Logs:

1. Overview

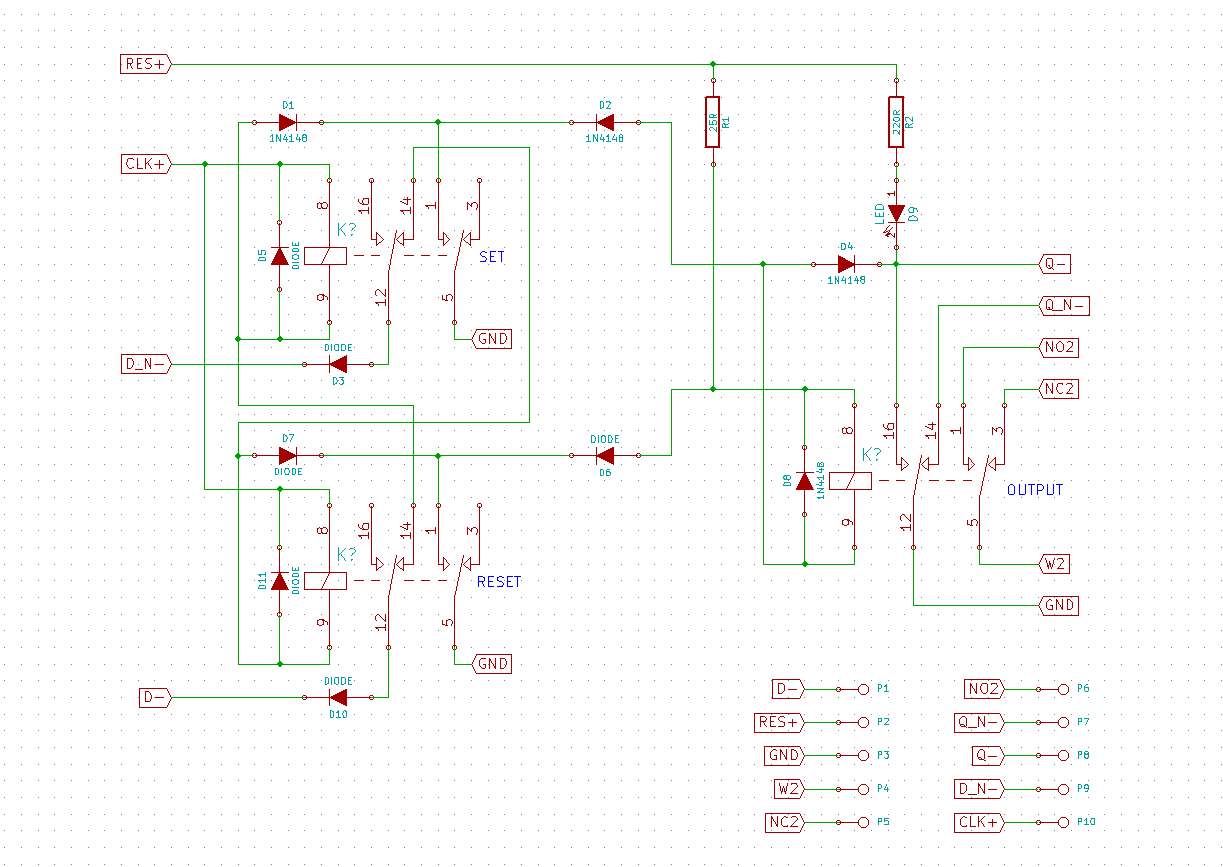

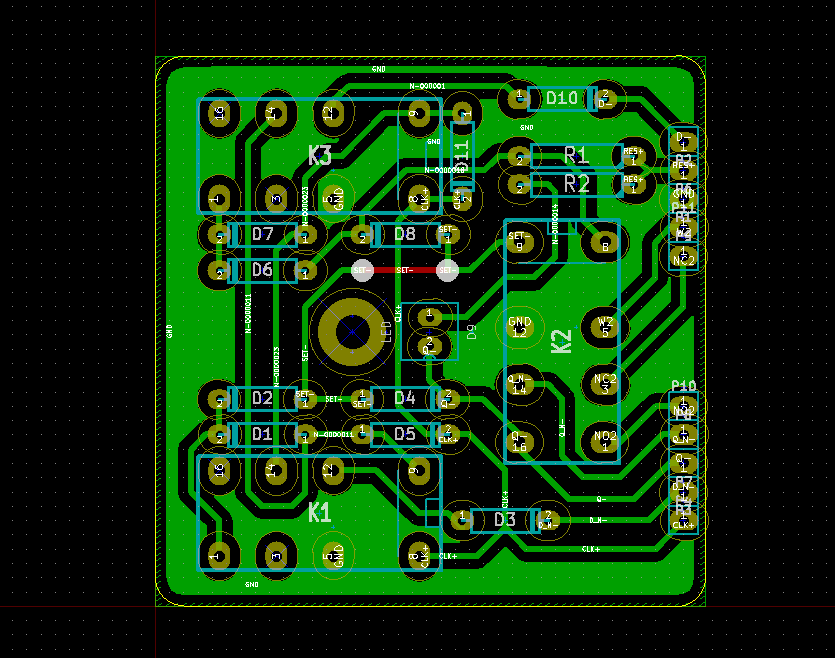

2. D-type Flip-Flops

3. The Decoders

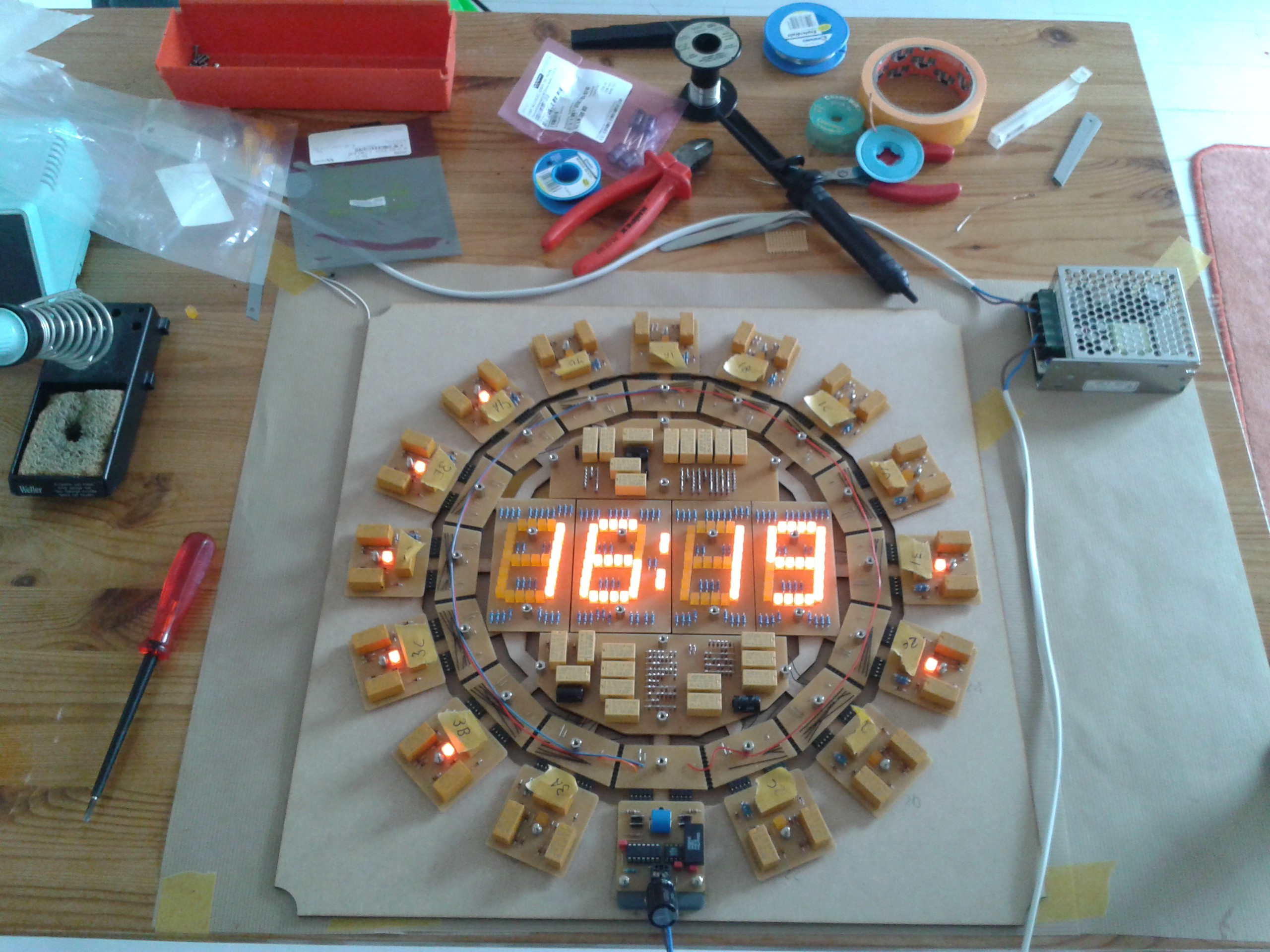

