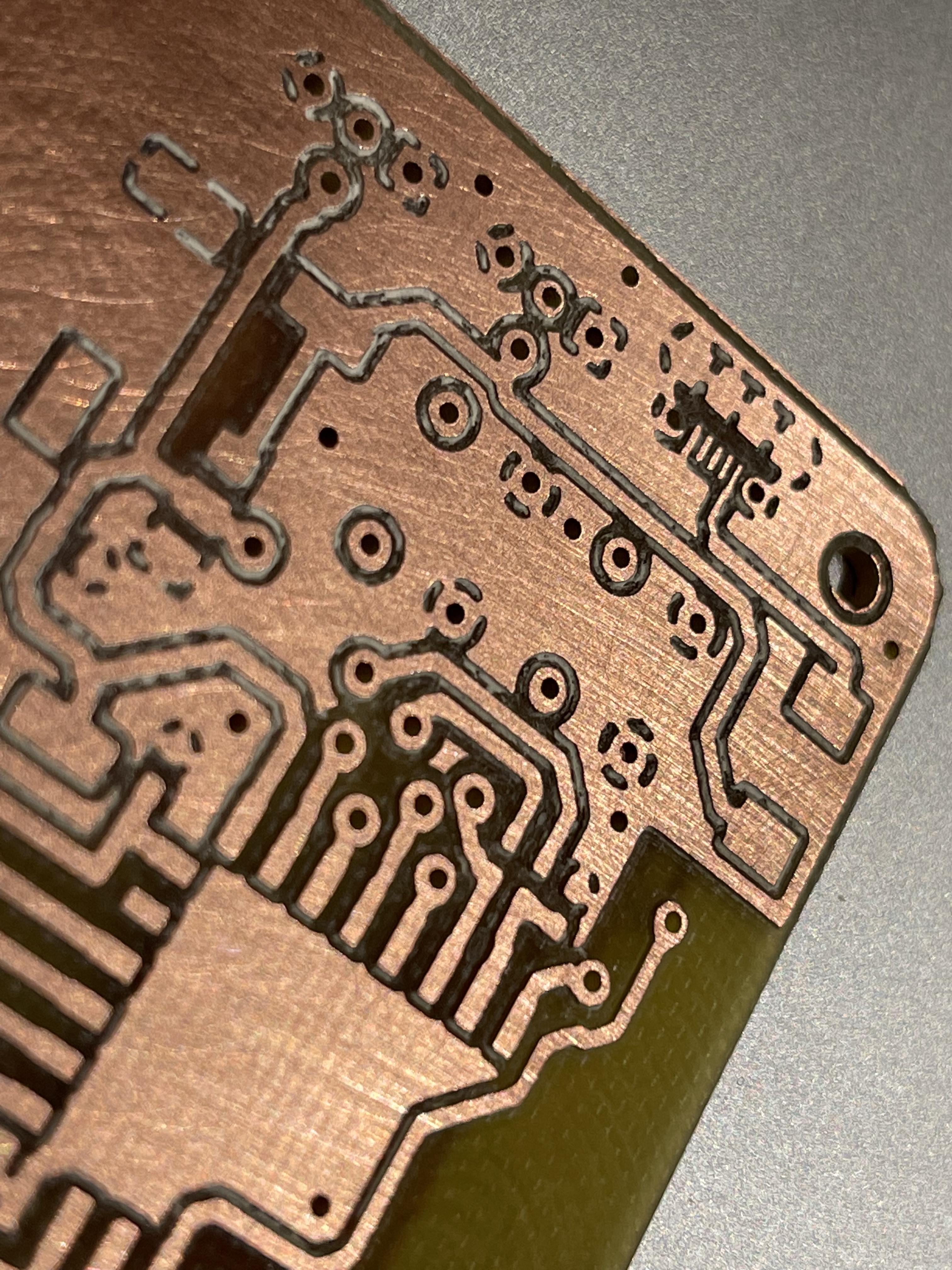

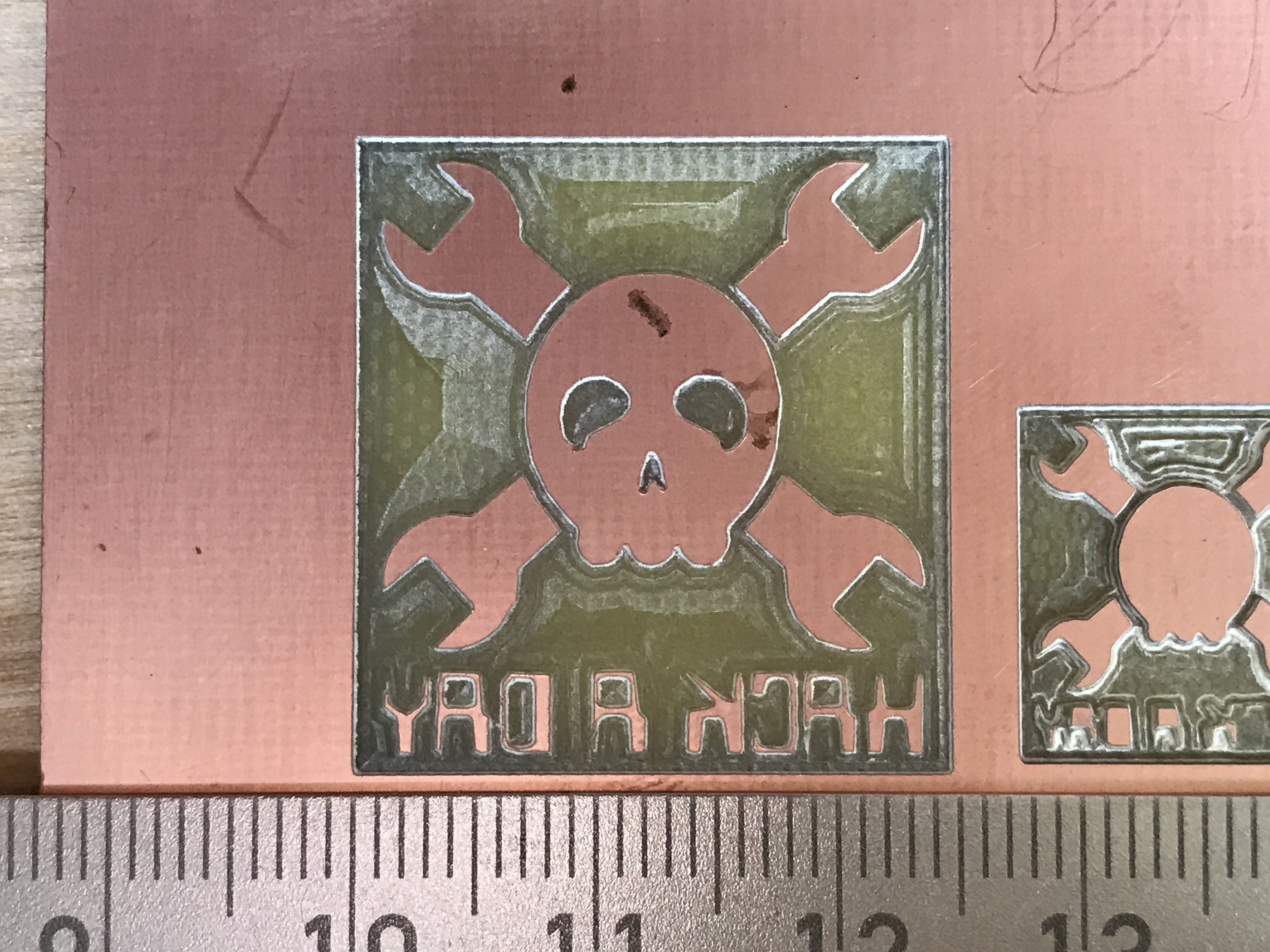

07/02/2017 at 22:36 • 0 commentsThere are a couple bugs left in the configuration and some gcode issues like the etch step is also used for drilling "again" for no reason. I need to fix that in the pcb-gcode script. However, the results are really cool!

-

Happy 4th of July!

