-

Version 2.0

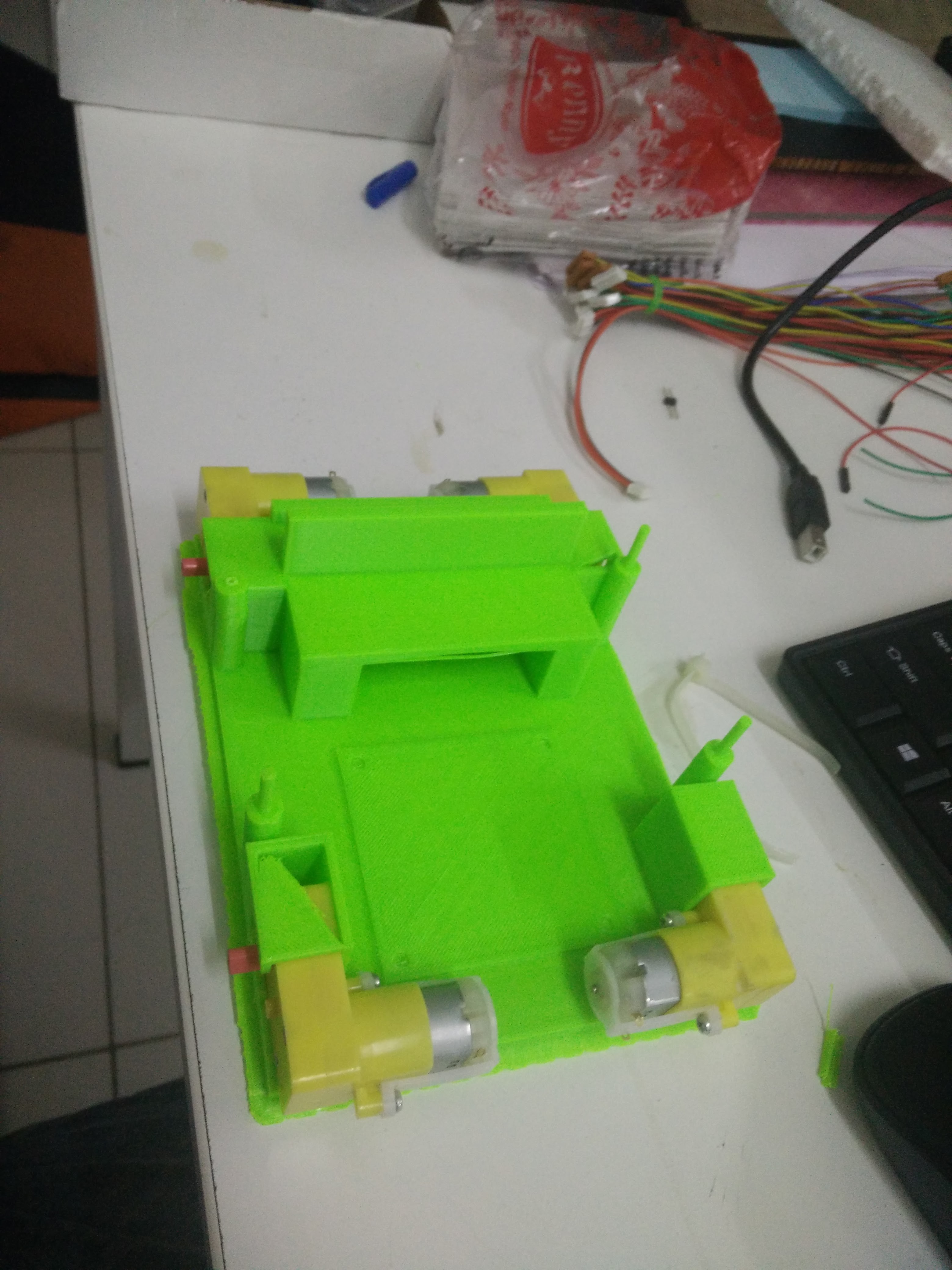

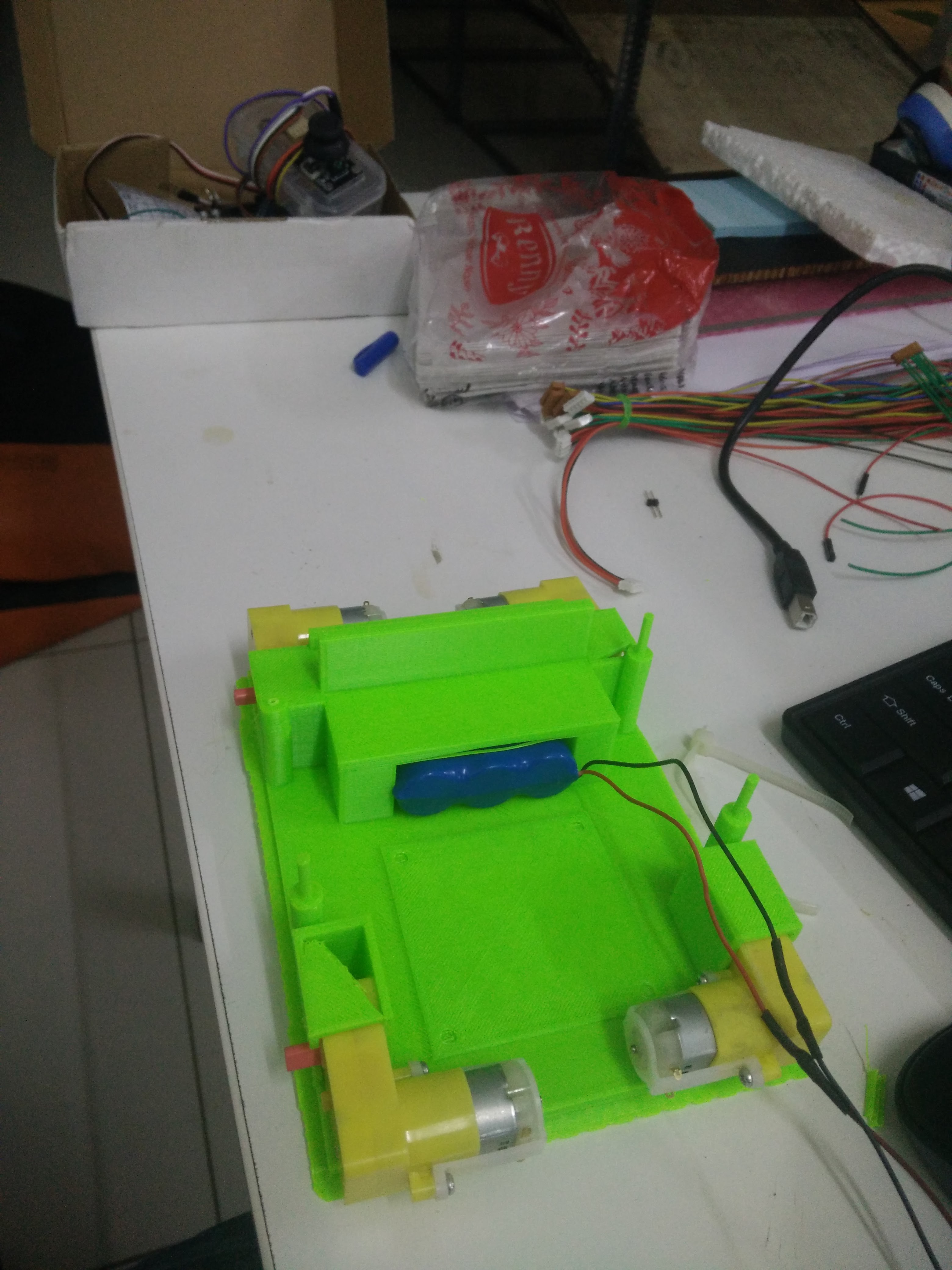

07/24/2017 at 13:58 • 0 commentsThe above prototype taught us a few lessons.