4. It's alive!

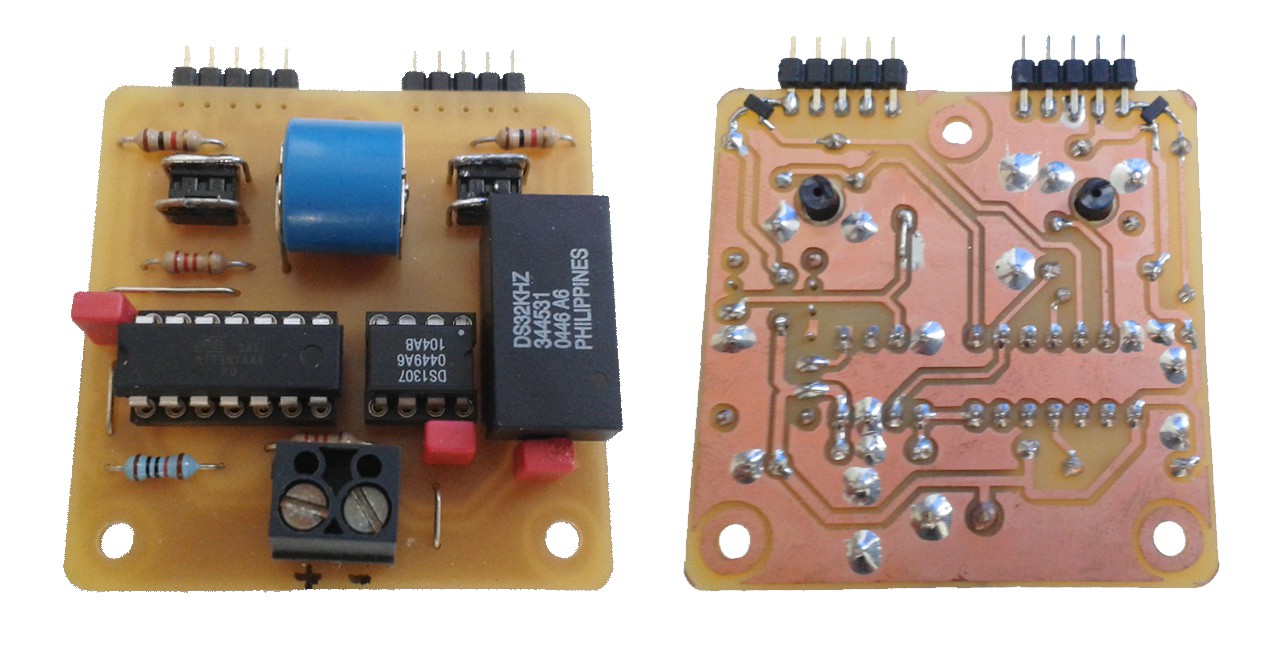

5. 2nd digit and RTC

6. Stuck... Unstuck... and redoing some work

7. Decoders continued...

8. Update June 2018

