-

Micro-coded controller deep-dive

12/22/2021 at 20:35 • 0 commentsIn this project, instead of using a standard embedded processor and programming it to execute 3 tasks at hand (parsing HEX character stream, generating HEX character stream, and writing character stream to video RAM driving VGA), I created 3 independent micro-coded controllers, each tailored per task, and which can all operate in parallel. They can also be taken out of this project and dropped to any other needing that functionality.

Creating such controllers is possible in standardized way using mcc - microcode compiler. The simplest of these is the tty_screen which was up and running in one afternoon. Here are the suggested steps.

(before digging in, reading this log could be useful to explain some microcoding basics and how they are leveraged in my standardized / parametric approach)

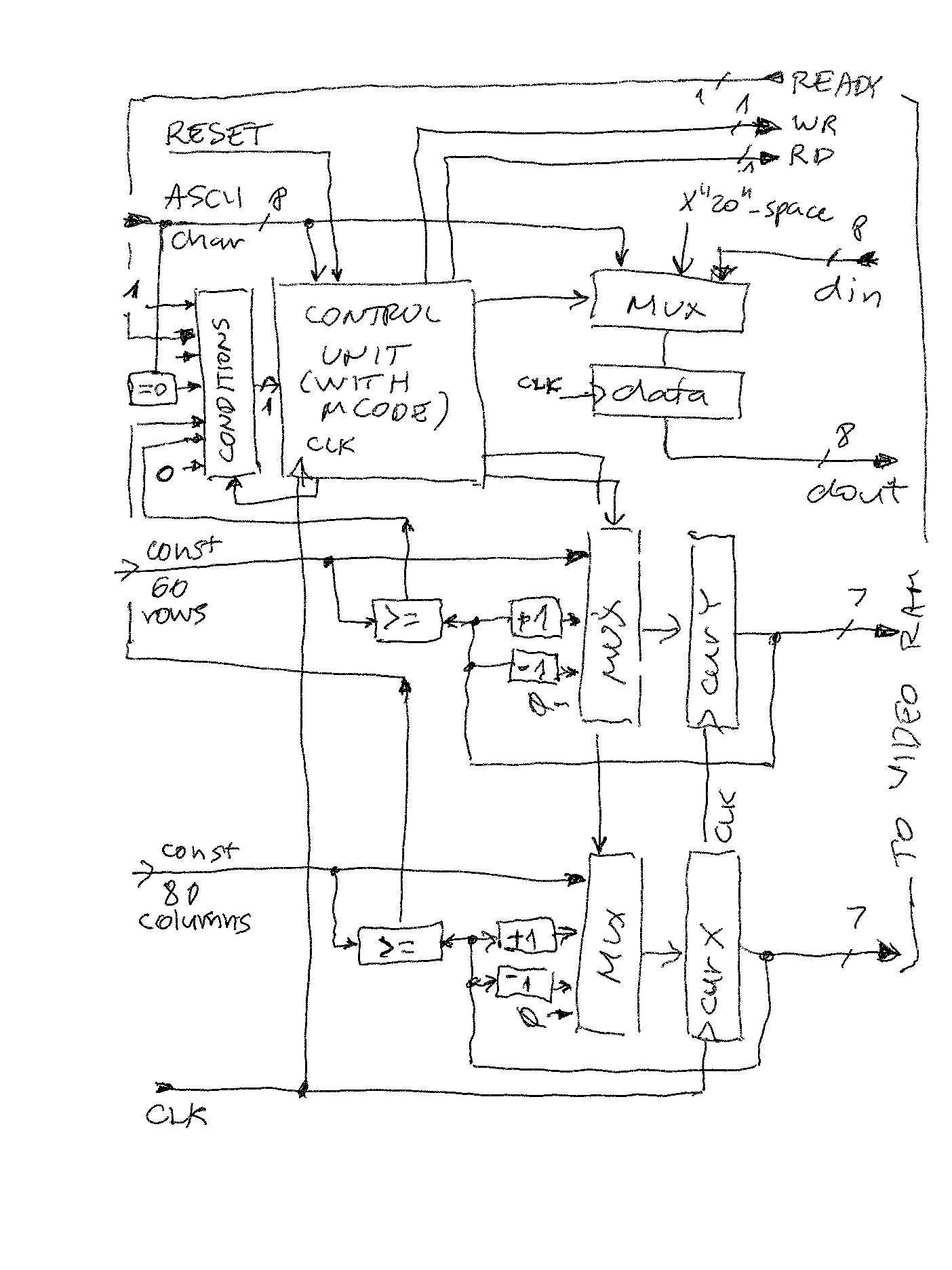

Define a high-level / draft design

![]()

It should be obvious that this is a custom memory access circuit, where the memory address is given by cursor X and Y positions which can go from 0..79 and 0..59 (for 640*480 VGA with 8*8 pixel font, actual VRAM address is A = 64Y + 32Y + X). Data written into the video RAM is either coming from ASCII char input, or from video RAM (in case of scroll). In the simplest case operation is VRAM[Y,X] <= char; X++; Of course when X reaches rightmost position, X <= 0; Y++; and when Y reaches bottom row image is scrolled up. There is also handling from CR, LF, CLS etc. (for example CLS is nested loop of X, Y: VRAM[Y, X] <= 0X20; (space)

Few things to note:

- no need to worry about the internals of the control unit - it will be auto-generated with all the right parameters

- it is good to define all the registers and where they will get their values from (other registers, external inputs), or from some ALU operations

- control unit will drive a conditions code MUX, because it eventually only consumes true/false at each instruction for executing either the .then or .else part - this conditions should be enumerated to find out if 4, 8, 16 or more will be needed

- control unit and internal registers are driven by same CLK (rising or falling edge is not important, but typically should be same)

- typically only the control unit consumes RESET, other parts can be initialized under microinstruction control

- control unit drives itself and the rest of the design, via direct signals (e.g. RD/WR in this design) or selecting MUXs in front of registers ("RTL")

- condition control bits can come from inside of the design (e.g. comparing registers with zero etc.) or outside (e.g. memory READY), or any logical combination of those

- signal width are good to note, but can be changed, they are not reflected in microcode

Define instruction register use and width

For a classic CPU, IR holds the currently executing instruction from the program stream. This controller processes ASCII stream, so it is useful to define the IR as currently processed character. If we care about 7-bit ASCII, that means 7-bit IR loaded from input 8-bit data input (MSB can be ignored). If char == 0x00 (NULL), that means no character to write to V-RAM.

Instruction register output is connected to mapper memory address (see here), defined as:

// mapper size is 128 words (as 7-bit ASCII code is used as "instruction") by 6 bits (to point to 1 of 64 microcode start locations) // also generate all memory file formats. Note prefix: for .vhd, which is used to prepend to all generated aliases and constants // this way multiple microcoded controllers can coexist in the same project even if their microfield have same name .mapper 7, 6, tty_screen_map.mif, tty_screen_map.cgf, tty:tty_screen_map.vhd, tty_screen_map.hex, tty_screen_map.bin, 1;Looking at the generated tty_screen_map.hex file it becomes obvious that this is an auto-generated lookup table:

: 01 0000 00 0A F5 : 01 0001 00 0B F3 : 01 0002 00 12 EB : 01 0003 00 0A F2 : 01 0004 00 0A F1 : 01 0005 00 0A F0 : 01 0006 00 0A EF : 01 0007 00 0A EE : 01 0008 00 0A ED : 01 0009 00 0A EC : 01 000A 00 13 E2 : 01 000B 00 0A EA : 01 000C 00 0A E9 : 01 000D 00 21 D1 : 01 000E 00 0A E7 : 01 000F 00 0A E6 : 01 0010 00 0A E5 : 01 0011 00 0A E4 : 01 0012 00 0A E3 : 01 0013 00 0A E2 : 01 0014 00 0A E1 : 01 0015 00 0A E0 : 01 0016 00 0A DF : 01 0017 00 0A DE : 01 0018 00 0A DD : 01 0019 00 0A DC : 01 001A 00 0A DB : 01 001B 00 0A DA : 01 001C 00 0A D9 : 01 001D 00 0A D8 : 01 001E 00 0A D7 : 01 001F 00 0A D6

All special ASCII codes point to microcode location 0x0A because they match via .map pragma the location of following microinstruction:

.map 0b00?_????; // special characters 00-1F are not printable, so just ignore nextChar: ready = yes, if char_is_zero then waitChar else repeat;But for example char 0x01 (CLS == clear screen) points to 0x0B as that one is mapped right after:

.map 0b000_0001; // 0x01 SOH == clear screen CLS: data <= space, cursory <= zero;Given that .map supports simple pattern matching using ? to indicate "don't care" bits, and .map can be "layered" (from less specific to more specific matches) this allows complex instruction decoding in a very simple way.