- The pillars need to be stronger - The ones designed for the motor driver broke off and had to be kept within the pillars of galileo.

- The compartments should be removable so that other components can be fitted into the same chassis.

- The robot still doesn't look so beautiful.

The above reasons and some more drove us in making the second revision which is under progress with VR possibility.

The github link for the code is - https://github.com/saipraveend/Snapbot_V2

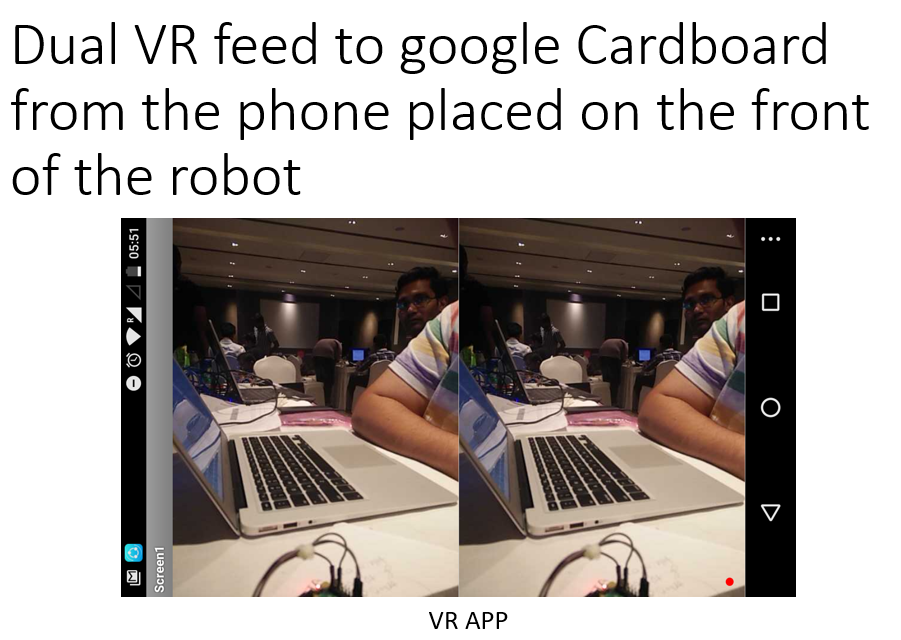

VR app for the V2 Robot.