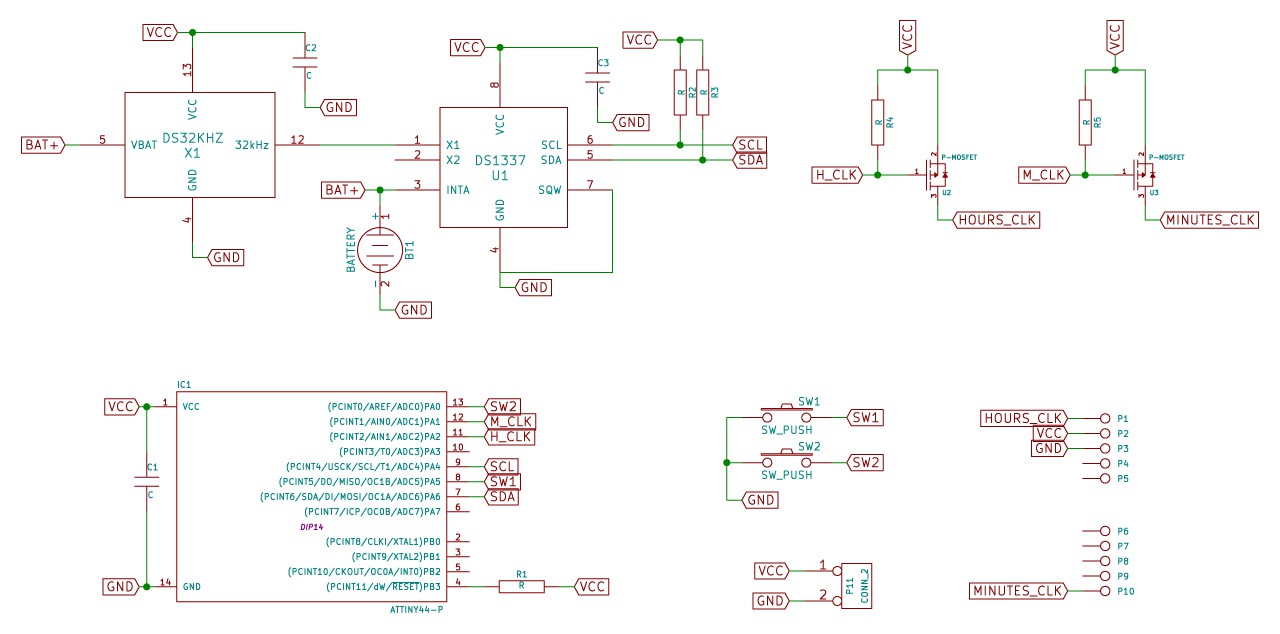

9. Timekeeping and RTC

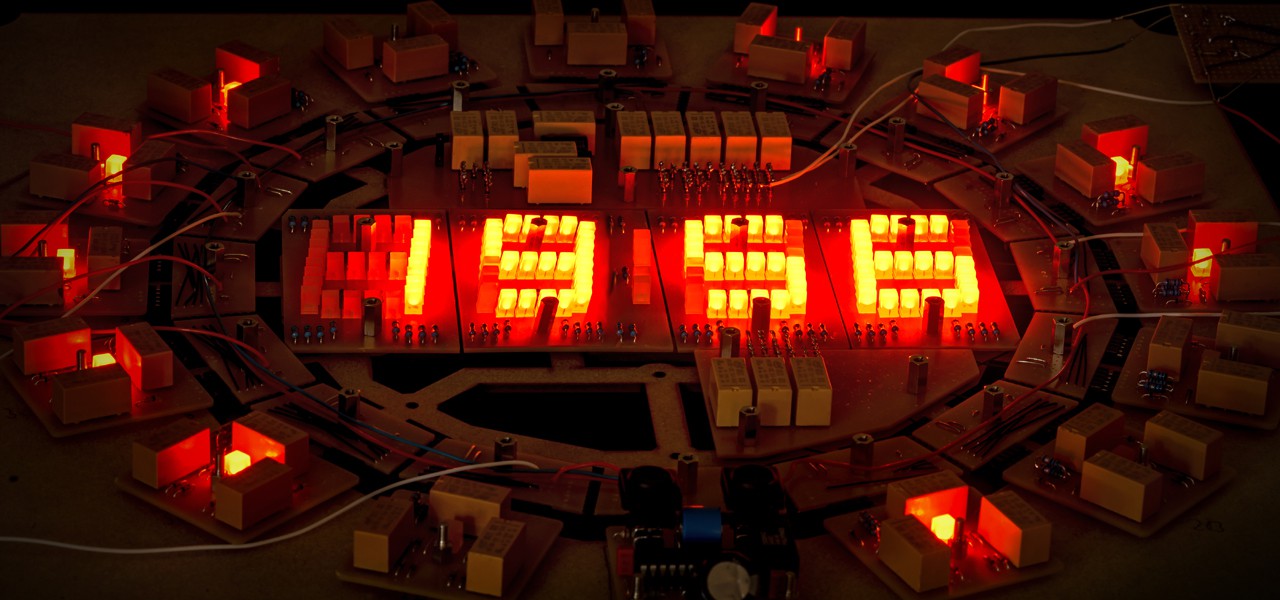

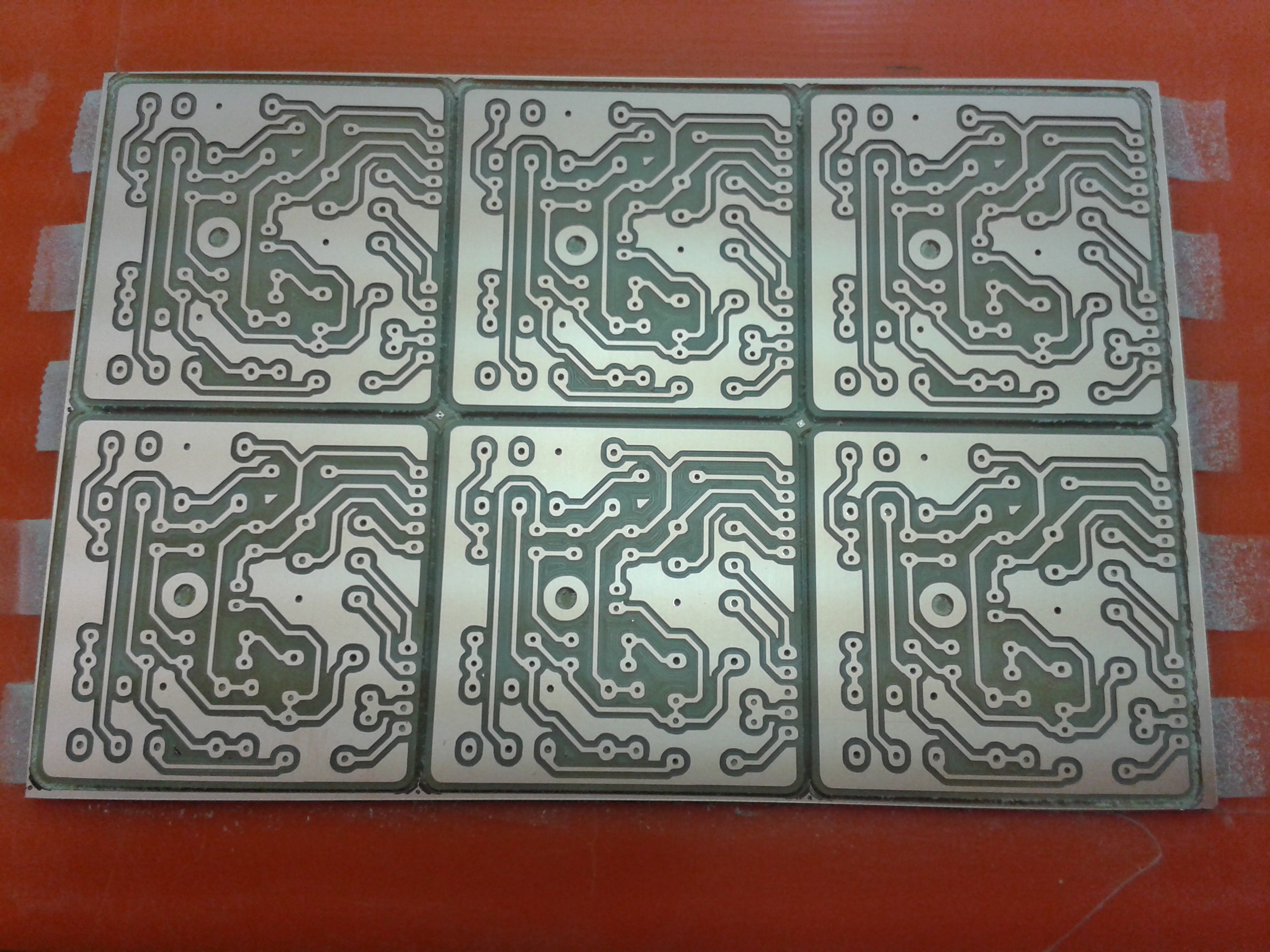

10. Foto update (Nov 2018)

