-

Assembly and tests of the third prototype

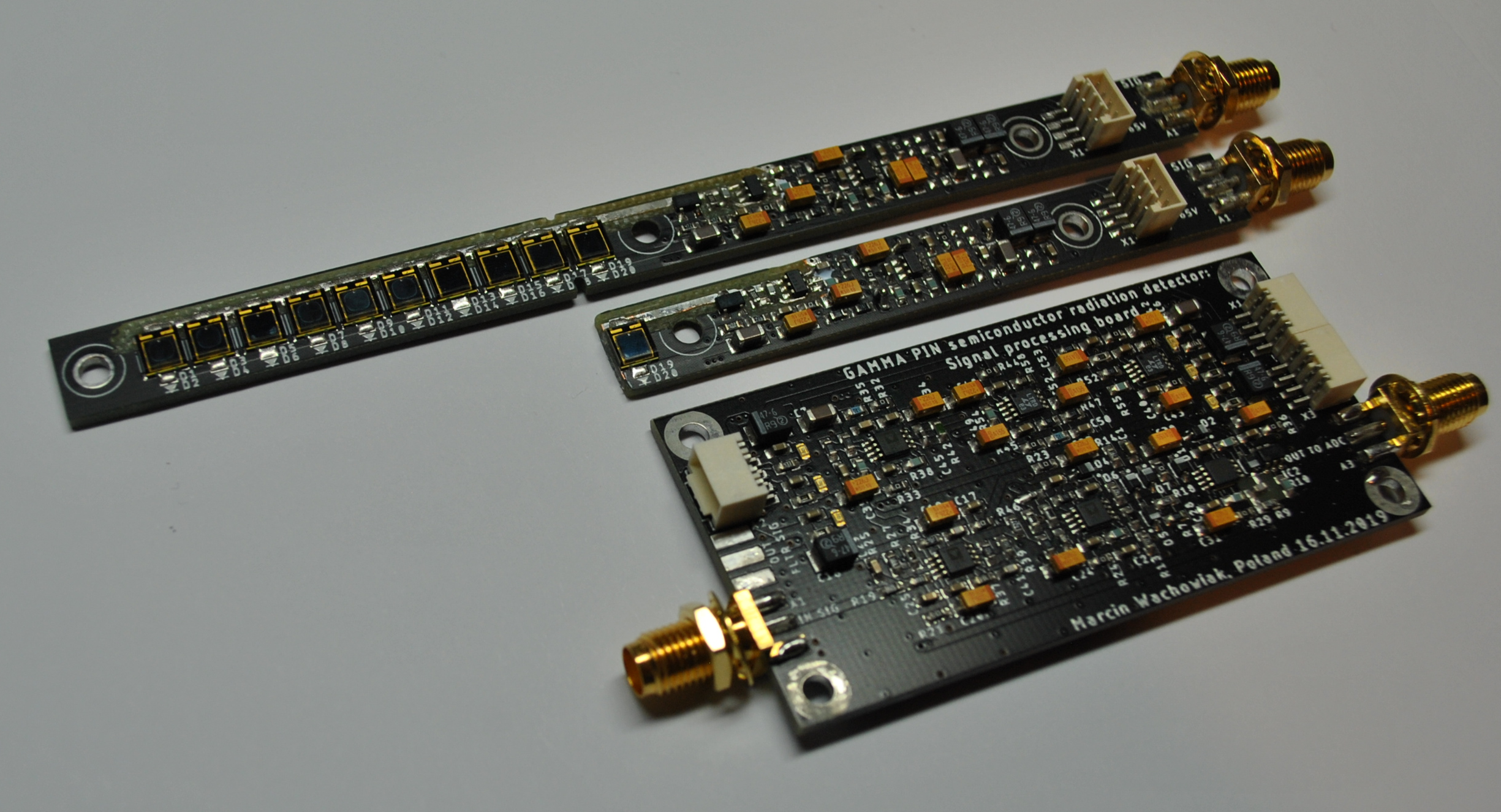

03/01/2020 at 17:56 • 0 commentsRecently I found a while to solder and test the latest prototype. All boards have been soldered using a hotplate made from an old iron. The soldering process took about 1 minute, because the iron didn't have a temperature controller to follow the reflow profile. The only thing that prevented burning the boards was a thermostat set around 230 °C. I hope to add a controller soon to improve the performance. There are a few neat controllers on the Internet, this one seems suitable for my needs - https://github.com/makermoekoe/Hotplate-Soldering-Iron

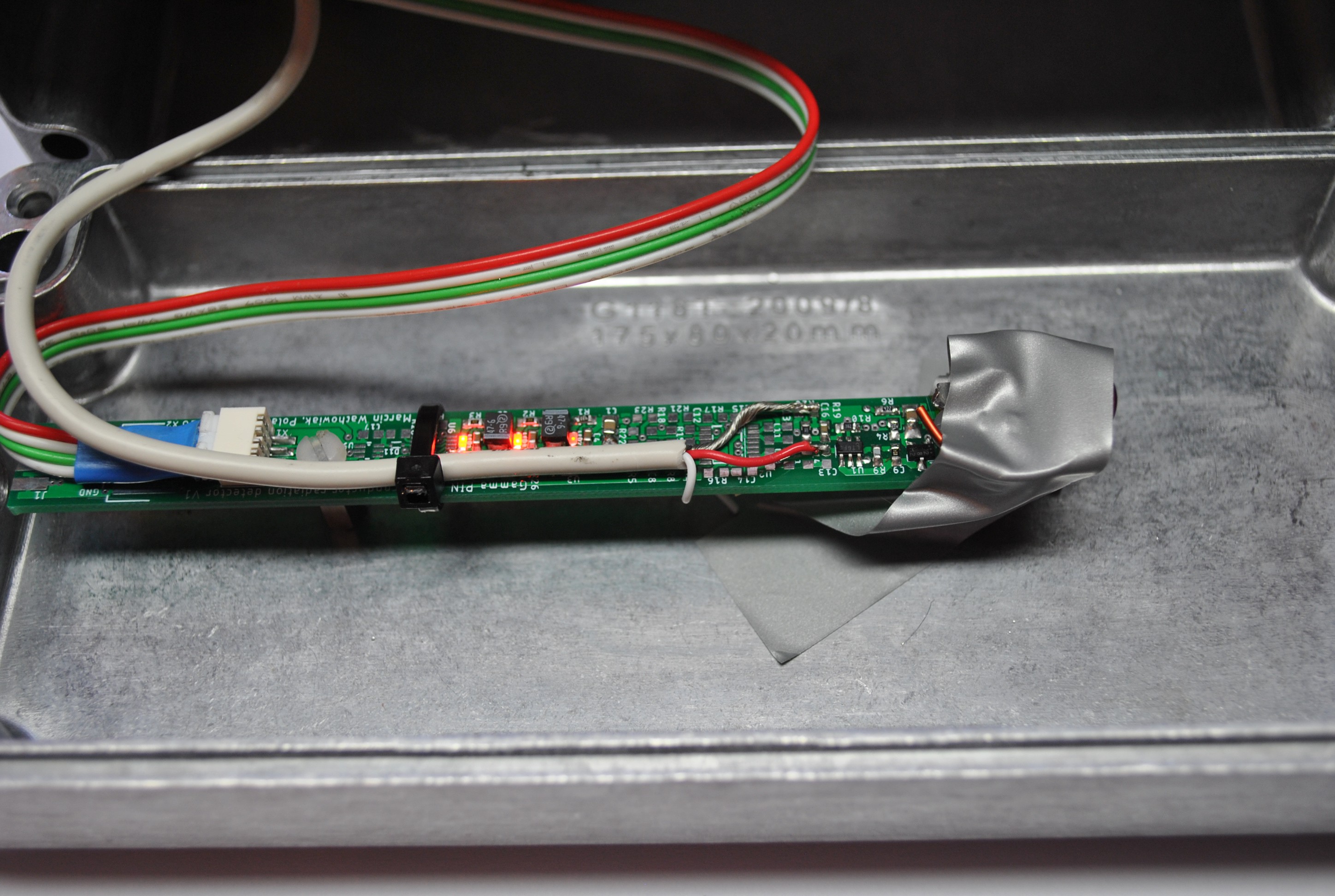

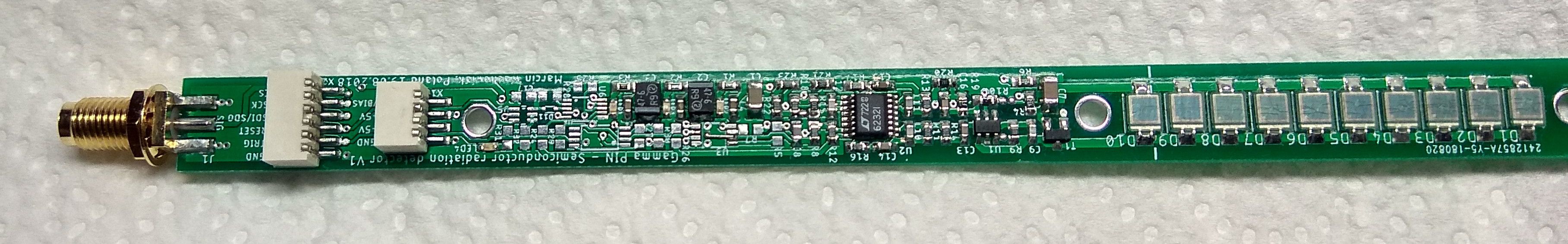

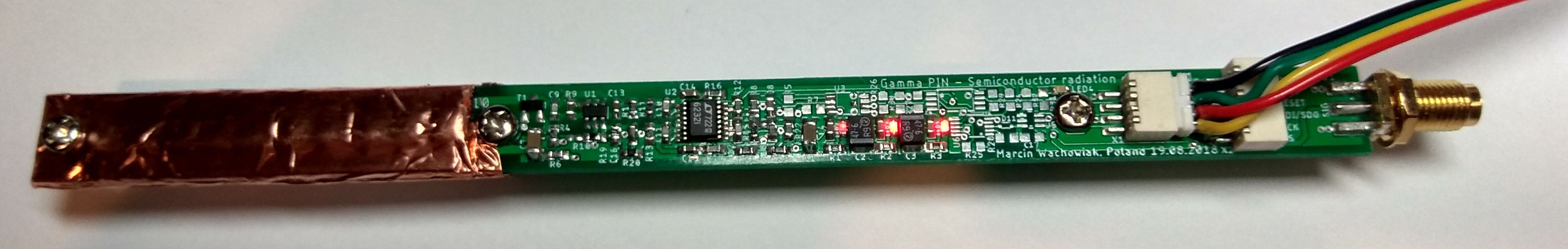

Assembled prototype Preamplifier

As you can see, I produced two versions of the preamplifier: one with a single diode and another with a full array of 10. The following results have been obtained using the single diode version as it is less noisy.

The boards turned out to have some flaws but still I managed to get them to work properly.

Issues with the preamplifier board:

- Guard ring introduced to reduce current leaks emerged to be a source of shorting. Exposed traces with components placed upon them were not a good idea. Covering the guard ring with solder mask would render it useless as it is supposed to prevent any currents flowing through surface form contaminations by shunting them to low-impedance node. (topic about it) I may consider to expose only thin edges of the trace and cover the wider areas susceptible to shorting. For the time being I have milled it out to get a functional circuit.

- The second op amp used on the board as subtractor with amplification requires a feedback capacitor to ensure the stability and prevent excitation. It should be around 22-33pF and can be simply placed on the top of the feedback resistor - R17.

- Voltage reference for the subtractor had to be altered to set the output signal baseline as close to the 0V as possible. In my case it required changing the lower resistor of the voltage divider from 92 to 110 Ohms. With such preset baseline of the output signal was at approximately 30mV.