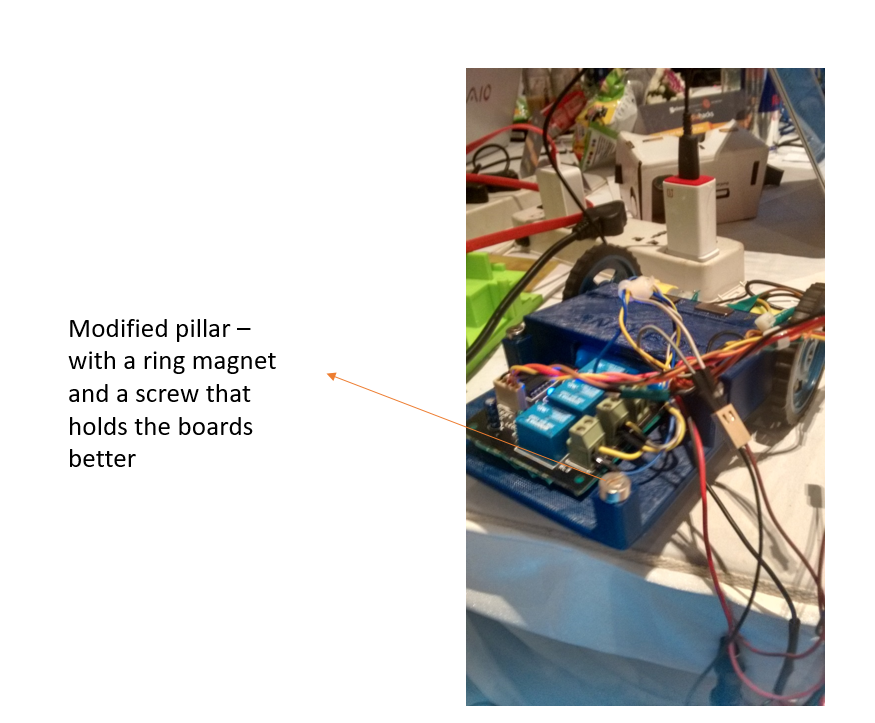

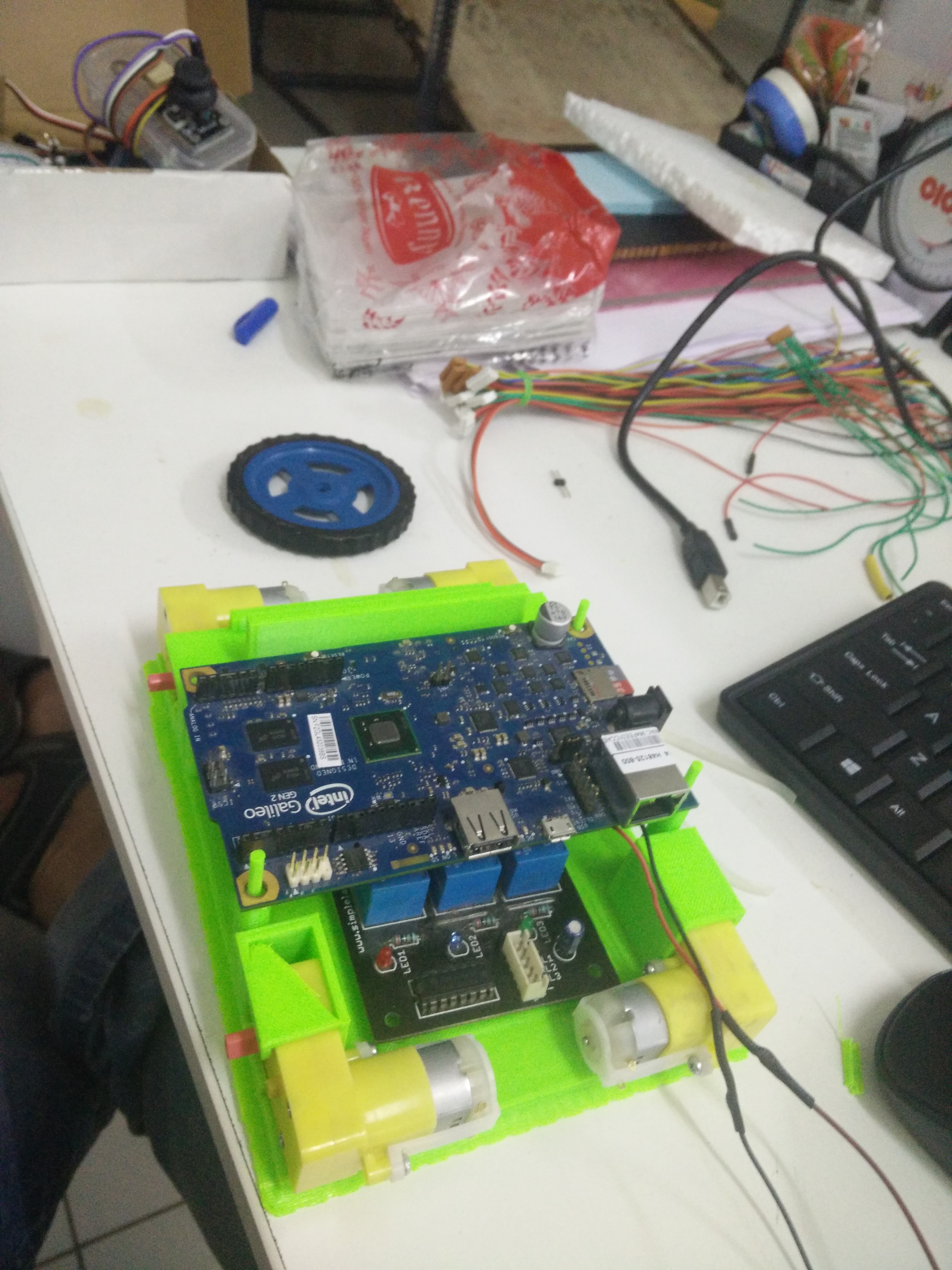

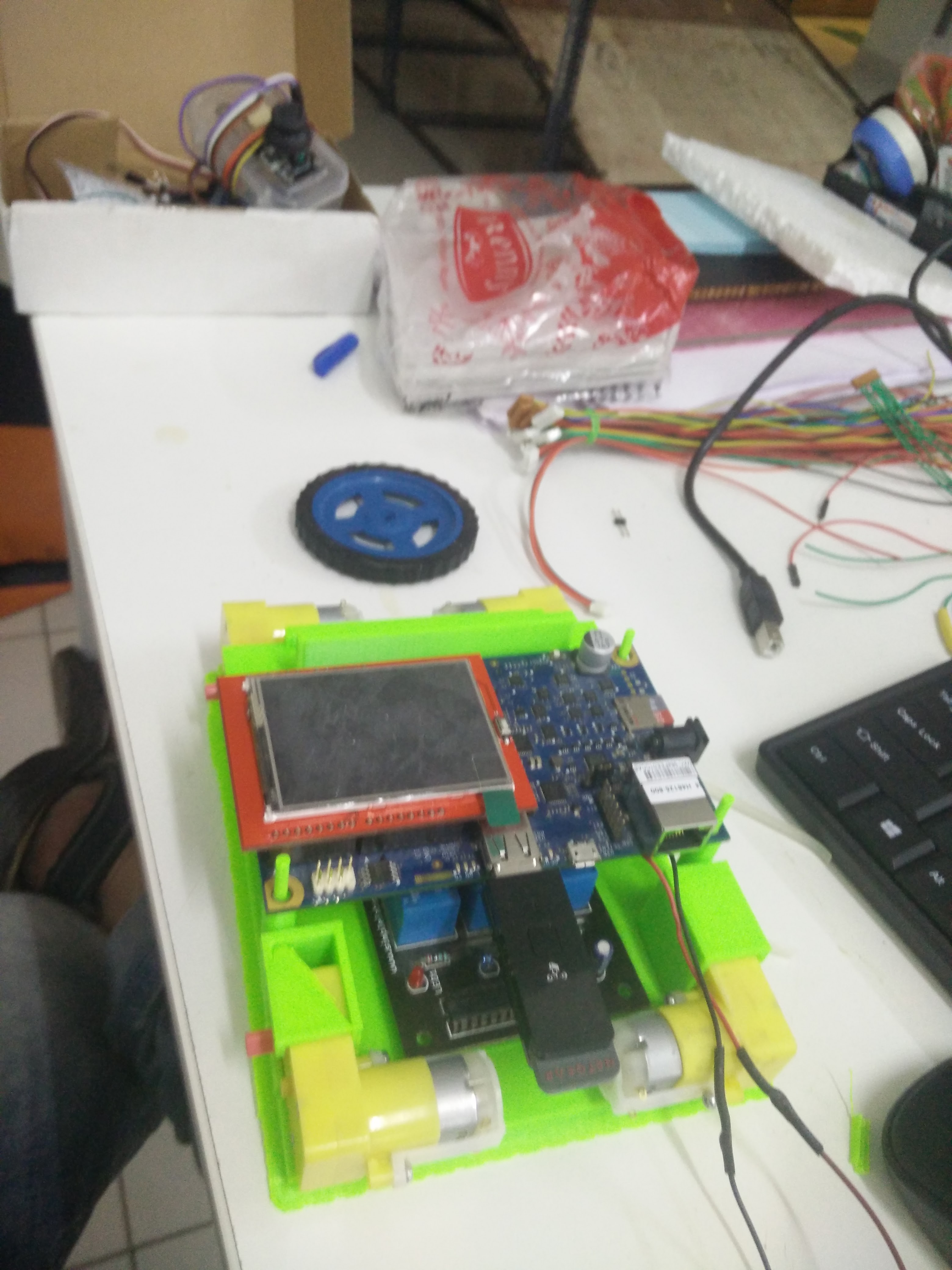

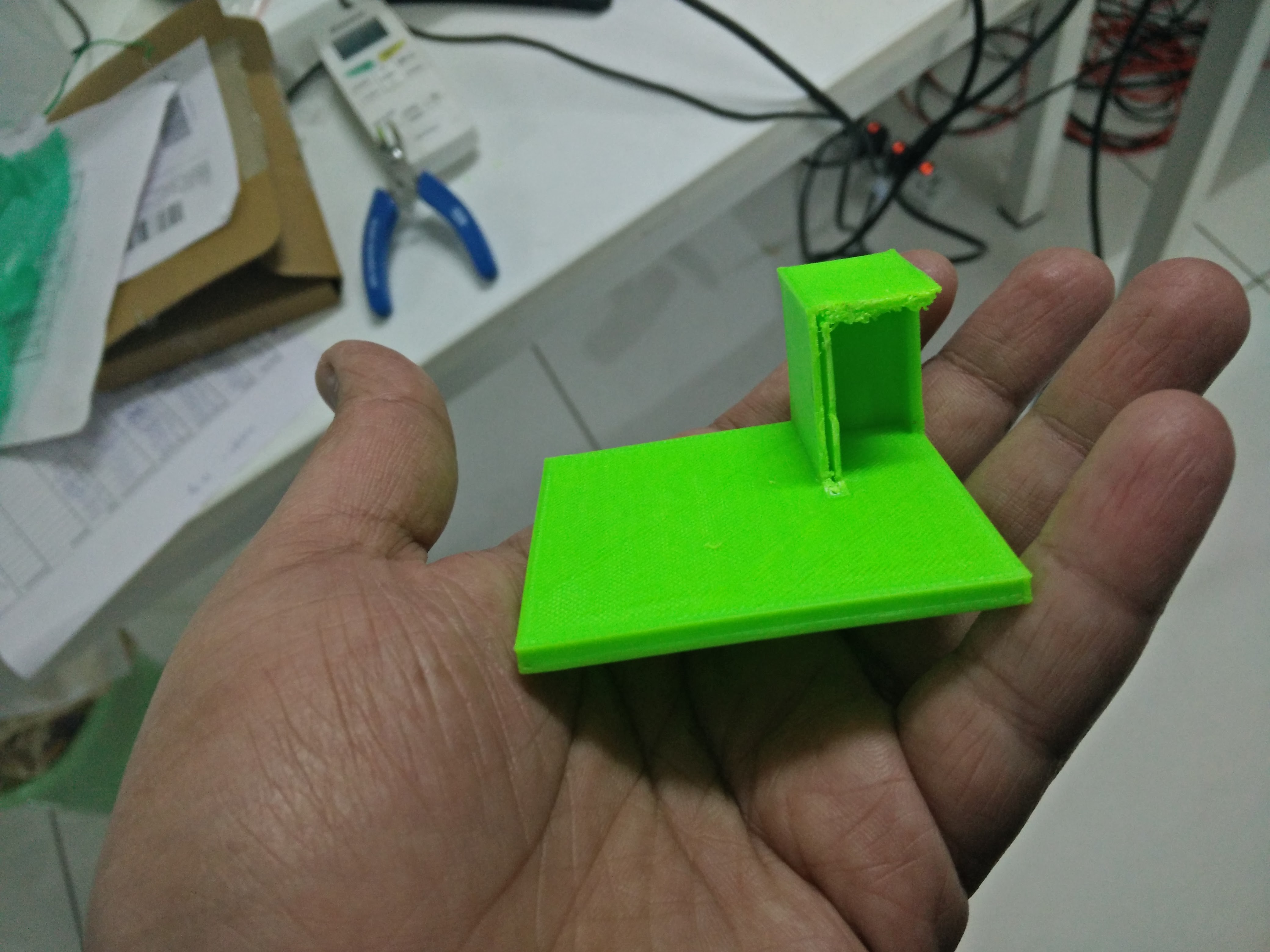

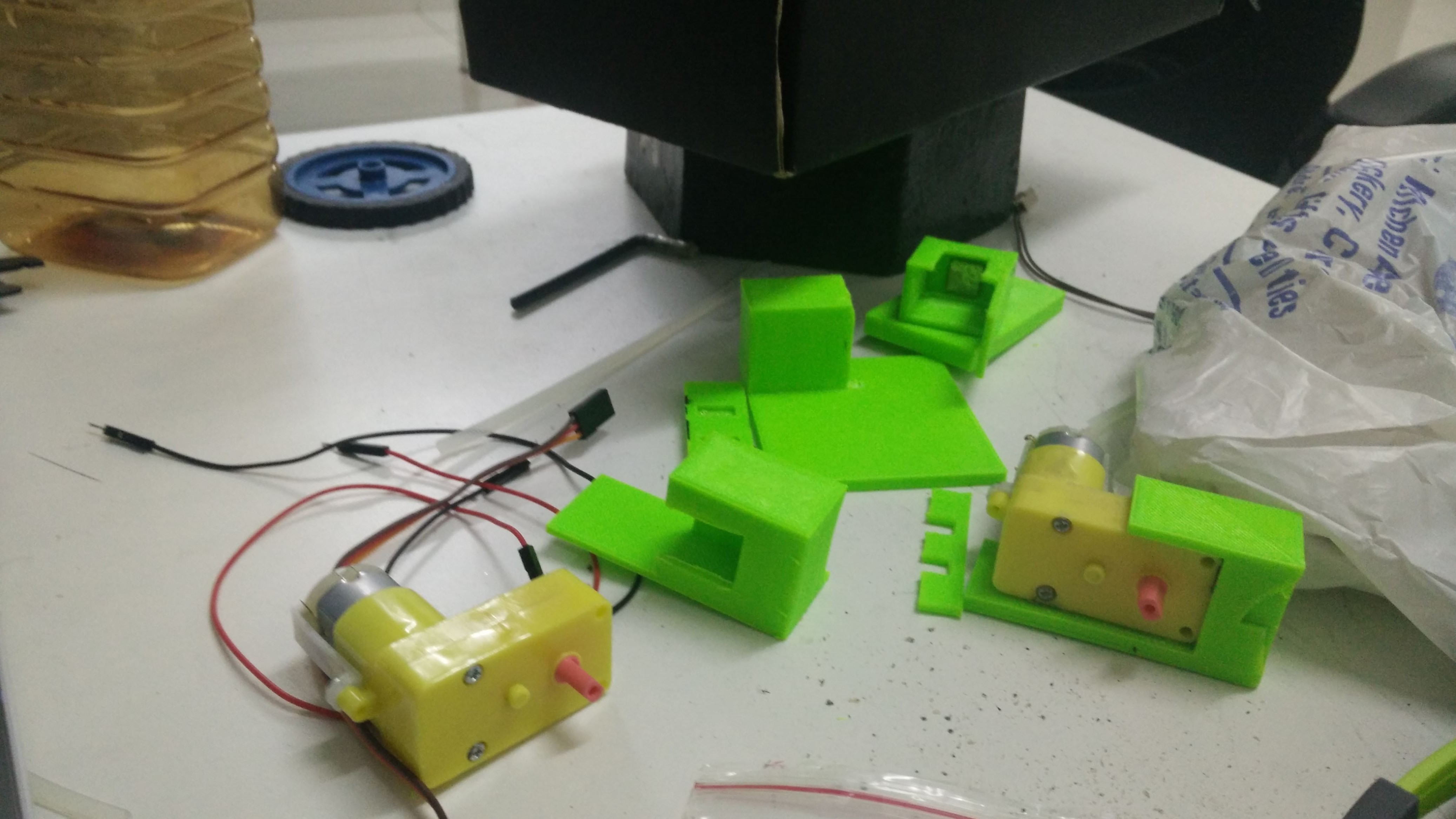

The below image indicates the two different parts of the version 2 robot - The one on the left is the main chassis, the one on the right is the exchangeable part. Both parts attach together with magnets shown.