11. It's finished!

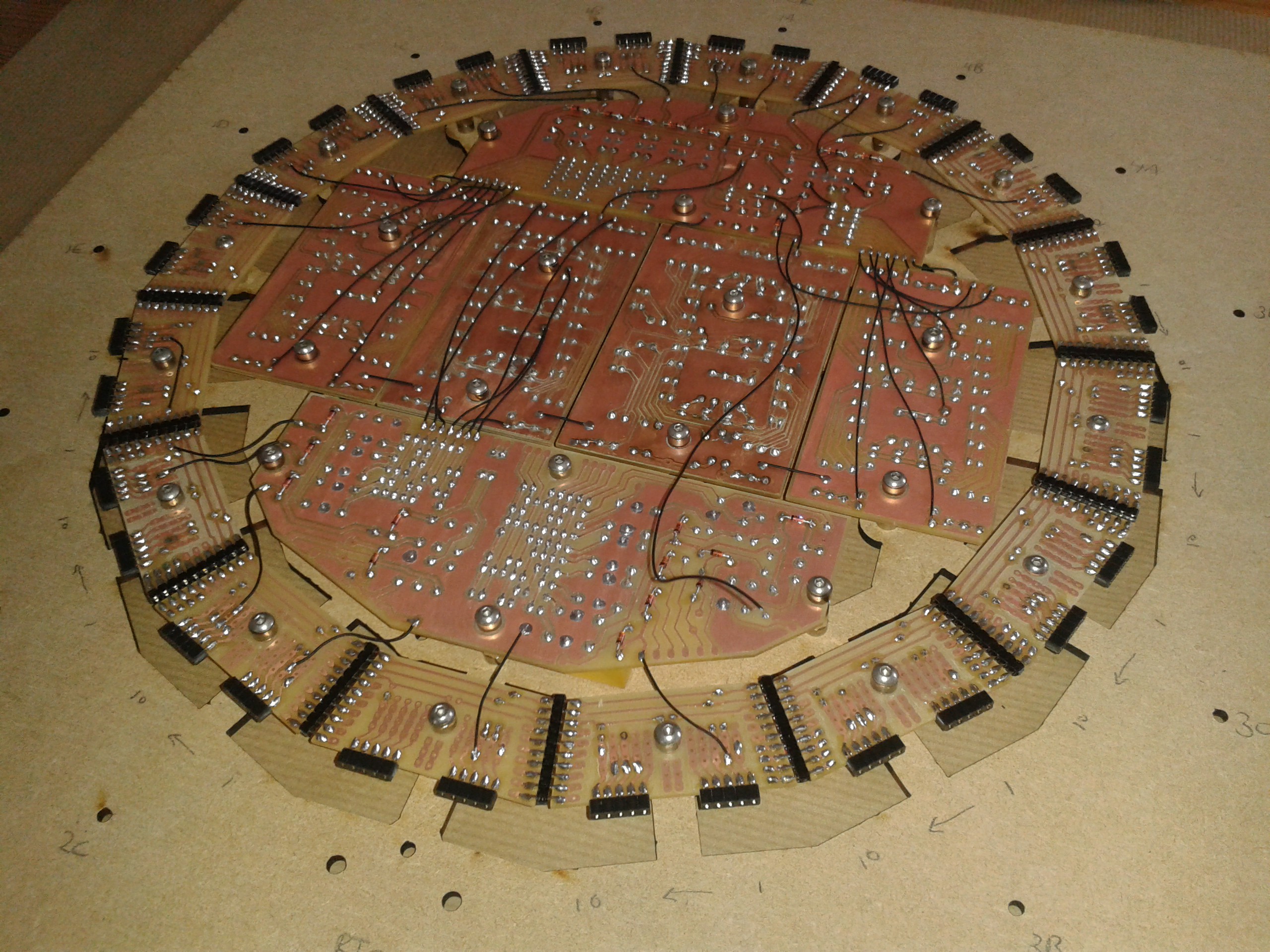

Relay Logic Clock

A digital 24 hour clock using only relays and diodes for the counting logic.

Dave Gönner

Dave Gönner

zaphod