Final piece here is "fork" control unit command. When executed, the uPC (micro program counter) is simply loaded from the mapper memory output, and next uI (micro instruction) is the start of the implementation routine:

waitChar: ready = char_is_zero, data <= char, if char_is_zero then repeat else next; if true then fork else fork; // interpret the ASCII code of char in data register as "instruction"Define microinstruction fields

Go over the design and indentify how many control signals each component needs, and if those control signals drive "registers" or "direct signals". For example:

CursorY register can be:

- cleared

- incremented

- decremented

- stay the same (no change)

- loaded with maximum row number

which translates to (note .regfield !!):

// Screen cursor Y position can stay the same, increment, decrement, or be set to maxcol cursory: .regfield 3 values same, zero, // top position inc, dec, maxrow default same;5 cases, for which we need 3 control lines. Default must be always specified, and that is "same" or "no change" - each microinstruction will have cursory <= same unless other value is specified.

The mcc compiler generates this code snippet:

alias tty_cursory: std_logic_vector(2 downto 0) is tty_uinstruction(11 downto 9); constant cursory_same: std_logic_vector(2 downto 0) := "000"; constant cursory_zero: std_logic_vector(2 downto 0) := "001"; constant cursory_inc: std_logic_vector(2 downto 0) := "010"; constant cursory_dec: std_logic_vector(2 downto 0) := "011"; constant cursory_maxrow: std_logic_vector(2 downto 0) := "100"; ---- Start boilerplate code (use with utmost caution!) -- update_cursory: process(clk, tty_cursory) -- begin -- if (rising_edge(clk)) then -- case tty_cursory is ---- when cursory_same => ---- cursory <= cursory; -- when cursory_zero => -- cursory <= (others => '0'); -- when cursory_inc => -- cursory <= std_logic_vector(unsigned(cursory) + 1); -- when cursory_dec => -- cursory <= std_logic_vector(unsigned(cursory) - 1); -- when cursory_maxrow => -- cursory <= maxrow; -- when others => -- null; -- end case; -- end if; -- end process; ---- End boilerplate codeThe labels are not commented out, meaning that design which includes this file will match the microcode source at all times.

library IEEE; use IEEE.STD_LOGIC_1164.ALL; -- Uncomment the following library declaration if using -- arithmetic functions with Signed or Unsigned values use IEEE.NUMERIC_STD.ALL; use work.tty_screen_code.all; use work.tty_screen_map.all;The sample implementation is commented out, it can be either copied over and uncommented, or left unused. mcc will even attempt to recognize usual operations as simple zero, and/or, inc/dec. These of course may not be most optimal, but will usually work and speed up development.

Video memory RD and WR signals are driven directly (note .valfield !!), plus they are also mutually exclusive which can be expressed with:

// video memory control bus, note that ordering of labels can be conveniently used to generate /RD and /WR signals mem: .valfield 2 values nop, // no memory access read, // mem(0) is RD write, // mem(1) is WR - // forbid read and write at same time default nop;So a 2-bit wide field will be needed.

Generated code:

alias tty_mem: std_logic_vector(1 downto 0) is tty_uinstruction(6 downto 5); constant mem_nop: std_logic_vector(1 downto 0) := "00"; constant mem_read: std_logic_vector(1 downto 0) := "01"; constant mem_write: std_logic_vector(1 downto 0) := "10"; -- Value "11" not allowed (name '-' is not assignable) ---- Start boilerplate code (use with utmost caution!) -- with tty_mem select mem <= -- nop when mem_nop, -- default value -- read when mem_read, -- write when mem_write, -- nop when others; ---- End boilerplate codeThe commented out code here is not very useful (note there is no CLK signal involved for .valfield), but the tty_mem(1) can be used directly as WR and tty_mem(0) as RD signals to memory (active high usually in FPGAs, as opposed to many discrete ICs).

Adding all bit field widths together will be most of the microinstruction width, but not all, as control unit also needs to consume some. That's the next step.

Define program control conditions

Key feature of this microcoded concept is that each microinstruction - in addition to any number of parallel control codes to drive the design can also execute 1 program transfer instruction in the form:

if <condition> then <cmd_true|label_true> else <cmd_false|label_false>

-or 1 subroutine call-

label() (implemented as if true then label else label)

cmd can be any of:

- next (uPC <= uPC + 1)

- repeat (uPC <= uPC)

- return (uPC <= saved uPC)

- fork (uPC <= map[instruction])

First, the conditions (seq_cond reserved label) must be defined. This is done by analysing the design and figuring out which conditions are needed to drive the algorithm, for example:

- register value is zero, negative, even/odd, same/below/over some value etc.

- ALU output flags (N, V, Z, C, P, etc.)

- external signal states (e.g. READY, START, STOP or similar)

- To these add the TRUE/FALSE (very handy to have)

In this design:

// microcontroller also consumes microinstruction fields, first 3 bits to select an IF condition // true and false are handy to have around in all designs // assignment only through IF condition THEN target_true ELSE target_false seq_cond: .if 3 values true, // hard-code to 1 char_is_zero, // all branch conditions needed by the design must be listed and brought into a n to 1 MUX cursorx_ge_maxcol, cursory_ge_maxrow, cursorx_is_zero, cursory_is_zero, memory_ready, false // hard-code to 0 default true;Translated into VHDL:

alias tty_seq_cond: std_logic_vector(2 downto 0) is tty_uinstruction(29 downto 27); constant seq_cond_true: integer := 0; constant seq_cond_char_is_zero: integer := 1; constant seq_cond_cursorx_ge_maxcol: integer := 2; constant seq_cond_cursory_ge_maxrow: integer := 3; constant seq_cond_cursorx_is_zero: integer := 4; constant seq_cond_cursory_is_zero: integer := 5; constant seq_cond_memory_ready: integer := 6; constant seq_cond_false: integer := 7; ---- Start boilerplate code (use with utmost caution!) ---- include '.controller <filename.vhd>, <stackdepth>;' in .mcc file to generate pre-canned microcode control unit and feed 'conditions' with: -- cond(seq_cond_true) => '1', -- cond(seq_cond_char_is_zero) => char_is_zero, -- cond(seq_cond_cursorx_ge_maxcol) => cursorx_ge_maxcol, -- cond(seq_cond_cursory_ge_maxrow) => cursory_ge_maxrow, -- cond(seq_cond_cursorx_is_zero) => cursorx_is_zero, -- cond(seq_cond_cursory_is_zero) => cursory_is_zero, -- cond(seq_cond_memory_ready) => memory_ready, -- cond(seq_cond_false) => '0', ---- End boilerplate codeNext, the "then" part must be defined using seq_then reserved label:

// then 6 bits (because need to jump/call 64 locations) to specify THEN (to select if condition is true) seq_then: .then 6 values next, // uPC <= uPC + 1 repeat, // uPC <= uPC return, // uPC <= saved uPC fork, @ default next; // any labelThe width of this field will typically match the depth of the microcode (64 instructions, therefore 6). The first four are hard-coded sequencer commands, the rest 60 values are labels pointing to any place in microcode except first 4 locations. This minor loss (4 first locations can be still used as handy reset sequence) is offset by a compact and simple design of the control unit.

Finally, the "else" part is defined using "seq_else" reserved label:

// then 6 values for ELSE (to select if condition is false) seq_else: .else 6 values next, repeat, return, fork, 0x00..0x3F, @ default next; // any label or valid range value (allow field to be reused for constantAs expected this is equivalent of .then but with a small tweak - arbitraty 6-bit values are allowed. This is handy for saving microinstruction width:

if true label else value;

Because condition is true, "value" part is never executed, it is a .valfield "for free"

Wrap-up microinstruction controller

For the templatized controller to work it need few more parameters:

- File name (.vhd only supported for now) where to generate the controller code

- Stack depth

- clock edge (rising or falling, default is rising)

Stack depth >0 allows microinstruction subroutine calls in format name() and return from them using return sequencer control code. 2 (single level subroutine calls allowed) is ok for simple controllers like this one, 4 is sufficient for moderately complex designs, and 8 is more than enough for complex CISC-like processors.

// controller generated will have a 2 level hardware return stack and will advance on low to high clock transition .controller tty_control_unit.vhd, 2, rising;This will generated following pre-canned control unit. Note that is actually has no stack pointer, but a simple LIFO set of registers. This way push and pop (call and return) can be both executed in one CLK cycle in a simple manner.

The clock edge can be defined as rising (microinstruction program counter, and all registers in the design) are updated with new values at rising_edge(clk), or as falling. The default is rising.

Assembling a microcoded instruction

mcc is a two pass compiler / two mode compiler (one mode is generating microcode, other mode is converting useful memory formats). The implementation of these passes can be followed here.

The final generated microinstruction can be thought of as a long binary vector. Each component of the vector is a field of fixed (but not same as other) size, and with a defined set of valid values. If a value of vector is not specified in the source code, the compiler picks the default - which must always be defined for every field.