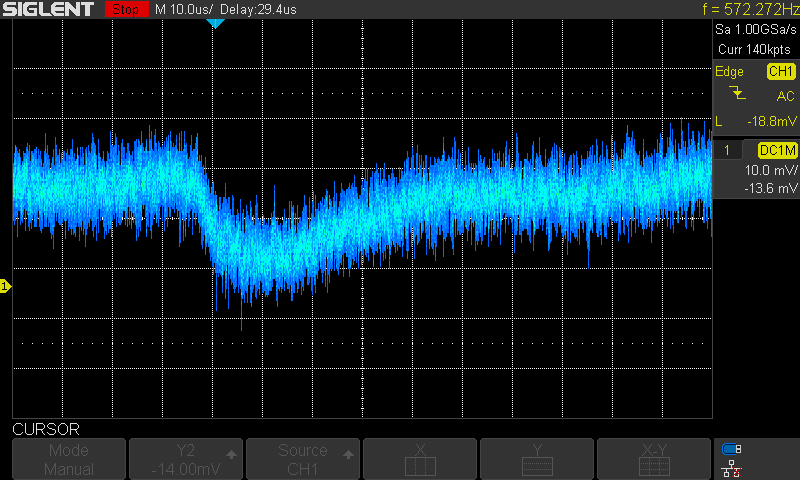

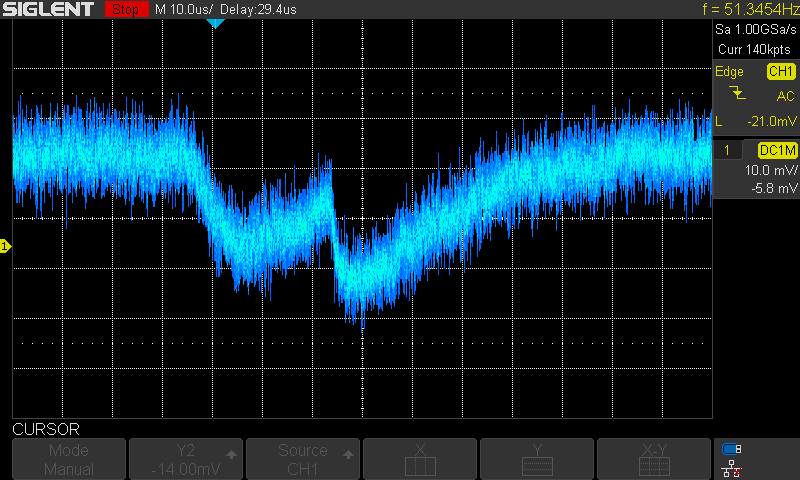

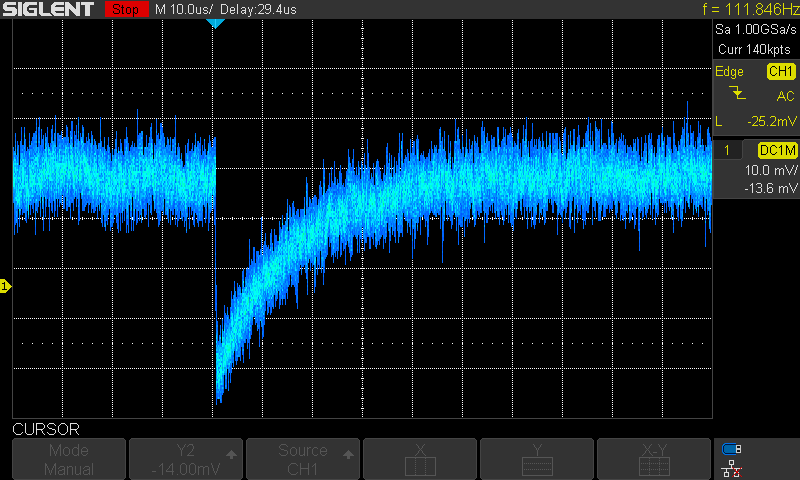

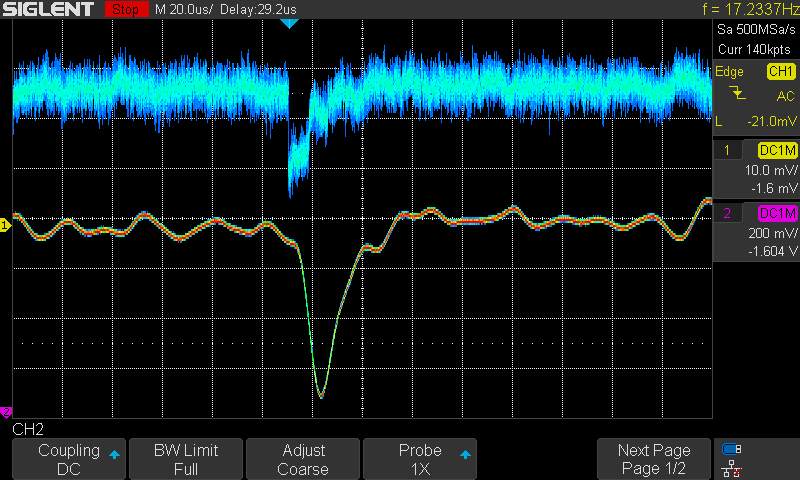

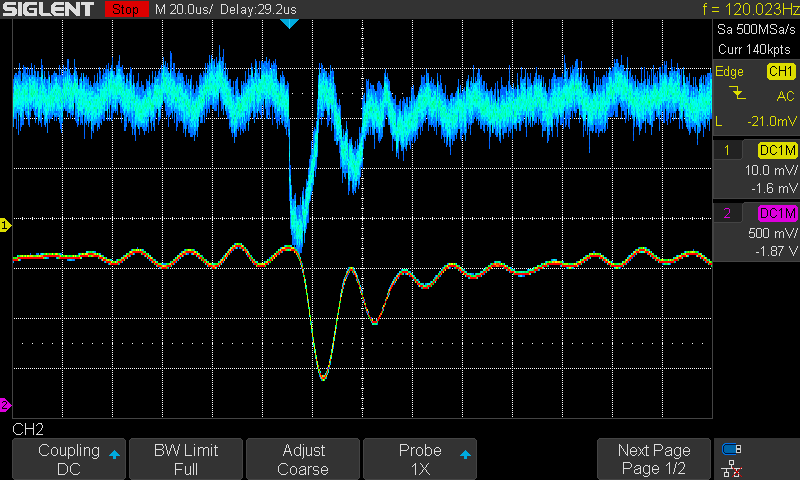

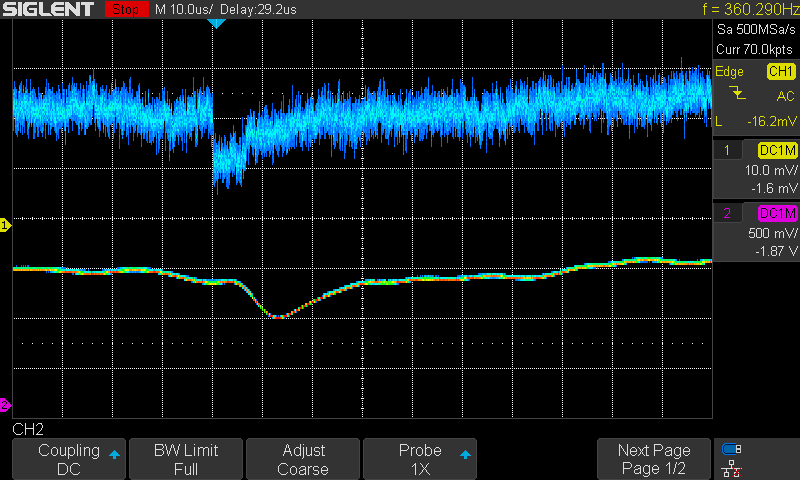

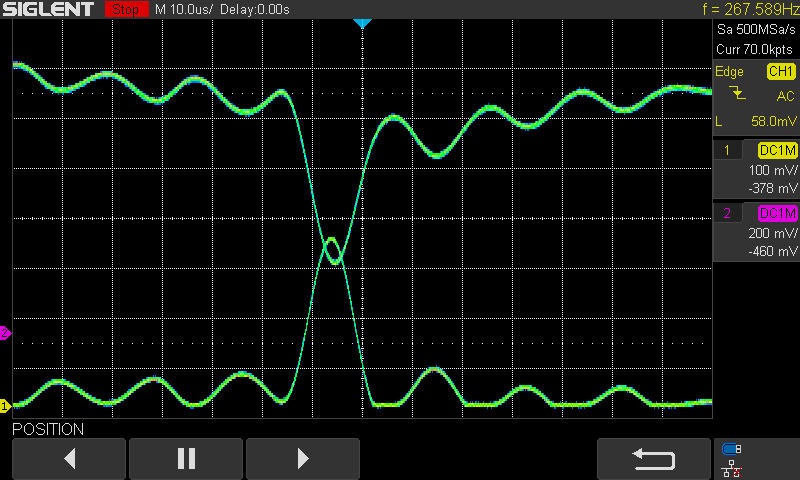

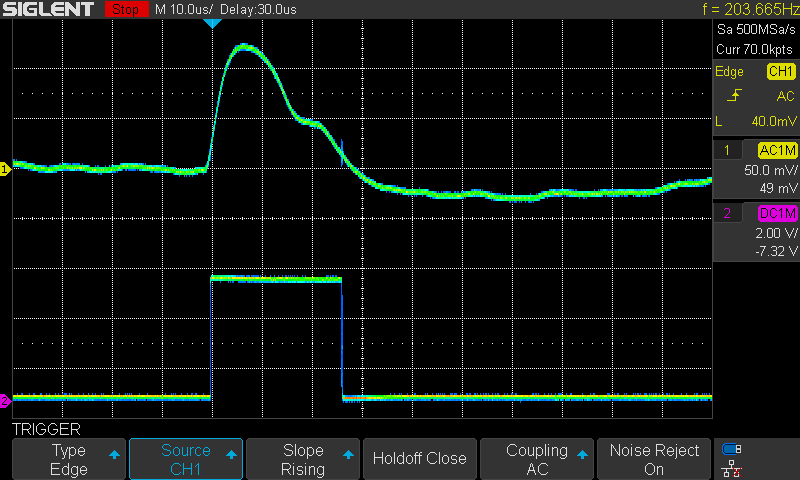

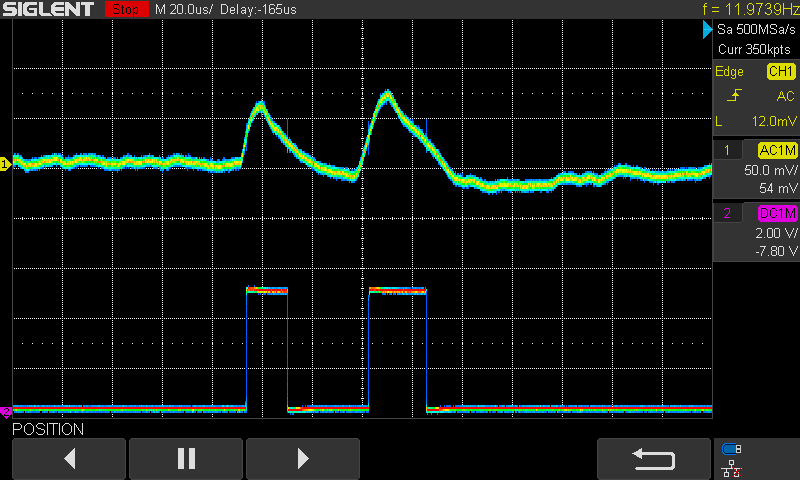

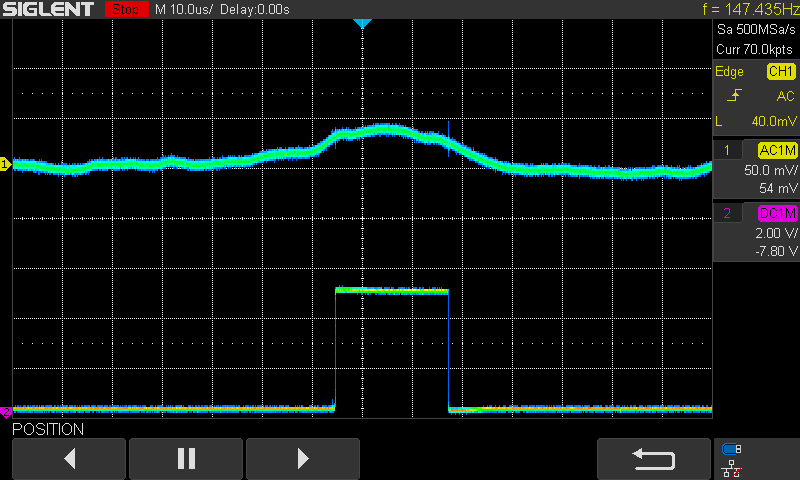

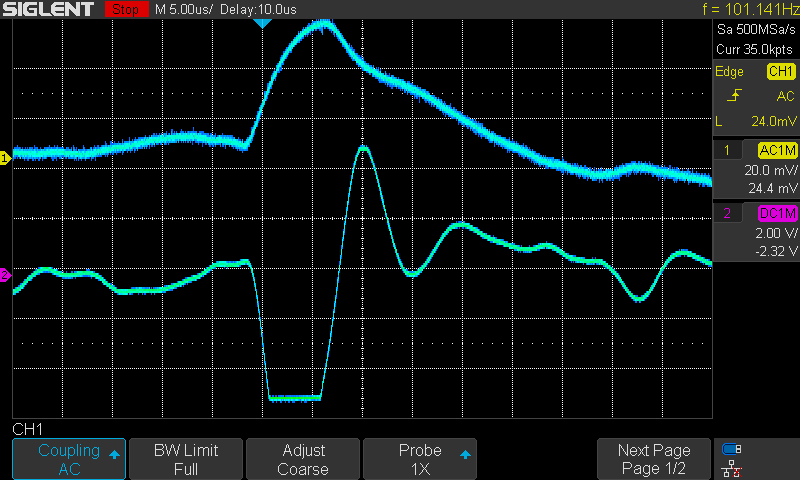

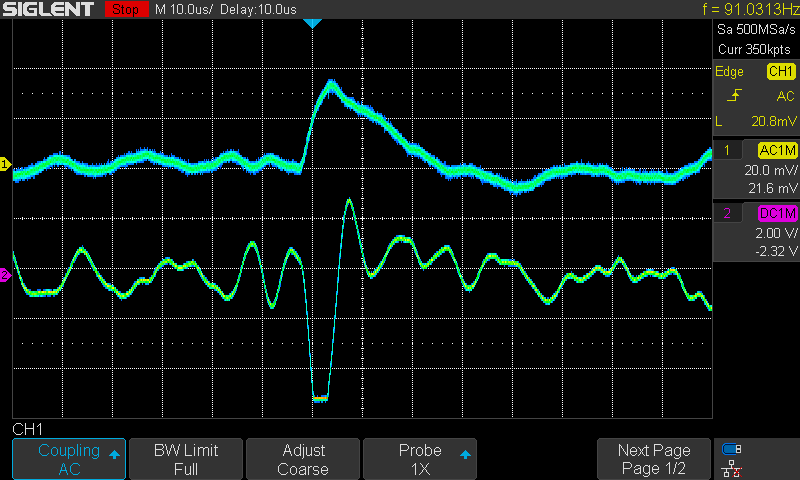

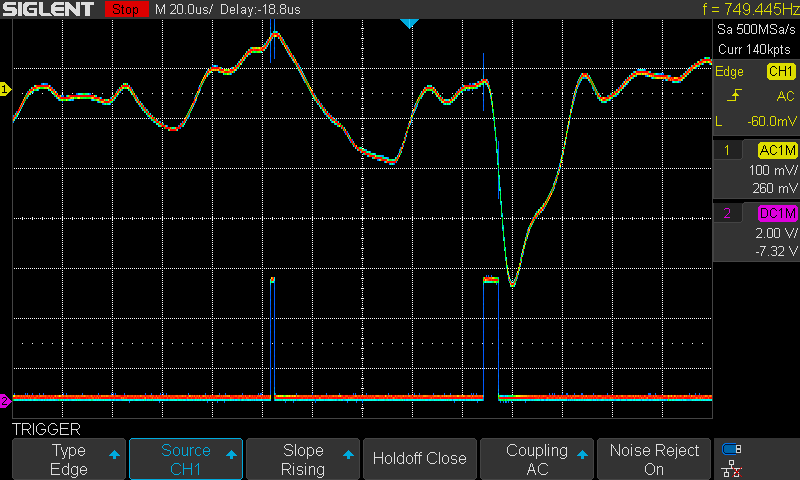

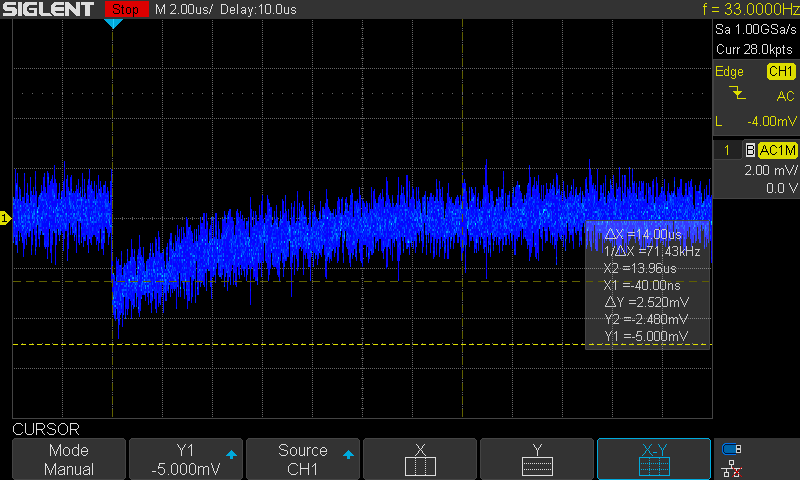

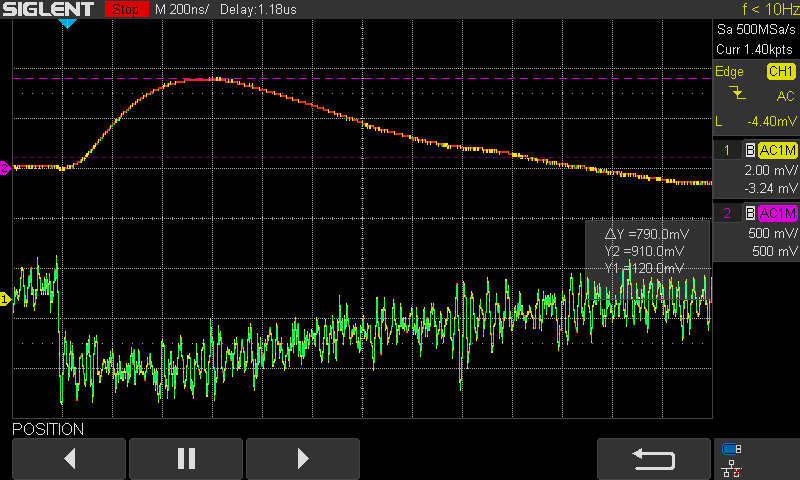

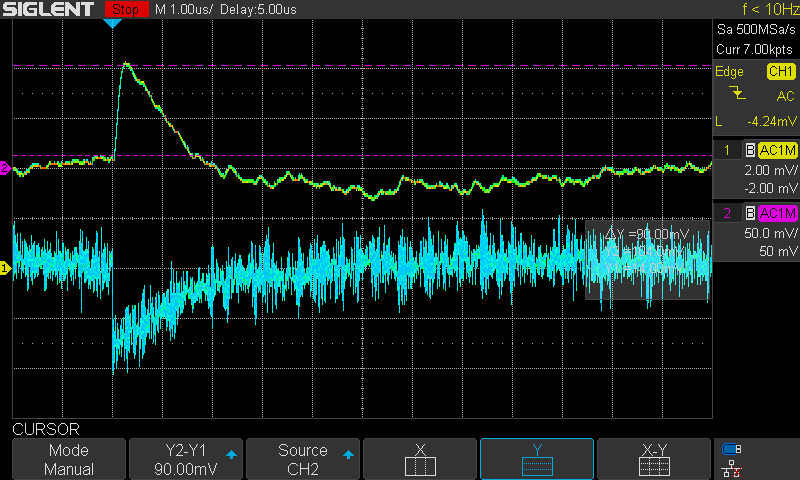

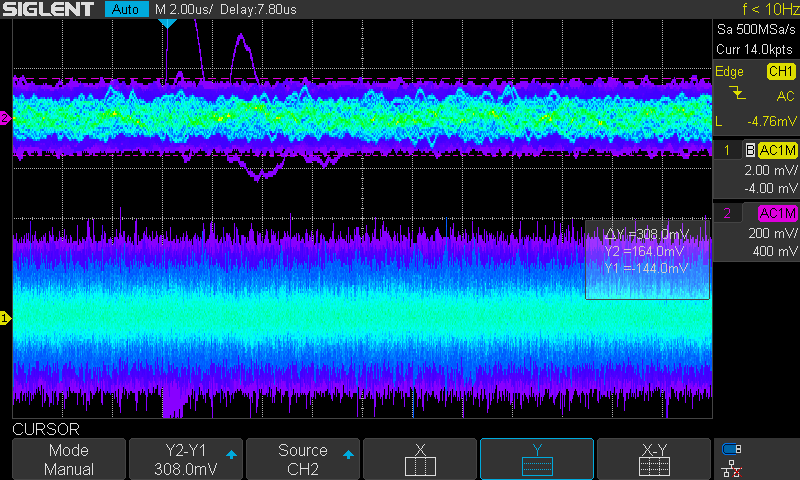

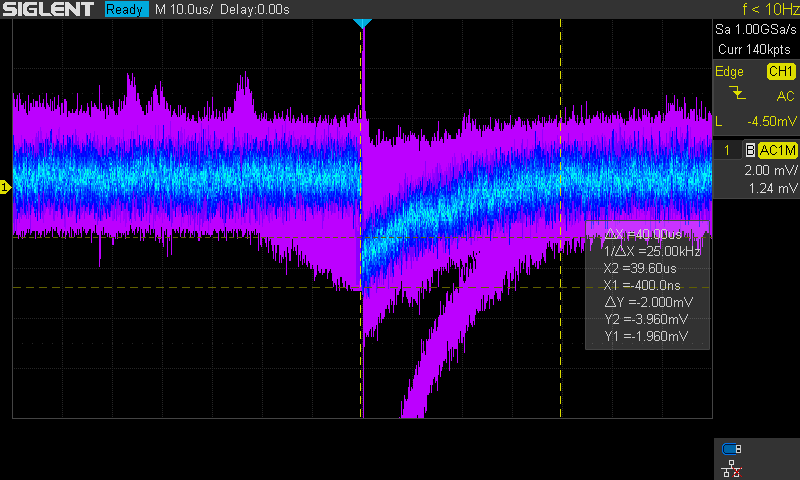

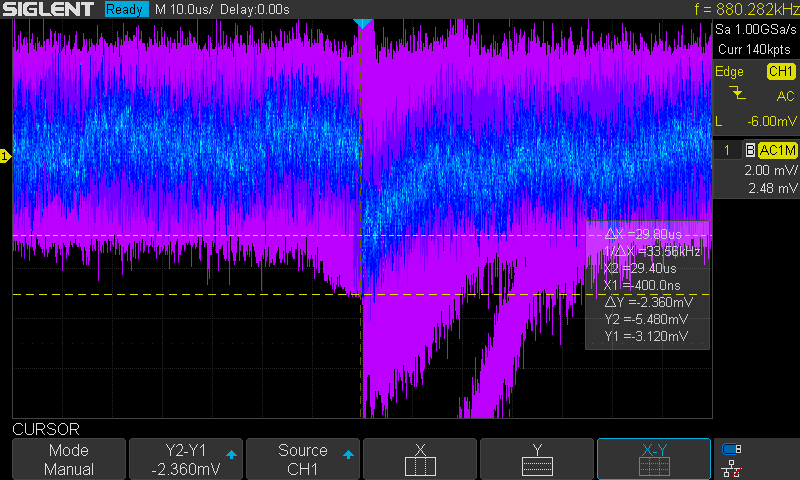

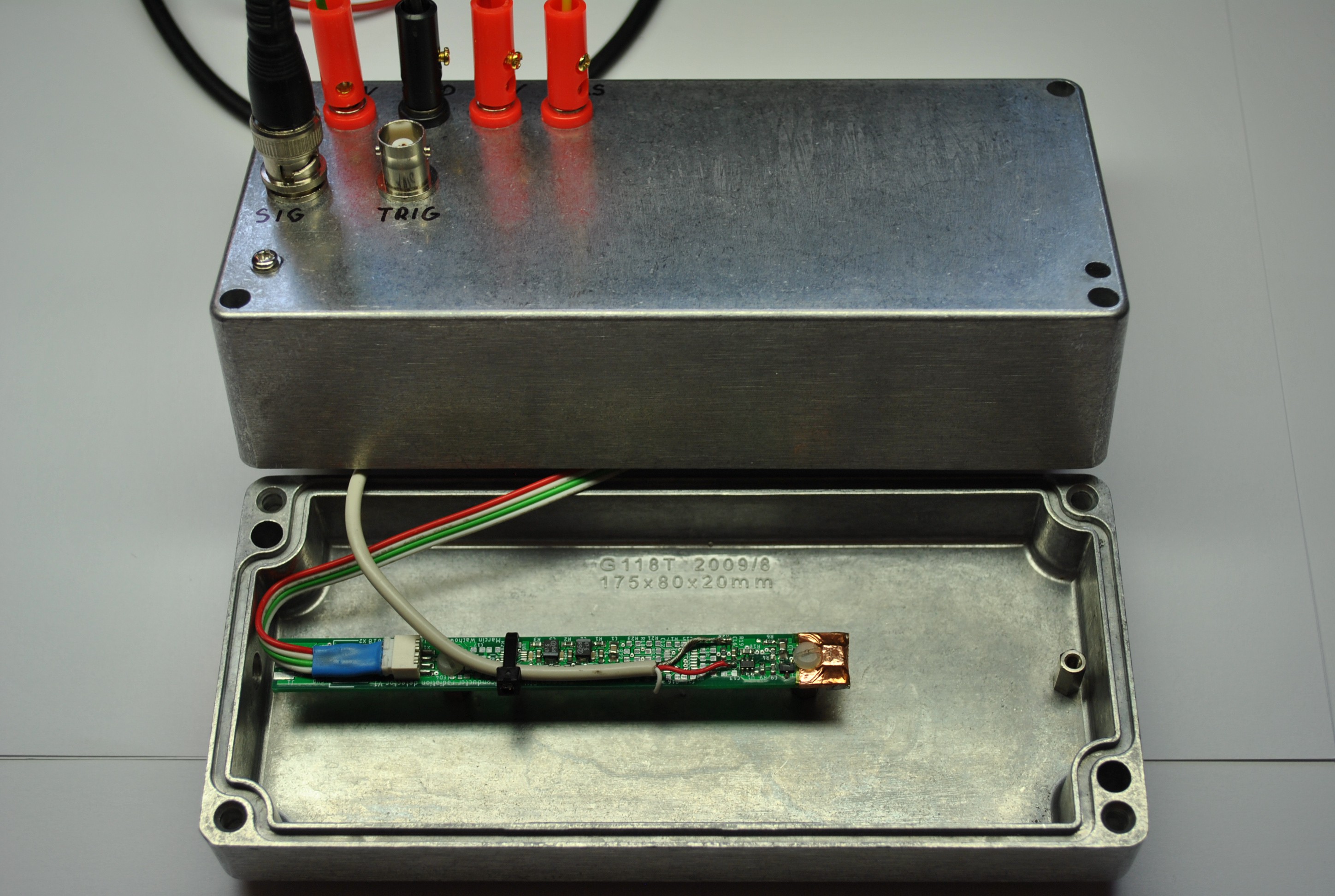

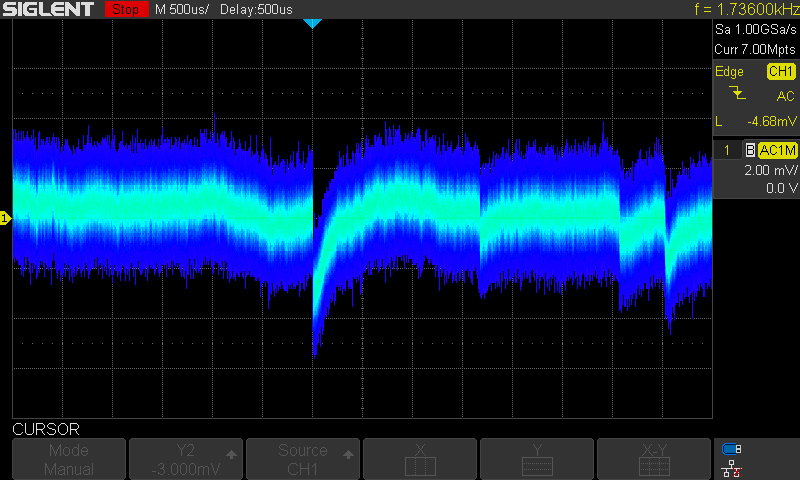

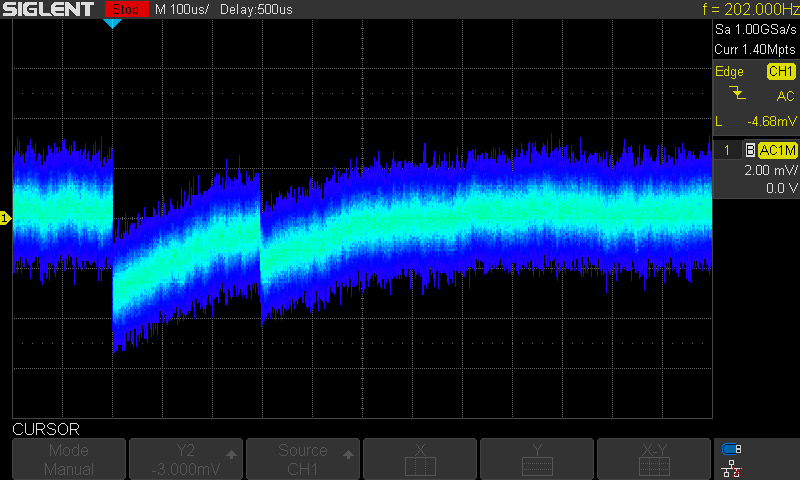

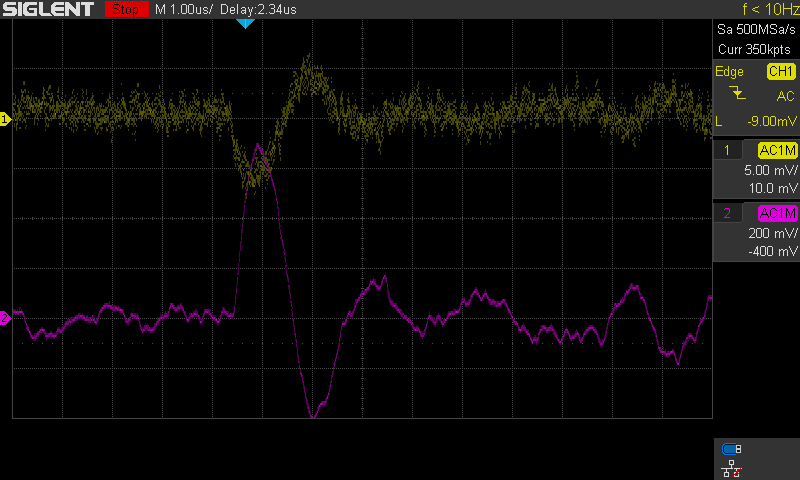

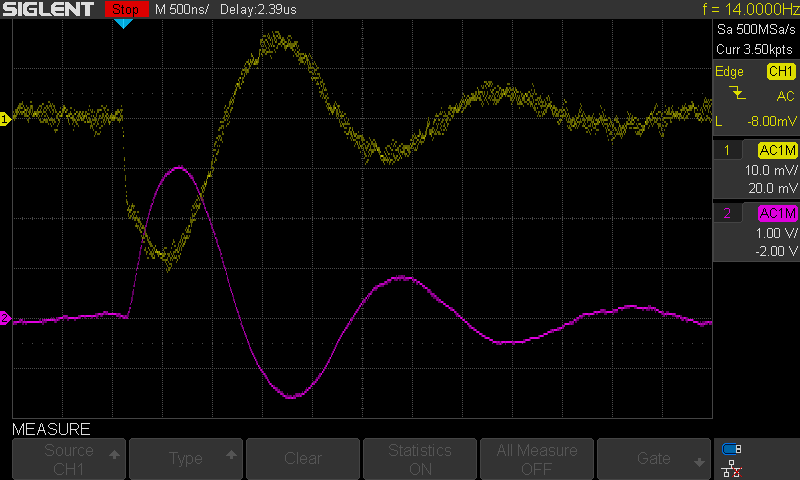

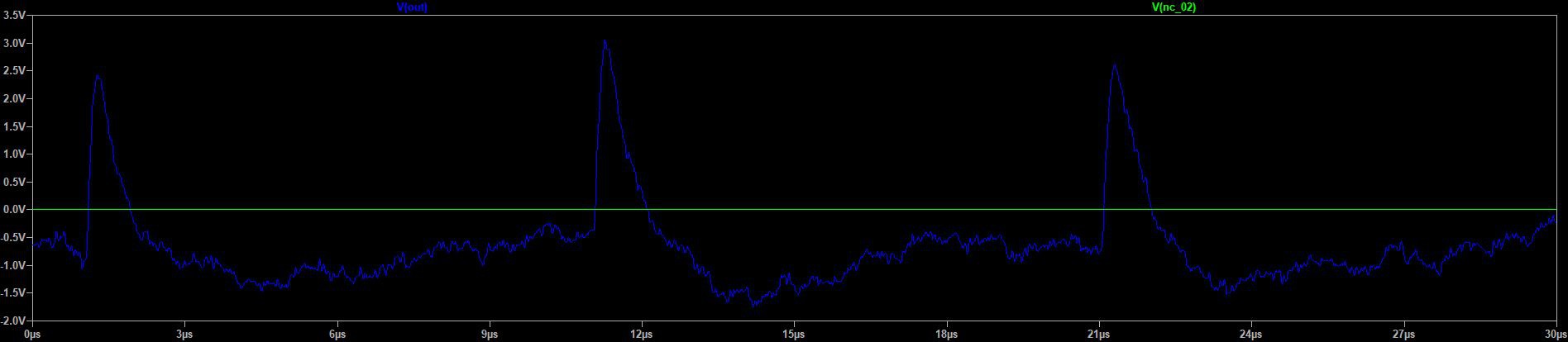

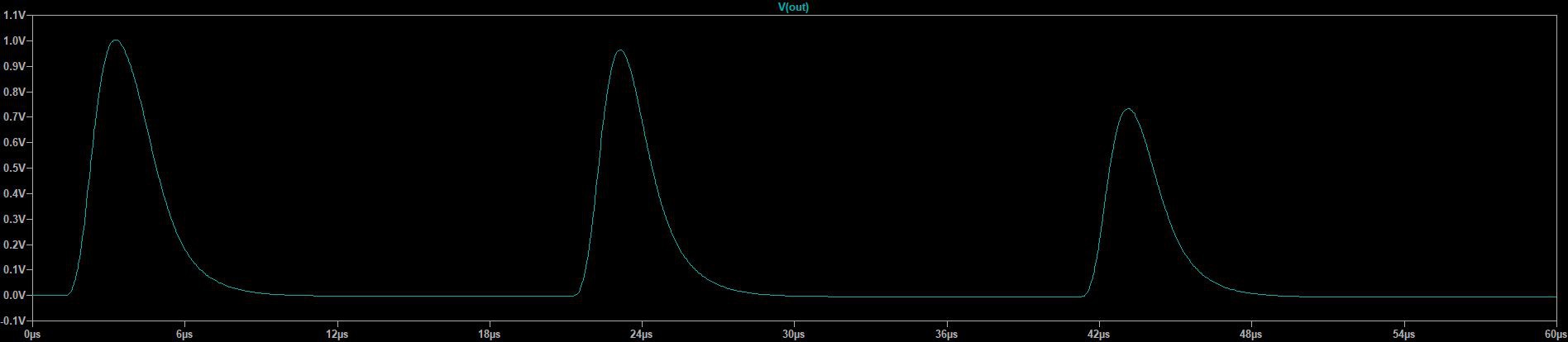

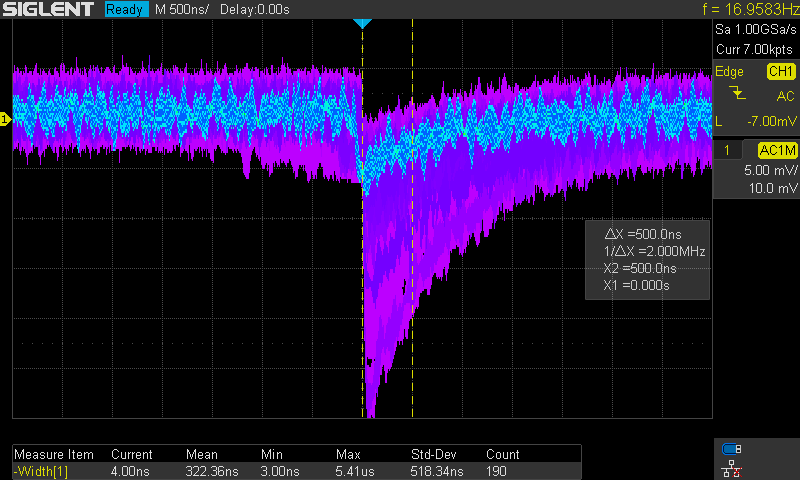

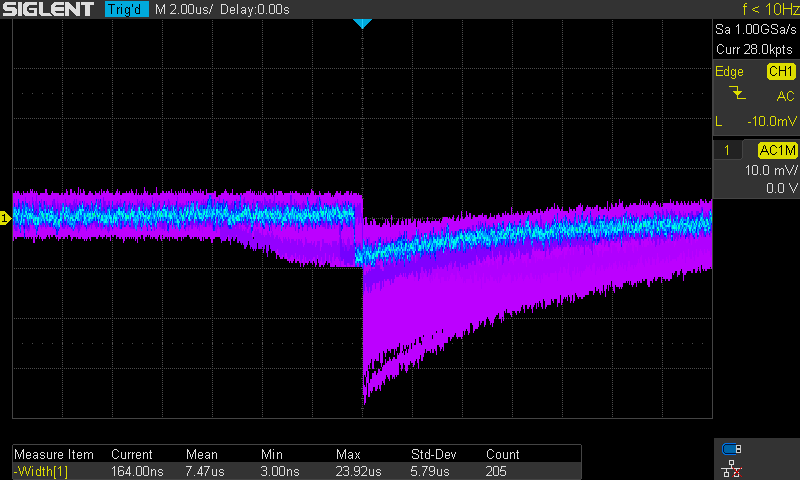

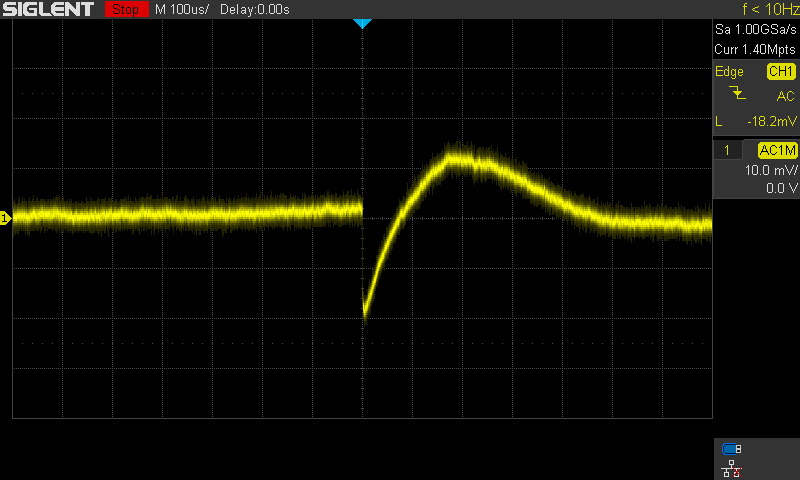

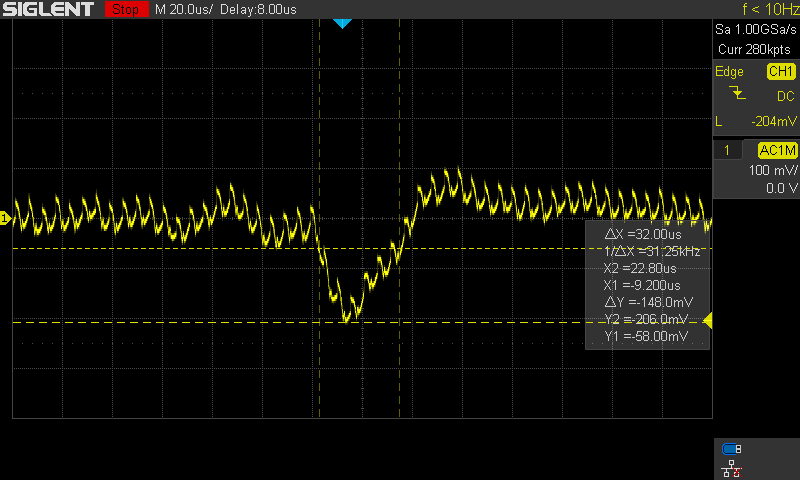

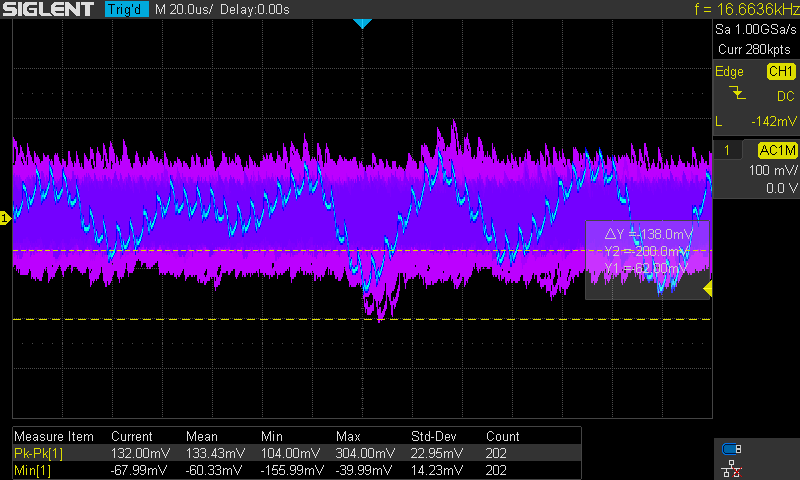

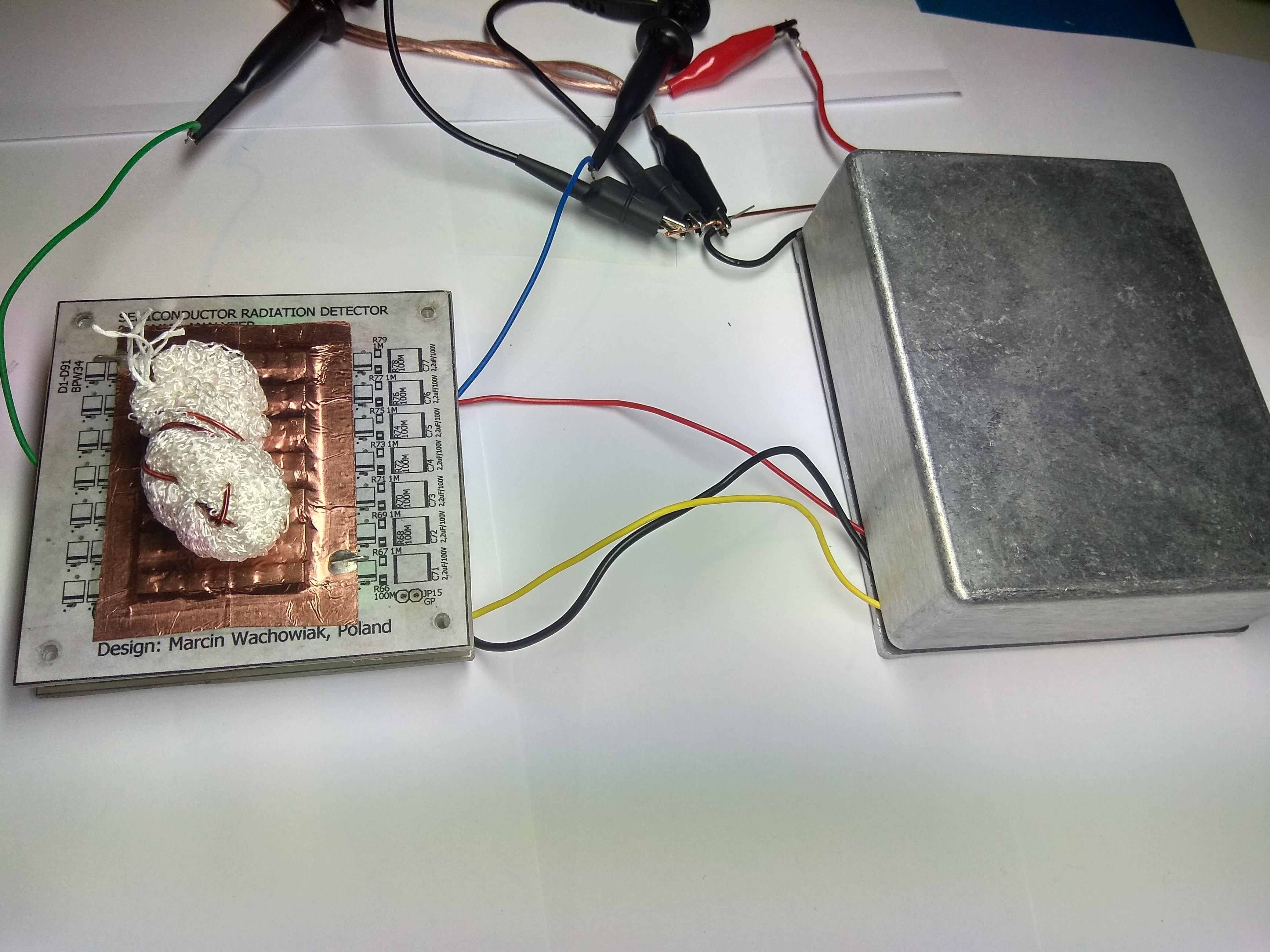

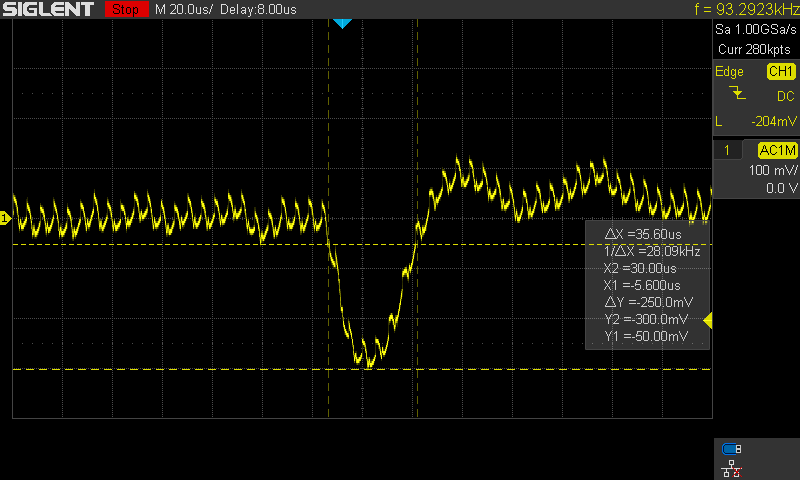

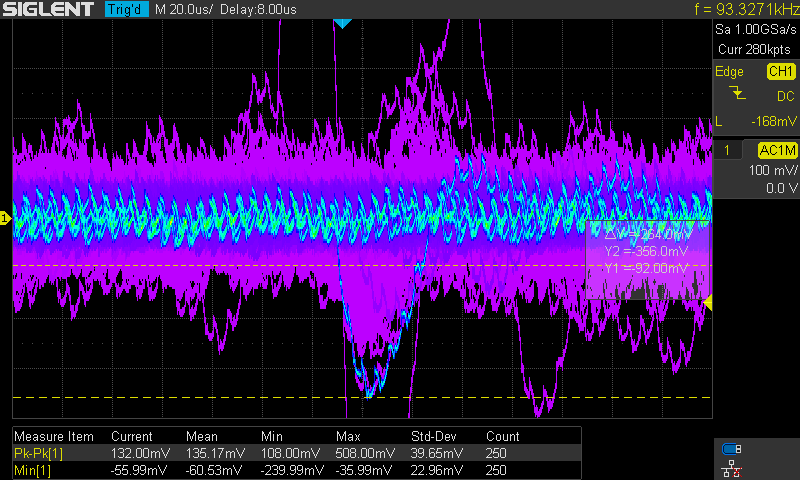

Modified board was mounted in the aluminum box with an Am241 source. This time the diodes were not shielded with copper foil as the box provided enough shielding. Unfortunately, the box was not light-tight so I had to cover the diodes with a single layer of black isolation tape. With that the working point of the TIA was at 2,5V as expected - meaning that there were no additional currents shifting the operating point. Some of the captured screens show the output of the preamplifier:

