-

PagedOut #6 published article about this project

04/01/2025 at 07:11 • 0 commentsThe new issue of 📖 PagedOut #6 is available, featuring my article 🚀 "The Way to the Zigbee Gateway" describing the project evolution.

Check out page #37.![]()

Besides that, there are plenty of interesting articles on 🛡️ cybersecurity, 💾 programming, and 🖥️ hardware.

📚 Happy reading! 😊

-

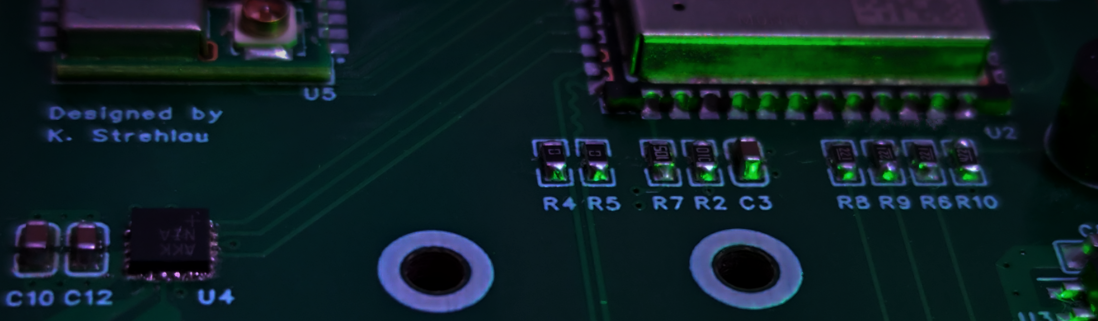

Step 8: Latest cosmethic changes

01/22/2025 at 07:04 • 0 commentsBe careful when considering ground pours on outer layers, as they are typically unnecessary for 4+ layer PCB stacks.

![]()

✅ After further research, I removed the ground pour from the top layer. It wasn’t needed and could introduce issues if not implemented properly. However, if you really need to ground pour the outer layers, ensure proper via stitching to preserve signal integrity.

✅ I also updated the module's firmware, enabling it to operate at a 115k UART speed, which significantly improved its stability and responsiveness.

✅ I have migrated to the new PCB, and now all my smart home devices are operating as they were before.

![]()

-

Step 7: It's stable, only minor changes!

11/28/2024 at 09:37 • 0 commentsI recently revised the PCB design to enhance its structure and manufacturability:

- The stackup was modified to position the ground planes centrally, ensuring optimal signal integrity.

- The bottom layer was divided into two sections: 5V and 3.3V, each with its own dedicated ground plane for the signals.

- Only two traces are routed on the bottom layer: one for the delay circuit (soft-start for the ESP32) and the other for activating the DAC circuit.

- A ground plane was added to the top layer, which does not affect the electrical performance but simplifies the manufacturing process.

- I also introduced a damper circuit to address potential issues related to the ferrite bead.

- Component values were adjusted, and all schematics and Gerber files were updated accordingly.

![]()

In terms of software, I implemented several changes, with a few key improvements as follows:

- The jingles (welcome, alert, and info tones) were updated to be more pleasant to the ear.

- The device no longer plays the welcome notification during app rotation (e.g., when WiFi reconnects after a router restart), which is particularly useful at night.

- Fixed issues related to voice notification playback.

- Introduced functionality to indicate active notifications via a blinking LED, controlled through MQTT in Home Assistant, based on the "persistent notification count."

The previous PCB has been operating flawlessly so far, reliably controlling devices in the home. The new version performs just as well!

Lastly, I’d like to share that the project was also featured in an article on Hackster. Thank you for discovering and mentioning it — it's incredibly motivating! Thank you, Gareth!![]()

If you want to read the article click here to read it on Hackster!