This is best visible in the "noop" instruction. In source code:

noop: .alias if true then next else next; ... _reset2: noop;In the generated VHDL:

-- L0114@0002._reset2: if true then next else next; -- ready = 00, if (000) then 000000 else 000000, cursorx <= 000, cursory <= 000, data <= 00, mem = 00, reserved = 00000; 2 => "00" & O"0" & O"00" & O"00" & O"0" & O"0" & "00" & "00" & "00000",Next instruction sets cursorX and cursorY "vectors" to their allowed values:

_reset3: cursorx <= zero, cursory <= zero;And becomes in VDHL:

-- L0116@0003._reset3: cursorx <= zero, cursory <= zero; -- ready = 00, if (000) then 000000 else 000000, cursorx <= 001, cursory <= 001, data <= 00, mem = 00, reserved = 00000; 3 => "00" & O"0" & O"00" & O"00" & O"1" & O"1" & "00" & "00" & "00000",And this difference can be seen in any other memory representation file generated:

%---------------------------------% WIDTH=32; DEPTH=64; ADDRESS_RADIX=HEX; DATA_RADIX=HEX; CONTENT BEGIN [0000 .. 0002] : 00000000; 0003 : 00001200; ...

Further reading

- Quick manual (basic syntax of the microcode source, some tricks and capabilities)

- Including micro-coded components into bigger FPGA projects

-

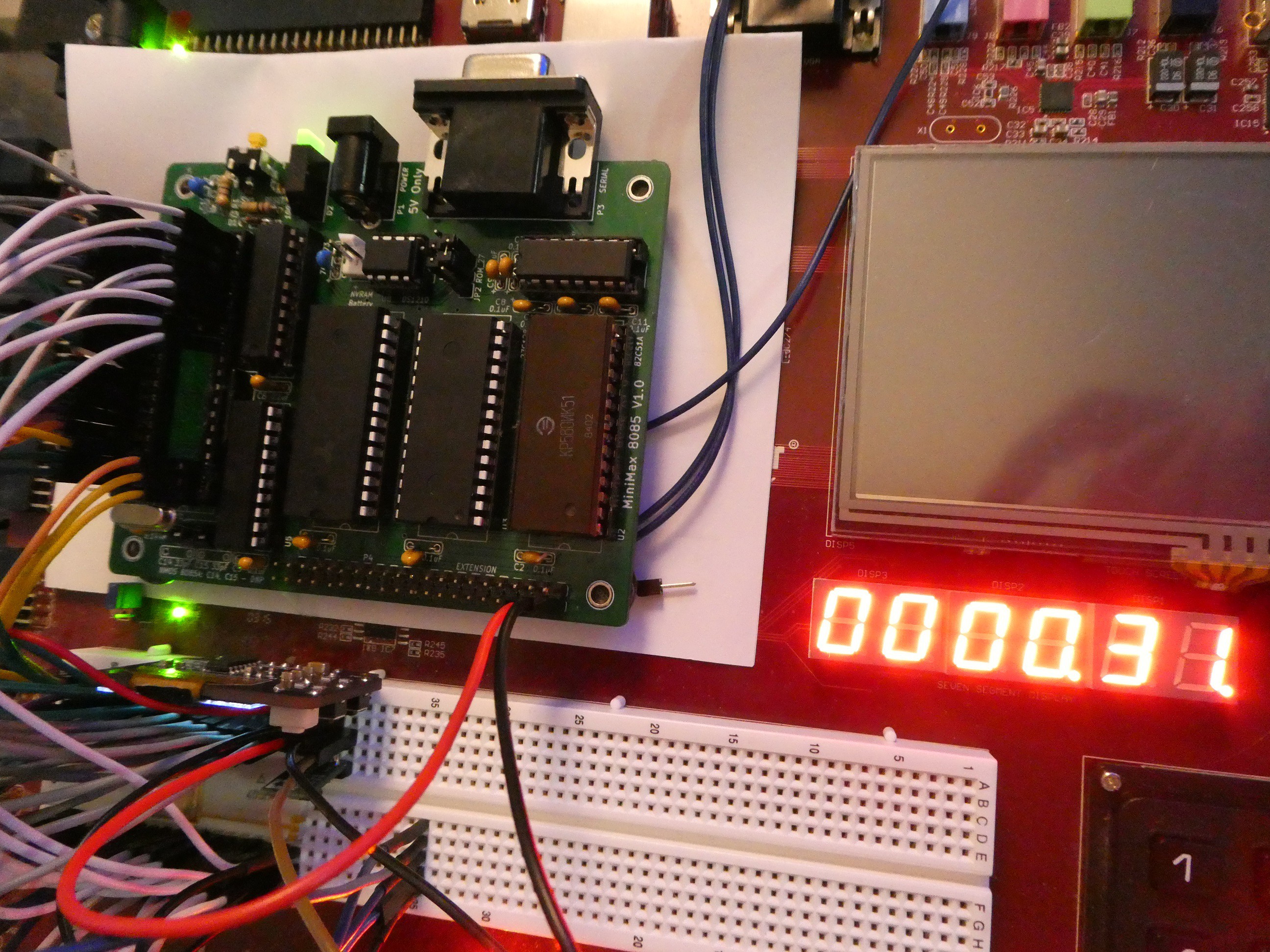

Machine cycle level debugging

12/19/2021 at 03:22 • 0 commentsWith the memory and I/O map looking good (see test approach in previous log), I decided to complete both MiniMax85 single board computers, expecting they would work.

Well, they didn't :-(After exhausting all the usual simple debugging steps (voltages and frequencies as expected on the right pins, testing ICs outside as much as possible (e.g. the EEPROMs), or changing ICs - I have 2 of each major chips) I still could not find the reason why the SBC was completely unresponsive on the serial port.

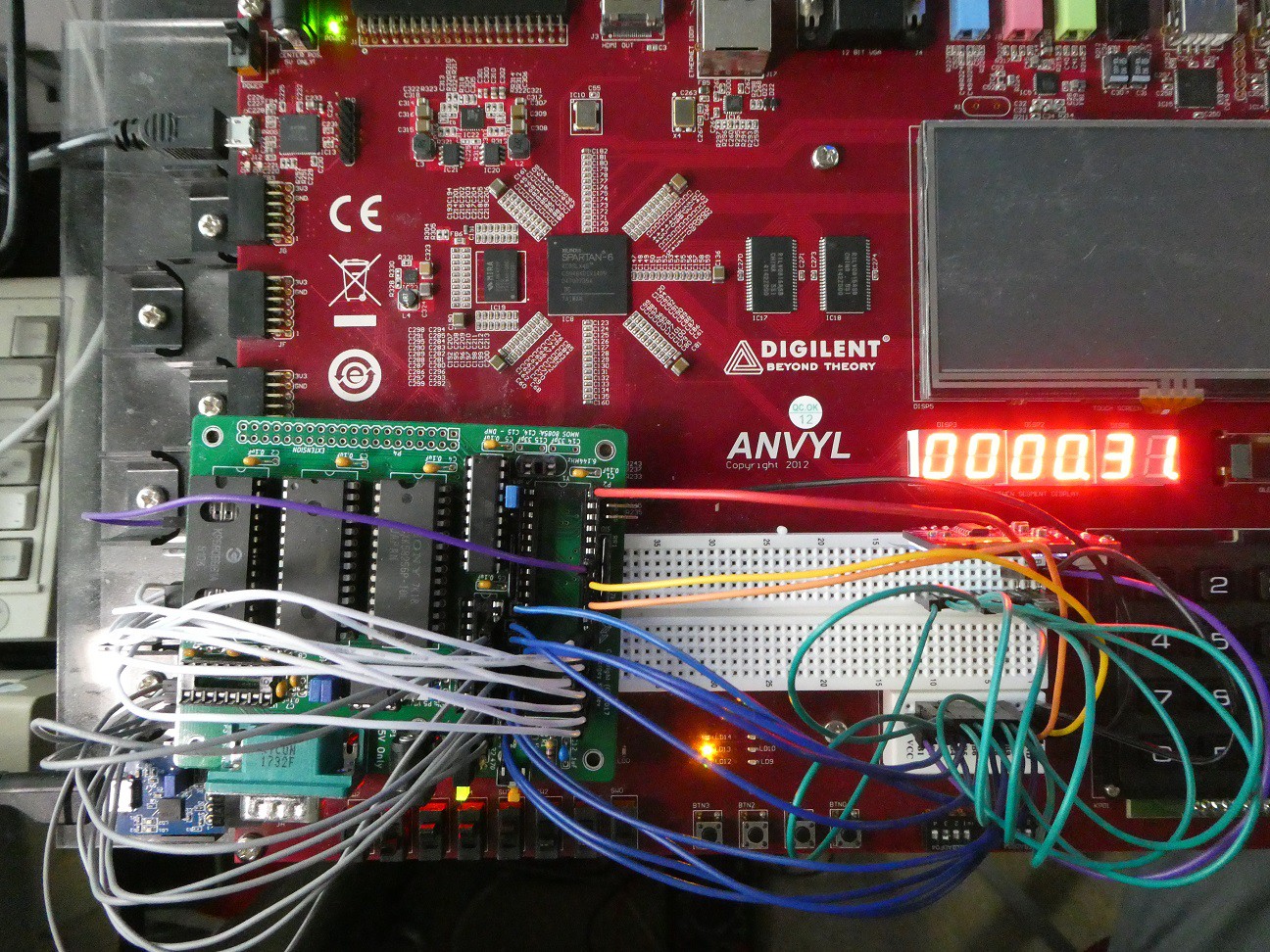

I decided to "re-wire" the FPGA to SBC for sort of custom "in-circuit emulator":

- Move the CPU from SBC to FPGA breadboard

- Wire one set of signals from breadboard to CPU socket on SBC (only those that are needed, for example SID/SOD etc. are not critical)

- Wire another set of signals from CPU to FPGA. These include address, data, and some control signals - these are "read-only" for FPGA as it is only "listening" to the state of CPU signals and displays/logs them.