Low energy pulse

Two pulse pile-up

High energy pulse Signal processing

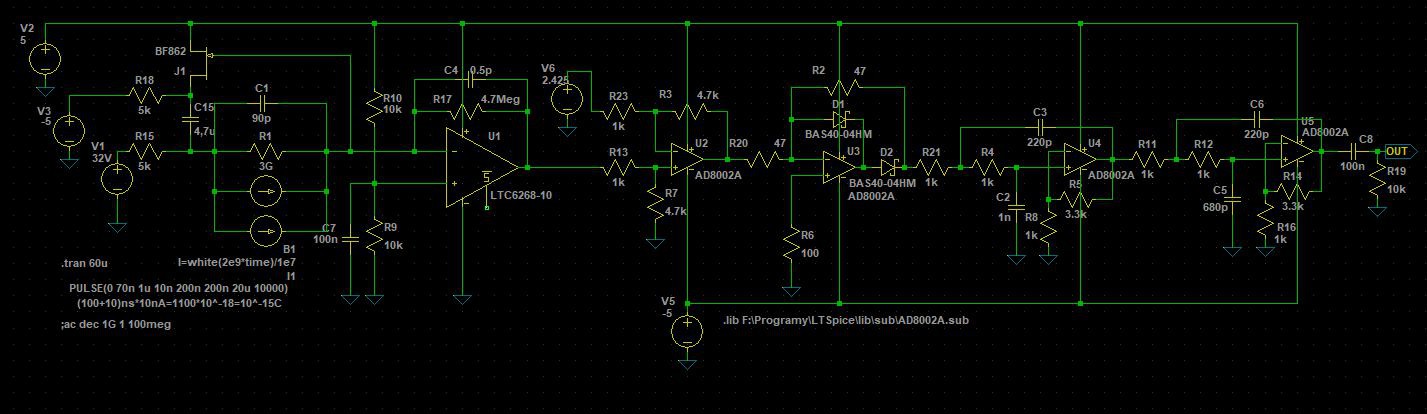

Having finished a fully functional preamplifier the next step was to process the raw noisy signal with the signal conditioner board. This was definitely more challenging as each segment had to be optimized in regard to the other blocks. Some of the values picked while evaluating the simulation did not provide required stability or operating points and had to be altered.General issues:

- Resistors or inductors used in power supply filtering need to have low resistance around 1-10 Ohms as any greater value causes unacceptable voltage drop across them.

- Double LED indicators on each side of the board are redundant as they signal the same thing. Only one group should be soldered.

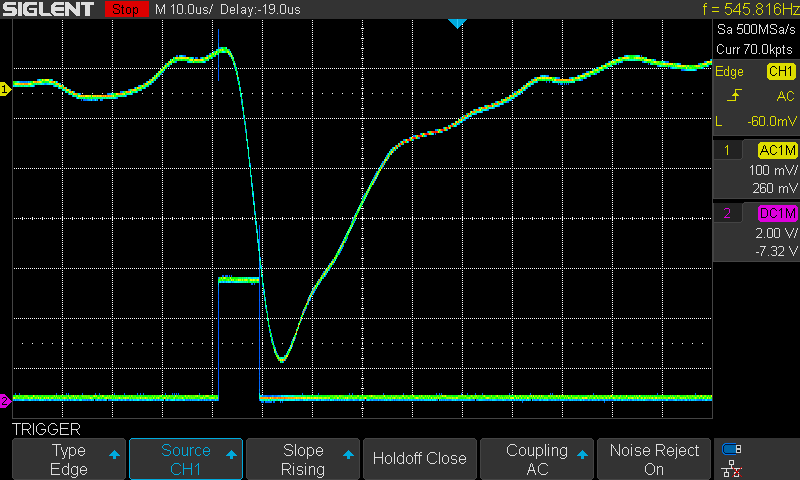

Filter

6th order Bessel filter based on Sallen-Key topology may be instable when high gains are set due to required component precision values. In my case I had to reduce the gain of the whole block to 60 and recalculate all values again with ADI Precision Studio. A simple change in the divider at the output of the amplifier will change the gain but the stability of the filter will be decreased dramatically. I also noticed that the filter block was not designed with noise optimization option available in the tool. For any further versions I am considering the 4-stage Multiple Feedback topology with improved stability and proper noise optimization.

