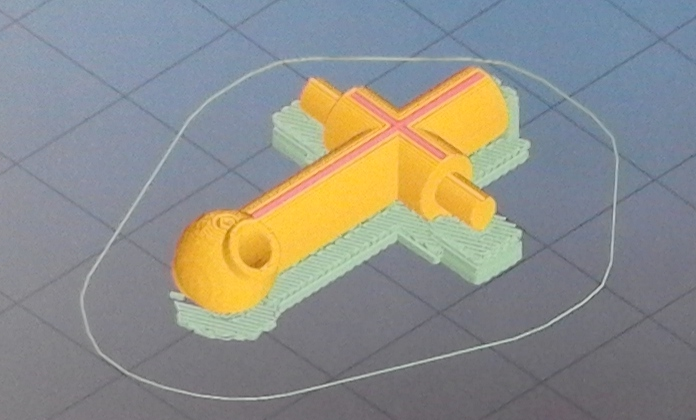

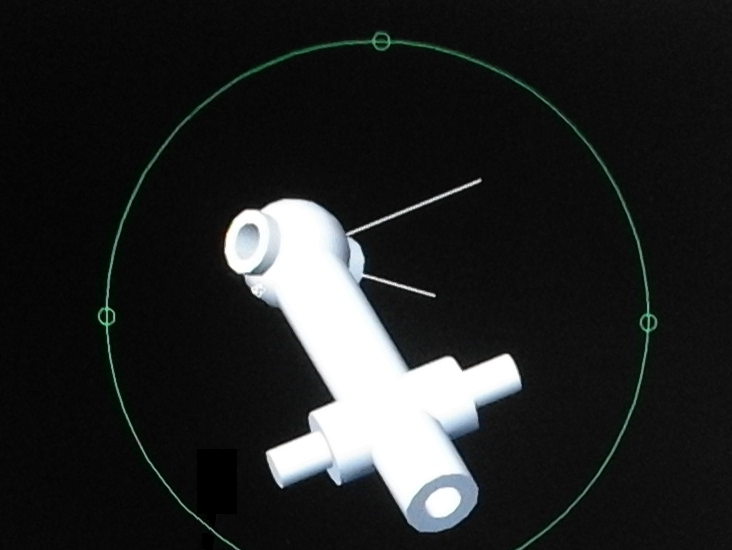

I had some experiences with printing things that fly and I wanted also to try my CAD designing skills in redesigning the Jesus nut of this rotor. I knew exactly that It would have to be a precision print if I wanted it to fly and I also knew about the limitation of my Prusa i2 3D printer. I knew that If I'm going to go for a 0.1mm layer height, this would cause the print to get heated up too much and deform while printing and I also knew that the pin of the blade grip set must oscillate and move freely inside this nut and any error could cause more problems than solutions.

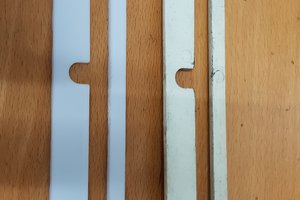

The result was spectacular. It was better than I expected and the RC toy lived to see better days. The PLA plastic seemed strong enough and it successfully withstand multiple crashes after the fix. In the beginning, I feared the the blade pin will not oscillate freely inside the 3D printed nut or that I will not be able to make a precision hole, but it seems that the PLA plastic is strong as the oak wood when it comes to drilling or sanding.

Stl files link can be found below in this document:

Marius Taciuc

Marius Taciuc

Yusuke Tanaka

Yusuke Tanaka

Hari Wiguna

Hari Wiguna

Aaron Christophel

Aaron Christophel

Bram Peirs @ FW2W

Bram Peirs @ FW2W

Cool fix!