07/01/2017 at 21:21 • 2 commentsMake something cool today!

-

What the YAD?

06/25/2017 at 01:27 • 2 commentsThe moment you realize....

Your X-axis is inverted. And I was like... Why the hack does the 'H' look so weird!!?? .... [long break] ... oh it's a 'Y'... darn.

-

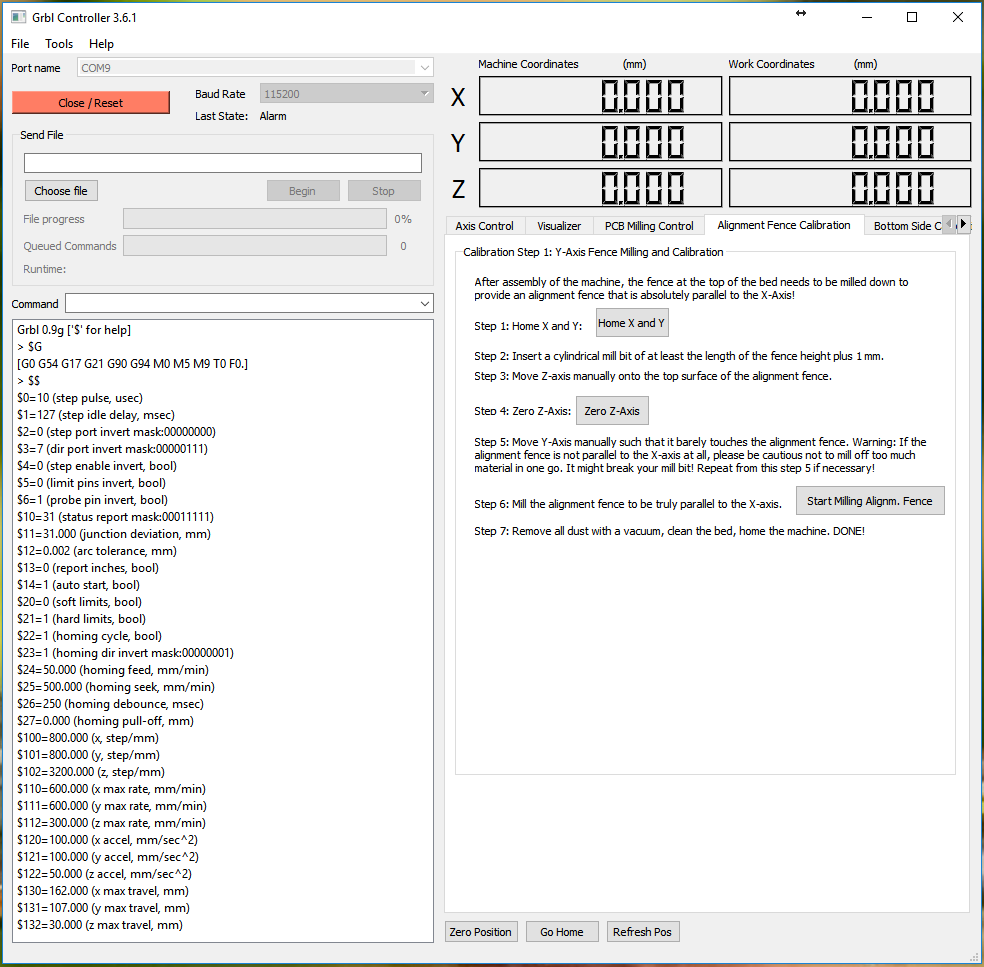

Calibration Wizards for Ease of Use

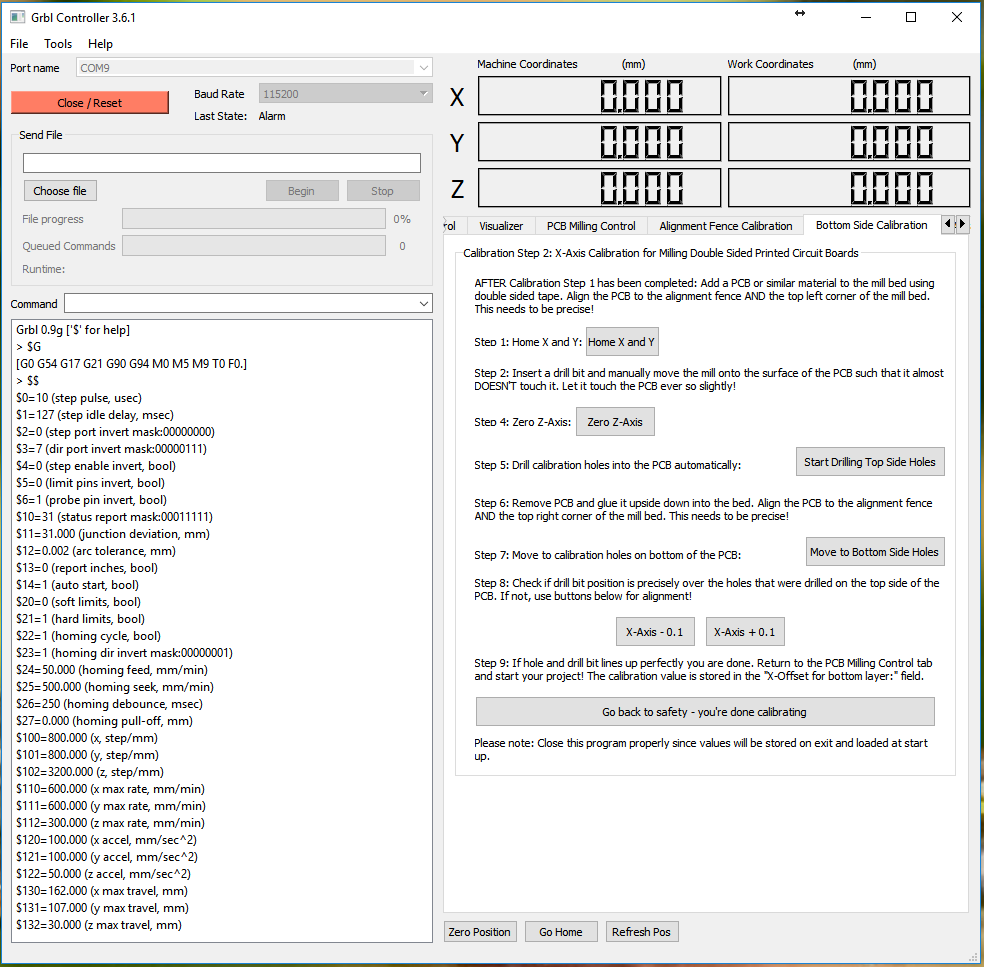

06/24/2017 at 23:26 • 0 commentsToday was a good day. After realizing that rewriting lost instructions makes no sense at all since I should be able to create a proper wizard for machine calibration in the same time, I did just that.

With grblController you now can

- Mill double sided PCBs without any hassle

- Calibrate / mill down your X-Axis Alignment Fence to be 100% parallel to your X-Axis

- Perform the X-Axis calibration for milling the bottom side of a PCB

Since my goal is to make everything as simple as possible to the user, I created a step by step instruction set on new tabs in grblController:

Above you see the options you have available for PCB milling. I think, this should give you all the tools that you might need to mill your double sided PCBs. But since you need to calibrate your fresh machine first, I added the calibration tabs.

This tab provides you with step by step instructions to properly mill down your X-Axis alignment fence. Please use one of these mill bits to mill the fence down and to make it absolutely parallel with your mills X-axis.

The bottom side is a bit more interesting, even though it will take much less time to get right. Just follow the instructions and you will end up with a perfectly calibrated machine.

One add-on I'm thinking about is storing the actual negative space coordinate system for milling the bottom side of the PCB into the grbl controller itself and not the software. It could be beneficial if you plan on moving the mill to another place and use it with different computers from time to time. But for now, I think it's fine that the settings are stored properly and platform independent on one computer.