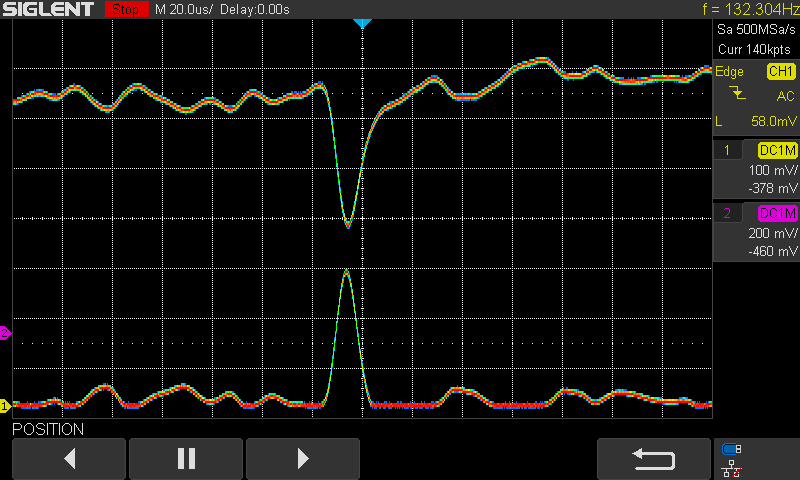

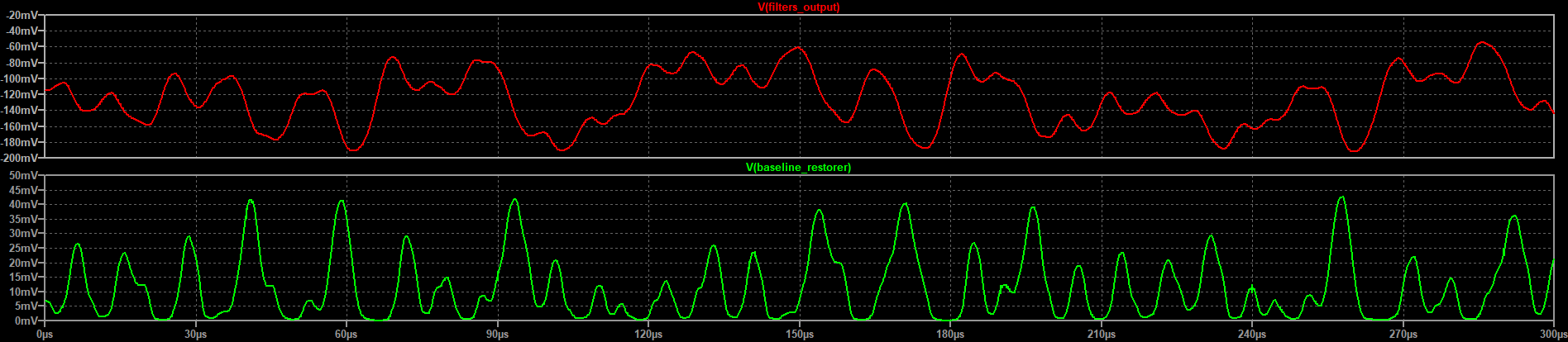

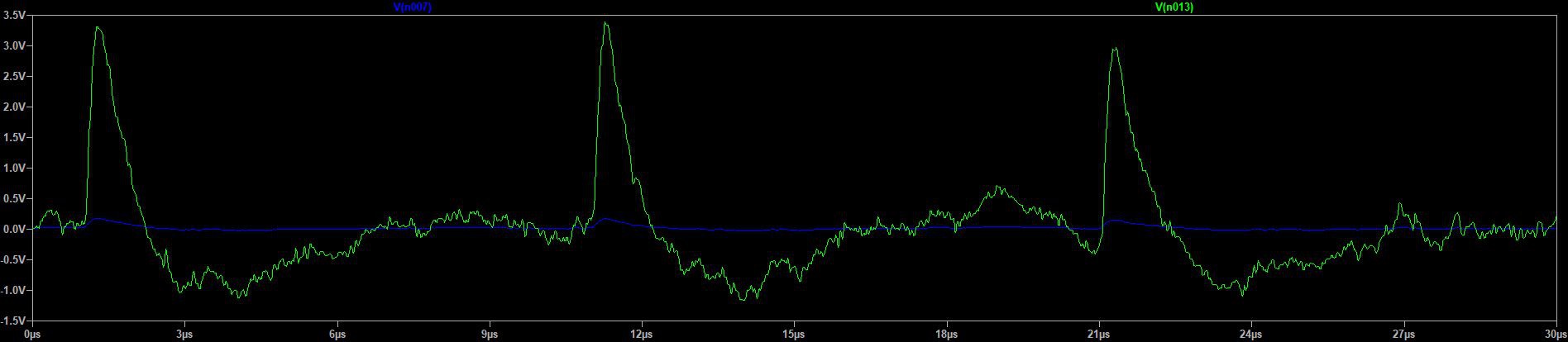

Filter segment output with comparison to the input signal. Poor filter stability is visible in ringing surrounding the pulse.

Filter output

Filter output

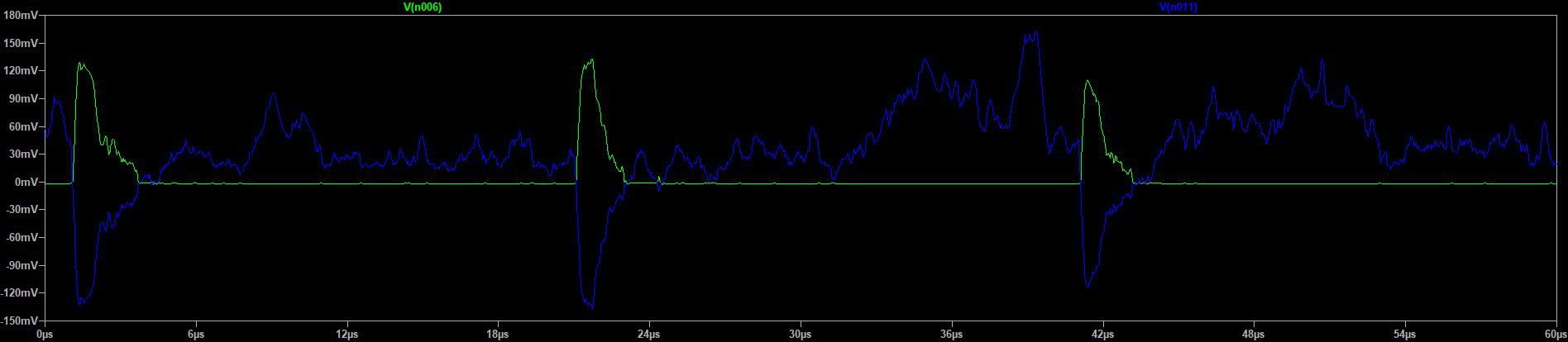

Filter output Baseline restorer

Baseline restorer circuit was introduced to reduce impact of DC shift or local baseline oscillation on measured impulse value. Because of the low amplitude at the output of the BLR a bunch of component values had to be altered. The input RC filter values of the block were set to 100nF and 510 Ohms. Then R7 was set to 300 and R8 to 33k to maintain the rule that R7<<R8 so that the output is remains to DC. The load resistor R18 was also changed to 1k. With such values the range of output amplitudes was extended. More information about this intricate circuit can be found here.

Oscilloscope screens presenting the output of the BLR in comparison to the filter output. The baseline shift cancellation effect is clearly visible.

Baseline restorer output

Baseline restorer output Baseline restorer output Peak detector

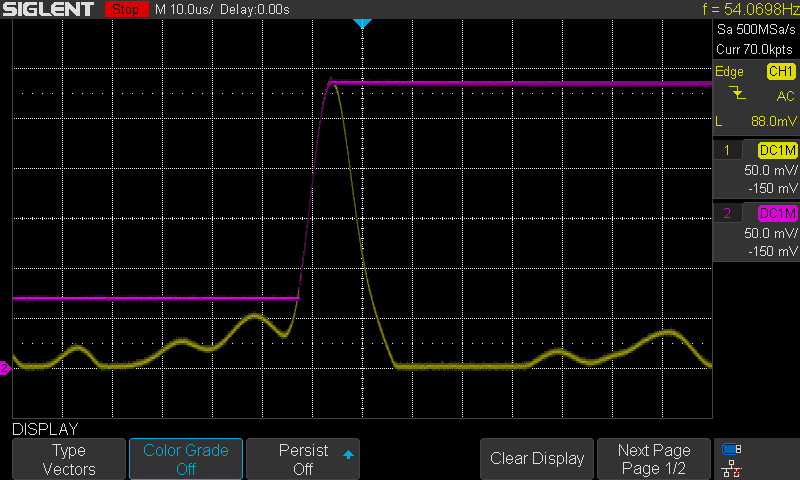

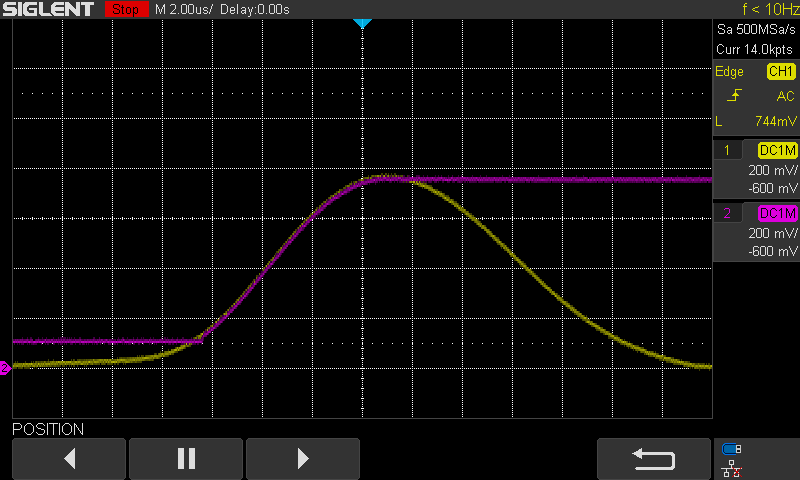

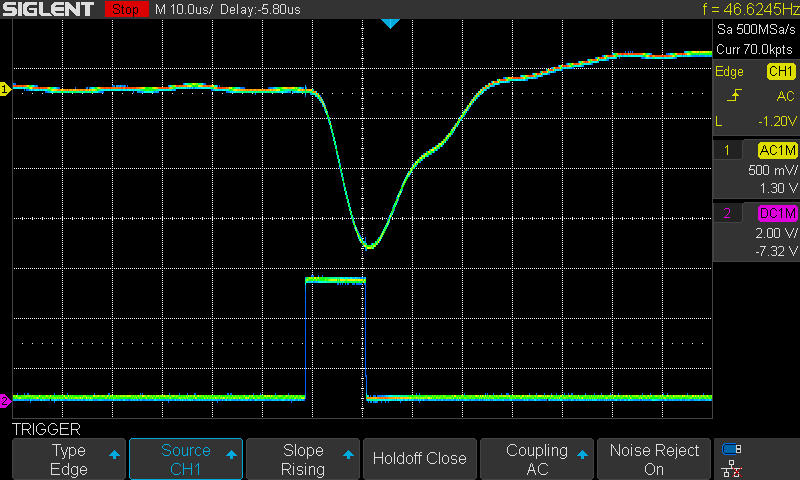

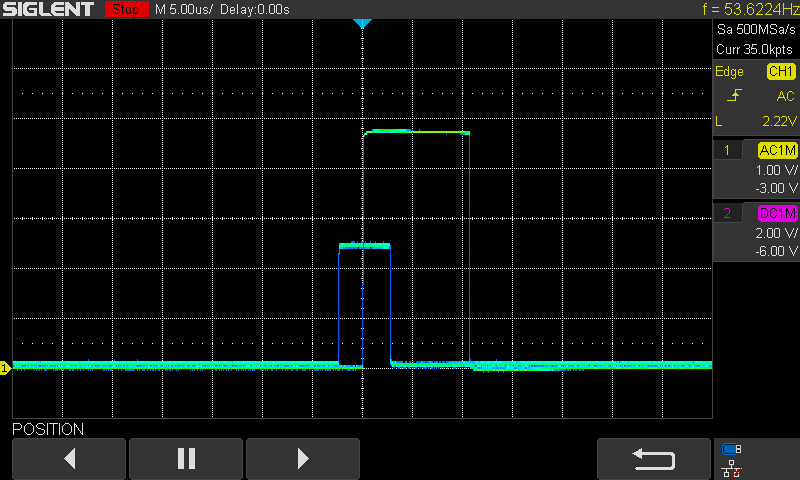

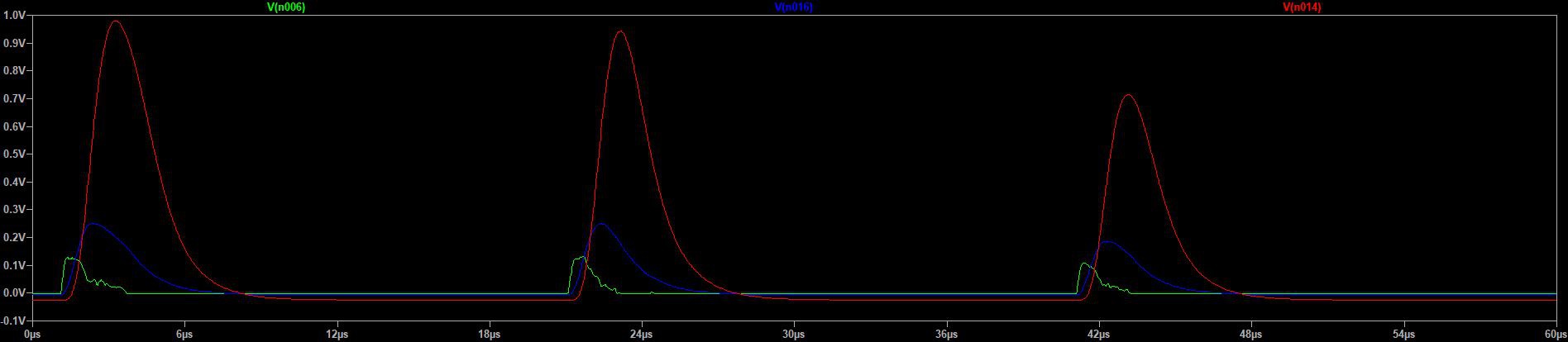

The only block that didn't require any action and worked from the beginning was the peak detector. The sample and hold circuit perform really well as expected. For the tests it was gated with a square wave with frequency about 1-2 kHz.

Screens depicting the performance of the S&H in reference to BLR output:

Peak detector output

Peak detector output

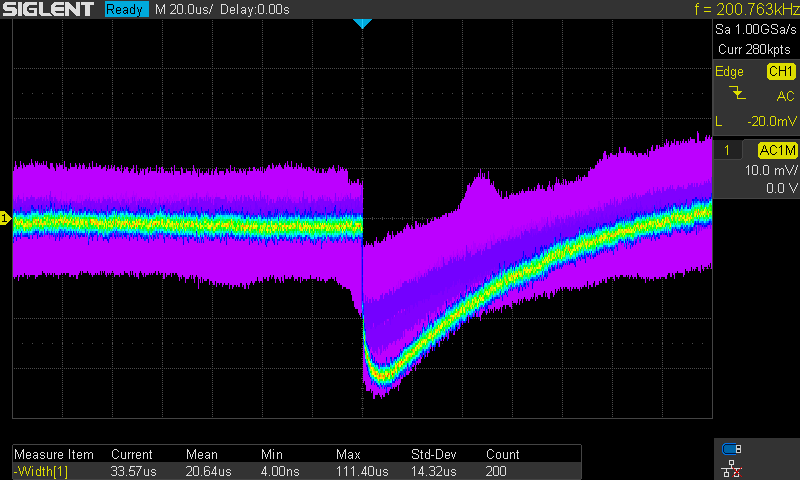

Peak detector output Pulse duration comparator

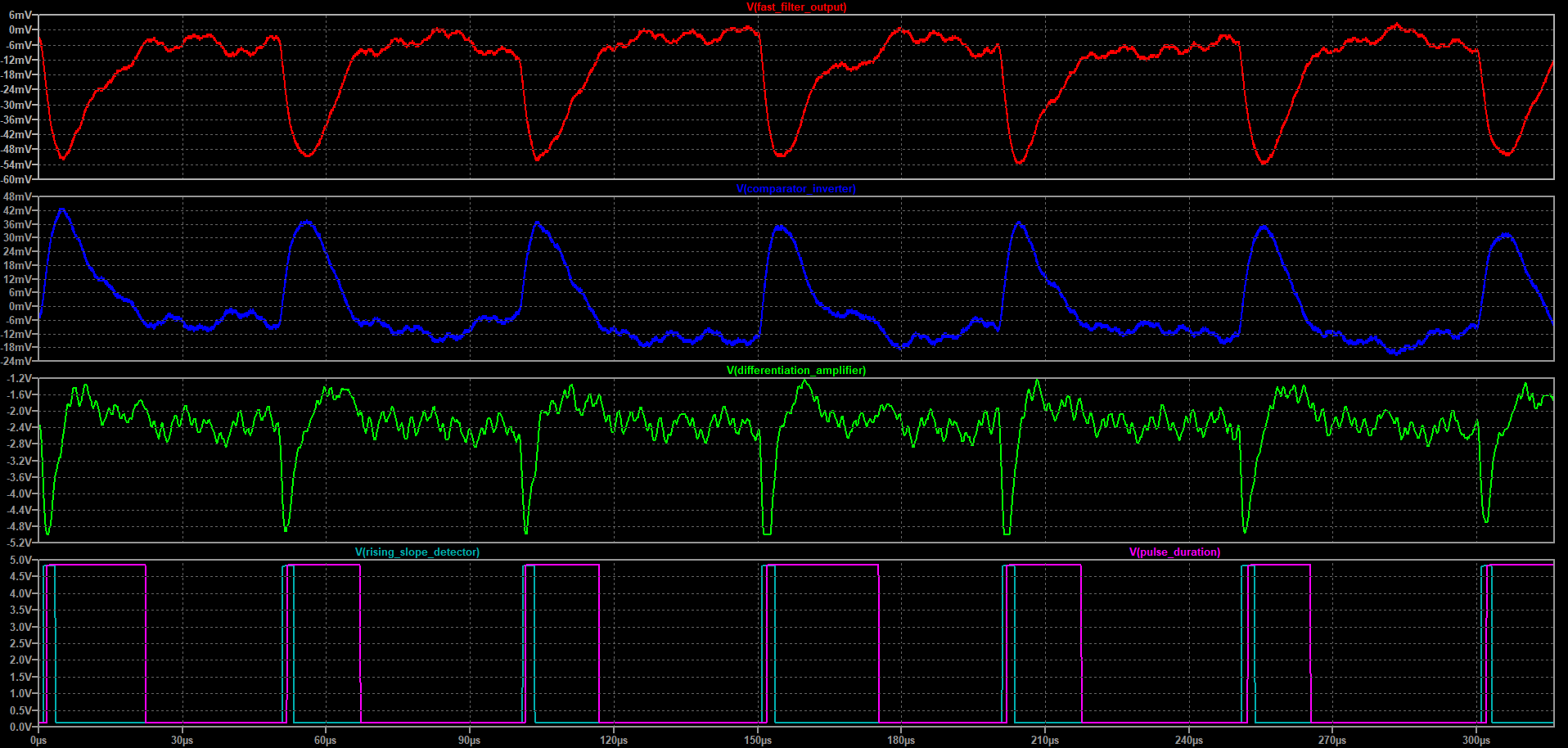

Parallel to the analogue signal processing a digital detection of the pulses with sufficient amplitude is performed. The fast-filtered signal is inverted using IC4A which may require an additional feedback capacitor of value about 10pF. In my case the AD8066 didn't require it but other fast op-amps may need one to prevent oscillations. Again, the reference voltage and hysteresis of the comparator had to be adjusted. Not only did I had to change the values but also the whole divider had to be arranged in such way that it provided positive voltage. The node previously connected to -5V had to be attached to +5V rail. The one connected to the GND remained intact. The reference voltage from the divider was set to 17mV with R47 = 7 and R48 = 2k Ohms in modified arrangement. Hysteresis was set to 13mV by changing the R53 to 256 Ohms and leaving the R58 with 100k.

Observed behavior showed no signs of double triggering but minimal transient oscillations were noticed in the filter output probably due to crosstalk or connected oscilloscope probes.

Pulse duration comparator output

Pulse duration comparator output

Pulse duration comparator output Differentiator amplifier

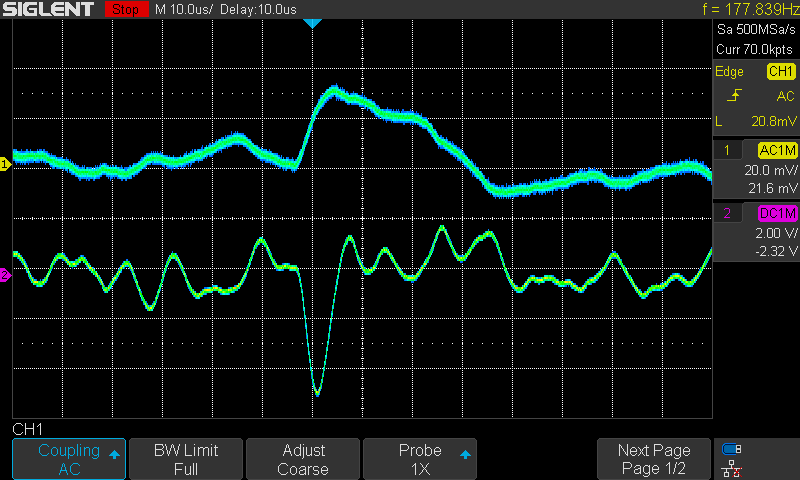

Additionally, to the pulse duration detection a rising slope detection circuit is implemented using a differentiating op-amp and comparator. To tune the differentiator to required sensitivity the input capacitor was replaced with 1nF and the feedback resistor value was increased to about 660k Ohms. With such values the circuit enables quick signalization of the rising slope with short recovery periods.

Oscilloscope screens showing differentiator output in regard to inverted fast filtered signal.