The two parts snapped to each other. The visible magnets are for the mobile stand. The PCB is the new compact motor driver (L293d).

-

Testing

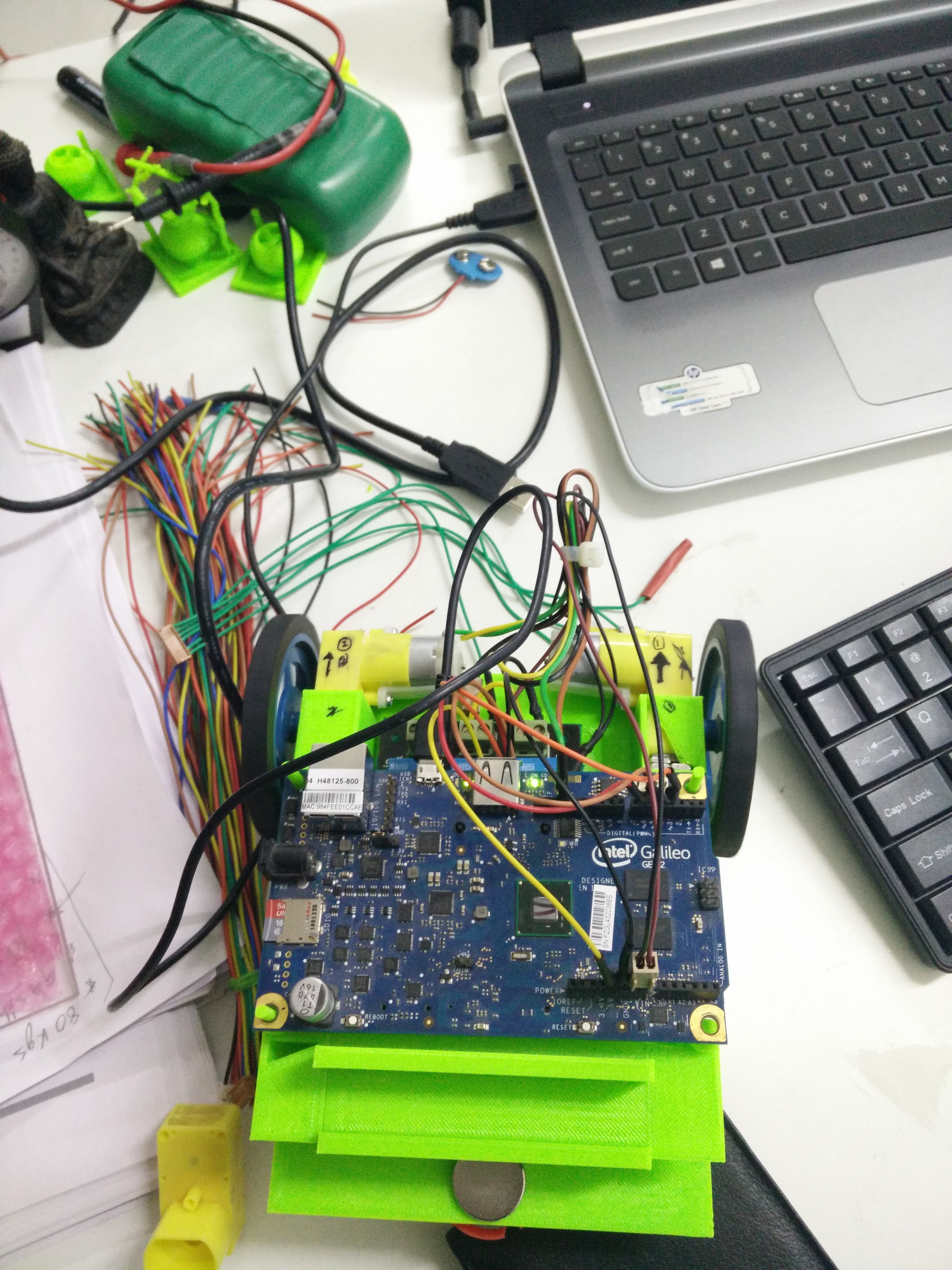

07/24/2017 at 13:45 • 0 commentsBasic motor run code test - with a castor wheel in the back for simplicity (Also stuck with magnet)