zaphod

Kris Slyka

Kris Slyka

Ted Yapo

Ted Yapo

Ken Yap

Ken Yap

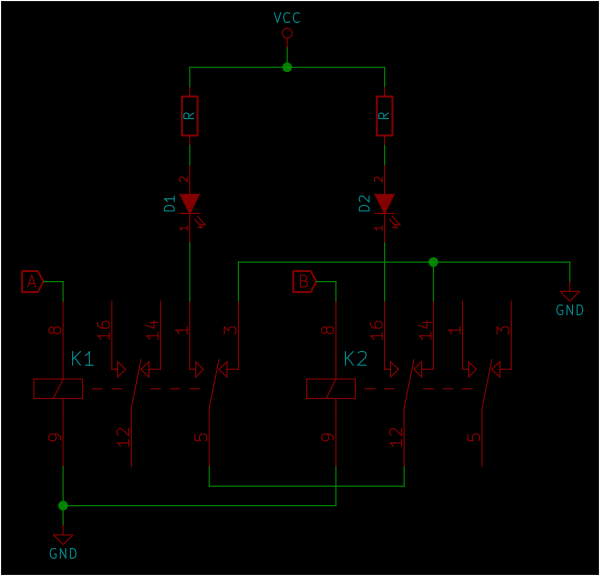

Someof your schematics are dark blue and dark red on a black background. This makes them very difficult to read.

Great project, I have always wanted to see someone actually use relay logic, but my eyes are killing me trying to read those schematics.