Differentiator amplifier output

Differentiator amplifier output

Differentiator amplifier output Rising slope comparator

After the differentiator amplifier a comparator is located to signal the rising slope by digital state to the MCU. The threshold was adjusted so that only slopes steep enough are detected. R49 = 2,2k R50 =2,9k the hysteresis value remained the same. Performance of the rising slope detector in regard to filter output can be seen on the screens below:

Rising slope comparator output

Rising slope comparator output

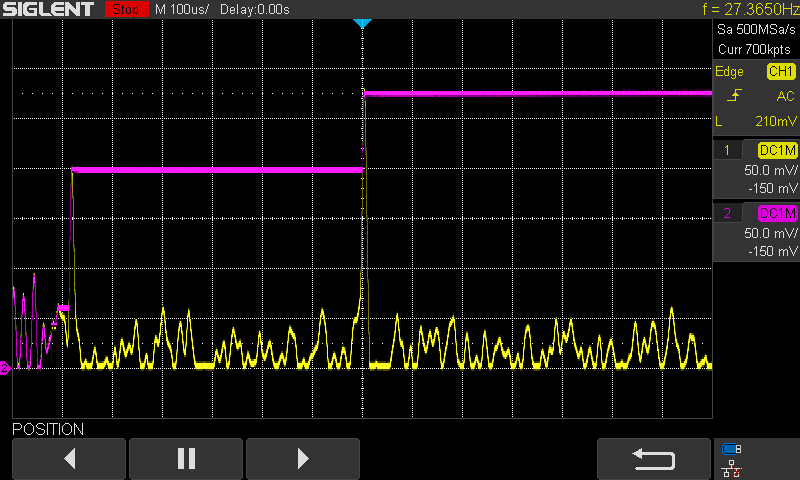

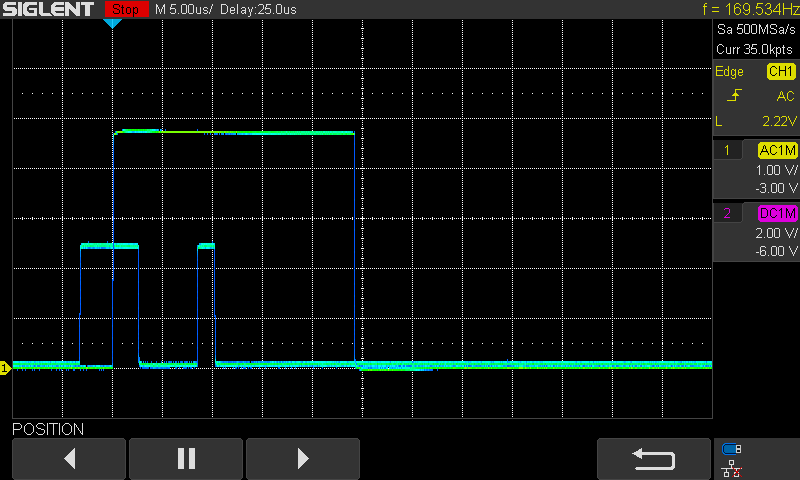

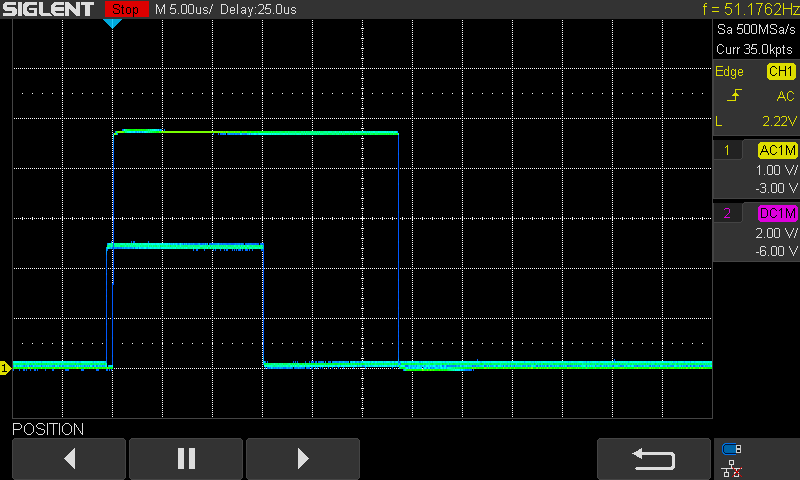

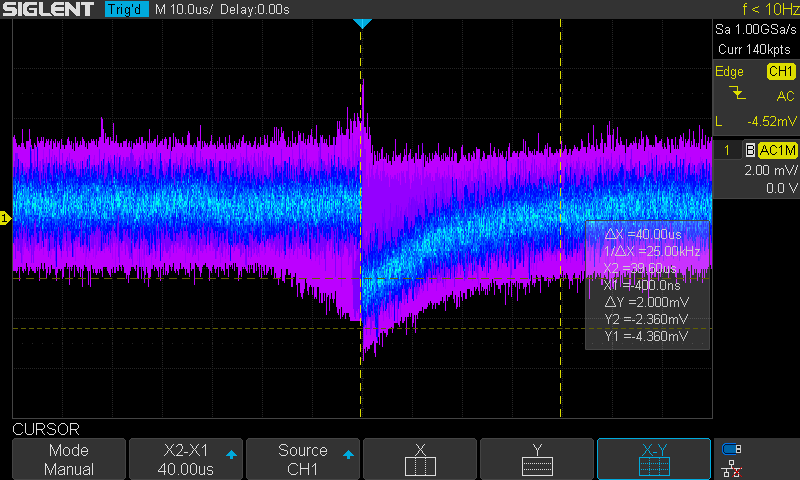

Rising slope comparator output To verify how well the digital detection work, I performed a simple comparison by observing the output signals of the comparators. As can be seen below the pulse duration signal is almost always preceded by a rising slope indicator. I even managed to capture a double trigger of the rising slope signal which indicates possible pile-up, in such case the sample should be rejected and not measured by the MCU.

Rising slope comparator output - lower amplitude, pulse duration comparator output - greater amplitude

Rising slope comparator output - lower amplitude, pulse duration comparator output - greater amplitude

Rising slope comparator output - lower amplitude, pulse duration comparator output - greater amplitude What's next?

Finally, the preamplifier and signal processing units provide acceptable signals and performance. With that I am able to advance further. The next step is to program the MCU - STM32 to capture the amplitude of the pulses, count them and maybe store them on the SD card. A lot of tests are required to verify if the "blue pill" MCU will meet up the expectations. The whole code structure and functionality needs to be carefully thought over. The core function is to measure the amplitude - energy and count the pulses. Whereas this will be performed in real time through serial port or during period set by user I am not sure. A lot of problems to be solved. It is quite unsettling that only then will I be able to tell if this whole design was worth the effort.

The fourth version should have all the improvements that I mentioned through the log and be just a little bit less flawed.

-

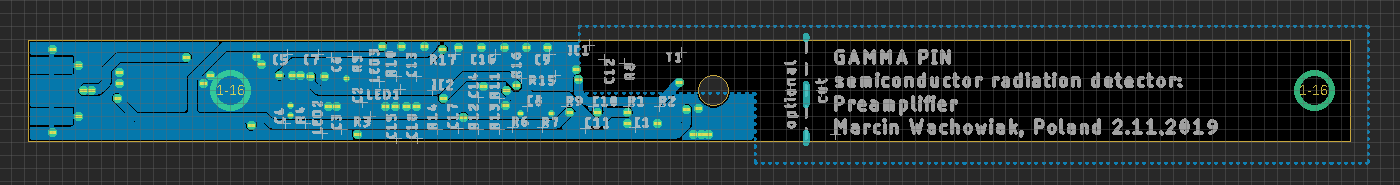

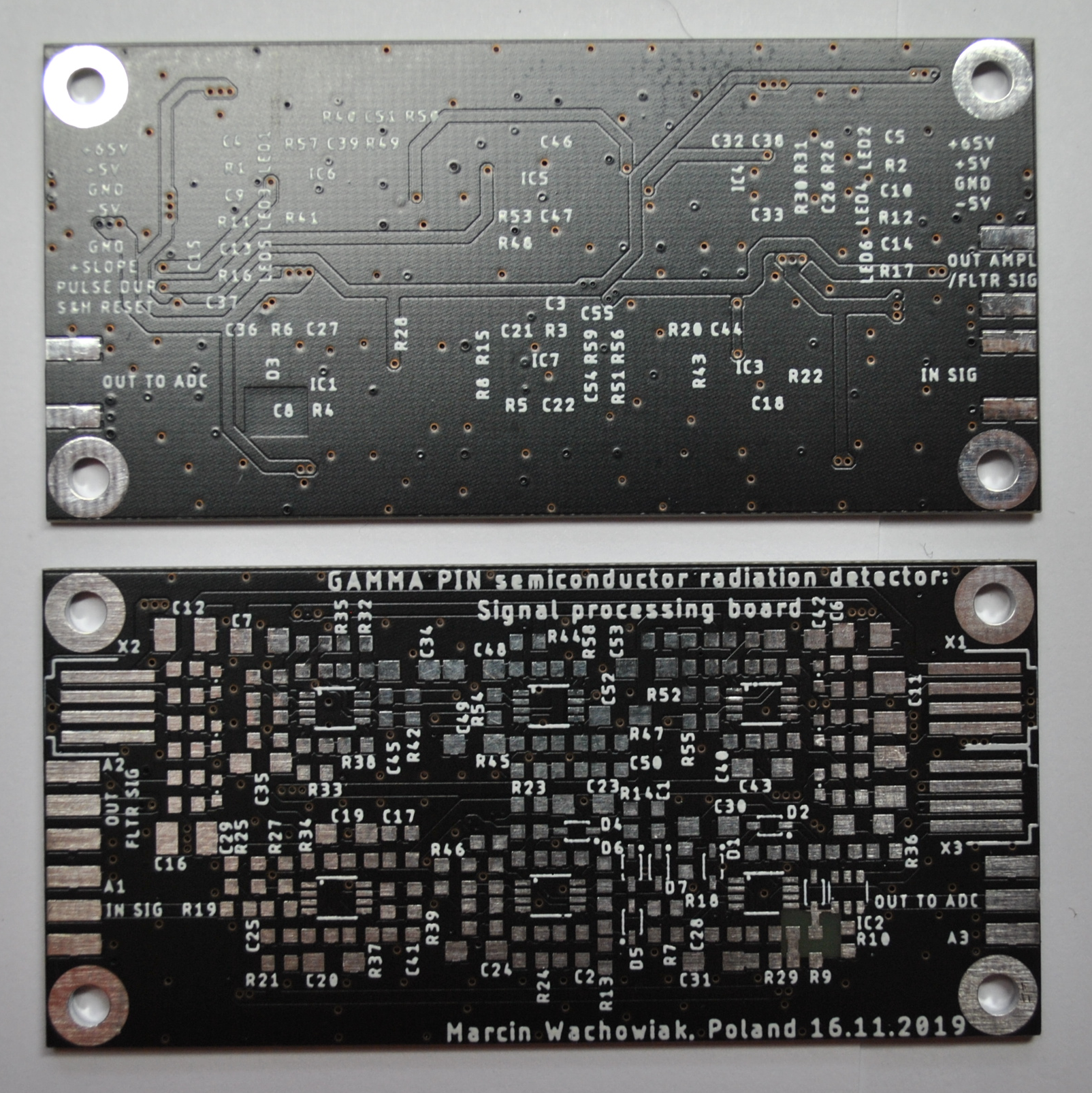

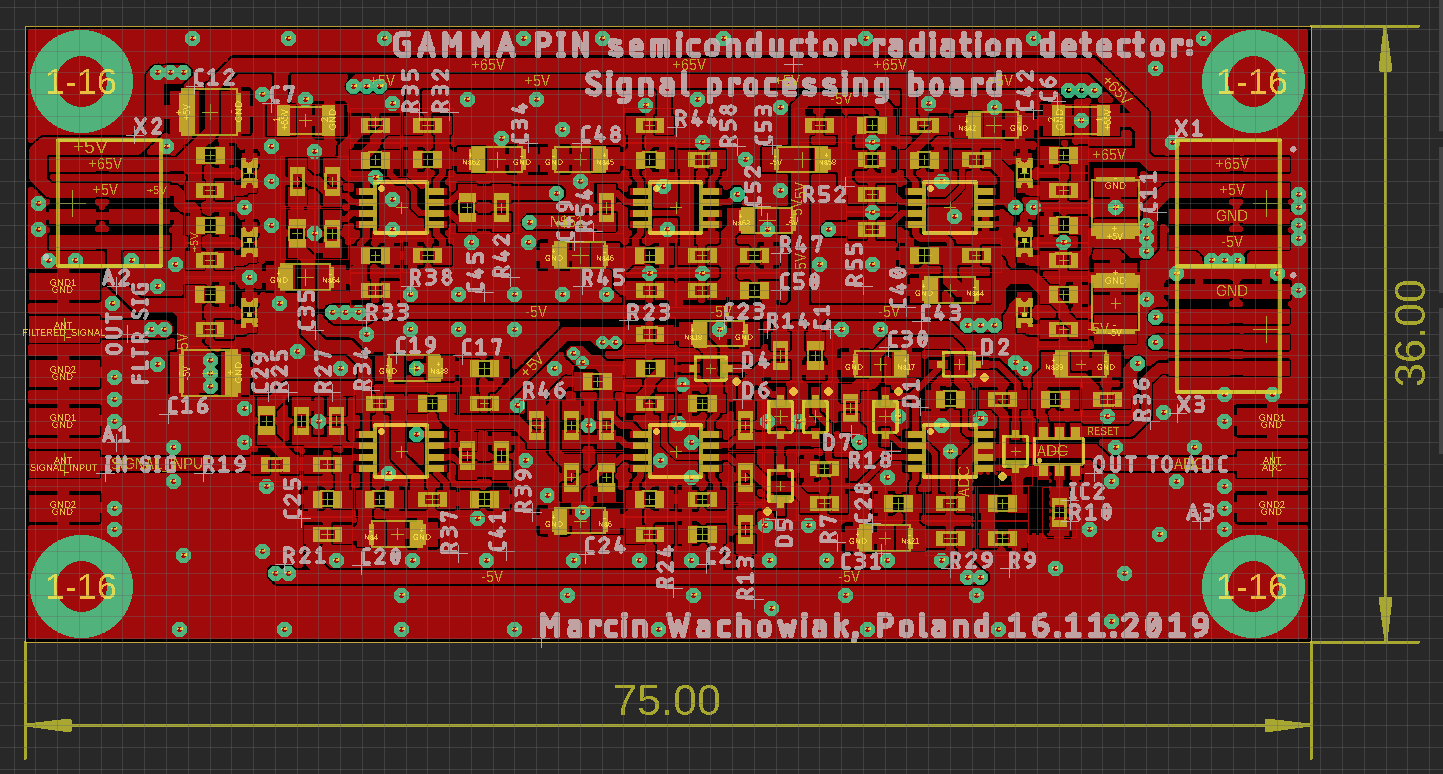

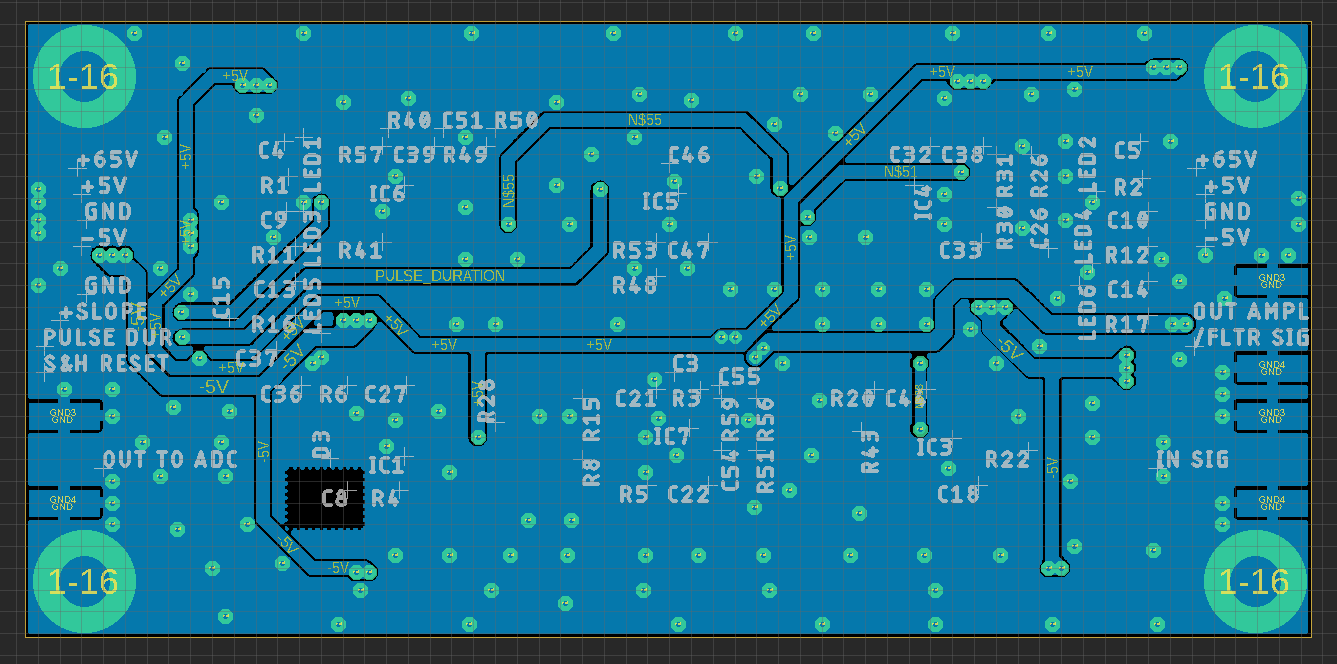

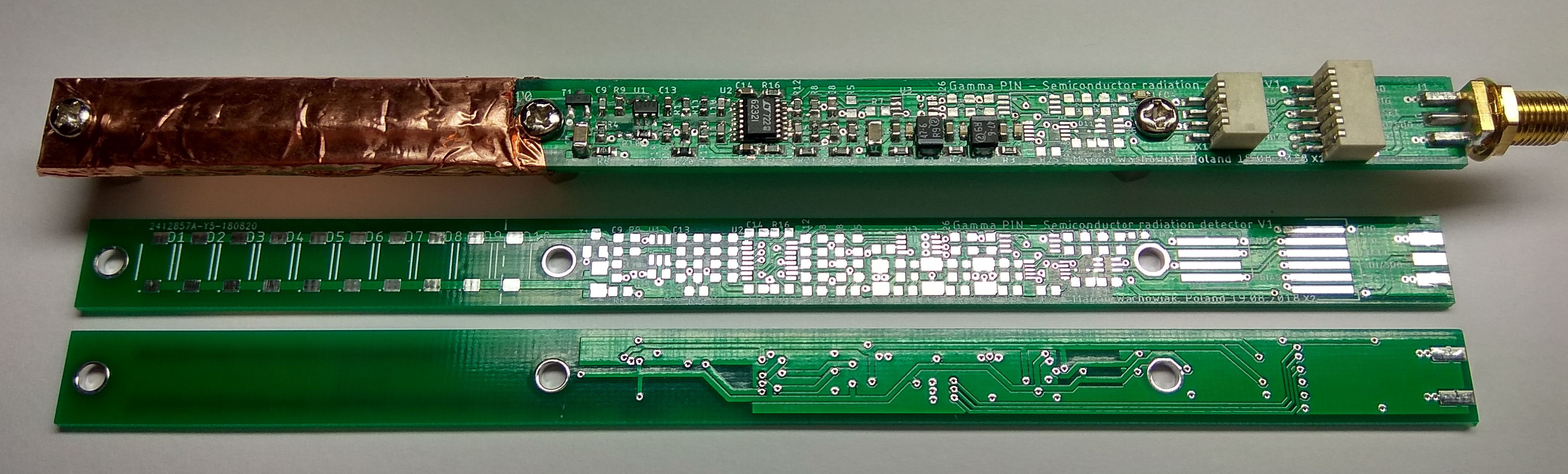

Third version prototype V3

02/16/2020 at 15:09 • 2 commentsRecently I have finished and produced the third version of the detector. Several improvements have been made considering the issues with the previous versions. All files including gerbers, schematics, boards and latest simulation can be found on my GitHub repository. Change log:

- The whole circuitry has been split into two separate boards named accordingly to their function: preamplifier and signal processing. This helped to organize the components properly and extract less sensitive components outside of the detector chamber which is a crude metal box. Separating fast switching comparators from the charge sensitive parts is also an additional advantage. All signals are handled through SMA interface to ensure minimal external interferences.

- Preamplifier segment required additional amplifier to boost the signal levels, before sending them to the processing boards. LTC6228 was added to handle this. Due to the fact that the design uses double amplifiers in a single package I had one additional amplifier left on the signal processing board which was used to increase the order of the low pass filter.

- The bootstrapping transistor BF862 was replaced with CPH3910 as the BF recommended by a design note (https://www.analog.com/media/en/reference-design-documentation/design-notes/dn399f.pdf) has been declared end of life. You can still come across the BF in shops as retailers have some reserves. Performed simulations show that there is no substantial difference in the performance. Probably the noise figures are a little bit greater. You can view the results in the discussion below this log.

- Signal processing board is equipped with “Filtered Signal” SMA output that can be used to connect the detector to a high-speed ADC or Multi Channel Analyzer for farther evaluation. This output is preceded by three stage low pass amplifier that can be altered to serve as normal amplifier without bandwidth limitation or any shaping effects.

- Signal processing board and preamplifier are now populated with many bypass capacitors as recommended in the application notes. There is also an additional power connector on the signal processing board which is intended to forward the power to the preamplifier to avoid mess of split cables.

- Preamplifier is now compatible with both VBPW34S and TEMD5010X01. There is additional milled line that should enable easy snapping or cutting of the board if you intend to use it with a single diode.

- Around the charge sensitive path, a guard ring was introduced to minimize current leaks. Exposed and tinned trace is connected to the voltage similar to the input of the TIA. Although it is not powered by buffer following the voltages on the trace it may improve the performance a little bit.

- At the bottom of the preamplifier an exposed pad was placed to provide grounding for metal screening of the diodes. You may simply solder the screen to mass without scraping the solder mask.

- Molex pico-spox horizontal connectors (87438-04) have been replaced with vertical ones (87437-0443), as the horizontal ones are no longer recommended for projects. The vertical orientation helps to insert the plug and the cable can be easily bend to minimize the space taken up by the detector.

Preamplifier board

Preamplifier top

Preamplifier bottom

Signal processing board

Signal processing top

Signal processing bottom -

Optional improvements to the detector

08/13/2019 at 19:25 • 0 commentsReducing noise contribution

The simulations I conducted in LTSpice show that even identical current pulses yield various voltage readings. The source of this distortion is a low frequency noise originating mostly from the detecting apparatus. Most of the high frequency noise is removed by the low pass filter, but the remaining passband range is enough to introduce a significant error. Using more selective passband filter is no help as its step response shape is invalid for peak voltage acquisition.