- Drive CPU's READY signal - READY low puts the CPU in the wait state which can last indefinitely. During this time most control signals are in "frozen" state.

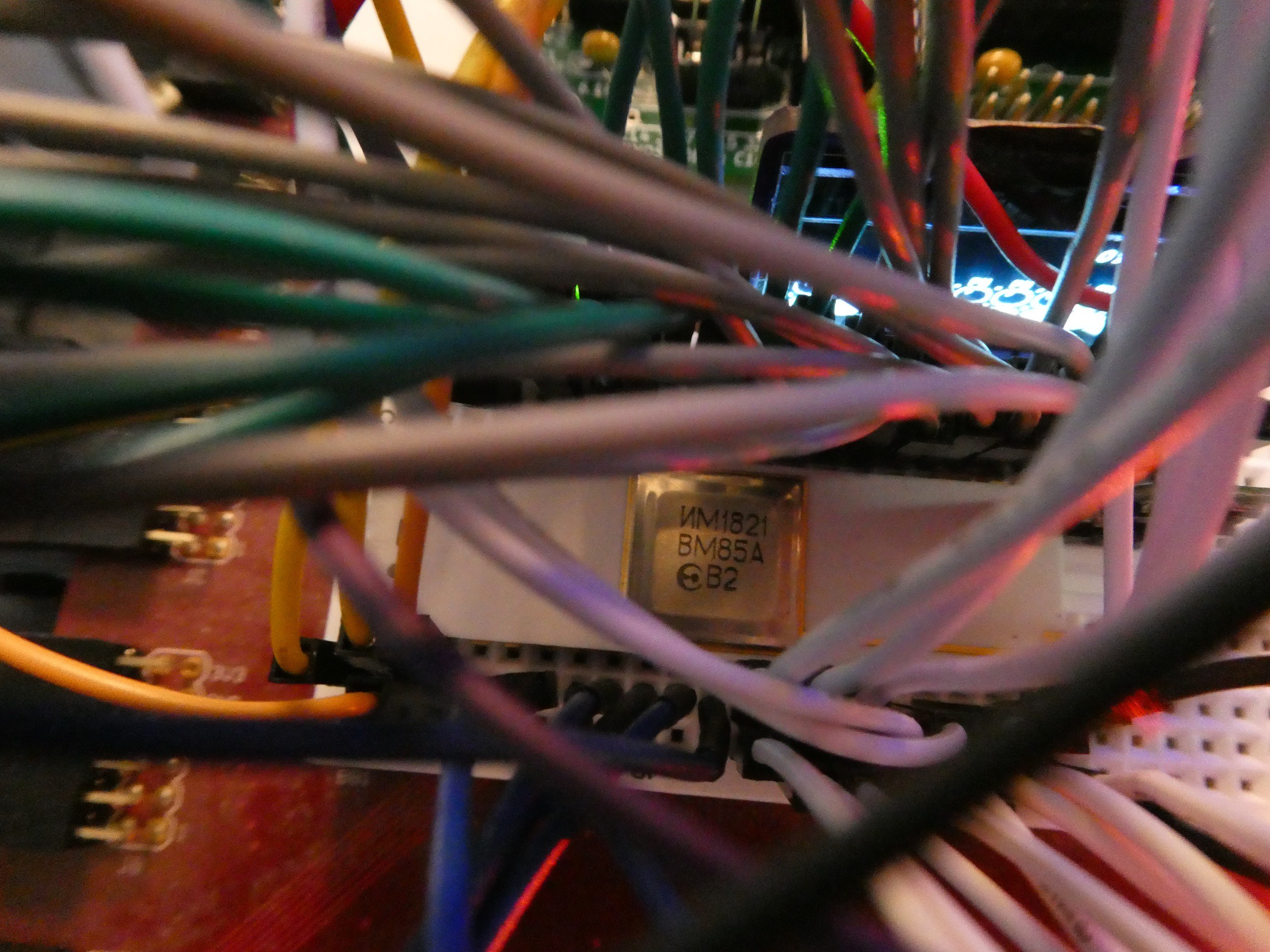

CPU is surrounded by wires, many pins have 2, one to SBC another to FPGA:

Overall connection is messy, but works (including the 6.144MHz crystal which is pretty removed from CPU XTAL pins against all recommendations)

With these connections, I went on to write a new FPGA design, with reusing much of the components I already had.

The key idea is to:

- spy on the machine cycle appearing on the bus (IO/nM, S1 and S0 signals are used for this, refer to 8085 documentation)

- be able to select any (or none, so CPU runs at full speed) of machine cycles of interest, and if hit, drive READY low

- while READY is low, pick up the state of CPU signals of interest (address, data buses) and display them on VGA and serial terminal (reusing existing components)

- When all signals are displayed, wait for manual "continue" signal (simple button click, or it can be held down)

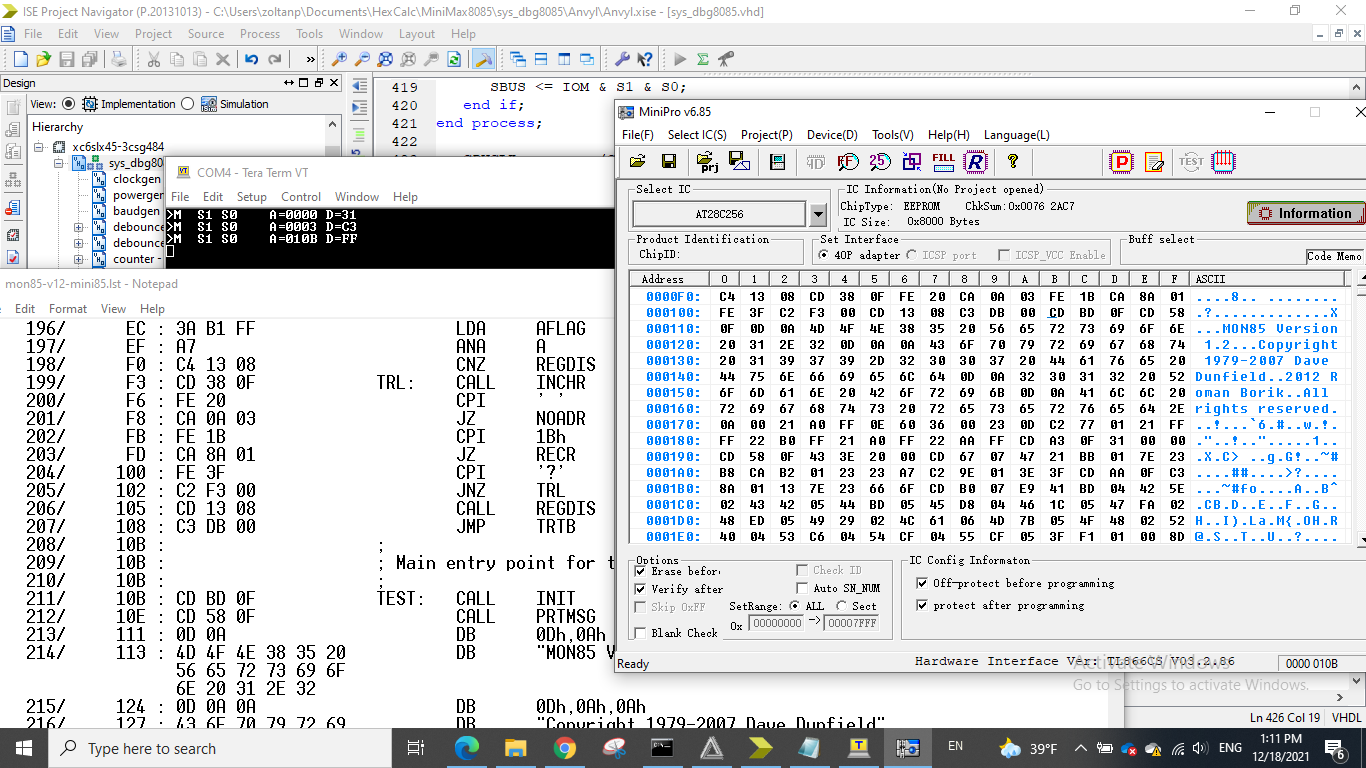

- Based on what is seen, figure out the bug

1 - 4 above worked great (and that's why I am documenting as it can be useful for other hobbyists) but I failed at 5. I see the bug, but not yet sure what is causing it.