-

Assembly

07/24/2017 at 13:30 • 0 comments -

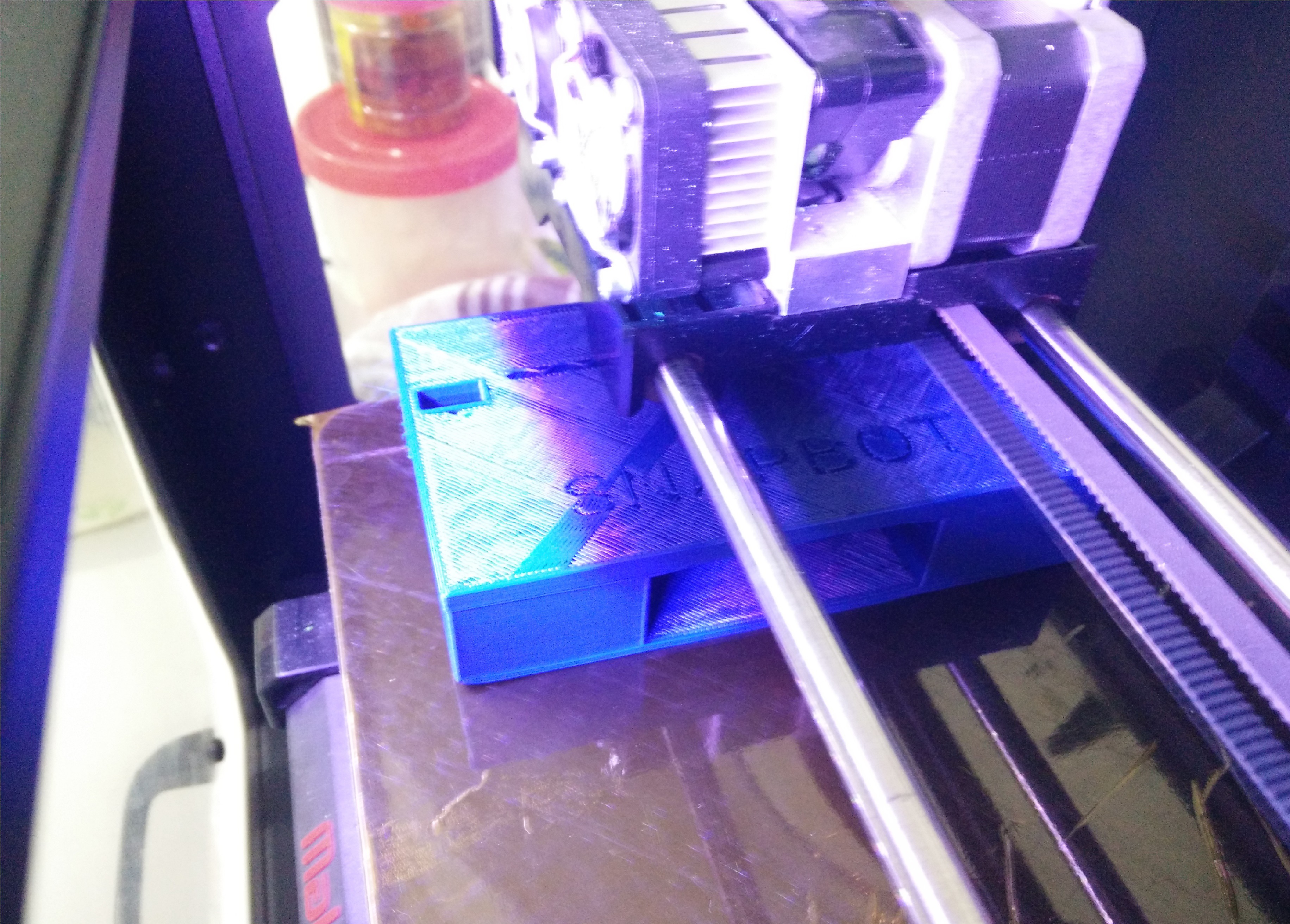

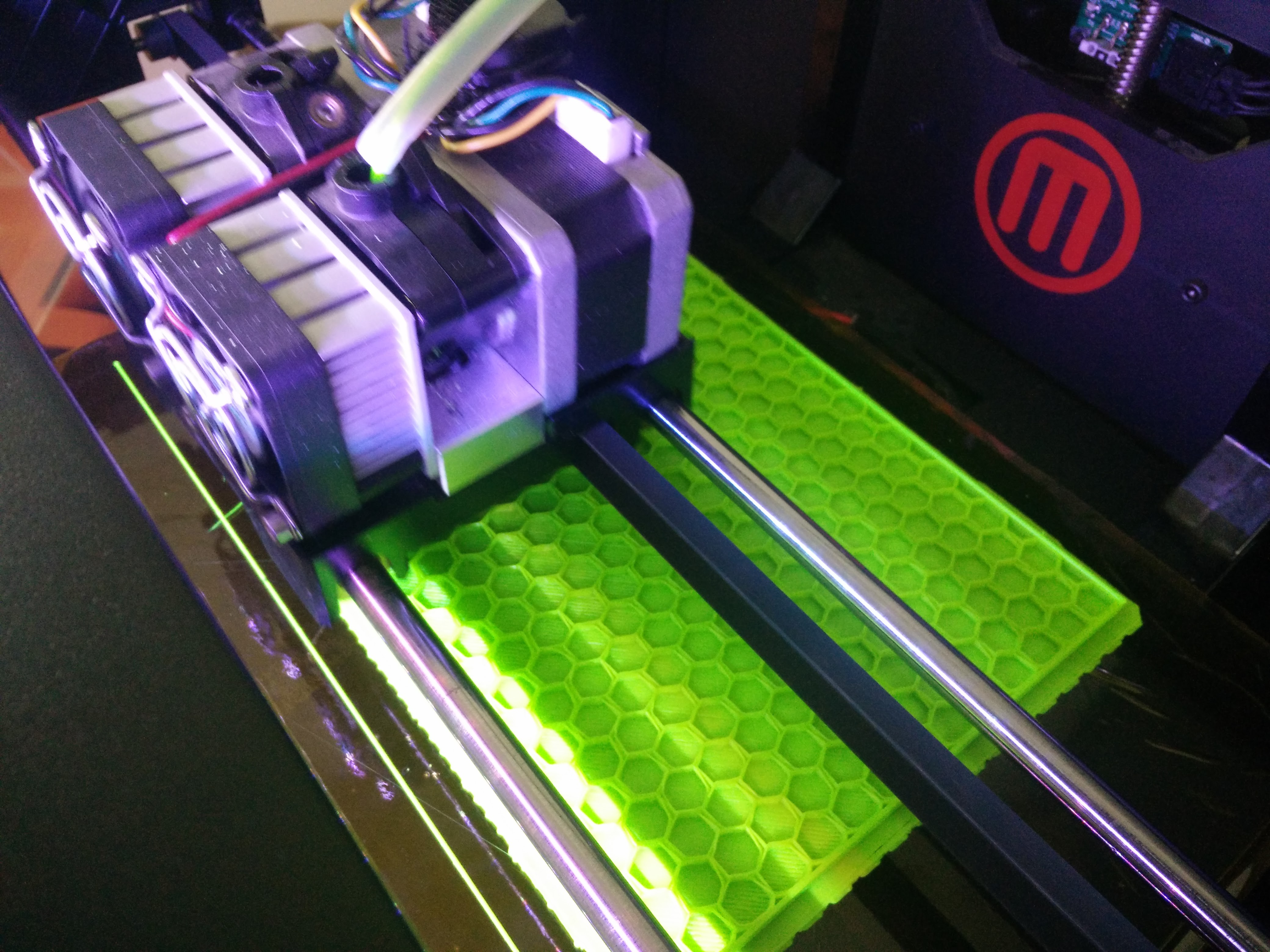

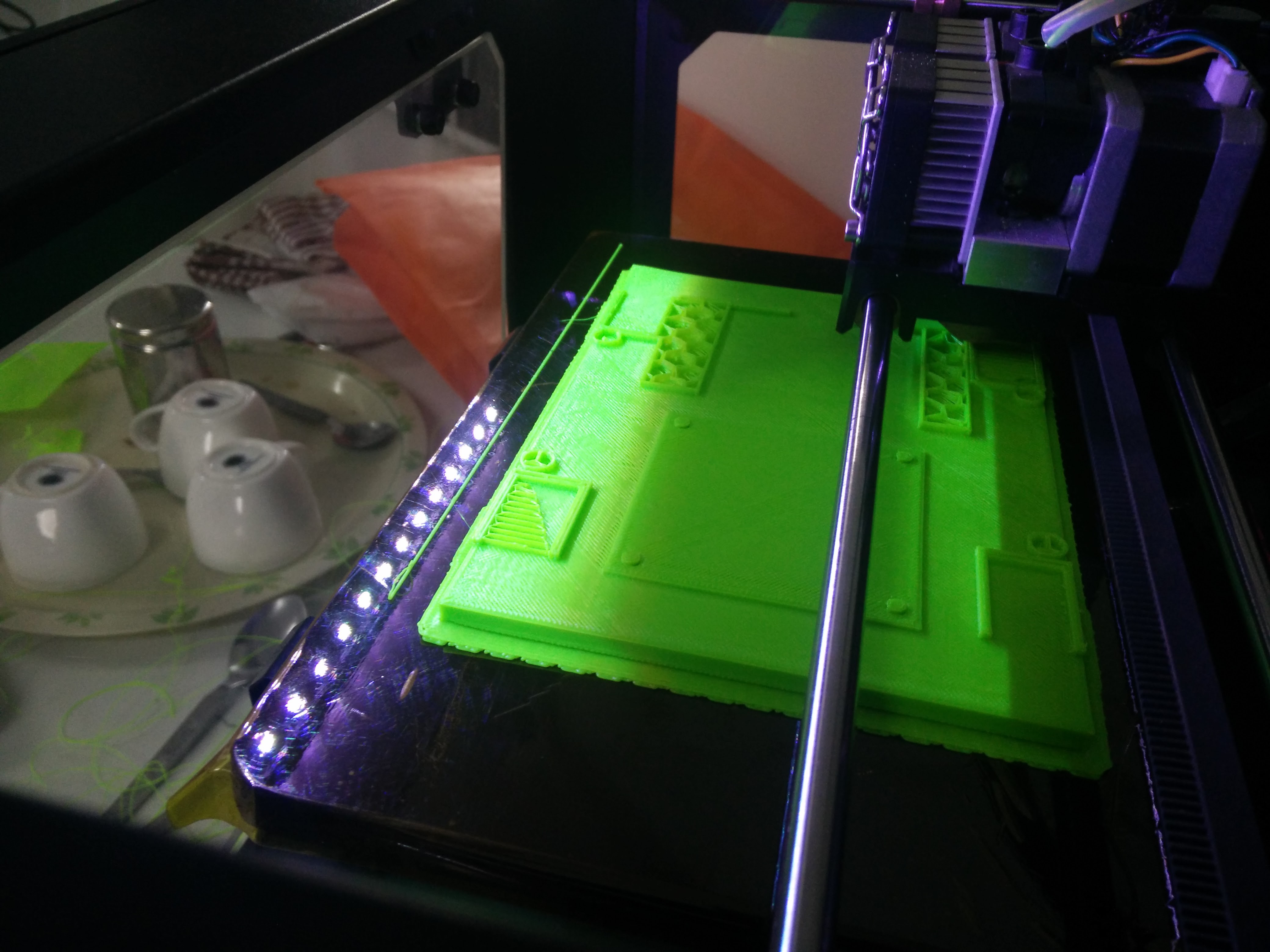

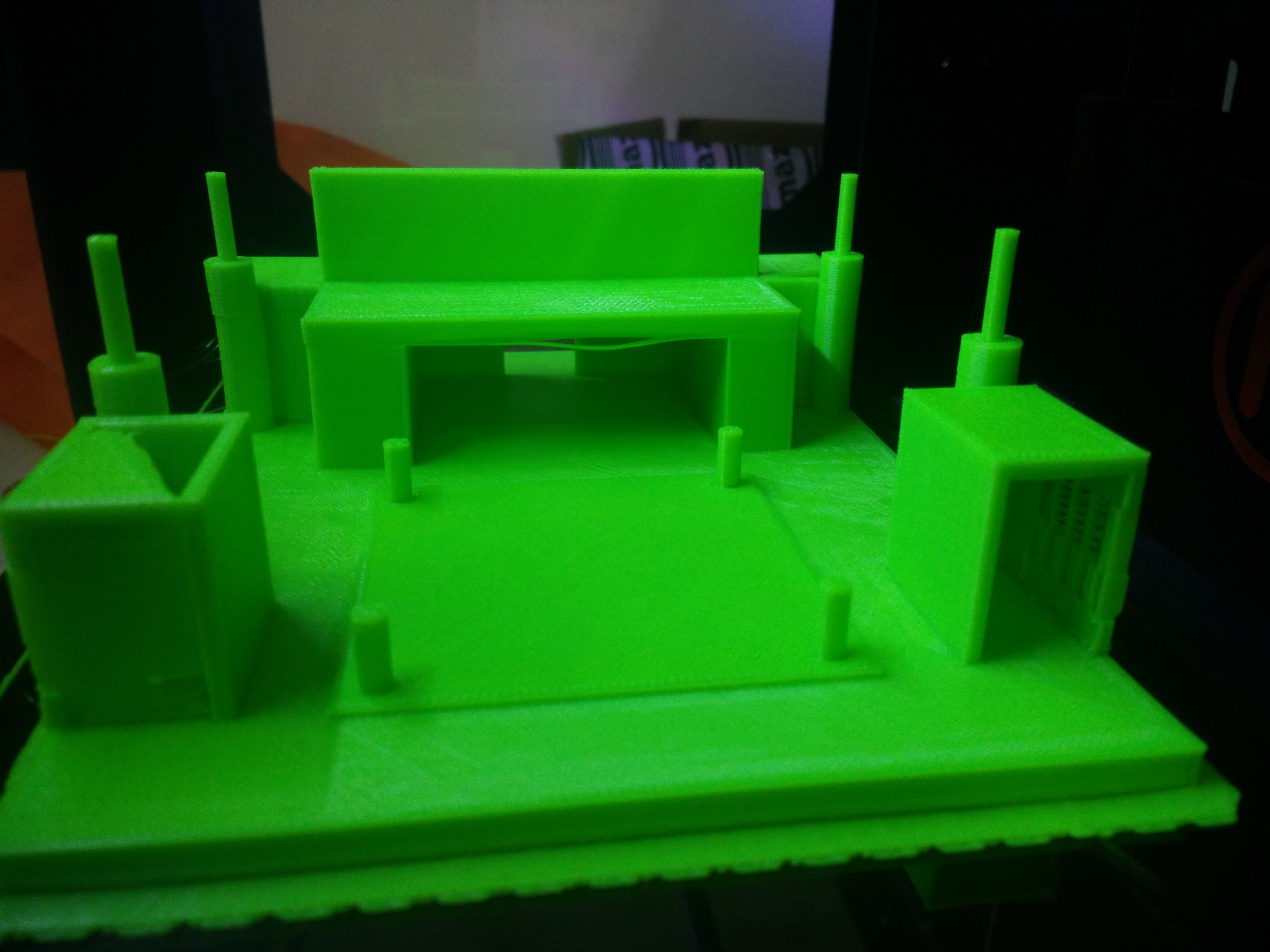

3D printing

07/24/2017 at 13:12 • 0 comments -

3D Modelling

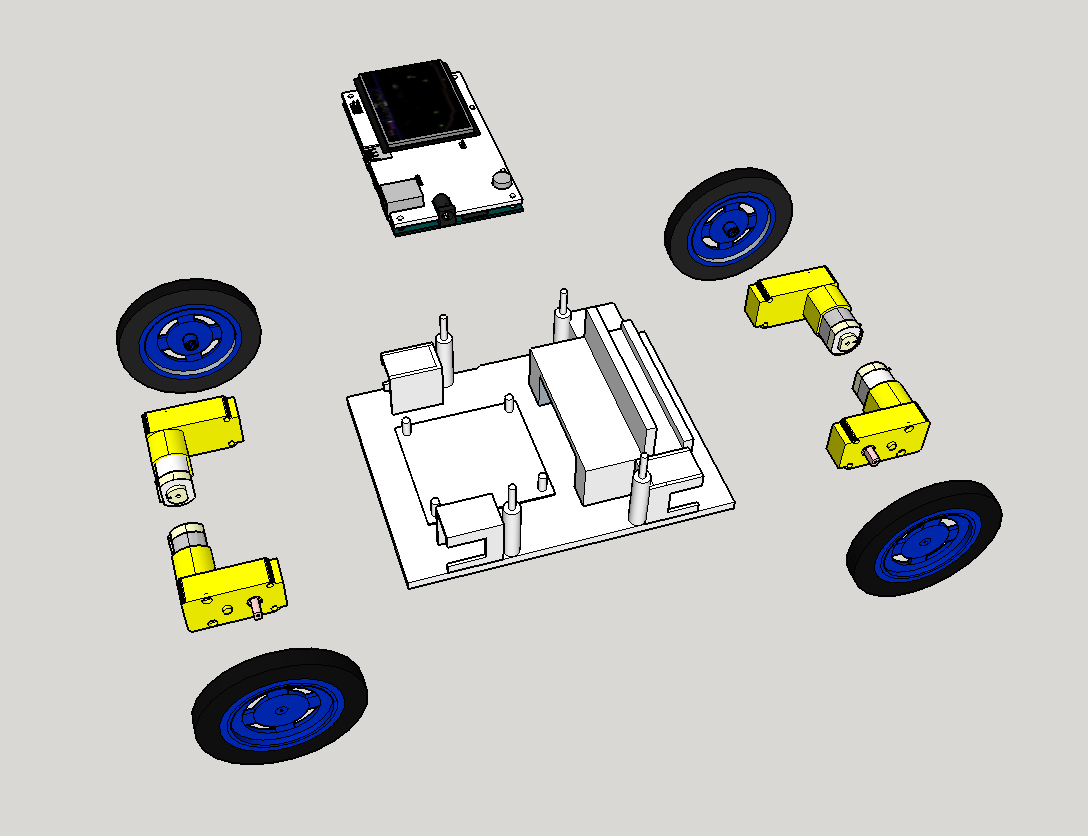

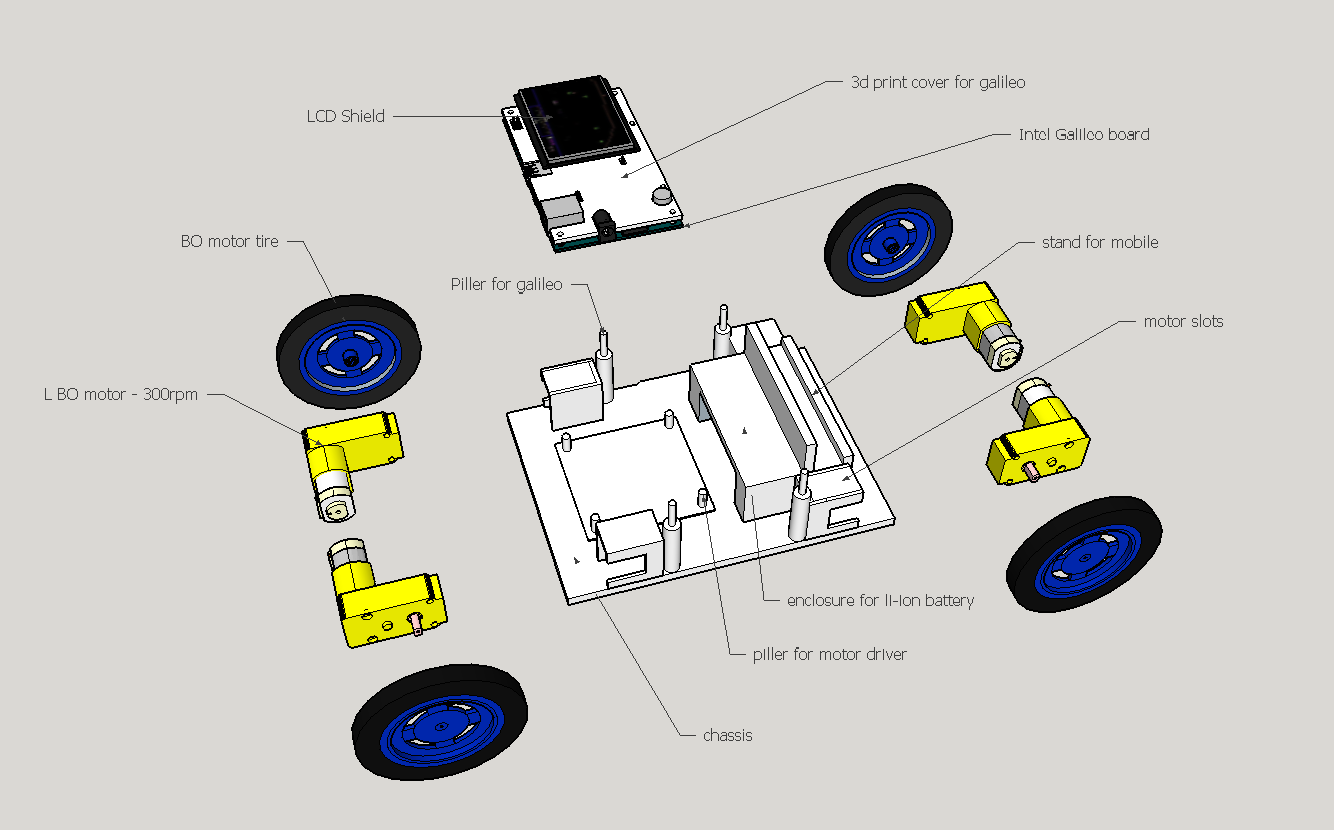

07/24/2017 at 12:57 • 0 commentsNext step is to model the entire robot to leave out any obvious mistakes.

Sketchup is my preferred software for 3d modelling as it is simple to use and the availability of many pre-modelled components.

The SketchUp file for the model is part of the files.

The phone provision is kept in a simple fashion, needs to be tested after printing.