High resolution of the detector strongly depends on the repeatability of the detecting circuitry. It provides that certain energy of captured radiation is represented by a specified voltage level. When the response varies within the span of the error introduced by noise, peaks that should represent particular isotope become blurred. Thin lines become wide enough to cover other smaller peaks and hide significant details.

There are a few ways of reducing the noise contribution:

- Lengthen the primary signal timespan by increasing feedback resistance in the TIA. With that a more selective lowpass filter can be applied and reduce the noise according to the needs. Note that this solution increases the dead time of the detector and maximum count limit, so that more active sources may saturate the detector.

- Use sensing elements with lower noise contribution and greater signal to noise ratio. In example: a photomultiplier tube with scintillator or high purity germanium or silicon detectors. In professional applications these devices are usually cooled with liquid nitrogen to really low temperatures to reduce the thermal noise to the minimum.

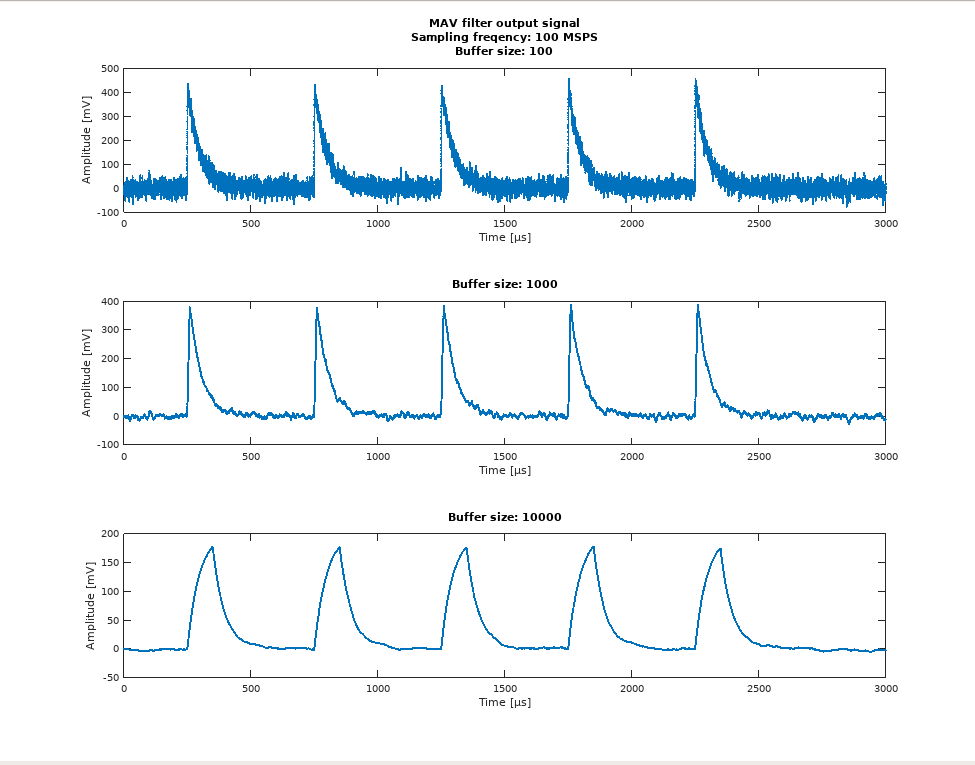

Proposed solutions either require a compromise between the parameters of the detector or are costly and out of reach. However, there is a digital filter that can tackle this kind of noise better than any of the analog kind. The best solution to the noise present at the output of the sensing element is the moving average filter (MAV). Widely described in this article: https://www.analog.com/media/en/technical-documentation/dsp-book/dsp_book_Ch15.pdf.

In short, the output signal sample is an average of all previous samples collected in a buffer of specified length. The samples are replaced subsequently by the newer ones, as the averaging window moves along.

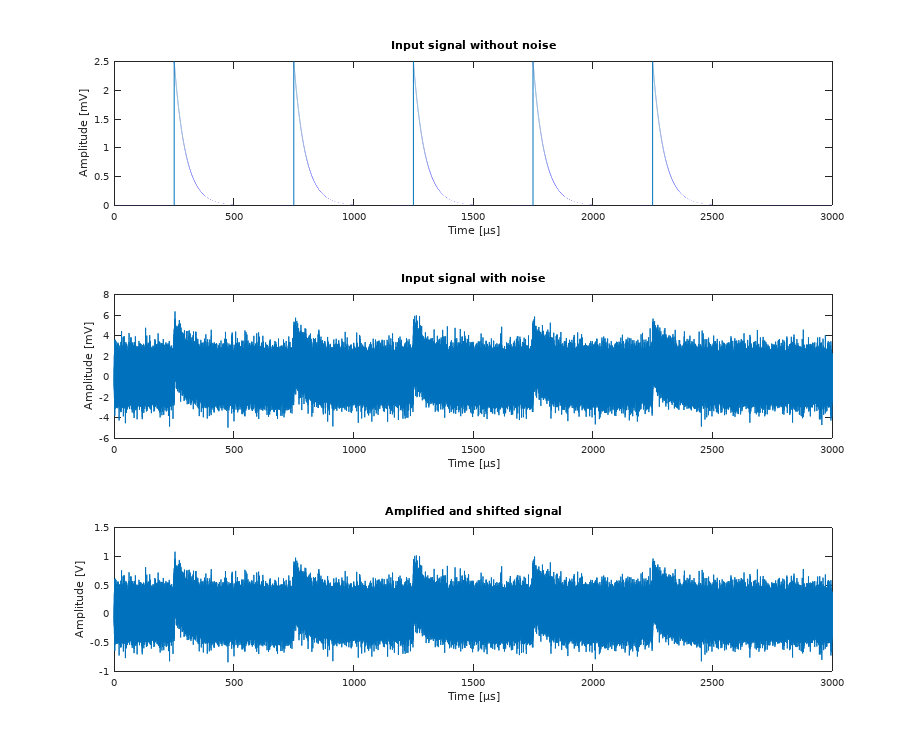

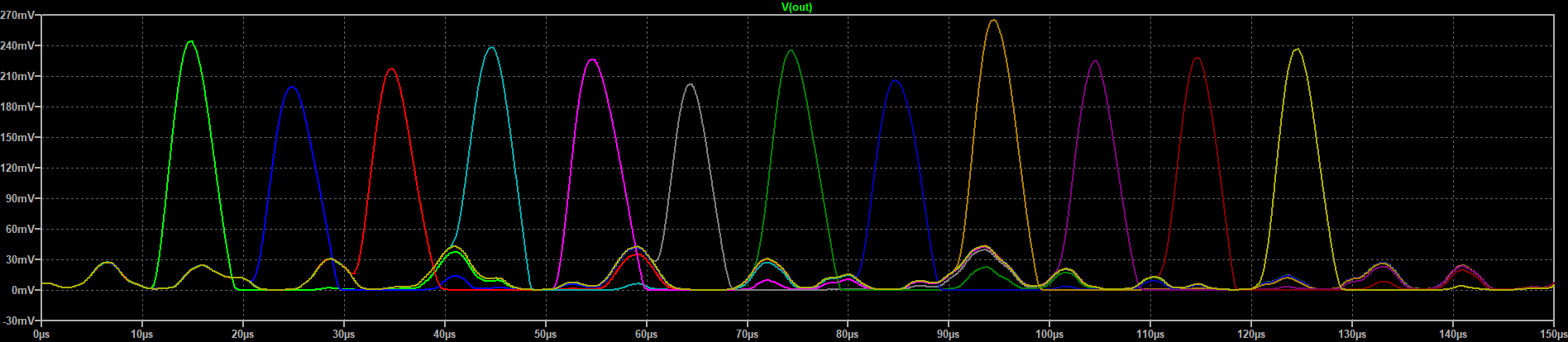

Input signal visualization As a result, the noise at the input of the filter is averaged to almost constant value. Depending on the length of the averaging, buffer pulses present at the input of the filter are smoothened and signal distortion is significantly reduced. Moving average filter provides greater repeatability of results at the cost of using a high-speed ADC and FPGA as a signal processing unit. On the other hand, such change enables easy alteration of signal processing path as everything can be implemented and updated in the software. I performed a few simulations with MAV to see how effective it would be. Simulations were performed using Octave, but will run with Matlab too. (available in my github repository) The signal present at the input is similar to the TIA output in the real case. With 100MSPS and a buffer of 10000 samples I was able to reduce the error to 5mV. Thinking of the third prototype there will be an additional analog output pad in case someone would like to try this approach.

Filtered signal visualization In comparison the analog filter and baseline restorer do not remove the noise too well. In the worst case the amplitude may vary even by 60mV. I hope that the spectral distribution of the noise will be a little bit different and easier to handle than a uniform one present in the simulations.

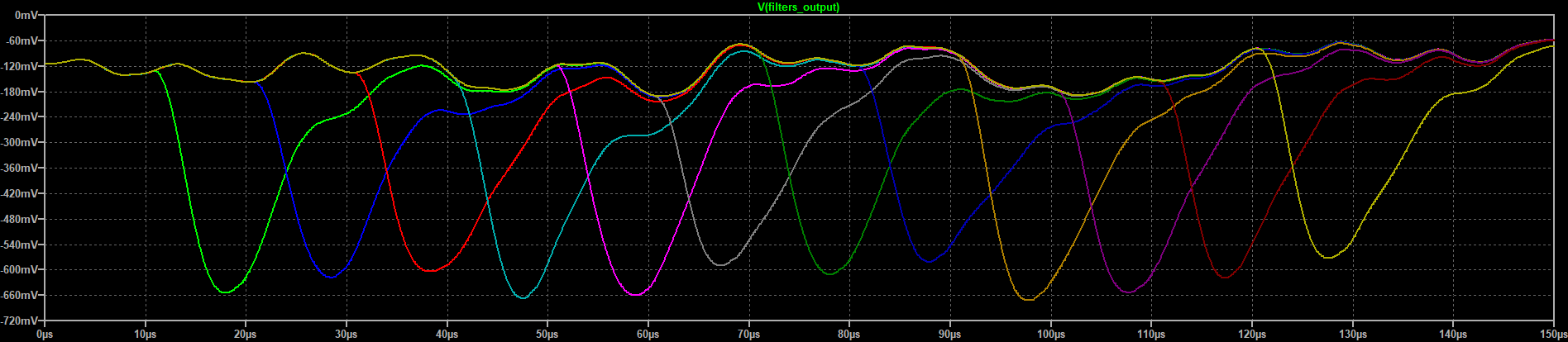

What is also interesting is that during LTspice simulations it turned out that the noise sources always have the same seed loaded. This means that the waveform of the noise signal will always be the same in each run. To see how the noise affects each peak I was forced to delay the pulse by various timespans.

No input signal noise Filters response to each delayed pulse

Baseline restorer response to each delayed pulse Increasing sensitivity to alpha particles

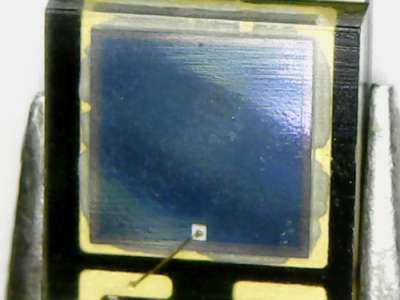

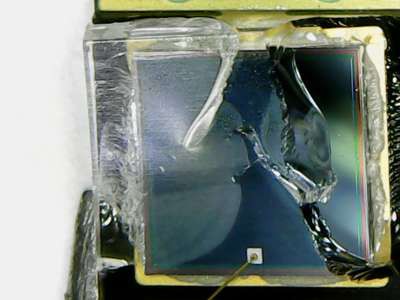

While soldering photodiodes to the board I noticed that sometimes there appeared an air bubble between the plastic case and junction. Especially in the TEMD diodes the transparent case seemed to become softer in the soldering temperatures. There were some ideas about increasing the detector sensitivity to alpha particles by sanding or milling the case untill the junction is almost exposed. Having seen that the package of TEMDs can be easily removed I prised part of the cover and investigated the bare junction. It is critical that the golden wire bonding the semiconductor plate with an electrode remains intact. Such exposed PIN diode may become useful in measuring alpha radiation, which is stopped almost by everything. In such case the detecting element cannot be separated from the source, but rather kept in an isolated environment with it.

TEMD photodiode before delidding

First attempt to remove the cover, notice the air bubble present underneath it

Final result of the modification

Remaining part of the cover providing that the bonding wire remains intact -

Designing and simulating the final version

05/03/2019 at 19:42 • 0 commentsAfter a long time spend testing and thinking about the right solution to all the problems, I have made multiple alterations to the current prototype. Some of them require a different design, so the new board including these signal processing units should be produced soon.

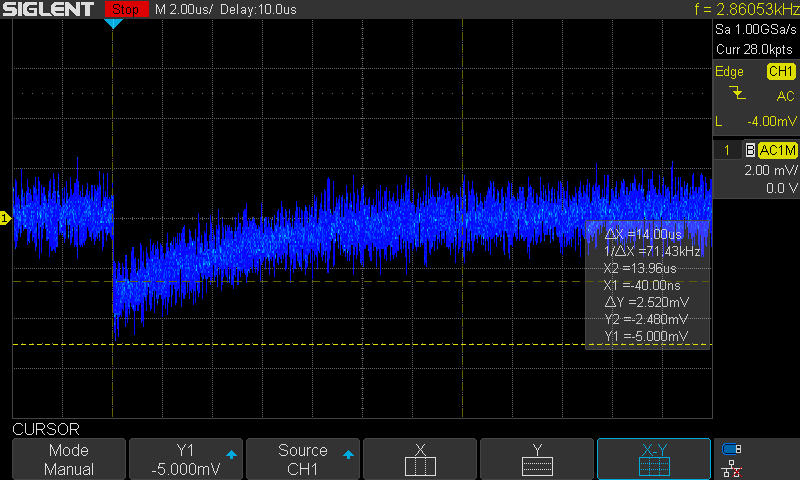

Noise figures

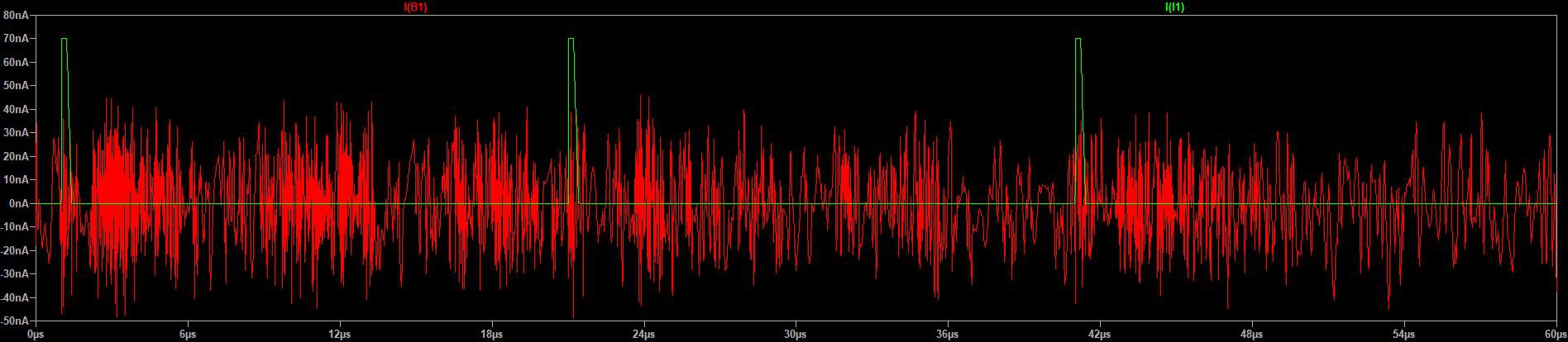

Almost all of the simulations I performed in LTspice were noiseless. The output signals were neat and easy to process. To consider a more real case I added a white noise signal to the output of the preamplifier so that it resembles 60keV pulses. After picking the right values I ended up with pretty dense noise of 8 mVpp and exponentially falling pulses of amplitude 2.5mV below noise floor. Such subtle changes rendered the old simulation completely useless. The old smooth signal was replaced with spiky and indistinguishable fluctuations. In the old version of the circuitry you could easily see that the peak value was repeatable, now it will be a lot harder.

Exemplary real case pulse (notice bandwidth limitation to 20MHz, reconstructed pulse has proper noise value)

Reconstructed pulse in LTspice Updated approach to signal processing

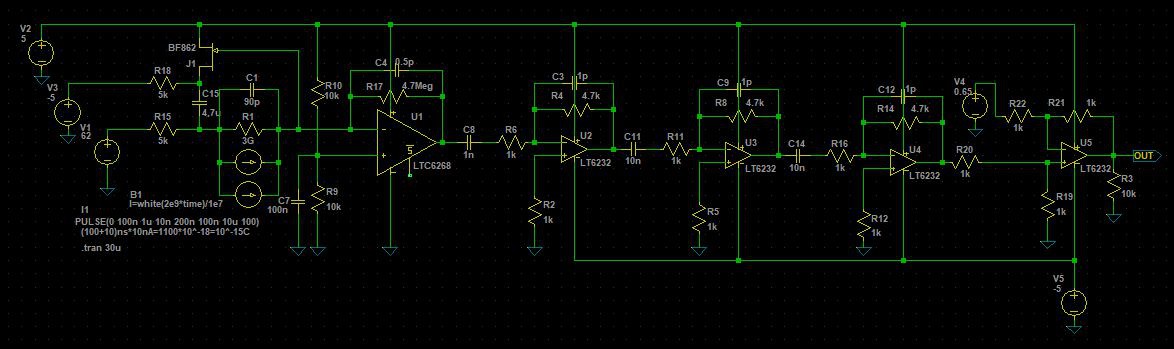

Because of all that noise present in the signal I had to redesign the whole signal path. It will no longer have any subtractors or rectifiers which would have to be set individually. Instead there will be some new blocks, which will help to extract and measure the peak from the ever-present noise. Here is a detailed schematic:

Schematic - Starting from the left the preamplifier feeds the signal to an inverting amplifier which is a preset subtractor. It reduces the DC of the signal close to 0V by subtracting the operating point of the amplifier which is about 2.45-2.50V. By this treatment the signal is ready for further processing without any undershoot that would be caused by capacitive coupling if we chose to use a capacitor to cancel the DC.

- Next functional block is 4th stage Bessel low-pass filter implemented using Sallen-Key topology. The gain of the whole filter block is set to 50V/V and the corner frequency to about 100kHz. Its aim is to reduce the high frequency noise and shape the pulses so that they resemble gaussian ones. The delay and overshoot are crucial for this application as well as variable gain that can be suited to application. Because of these reasons Bessel type and Sallen-Key topology is used. To design these filters, I used online calculators available from Analog Devices and Texas Instruments.

Notice that after the first stage the signal is fed to the comparator segment for further processing. It is necessary for the comparators to work with quickly shaped signal without huge distortions in order to give reliable results concerning pulse duration and its rising slope before it is properly shaped and prolonged.

Pulse shaping by filters

- From the filters the signal is fed onto the baseline restorer which function is quite peculiar. Baseline restorer recreates input pulses removing any undershoot from the signal and providing pulse output height in response to the input signal level difference. With a proper baseline restorer any subtractors become obsolete and high dose rates can be handled without any errors caused by a temporary baseline shift.

- The finishing stage of the signal path is a fast peak detector with reset. This time it is based on common amplifiers. Despite the fact it is fast and accurate. Its topology is extended to prevent capacitor discharge through rectifying diodes. Another addition is a digital switch serving as a reset, which will be triggered by MCU.

Baseline restorer and peak detector signals

Below the analog signal processing path is the semi-digital segment responsible for pulse detection:

- The signal from the fast filter is AC coupled and inverted so that comparators can work with positive pulse without any DC. The undershoot does not play any significant role in this segment, because the amplitude is not that important as long as it is above a certain level. This buffer block is not absolutely necessary, but it was placed to meet an even number of operational amplifiers in the design.

- Conditioned signal is later supplied to a non-inverting comparator with hysteresis that acts as pulse duration indicator.

- Before the second comparator input a differentiator block is placed. It is adjusted to quickly go into negative saturation as soon as a rising slope is detected. Following this differentiator block is an inverting comparator with hysteresis, which translates the analog op amp signals into digital states, indicating rising slope.

Comparators response signals This double comparator block job is to detect pile up and send trigger signal to the MCU. If there appear at least two rising slope pulses while pulse duration is still triggered the MCU will not measure such pulse, as its height certainly was affected by occurring pileup. The exact values of components in the third prototype have to be yet properly calculated and checked. Voltage sources present in the simulation are for ease of altering the parameters and will be replaced by voltage dividers stabilized with a capacitor in the practial design

Detector resolution with noise

Observing the output signals that will be later sampled by an ADC it is easy to notice that even the same energy signals end up represented by different voltage levels. It is due to significant noise amplitude that affects the actual peak value. Even with the low-pass filters the fluctuations in the signal remain and error is still present. This causes the spectrum of certain energy to be spread and not visible as a single bar in the graph. The main source of the noise are PIN diodes and the preamplifier. By changing the detector to a photomultiplier tube with scintillator I might be able to improve the resolution, but that Is yet to be tested. Currently the circuitry of the detector will be tuned to minimize the noise impact on the pulse readout, having in mind that semiconductor detectors have their limits.

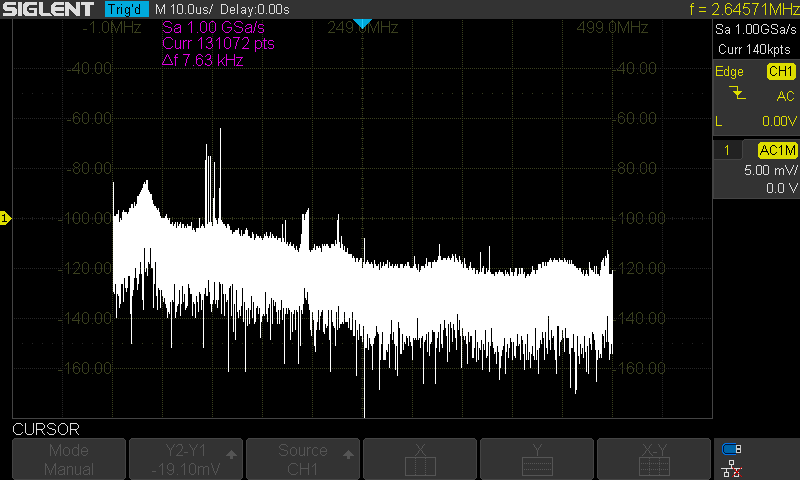

One way to minimize the distortion in the pulse is to increase the feedback resistance in order to extend the pulse duration and eliminate the high domain frequencies using a low-pass filter. It proves itself effective as far as simulation is concerned. On the one hand it reduces the amplitude spread and noise distortion, but on the other increases dead time of the detector. The detector is also extremely sensitive to electromagnetic interference and RF signal coming from the radio stations and BTS. Radiation pulses are in low frequency domain and in order to measure them without greater distortions a low pass filter is absolutely crucial.