In the boot sequence, jump to 0x010B is successful, but at that location CPU reads 0xFF (RST 7) instead of 0xCD (CALL) - RST 7 of course calls into interrupt vector entry point (0x0038) and executes that instead of the required init routine. The AT28C256 contains the right value at that address (as read by legendary TL866). I observe with simple volt meter (at this point all signals except CLK are frozen) /OE and /CS low, but all data bus high.

![]()

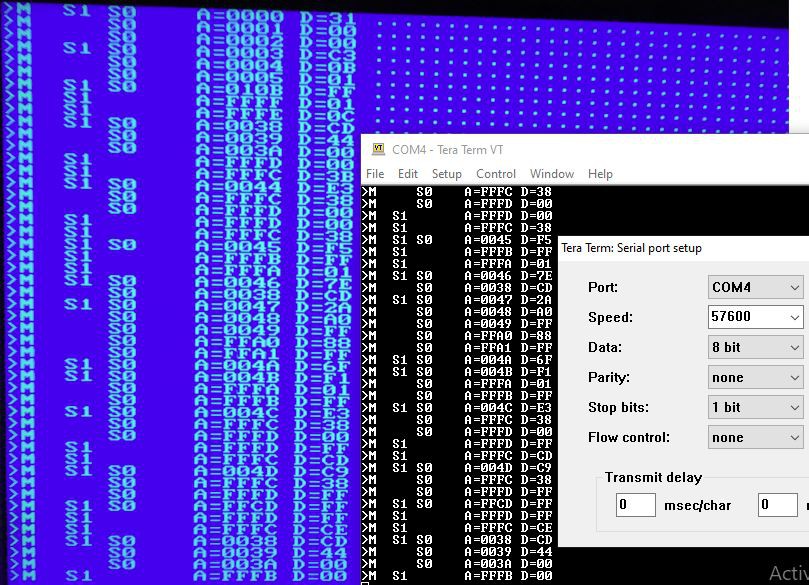

Bug or not, it is fascinating to observe CPU in action, going through its cycle exactly as it is described.

Session with only instruction fetch traced (IO/nM & S1 & S0 = "011")

And a session with all memory access traced (IO/nM & S1 & S0 = "0XX")

The core of the design are 2 registers ("process" in VHDL parlance). The first register captures the machine state and trailing edge of ALE (same moment multiplexed AD bus has the address bits A7 .. A0):

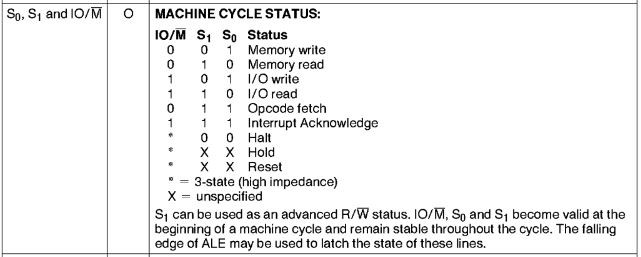

-- capture low address bus as ALE goes low on_ALE: process(ALE, DBUS) begin if (falling_edge(ALE)) then ABUS(7 downto 0) <= DBUS; -- "SBUS" is handy 3-bit indicator of the access; SBUS <= IOM & S1 & S0; end if; end process;Note that SBUS can only have 8 discrete states, as described here:

These states are evaluated at each CPU clock cycle (which is also spied on by the FPGA) and rdy_ff (ready flip-flop) state updated:

on_CPUCLK: process(CPUCLK, SBUS, reset) begin if (reset = '1') then rdy_ff <= '1'; else if (falling_edge(CPUCLK)) then if ((thaw and button(0)) = '1') then rdy_ff <= '1'; else rdy_ff <= not switch(to_integer(unsigned(SBUS))); end if; end if; end if; end process;At RESET or when "thaw" (tracer has finished displaying the bus status record) or "continue" button(0) is pressed, READY should go high, and if switches select any of the desired machine state to be inspected, it should go low. Setting all switches low means there will be no match with any of the 8 different possible machine states, and CPU will not be stopped.

When READY is high, that is also a RESET signal for the tracer component. So when CPU runs, tracer is frozen, and vice versa. Once READY goes low, tracer can start going through a sequence of outputting values picked up from the bus:

tr: tracer Port map ( reset => rdy_ff, clk => baudrate_x1, start => freq_2048(6), continue => not freq_2048(6), data(15 downto 0) => ABUS, data(23 downto 16) => DBUS, data(31 downto 24) => X"00", -- not used flags(7) => nINTA, -- trick to display 2 characters per 1 flag flags(6) => nINTA, flags(5) => S0, flags(4) => S0, flags(3) => S1, flags(2) => S1, flags(1) => IOM, flags(0) => IOM, tracechar => tracechar, tracechar_send => tracechar_send, trace_done => thaw );The tracer outputs single ASCII character at a time on tracechar port, and when the character is ready asserts tracechar_send high. Both the UART sender and TTY2VGA are driven by these signals so there is simultaneous output to both:

The tracer component reads the state of signals of the stopped bus, converts them to a stream of ASCII characters and drives the output to TTY or UART. It is not much more than a counter that goes character by character passed in as "traceformat". If the character is printable ASCII (0x00-0x7F) it is output verbatim. However if it is in the range 0x80-0x87 address and data bus values are picked up in 4-bit nibbles to be displayed as HEX, and if in range 0xC0-0xC7 single flag bits are resolved into ASCII characters using the flag2char lookup table passed in:

tr: tracer Generic map ( traceformat => ( get_byte('>'), X"C0", X"C1", get_byte(' '), X"C2", X"C3", get_byte(' '), X"C4", X"C5", get_byte(' '), X"C6", X"C7", get_byte(' '), get_byte('A'), get_byte('='), X"83", X"82", X"81", X"80", get_byte(' '), get_byte('D'), get_byte('='), X"85", X"84", get_byte(' '), X"0A", -- LF X"0D", -- CR X"00", -- done X"00", -- done X"00", -- done X"00", -- done get_byte(' ') -- last entry must be !=0 ), flag2char => ( get_byte('M'), -- flag 0, value 0 get_byte(' '), get_byte(' '), get_byte(' '), get_byte(' '), get_byte(' '), get_byte('I'), get_byte('A'), -- flag 7, value 0 get_byte('I'), -- flag 0, value 1 get_byte('O'), get_byte('S'), get_byte('1'), get_byte('S'), get_byte('0'), get_byte(' '), get_byte(' ') -- flag 7, value 1 ) ) Port map ( reset => rdy_ff, clk => baudrate_x1, start => freq_2048(6), continue => not freq_2048(6), data(15 downto 0) => ABUS, data(23 downto 16) => DBUS, data(31 downto 24) => X"00", -- not used flags(7) => nINTA, -- trick to display 2 characters per 1 flag flags(6) => nINTA, flags(5) => S0, flags(4) => S0, flags(3) => S1, flags(2) => S1, flags(1) => IOM, flags(0) => IOM, tracechar => tracechar, tracechar_send => tracechar_send, trace_done => thaw ); -

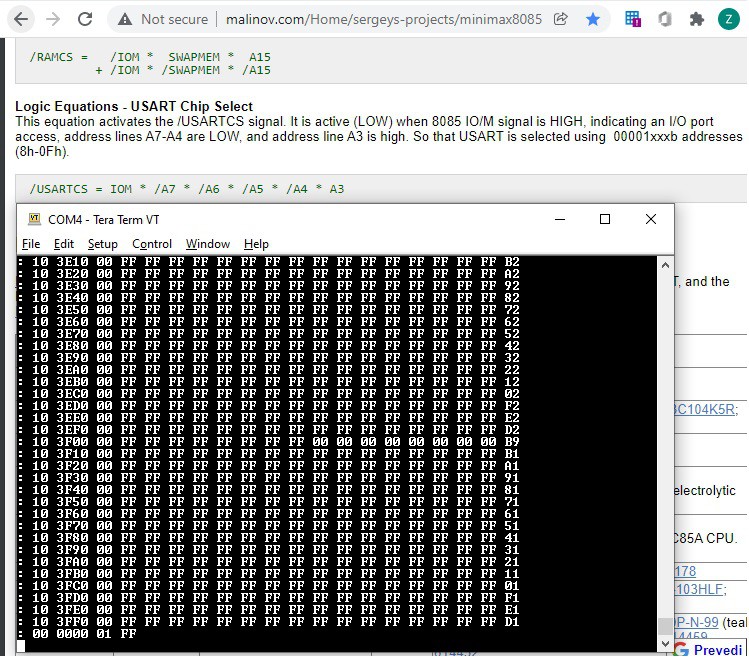

Operation mode 0 - Read memory contents and emit as Intel HEX format ASCII stream

12/08/2021 at 05:47 • 0 commentsThe key component in this mode is predictably the Mem2Hex described here. This is how the component is hooked-up:

hexout: mem2hex port map ( clk => hex_clk, reset => reset, -- debug => hexout_debug(15 downto 0), -- nRD => nRead, nBUSREQ => hexout_busreq, nBUSACK => hexout_busack, nWAIT => nWait, ABUS => ABUS, DBUS => DIN, START => button(0), BUSY => LDT1Y, -- yellow LED when busy PAGE => page_sel, -- select any 8k block using micro DIP switches COUNTSEL => '0', -- 16 bytes per record TXDREADY => tx_ready, TXDSEND => hexout_send, CHAR => hexout_char );Few notes:

- I copied the VHDL and microcode (split) because I expected more changes to do to the design, but in the end they were mostly cosmetic.