The slots have considered the spacing after measuring using vernier. ( Note : Measuring the magnets using the vernier was a torture as they kept getting stuck in the wrong places - If you have a good idea - do leave in the comments )

-

The doubt

07/24/2017 at 12:44 • 0 commentsAs the googling progresses the doubts have started to build up. The questions and solutions thought as logged below.

- How will the components withstand the vibrations ?

The components should be supported properly, encased so that it does not come out of the holding of the magnet.

- Will the magnets affect the working of the motors, electronics?

Maybe, but instead of reading piles of papers or articles lets build it and see.

- What magnet to use?

There is an option to go with ferrous or neodymium. So we got both types of magnets and compared their working, neodymium was the winner.

- Which shape of neodymium to buy?

There are plenty of options in each shape, we decided to buy some cylindrical ones, some rectangular and figure it out as we are building it.

-

The Idea

07/24/2017 at 12:34 • 0 commentsEach time we made a wheeled robot, the most time-consuming part is assembling the components and making it look neat (beautiful).

So this time when we wanted to make an IoT robot this idea struck upon us to make an easy to assemble 3d printed chassis for the robot where the components would be connected to the chassis using magnets only.

So the googling starts for similar implementations and how to encase the magnets within the plastic.

SnapBot

SnapBot is a modular platform to help educators and students learn about programming, IoT, and Robotics.

saipraveen

saipraveen