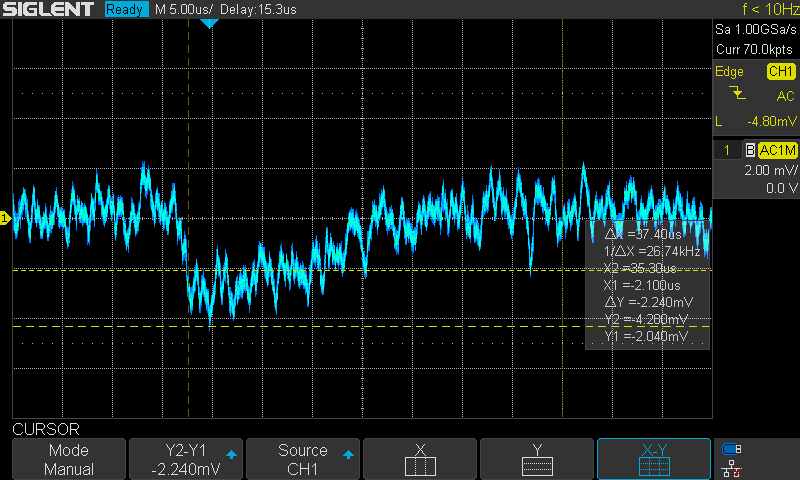

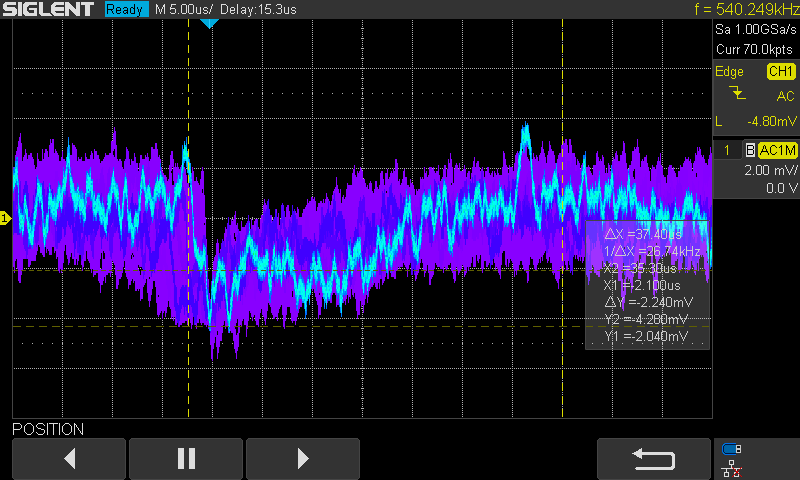

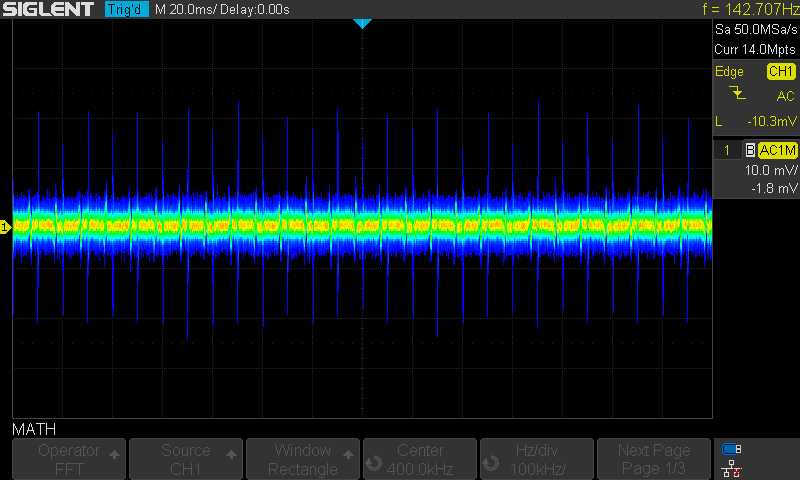

FFT of preamplifier output signal Preamplifier with LMP7721 test

To check if a lower GBW and lower noise operational amplifier would improve the TIA stage I performed a few tests with LM7721. The presets were similar to the 1 diode tests with bootstrap and LTC6268. The noise frequency was lower due to the bandwidth limitation as LMP7721 GBW is only 17MHz. The overall amplitude of the pulse was about 2-2.5mV below noise floor which was quite the same in comparison to LTC6268. The parameters have not changed in any favorable way. The TIA design will remain with LTC6268.

LMP7721 single radiation pulse

LMP7721 radiation pulse collection Triple amplifier tests

To verify how simple amplification affects noisy signal I mounted amplifiers in the prototype and set overall gain to about 250V/V. From the screens taken you might see that the dense noise is not amplified because of the limited GBW of used amplifier (LT6232). Furthermore, there is an undershoot visible as amplifiers are connected through a capacitor. On the whole, even common amplifiers provide some kind of filtering that removes the high frequency noise. Sometimes the simulation in LTspice may provide too ideal data, and signals resembled without including the imperfections of the components, design, amplifiers or parasitic effects. I hope that some imperfections may actually improve the signal to noise ratio, but that will be verified in the third detector design.

Pulse after 3 stage amplification

Noise amplitude comparison top: 3x amplification bottom: TIA output -

Measurements, conclusions and upgrades preceding the third version

05/02/2019 at 19:40 • 0 commentsEvaluation of the preamplifier stage

To achieve the best resolution possible the charge sensing stage and its response had to be tested against various feedback resistance values. To conduct these tests, I used a source with known energy emissions. The only one I could easily acquire was Americium-241 from dismantled smoke detector. According to the Table of Radioactive Isotopes the detector should get readings of photons of energy of about 60keV (59.5412keV) which makes up for 35.94% of Am241 emissions.

Am241 from disassembled smoke detector mounted on a metal plate Having a stable source, I was enabled to perform a reliable comparison while altering the circuitry.

Bootstrap circuit alteration and efficiency

As mentioned in previous logs I am trying to implement a bootstrapping circuit to be able to work with bigger – high capacitance detectors. Unfortunately, BF862 - the JFET used in the application note concerning bootstrapping is no longer manufactured. Moreover, the whole family of BF86X has been declared end of life. Although you might still come across it in some local shops, I had to find an equivalent to keep the project up-to-date. After a bit of searching the best, I could come up with was CPH3910 from ON Semiconductor. It has quite similar parameters and should be a fit substitute.

To verify whether the bootstrap improves of degrades sensitivity I performed a few tests. The tests were performed in two configurations using 1 and 10 sensing diodes, respectively with and without bootstrap. With following presets: Source: Am241 (60keV), Rf = 22M, Cf = 0.47p, Oscilloscope BW = 20MHz and operational amplifier LTC6268. Notice that the values marked with the cursors are the ones that repeated the most – the most probable.

The first test: 1 PIN diode:

Without bootstrap - Bootstrap inactive

Collected pulses, one diode, without bootstrap With bootstrap - Bootstrap active

Collected pulses, one diode, with bootstrap In the one diode case the bootstrap had little impact on the signal quality because of the small diode capacitance. But from the noise figures I could read that it improved the low frequency components of the signal, which are more significant as the radiation pulses are in this domain. The pulse height did not change significantly enough in any way for me to notice. On the screen from oscilloscope you might see a trace of a high energy pulse, but that was probably just some random emission from the source which

I don’t want to misinterpret. Maybe the bootstrap might have enabled the preamplifier to capture it.The second test: 10 PIN diodes:

Without bootstrap - Bootstrap inactive -preamplifier unstable:

Collected excitation pulses, circuit unstable, 10 diodes, without bootstrap With bootstrap - Bootstrap active

Collected excitation pulses, circuit unstable, 10 diodes, without bootstrap Whereas in the 10-diode scenario the circuit was unstable without the bootstrap. It started to generate regular spikes as a form of excitation. After applying the bootstrap, the preamplifier became stable again. I checked the stability twice and in each individually assembled prototype the situation was the same. Even increasing the input capacitance did little to reduce the spikes of excitation, not to mention that it drastically decreased sensitivity. After returning to the preset feedback capacitance of 0.47pF and mounting the bootstrapping JFET the circuit once again detected radiation pulses. The bootstrap has helped to handle the capacitance of the diodes so that the amplifier excitation criteria was not met. Examining the captured pulses, it is clearly visible that 10 diodes introduce greater noise. Distortions amplitude has increased and there are greater fluctuations in the noise baseline. Despite the increased noise the undisturbed pulse height (below noise floor) remained approximately the same as with one diode. I also noticed a tendency that greater energy pulses start to become visible after the bootstrap was applied. It speaks for the usefulness of it.

To sum it up, from the tests it can be seen that the bootstrapping circuit:

- Increases the sensitivity and stability of the preamplifier

- Alters the noise spectrum so that low frequencies become more exposed

- Can be applied even for low capacitance scenarios without signal degradation

Because of these advantages the bootstrapping circuit will be used in further detector development.

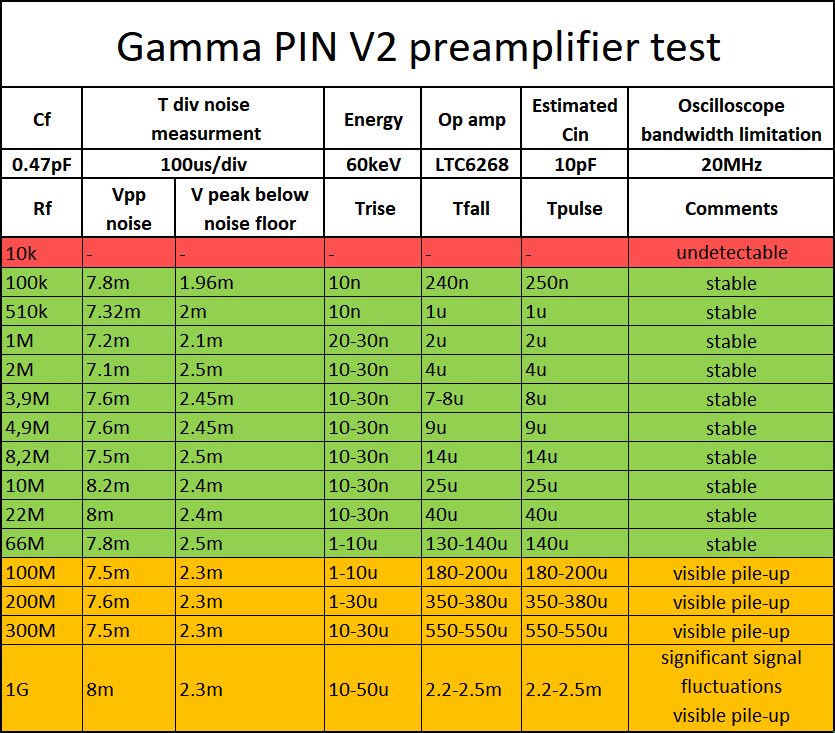

Feedback resistance impact on the amplitude and shape of the pulse

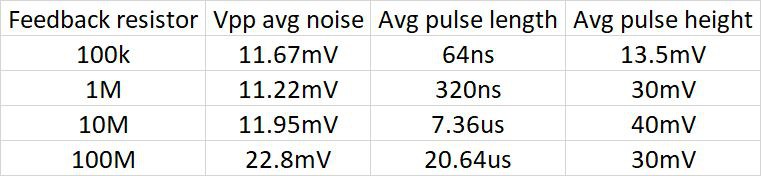

To understand how the feedback resistor influences the pulse, I performed a sweep of Rf values starting from 10k to 1Gig. The data gathered included: Vpp noise, pulse height below measured noise floor, pulse length. Most of these measurements were performed in display persist mode. After a while of collecting pulses or noise, the average (most repetitive) value was measured and saved. I am aware of the inaccuracies of this method, but in a random phenomenon like radiation this was the one I found at hand. For the tests the oscilloscope bandwidth was limited to 20MHz so that the pulses were visible more clearly. Response was measured with one diode and presets as mentioned before.

Experimental setup Radioactive source application

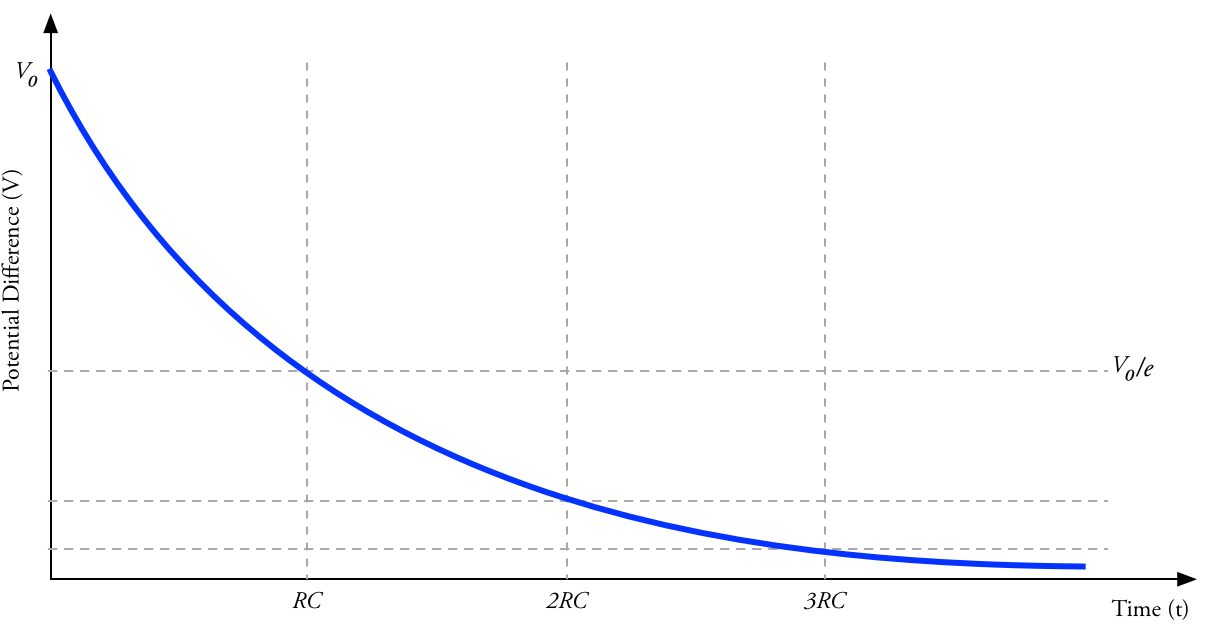

Measurements and results From the data gathered it is visible that above certain value the feedback resistor does not increase pulse height and signal to noise ratio remains approximately the same. What it does change is the pulse duration and length of the pulse tail. The pulses have a characteristic shape of a capacitor discharge curve with a steep charge moment. From this shape and the constant peak amplitude I assume that the transimpedance amplifier works in a different way than expected before.

Capacitor discharge curve

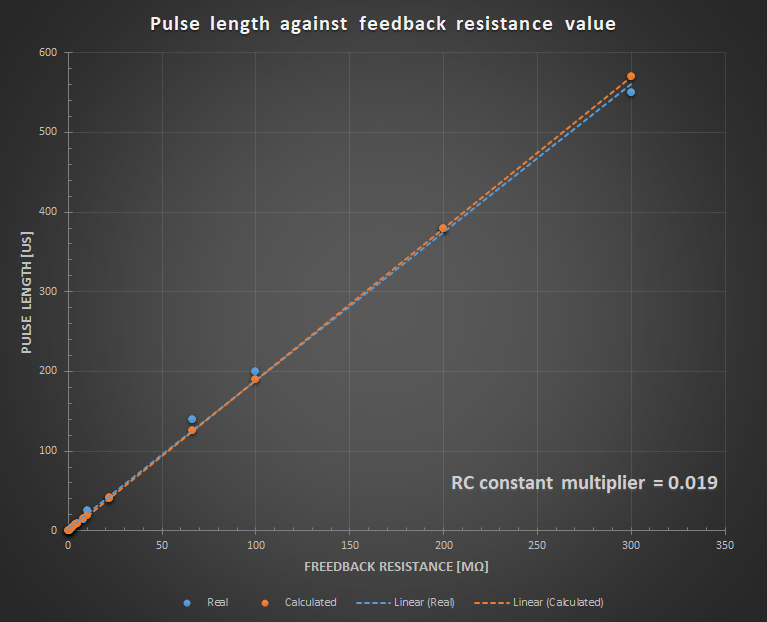

Exemplary captured pulse Due to huge feedback resistance values and capacitances connected to the op amp it works as an integrating amplifier. It is unexpected but yet very useful, because integration delivers the exact information about energy of a particle or photon. The charge injected and deposited from radiation is equal to the peak value of the pulse from the preamplifier. The detector behaves as a capacitor with random charge injections. To verify if the first stage of the detector follows the typical capacitor discharge curve, I created a graph. It shows linear dependence of the pulse length from the feedback resistance value. The measured values differed from the ones calculated from the estimated values. But after applying a RC multiplier the two series of values almost covered one another.

Having this graph, estimation of the pulse duration and the dead time of the detector will be easier.

Pile-up effect

When the feedback resistance value was pretty enormous and thanks to it pulse, length was extended. I could observe pulse pile-up, which introduced misrepresentation of pulse amplitude. When baseline is shifted in some way the pulse readout becomes useless and the detector can only count them. To prevent this from happening feedback resistance has to be adjusted so that the dead time would not be too long to choke the detector neither too low to degrade the signal to noise ratio. In the oncoming third version of the detector this obstacle will be addressed with a proper baseline restorer solution and a rising slope detector.

Visible pile-up

Visible baseline shifts due to pile-up

-

Improvements to the second design

10/06/2018 at 12:24 • 0 commentsThe first prototype is quite fine but it has some errors that I noticed during the assembly and testing. The detector will be still developed. I hope that the second version will be satisfactory enough to meet the requirements for the first spectroscopy. During the tests I became acquainted with the STM32 ADC and DAC. The detector is so sensitive that uploading the program to the development board caused oscillations. Having noticed this to prevent additional digital noise I decided to use non-volatile programmable potentiometer. Once the value on the MCP4161 is set. It will be disconnected to except any distortions from the signal busses. I am currently working with NUCLEO-H743ZI but after the prototyping is finished the detector should run with a “Blue Pill” board featuring STM32F103C8 microprocessor that should handle everything easily.

Things to improve:

The signal processing

- In the first version the pulse from TIA is simply amplified three times and then "lowered" so that only the meaningful peaks are positive. Then they are acquired by the ADC. Apart from the desired signal, the noise is also amplified. It results in distorted and spiky pulse with very short peaking time, blurred amplitude and unnecessary restriction of op-amp amplitude range. The capacitive coupling of the inverting amplifiers also causes massive undershoot and tail oscillations, that disturb the baseline and amplitude of the following pulse.

Signal after amplification with visible distorted peak

Signal after amplification with visible tail oscillation - baseline fluctuation - To avoid the pulse distortion the noise floor should be removed first and then the resulting peak should be shaped to resemble the gaussian function. It can be done by using 3-4 op amps just by changing the order of the processing. First there should be a subtractor that will "lower" the signal in order to make only the significant pulses negative. Then the signal is fed to an ideal negative rectifier based on another op amp. Finally, it's processed by double Sallen-Key filter which serves as Gaussian shaper. After these alterations the signal is connected to the acquiring segment by a single decoupling capacitor so that its normal level is around 0V.

- The simulations with the described above configuration nicely visualize the signal processing. To improve accuracy in the LTspice model I added a white noise current source in parallel. It should resemble the thermal noise of the semiconducting PIN diode.

Old version simulations with noise

V1 prototype with noise source added

Current pulses with noise background

Singal after processing with V1 simulation model

Signal after substraction New version configuration

V2 simulation schematic

Signal after the first stage of substractor and rectifier

Previev of the signal shape through the circuitry

Output signal suitable for farther processing Supply filtering

- Fast, wide bandwidth op amps and comparators generate interference that unfortunately excites more sensitive parts. The whole detector is extremely sensitive to any change of charge. The additional pulses generated by switching caused it to oscillate. At first, I thought this was caused by the high integration of the board and crosstalk. But in the end, it turned out to be just lack of decoupling capacitors, that easily prevent the excitation. The few capacitors placed at the distant end of the board were not enough.

- To solve these instability issues, every integrated circuit supply node will be powered through a 100 ohm resistor with two capacitors attached. One ceramic 100nF and one tantalum 4,7-22uF placed as close to the pins as possible. It may seem overengineered but it is neither an expense nor it would have saved lots of space on the board.

Set of capacitors, each connected to its own IC

- To solve these instability issues, every integrated circuit supply node will be powered through a 100 ohm resistor with two capacitors attached. One ceramic 100nF and one tantalum 4,7-22uF placed as close to the pins as possible. It may seem overengineered but it is neither an expense nor it would have saved lots of space on the board.

Compatibility

- My aim is to make this detector an accessible tool to measure and analyses radiation. Therefore, I have decided to switch from quad op amps to dual ones in MSOP-8 (V2 will include AD8002) package (with common AD pinout). It will enable a wider range of cheap replacements that will be later suggested for any widespread distribution or testing. There will be also an extended solder pad to mount the TEMD photodiodes too. The long array will have a V-cut at the end so that it could be snapped to install bigger detecting diodes horizontally closer to the TIA stage.

The case of undershoot and baseline restoration is still open and it will be verified whether the removal of the coupling capacitors and inverting amplifiers has solved the issue. If not, there are some proposed solutions in the nuclear research papers. Another thing to consider is addition of pile up rejection circuit and coincidence detector.