- clk (IN) - 12.5MHz, but this is not critical, it can go from 0 to 50MHz.

- reset (IN) - Anvyl has no "hardware reset" button, so pressing all BTN together is a "reset"

- debug (OUT) - state from microcode controller driving the design is output and can be shown on 7seg LED (useful to single step through microcode)

- nBUSREQ (IN), nBUSACK (OUT) - Z80 syle DMA signals.

- nWait (IN) - there is a common WAIT state generation circuit shared by Mem2Hex and Hex2Mem (described above)

- ABUS (OUT), DBUS (IN) - connected to outside world, along with nRD

- START (IN) - triggered manually (see my finger on the button in video below :-) )

- PAGE (IN) - original component supports selecting any combination of 8k pages. I ran out of switches so I combined 2 bits per DIP to configure the memory to be output, so it is 16k blocks ("page_sel")

- COUNTSEL (IN) - allows 16 (0) or 32 (1) bytes per record.

- TXDREADY (IN) - handshake signal for character output. Microcode waits for this signal to go high before next character is emitted.

- TXDSEND (OUT) - if TXDREADY is high, then a character is put into outside buffer and this signal driven high. The UART par2ser implements the reverse side of this protocol. A FIFO could be injected between them.

- CHAR (OUT) - ASCII code of the HEX stream generated appears here.

Here is how the send character handshake appears in the microcode:

// "UART" is supposed to signal TDXREADY = 1 when presented 0x00 or when serial trasmit is done emit: if TXDREADY then next else repeat; // sync with baudrate clock that drives UART if TXDREADY then next else repeat; if TXDREADY then next else repeat; if TXDSEND then return else return;TDXREADY is checked 3 times in a row to prevent any clock domain glitches. Finally, the TXDSEND is checked, but this condition is hardcoded to "1", means it will always return to the caller at this point, but a simple comparator is hooked up to look for check of this condition to generate the send pulse:

-- hack that saves 1 microcode bit width TXDSEND <= '1' when (unsigned(m2h_seq_cond) = seq_cond_TXDSEND) else '0';Sanity check for I/O:

Reading the I/O space can give some indication if it "sniffs right", like in this case. The only IC hooked up to I/O space is 8251 UART, which is enabled when address is XXXXXXXX0001XXXX - when dumping out addresses that match it is visible that "something" appears in those locations, while everywhere else the DBUS returns the default float high.

-

Operation mode 1 - Parse ASCII stream in Intel HEX format, and write to memory

12/08/2021 at 05:32 • 0 commentsThe key component here is Hex2Mem which I intend to document better on its own page. But few explanations here until I get around to do it. Refer to slightly modified VHDL and microcode.

Basic operation is as follows:

- Wait for ASCII character

- If there is one, branch to location that processes it (the ASCII code can be thought of as an "instruction")

- If invalid, output error, go to step 1

- If valid, process it based on which it is and what is expected or not (for example ":" can come only once at the beginning of line, spaces or tabs anywhere but will be ignored, unless they are between hex digits that should not be split (e.g. data bytes)

- Each two digits are written into one internal byte memory location (there is a small 64 bytes buffer)

- As a byte is written into internal RAM, the checksum is updated

- The number of bytes received is checked with expected record length, for error check

- Final byte received is the checksum. Added to accumulated checksum it should result in 0x00 in the LSB of the checksum register

- If checksum is correct, the data bytes are written in a burst to external RAM bus. This means RAM will not be thrashed by bad checksum record

- Either CR and/or LF indicates end of record, this increments the line counter, clears the character counter (these are only used to show error message) and processing of new record can start.

This is how it is hooked up into the design:

hexin: hex2mem Port map ( clk => hex_clk, reset_in => reset, reset_out => open, reset_page => page_sel, -- not really used but i8080-like system would reset at lowest 8k updated -- debug => hexin_debug(15 downto 0), -- nWR => nWrite, nBUSREQ => hexin_busreq, nBUSACK => hexin_busack, nWAIT => nWait, ABUS => ABUS, DBUS => DOUT, BUSY => hexin_busy, -- yellow LED when busy -- HEXIN_READY => hexin_ready, HEXIN_CHAR => hexin_char, HEXIN_ZERO => open, -- TRACE_ERROR => dip_traceerror, TRACE_WRITE => dip_tracewrite, TRACE_CHAR => dip_tracechar, ERROR => LDT2R, -- red LED when error detected TXDREADY => tty_sent, TXDSEND => hexin_debug_send, TXDCHAR => hexin_debug_char );Signals:

- clk (IN) - common 12.5MHz, can be virtually any speed, but fast enough to be able to keep up with incoming baudrate

- reset_in (IN) - classic reset

- reset_out (OUT) - will generate a pulse if write is detected to any of the "reset_page" 8k blocks. Typically this would be 0x0000 - 0x3FFF for "PC starts at 0" CPUs (808X, CDP1802), and 0xC000 - 0xFFFF for "reset vector" CPUs (65XX, 68XX, 99XX)

- reset_page (IN) - 8 bits, each indicates 8k block

- debug (OUT) - signals from microcode controller unit, useful for single stepping through microcode

- nWR (OUT) - Z80 style memory write signal

- nBUSREQ (OUT), nBUSACK (IN) - DMA signals. The first time nBUSREQ will be generated when a valid HEX record has been received. At that point, memory write can be allowed if nBUSACK goes low. Which will only happen if operation mode is this one.

- nWAIT (IN) - see description below

- ABUS (OUT), DBUS (OUT) - connections to system bus (in this case, wires to 8085 SBC board)

- BUSY (OUT) - blinkenlight :-)

- HEXIN_READY (IN) - connected to UART, when a valid serial character is received, UART generates which pulse which captures the received character to process.

- HEXIN_CHAR (IN) - 8 bit ASCII character from input stream

- TRACE_ERROR, TRACE_WRITE, TRACE_CHAR (IN) - 3 independent switches that enable tracing when error, when writing to memory or when character is received. These are simply conditions for microcode, if true then execution branches to tracing (output of a text string). This is a fundamental advantage of microcoded designs as the debug facility can be written along (or best - before) the rest of the design / code!

- ERROR (OUT) - red blinkenlight!

- TXDREADY (IN), TXDSEND (OUT), TXDCHAR (OUT) - these are connected to TTY which allows tracing to be shown on VGA. Note that writing to VGA still takes some time so the input stream should be delayed by character or line when extensive tracing is turned on.

The video is a shaky recording of a session to input from a test HEX file into the memory. It wasn't successful because I forgot to clear the wait mode, so the component was stuck waiting to write a byte (false condition, so repeat kept executing):

// ask CPU for memory, then write 1 byte with any number of optional wait cycles writemem: ram_addr = bytecnt, nBUSREQ = 0; ram_addr = bytecnt, nBUSREQ = 0, if nBUSACK then repeat else next; ram_addr = bytecnt, nBUSREQ = 0, nWR = 0; ram_addr = bytecnt, nBUSREQ = 0, nWR = 0, if nWAIT then next else repeat;Finally, I typed a few random characters to show how it detected bad input and emitted error message about it:

// error codes are 1 to 6, 0 means no error errcode: .regfield 3 values ok, err_badchar, // ERR1 err_unexpected, // ERR2 err_badchecksum, // ERR3 err_badrecordtype, // ERR4 err_badrecordlength, // ERR5 same default same;While I was fiddling with WAIT, the host was sending data, and because there is no handshake, many bytes got lost. Eventually it sync'd up with ":" record start character and after that it wrote to RAM and output the trace:

if TRACE_WRITE then next else nextaddr; emit(char_A); // A[address]=data emit(char_open); printaddr(); emit(char_close); printram();The wait circuit is implemented in top level component, because it is reused by HEX2MEM and MEM2HEX. It is triggered by either component activating nRD or nWR signal (nAccess signal). That means memory operation is requested. If the WAIT is enabled (a S/R flip/flop controls that) then nWAIT is locked low until a button is pressed. This way each memory access can be inspected (the A and DBUS values appear on the 7seg LED which is conveniently 6 digits on Anvyl so 4 hex A and 2 hex DBUS can be displayed).