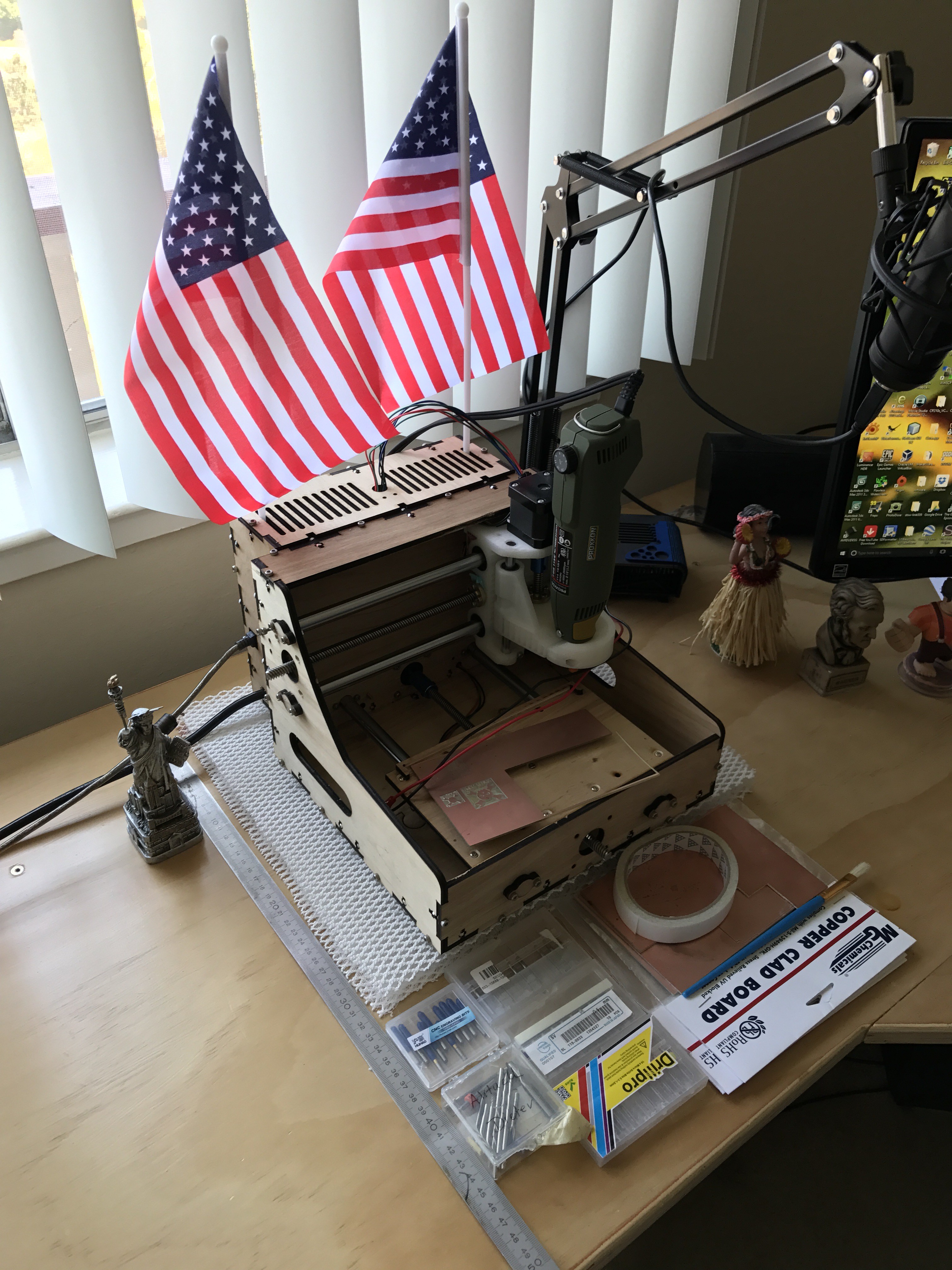

Sub $200 PCB Mill that doesn't suck!

A PCB mill inspired by open source CNC 3D printers with a custom design to fit standard size copper clad boards (6" x 4" / 160mm x 100mm)

Timo Birnschein

Timo Birnschein