- In the first version the pulse from TIA is simply amplified three times and then "lowered" so that only the meaningful peaks are positive. Then they are acquired by the ADC. Apart from the desired signal, the noise is also amplified. It results in distorted and spiky pulse with very short peaking time, blurred amplitude and unnecessary restriction of op-amp amplitude range. The capacitive coupling of the inverting amplifiers also causes massive undershoot and tail oscillations, that disturb the baseline and amplitude of the following pulse.

-

Tests and measurements of the V2 prototype

09/07/2018 at 15:28 • 0 commentsAs the boards arrived I started the assembly of the first prototype. The power filtering first and then the sensing and the transimpedance sections. There was a serious mistake in the BPW34 Eagle library - dot marking the anode was at the wrong side of the part. Unfortunately a few of the diodes were damaged after I found the cause.

Proper TIA feedback resistance value

Currently I am focused at the TIA stage and the proper signal processing. With a live working detector, I am able to measure the real data and see the simulated circuit in the real conditions. There is a significant dissonance between the simulations and real circuits in this case.

Here are some results I gathered with a few Rf values:

I also conducted tests with the value of 1 Giga Ohm, but no pulses were detectable even with the radioactive source present. The op amp that was used (LTC6268) had a bandwidth of 500MHz, there is also an upgraded version of it with the BPW of 4GHz, I hope to test it soon and see if the optimal working point will shift upwards in favor of greater resistance values. From the data gathered I estimated that the Rf value should be somewhere between 1-10M Ohms. I guess aiming at the 2,2 to 4,7M will provide the pulses of length about 1us with the sufficient amplification and sensitivity - ideal for subsequent processing.

Noise issues

The new detector design is extremely sensitive to noise. The PIN diodes generate a lot of it and additional high voltage sources like energy saving lightbulbs or CRT affect it and distort everything. The simple switching of a soldering station renders a spiking in the signal. The shielding is an absolute necessity unless the circuit is enclosed in a grounded metal case where the measurements will take place. The noise level is about 12mV peak to peak, but still the pulses are distinguishable, which is nice.

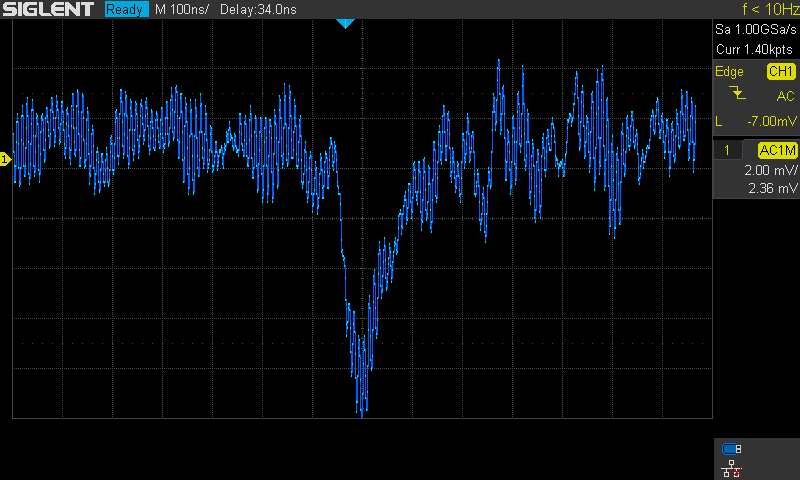

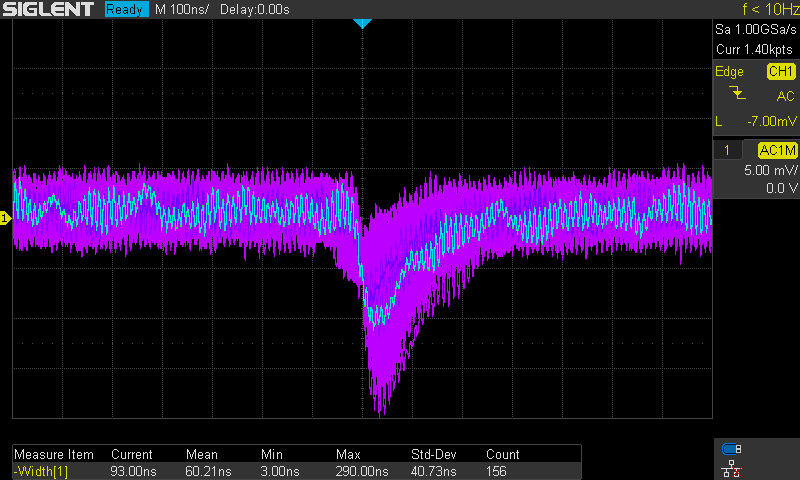

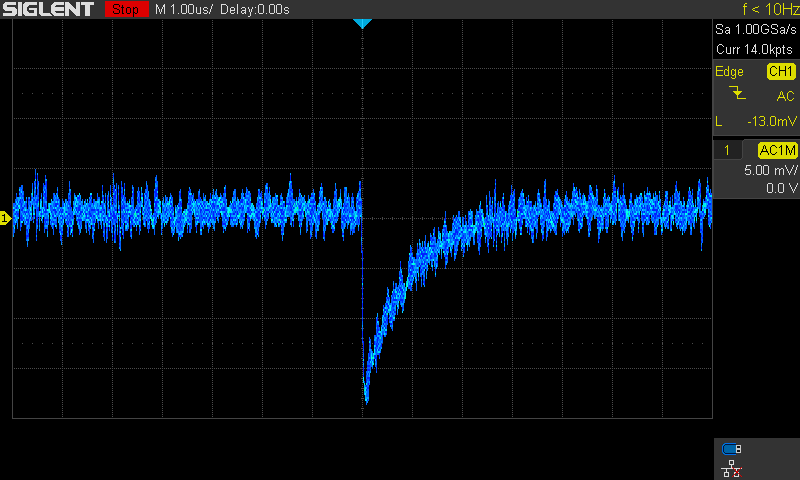

I am thinking of a new way to process the signal to prevent the undershoot and eliminate the constant noise level at the early stage by a simple subtractor and ideal rectifier circuits made with op amps. Then an additional stage of two Sallen-Key filters acting as a gaussian shapers and the signal would be ideal for acquisition.Rf = 100k measurements:

Rf = 1M measurements:

Rf = 10M measurements:

Rf = 100M measurements:

-

Finished new prototype design

08/21/2018 at 09:24 • 0 commentsAfter two weeks of designing the PCB and optimizing all the routes I finally managed to send the Gerber files to manufacture. As previously mentioned I wanted the board to be in a shape of a thin stripe, so the result is board with all components on one side having dimensions of 160x11mm. Whole design is with regard to parasitic capacitances, that should be minimalized to allow the best performance.

The detecting "stripes" may later be aligned to form a multi-layer matrix to perform some particle trajectory or coincidence research. I have aimed to make it quite universal so there is a dashed line where the board may be cut to solder the photodiode in right angle. There is also an option to bypass the MCP4161 by connection its 2nd and 6th pad which are in a straight line and use external DAC to set the noise cancelling level.

Board design

Gerber files view I ordered 50 boards from the JLCPCB, so if you want to test this design contact me and I may sell some to you. The schematic includes all the blocks mentioned in the description and some additional capacitors for filtering the power lines. The power stabilizers and IC are to be located on external board from which all the stripe detectors will be powered all together.

Schematic of the next prototype In a few days’ time when I get the boards I shall begin assembling the detector stage by stage to test it all. I have acquired all the necessary parts and am ready to proceed to the next stage.

Parts for the assembly -

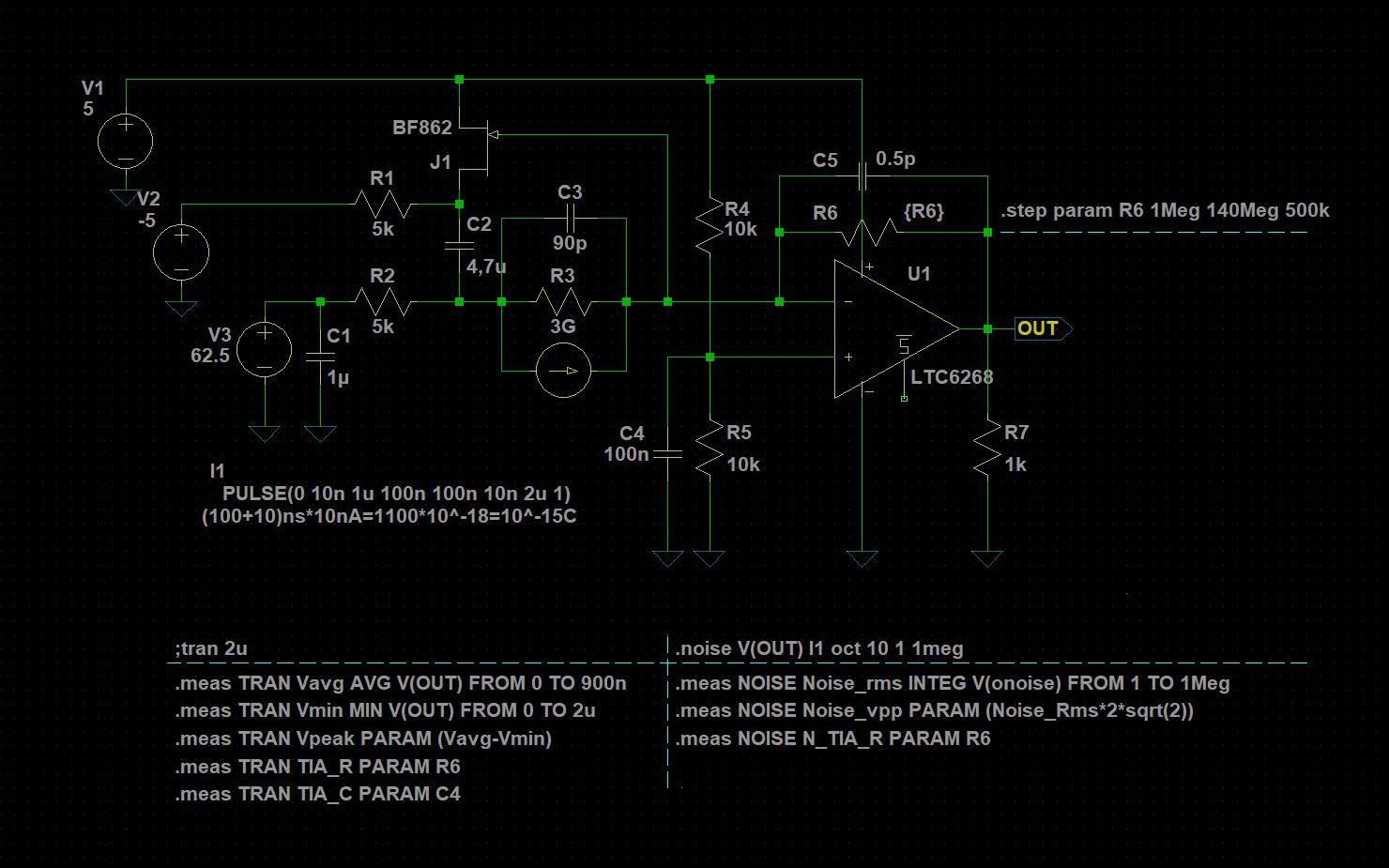

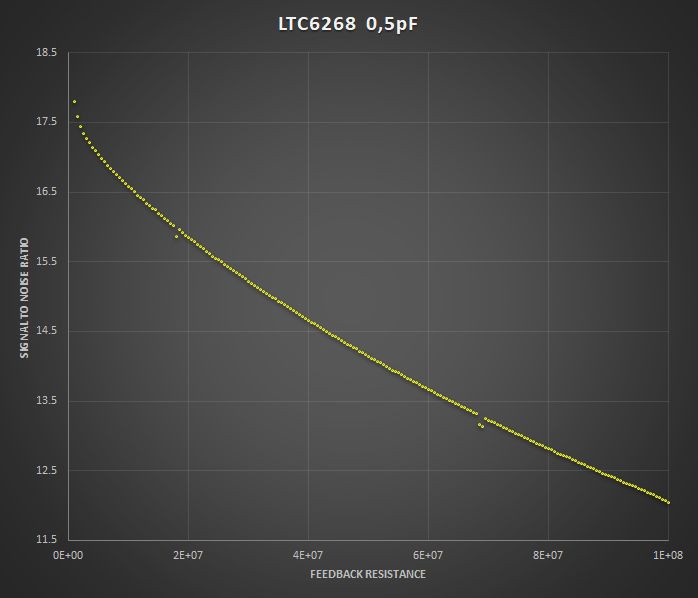

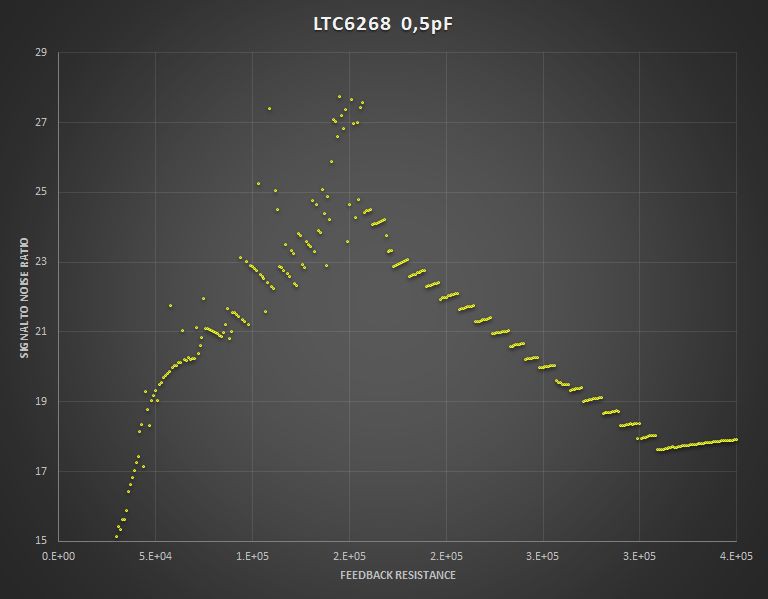

Inconclusive simulations

08/01/2018 at 12:00 • 0 commentsRecently I have tried to simulate the transimpedance amplifier once more to optimize the components for the best singal to noise ratio. This proportion is mostly affected by the feedback resistance, which determines how large the output signal will be. The additional feedback capacitor shuld be kept at lowest value preventing the op amp from disastrous oscilations.

Simulated circuit The pulse coming from the detector had an estimated length of about 300ns and carried charge of one femto Coulomb. The feedback resistance was stepped in two scopes one ranging from 1M-100M. The other one was more focused on the peaking that ocurred in the scope 10k-350k. For resistances greater than 140M the simulations didn’t provide any reliable or sensible results. Results of this analysis also varied with the noise integration range. For this case I have set it to be from 1Hz-1MHz.

Rf: 1M-100M scope

Rf: 10k-350k scope

Estimating results even in the simulations is really complicated as all the parameters are dependent on one another. This circuit needs to meet a few criteria:- Huge amplification for the ultra low current pulses

- Highest possible SNR - Signal to noise ratio

- Wide bandwidth to amplifiy even the shortest events and measure high doses

This simulation does not include the thermal noise coming from the photodiode and the numerical analysis has its limitations. In the range of extremely large resistances or low currents it is unwise to relay only on them. Even though I ran lots of simulations still the results varied depeding on the scope. Finally, I decide to design the board and work on the prototype to pick the optimal values. One part after another I will assembly the detector and gather the data that earlier I could only estimate without certainty.

The first examination will focus on the TIA - transimpedance amplifier . I intend to focus on the feedback resistor to see what results provide various resistors starting from 100k to 1G. I'm also curious about the noise from the photodiodes.

If you have any suggestions about the simulations I am open to any discussion as it feels a little bit as if I was walking in the dark. I wish I could find one and only optimal value for the TIA, but the whole thing seems to be floating. Maybe PSpice has some better numerical analysis or tools, but unfortunalety the LTspice models/libs are coded and availible only for LTspice.

-

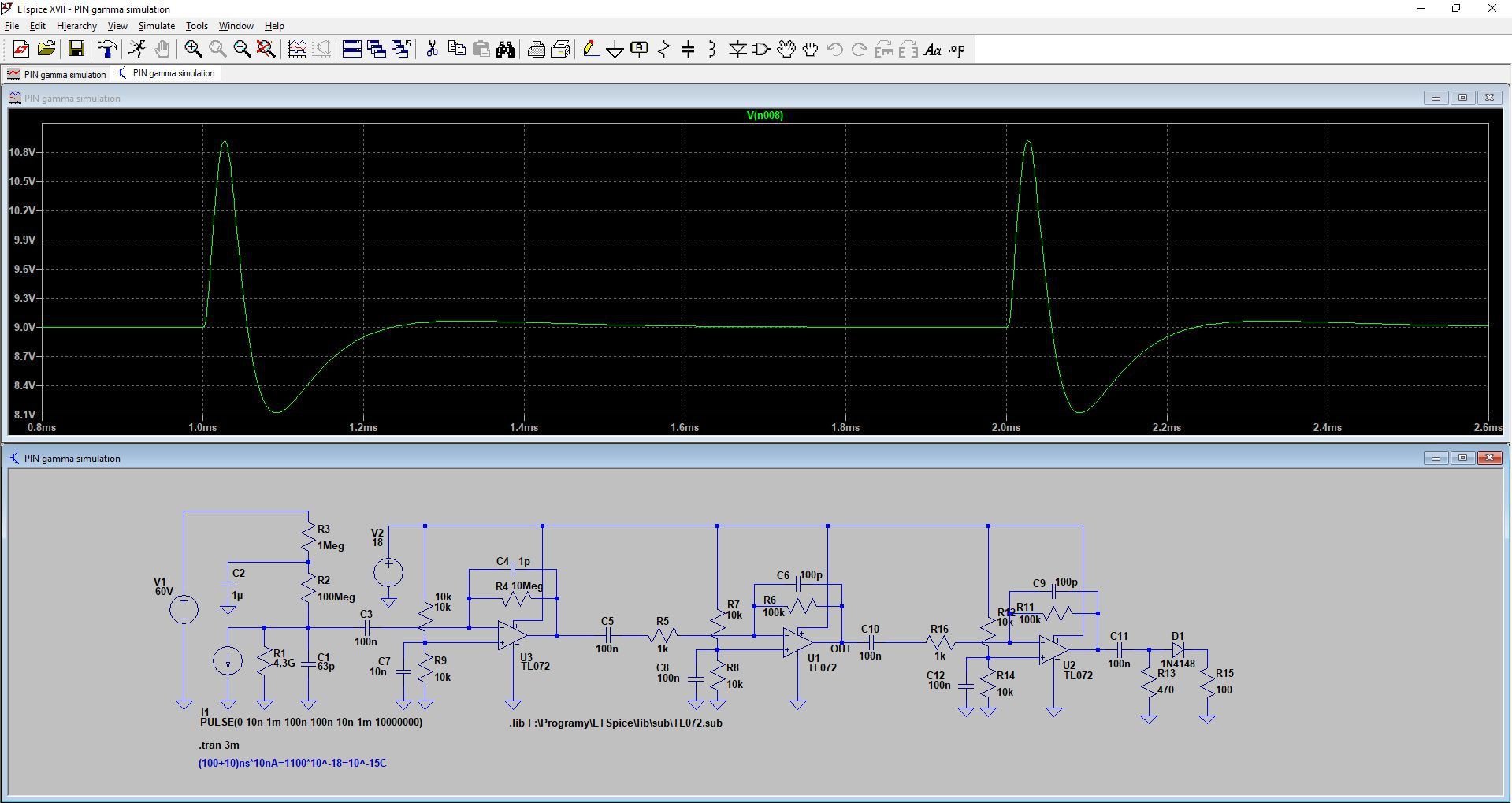

Evaulation of the old prototype based on TL072

07/28/2018 at 15:16 • 0 commentsThe early stage prototype of the detector was designed to have an array of about 50 PIN diodes.

To distribute them equally I divided the array into 7 rows with 7 diodes each. Every single row had

it’s own sensing amplifier construced using TL072. This common and easily accesible solution was supposed to give me an insight to futher work with this kind of detectors. The design was preceded with simulations in LTspice to check what results may I expect.

LTspice Gamma PIN prototype simulations

Early stage TL072 design

This prototype was created in a wafer fashion to make it smaller and stackable. The power supply was based on common step-up inverters using LM2577. By changing the feedback resistor they may work up to 65V. TL072 worked at 18V and diodes were biased by 60V. These power modules were shielded to reduce the noise emitted by the coils.

Whole device

Board footprint

Unfortunatelly, in the final stage of the signal processing there have occurred an error stopping the grid detector from functioning properly. The pulse signal is negative and in the circuit there is diode added at the output of the TL072. It was supposed to prevent the signals from mixing if they were positive. This awful mistake is still present in the PCB files. If you wish to test your own detector make sure you have replaced the diodes with a proper solution that would stop the signals from interfering.

Schematic of the early design

I still managed to get use of the single row to measure some radiation. The first measurment was without any source. Even the background radiation managed to leave a trace, although the pulses were significantly smaller and happened less often.Low energy pulse coming from the background radiation

Image of the collected pulses through short time with no source present Then I placed a thoron mantle at the sensing area. Simultaneously the pulses were higher and more frequent. For a single singal trigger I didn’t have to wait even a second.

Detector with a thoron mantle placed upon it

High energy event - particle coming from thoron mantle

Pulses collected with the source present On the whole, this prototype has allowed me to focus on a few problems that will need to be solved:

- Noise and parasitic capacitance should be kept as low as possible. The whole instrument for proper working conditions, will have to be enclosed in a grounded metal chasis.

- The power supply circuits will need to be with reduced EMI and voltage ripple. This induces

me to use charge pump voltage regulators, which should be suitable for the job. - For any future applications the single row detector should be made modular and portable to enable easy use. The sensor will be in a shape of a thin stripe with a connector at the edge.

The early design was quite a crude one. The second one is going to be well thought over to provide reliable results.

Gamma PIN - Semiconductor Radiation Detector

An attempt to design and deliver universal and accessible radiaton analyser to be used in nuclear spectroscopy