The FF below has a little trick - the clock itself is multiplexed depending on its state. When not in WAIT mode (nWait = '1') it will be triggered on nRD or nWR going low, but once waiting, then press on the button(3) flips in around. Therefore:

- start wait mode: button(1)

- advance: button(3)

- stop wait: button(2), reset, or changing mode (reset_sw signal)

-- Wait signal wait_ena <= not (reset or reset_sw or button(2) or wait_dis); wait_dis <= not (button(1) or wait_ena); wait_clk <= (not nAccess) when (nWait = '1') else button(3); on_wait_clk: process(reset, wait_clk) begin if (wait_dis = '1') then nWait <= '1'; else if (rising_edge(wait_clk)) then nWait <= not nWait; end if; end if; end process; -

Test mode 2 - display UART baudrate and host to TTY/VGA loopback

12/08/2021 at 05:26 • 0 commentsAnother test mode which:

- Displays real baudrate (BCD format) on the LEDs

- Also provides character loop-back just like mode 3

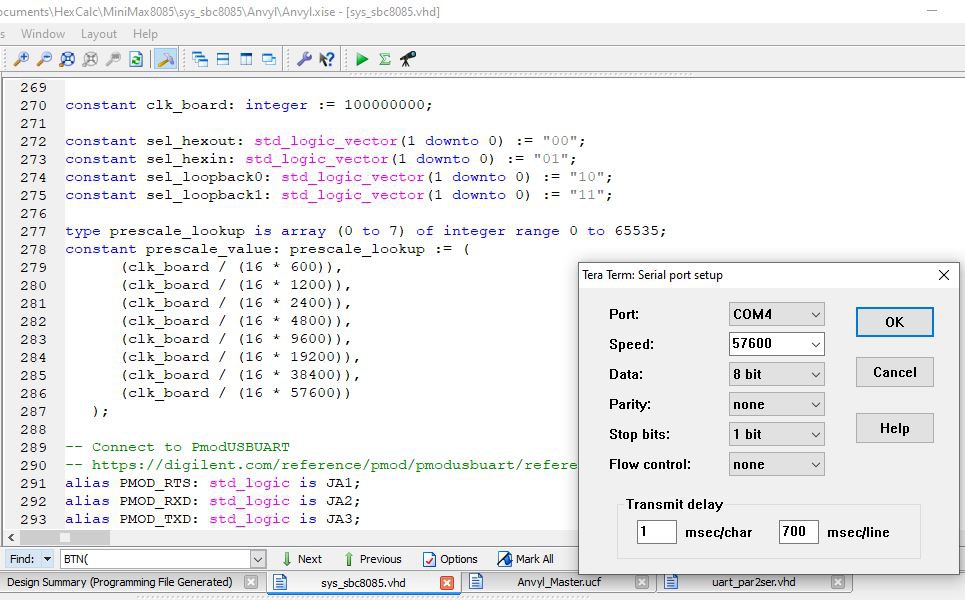

Anvyl switches SW5..3 select the baudrate from 600 (000) to 57600 (111). Note that the number displayed is not exactly the typical standard rate. The reason is that the frequency is actually measured on the board. First, the FPGA 50MHz board frequency is divided by two prescale factors, one leads to freq_4096 that can be divided by powers of 2 down to 1 Hz, and the other based on the selected divide value to get baudrate_x8 frequency:

prescale: process(CLK, baudrate_x8, freq4096, switch_uart_rate) begin if (rising_edge(CLK)) then if (prescale_baud = 0) then baudrate_x8 <= not baudrate_x8; prescale_baud <= prescale_value(to_integer(unsigned(switch_uart_rate))); else prescale_baud <= prescale_baud - 1; end if; if (prescale_power = 0) then freq4096 <= not freq4096; prescale_power <= (clk_board / (2 * 4096)); else prescale_power <= prescale_power - 1; end if; end if; end process;Eventually these two are used to feed into a counter that counts in BCD (more precisely, it has a 32-bit adder inside that can add in BCD or binary):

counter: freqcounter Port map ( reset => RESET, clk => freq_2048(11), freq => baudrate_x1, bcd => '1', add => X"00000001", cin => '1', cout => open, value => baudrate_debug );The counter assumes that the "clk" signal is 50% duty cycle, as it has 2 counters which work on opposite sides of the clk level. Counts accumulated on "high" side are displayed on "low" side and vice versa, with the net result that each 1s the count ("freq" signal) is refreshed. Because 50MHz cannot be divided by some integer to create exact baudrate, they are off by less than <1% which is of course well within timing tolerances.

This way the crucial UART frequency generation, LED debug display etc. are tested.

-

Test mode 3 - display UART mode and host to TTY/VGA loopback

12/08/2021 at 05:17 • 0 commentsTo have confidence in a test circuit, it is useful for the test circuit to test itself :-) This mode:

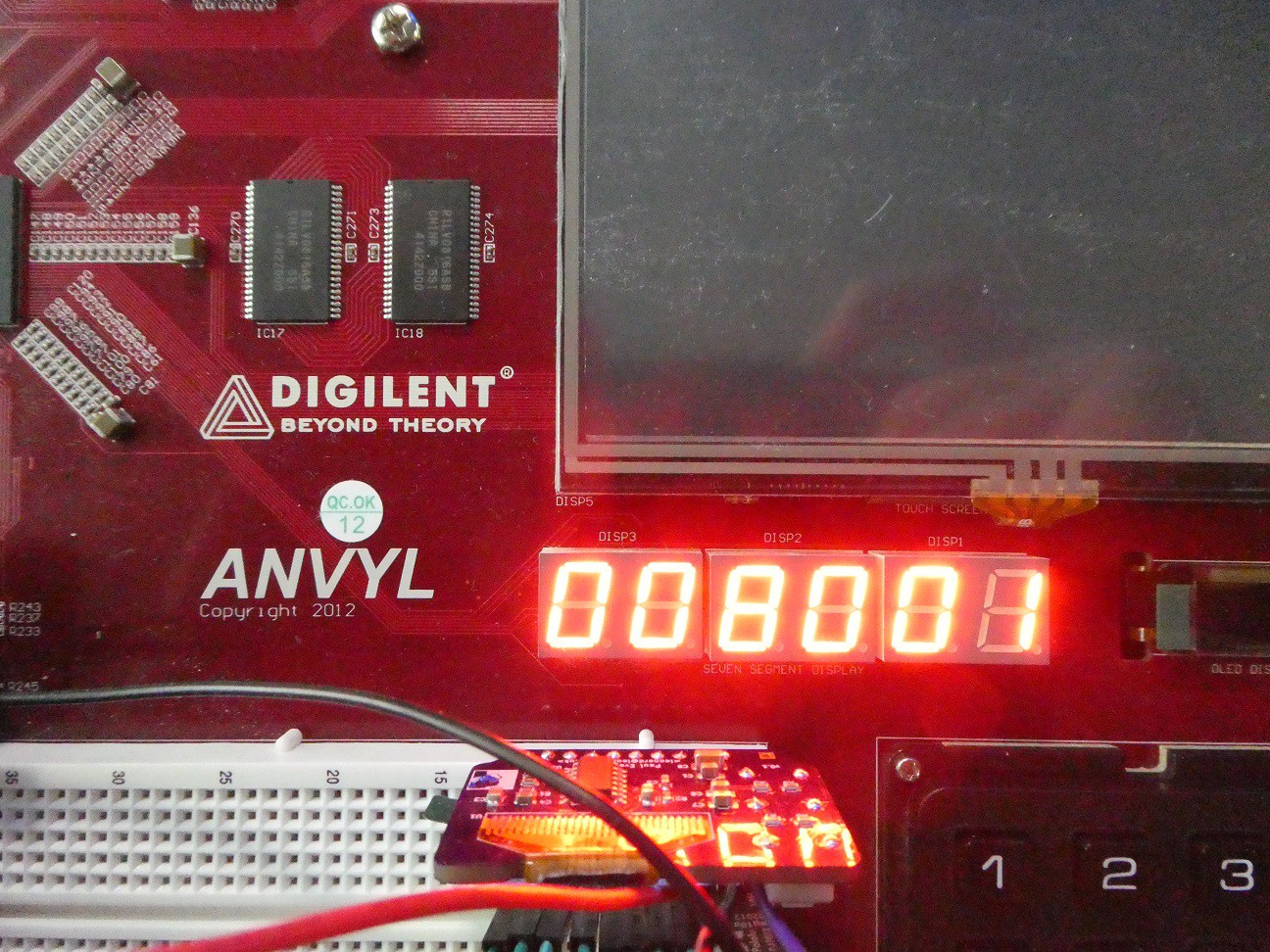

- Displays the UART mode in somewhat cryptic way in 6-digit 7-seg LED

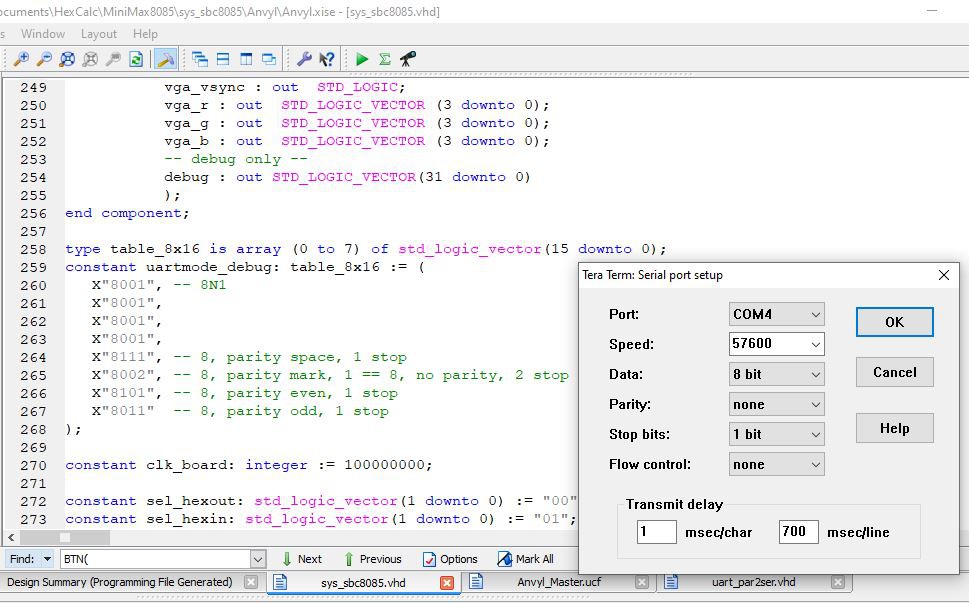

UART is two separate circuits (SER2PAR and PAR2SER) that I reuse in many projects. They support a variety of 8-bit per character transmit and receive frames. The terminal program on the host should be set to same setting (8-N-1 in this case)

Anvyl board switches 2..0 select the mode as visible in the image below.

(note 700ms delay per line - this is to allow time for the trace of HEX2MEM microcode to display before processing next incoming character, more about this below)

- Echos the characters coming from UART input (RX) back to output and also to TTY2VGA. This allows testing those components too.

To simplify top level object, the TTY, video RAM, chargen RAM and VGA controller are wrapped up in one component called TTY2VGA:

- VGA mode: 640*480, 25MHz pixel clock

- Text mode: 80*60 characters, 8*8 pixels

- Video RAM: 4k, dual port. The port connected to TTY controller is read/write (read is used when scroll-up is needed, this is of course a bad design as a top-row register pointer could allow using write on that side) and the port connected to VGA controller is read only. Both ports take x, y (row/col) and internally a hardware "multiplication" is done to find out the character code address (A = Y*MAXCOL+X)

- Character generator ROM: 128 characters (0-127 ASCII, 128-255 are simply inverted in the circuit), total of 1k

- Hardware cursor in two modes (underscore and block)

- Color is hard-coded but could easily be extended by addition of 4k color RAM, similar to video RAM

-

Software

12/08/2021 at 05:08 • 0 commentsThere are 3 different toolchains and languages coming together in this project:

- Intel HEX file - there are innumerable systems and tools producing and consuming this old but still useful format, most notably all the assembler, cross-assemblers etc. in 8080/Z80 ecosystem on one side, and bunch of programmers, emulators etc. on others. Any can be used in combination with this project - as long as it is "old enough" (producing just 64k address space and 00 and 01 type records only)

- VHDL (using Xilinx ISE 14.7) - to compile it all together and generate a .bit file, standard FPGA toolchain flow. Few notes:

- No Xilinx specific "IP" components are used, in other words, "vanilla" VHDL could be recompiled for other FPGA vendors

- Lot of VHDL code is auto-generated by the microcode-compiler as a boiler plate to include and/or copy from to create the microcoded controllers

- Microcode - this is custom "language" I "invented" to simplify creating templatized controllers. There are 3 such microcoded controllers in this project:

- HEX2MEM - accepts stream of ASCII characters, interprets them as valid Intel HEX file stream, and generates memory write signals

- MEM2HEX - generates memory read signals, bytes read are assembled into Intel HEX file output ASCII stream

- TTY_Screen - accepts ASCII character stream (including some special characters such as CR, LF, CLS, HOME) and writes into a memory organized as MAXCOL columns and MAXROWS rows (in this project 80*60 for a text based VGA, but could for example be a 16*4 LCD etc.)

The software components are best explained by going through the 4 supported modes of operation:

--------------------------------------------------------------------------------------------- -- SW7 SW6 Mode TTY (VGA) UART TX 7seg LED --------------------------------------------------------------------------------------------- -- 0 0 sel_hexout - Generated HEX mem2hex debug port (or bus if nWait = 0) -- 0 1 sel_hexin Microcode trace Echo UART RX hex2mem debug port (or bus if nWait = 0) -- 1 0 sel_loopback0 Echo UART RX Echo UART RX Baudrate (decimal) -- 1 1 sel_loopback1 Echo UART RX Echo UART RX UART mode ---------------------------------------------------------------------------------------------See other project logs for description of each of these modes of operation.

-

Hardware

12/08/2021 at 05:03 • 0 commentsFor this project I used a cool little 8085-based single board computer (8085 Minimax) described and graciously provided to me by Ken Yap (thanks again!). I was actually in the process of soldering together the board, and decided to use a verification step before plugging in my vintage Soviet CPU to see if there will even be a chance for it working or not...

The hardware setup is simple but a bit messy affair:

Few notes:

- 8085 IO/M signal (purple wire) is simply switchable to IO (high) to M(emory) (low) using a micro-DIP on the FPGA board. The HEX I/O has no idea about it, it just sees IO space as another 64k address map space (of course with 256 repetitions because typically in 8080-family systems upper 8 address lines are not decoded (Z80 introduced 16-bit IO to some degree, and then HD64180 has a full 64k IO address map)

- 8085 has multiplexed lower address A7..A0 with data bus D7..D0, giving AD7..AD0 bus. Typically a 8-bit latch (like 74x573) enabled by ALE captures the low address early in memory access cycle. To simplify, I left this IC unpopulated on the board and connected the low memory address wires (gray) directly to its output socket pins.

- Minimax 8085 of course takes +5V DC - I am sourcing its modest consumption (esp. because the power hungry NMOS CPU is not there!) with a 3.3V to 5V step-up regulator.

- Connecting nominal 3.3V (FPGA) to nominal 5.0V (SBC) is a "circuit crime". But I could get away with it in this case as the modern RAM / ROM used has max "0" voltage and min "1" voltage signals that are within margins.

- 4 additional PMOD signals are used for UART - this is how the Intel HEX files are uploaded/download during runtime.

This is how these connections look in VHDL (top file of the project):

--PMOD interface JA1: inout std_logic; -- Connected to USB2UART JA2: inout std_logic; -- Connected to USB2UART JA3: inout std_logic; -- Connected to USB2UART JA4: inout std_logic; -- Connected to USB2UART JB1: out std_logic; -- GRAY 74F573.19 A0 JB2: out std_logic; -- GRAY 74F573.18 A1 JB3: out std_logic; -- GRAY 74F573.17 A2 JB4: out std_logic; -- GRAY 74F573.16 A3 JB7: out std_logic; -- GRAY 74F573.15 A4 JB8: out std_logic; -- GRAY 74F573.14 A5 JB9: out std_logic; -- GRAY 74F573.13 A6 JB10: out std_logic; -- GRAY 74F573.12 A7 JC1: out std_logic; -- WHITE 8085.21 A8 JC2: out std_logic; -- WHITE 8085.22 A9 JC3: out std_logic; -- WHITE 8085.23 A10 JC4: out std_logic; -- WHITE 8085.24 A11 JC7: out std_logic; -- WHITE 8085.25 A12 JC8: out std_logic; -- WHITE 8085.26 A13 JC9: out std_logic; -- WHITE 8085.27 A14 JC10: out std_logic; -- WHITE 8085.28 A15 JD1: out std_logic; -- PURPLE 8085.30 IO/M (low for memory access) -- breadboard signal connections BB1: inout std_logic; -- BLUE 8085.12 AD0 BB2: inout std_logic; -- BLUE 8085.13 AD1 BB3: inout std_logic; -- BLUE 8085.14 AD2 BB4: inout std_logic; -- BLUE 8085.15 AD3 BB5: inout std_logic; -- BLUE 8085.16 AD4 BB6: inout std_logic; -- BLUE 8085.17 AD5 BB7: inout std_logic; -- BLUE 8085.18 AD6 BB8: inout std_logic; -- BLUE 8085.19 AD7 BB9: out std_logic; -- ORANGE 8085.31 nWR BB10: out std_logic; -- YELLOW 8085.32 nRD

Custom circuit testing using Intel HEX files

Download / upload memory contents into computer motherboards or other devices for test or debugging (using 3 micro-coded controllers)

zpekic

zpekic