-

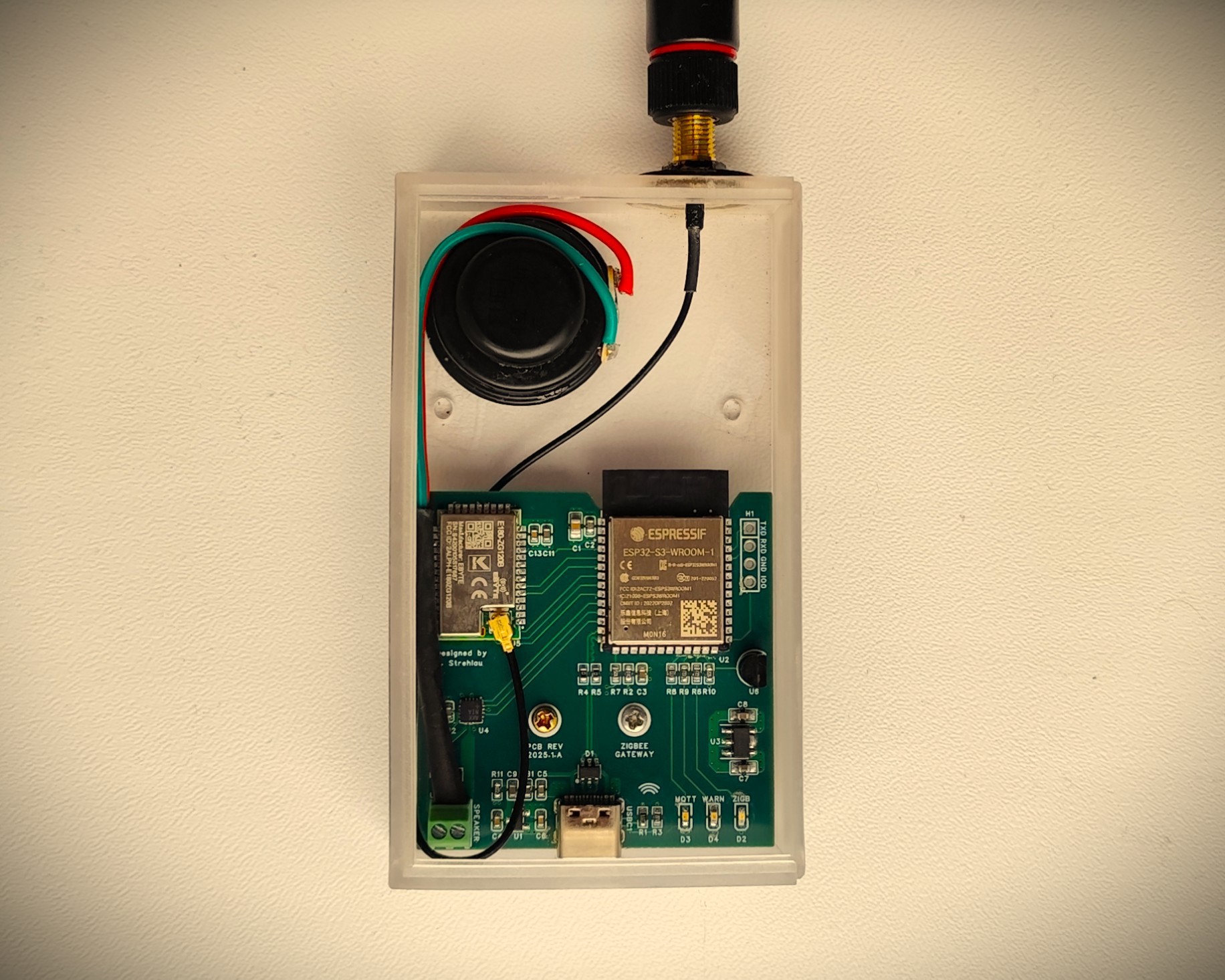

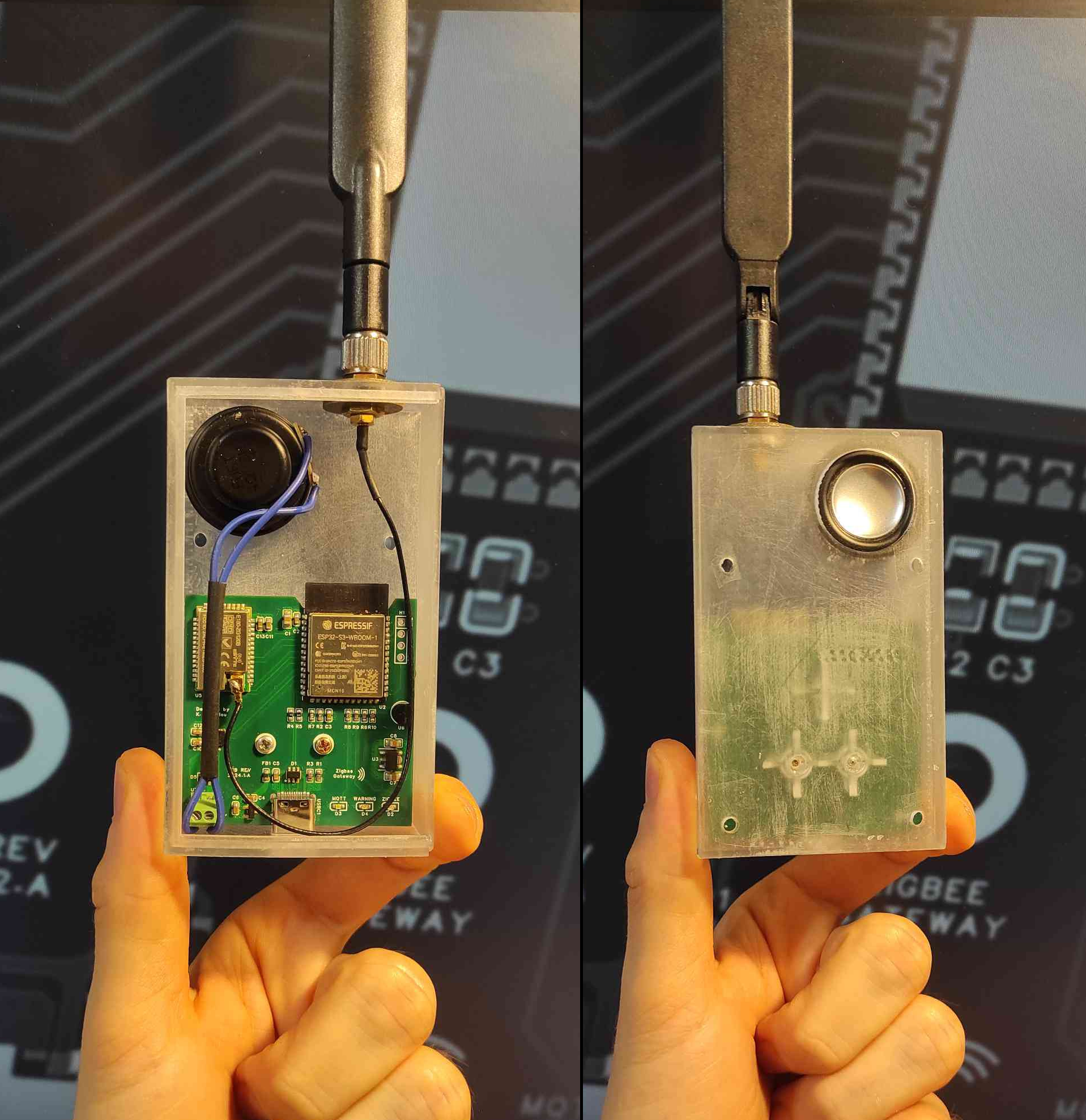

Step 6: Enclosure

03/19/2024 at 14:25 • 0 commentsThe 3D-printed enclosure has recently arrived. Unfortunately, I made a mistake and the mounting holes are on the reverse side.

The housing consists of two parts. The larger part can be seen in the photo and the other part is the sliding cover. The printed circuit board is attached to the housing with two screws.

![]()

-

Step 5: Minor improvements

03/06/2024 at 22:42 • 0 commentsThere's still some work remaining in the firmware, before the device can be mounted on the wall.

Some latest improvements include:

- Implemented playlist support in Audio component. Now TTS can be mixed together with flash-hosted files. Example usage - alarm jingle followed by TTS audio description.

- Implemented proper GPIO cleanup on Audio component destruction.

- Implemented proper GPIO cleanup on Temp Sensor destruction.

- General stability improvements, including audio decoding library updates.

- Improvements in ksIotFrameworkLib targeting Device Portal (device info, input data types) and device config storage.

-

Step 4 - Code cleanup and more

02/22/2024 at 21:04 • 0 commentsRecently I have been mainly involved in firmware development.

I've introduced few smart tricks:

- CPU is set to 240 MHz only when decoding audio stream and then goes back to 80 MHz when no more data is in the buffer.

- New LED driving mode - using pullup/pulldown to significantly decrease the amount of emitted light.

- Automatic baud rate detection, which means the device is able to talk at 57600 and 115200 and will doscover the speed automatically.

I have also improved some things in the framework.

The other thing I managed to achieve is OTA Zigbee Gateway Firmware update, which turned out to be simple to integrate into the Elelabs Flasher (added raw mode for flash and serial over LAN).

Now the firmware update is really simple:

- The user starts the device portal.

- After logging in, zb-bootloader command is issues by the user on the terminal tab.

- The user starts python script to flash the .gbl file via xmodem protocol (uart over network)

- The module is restarted using zb-reboot terminal command.

I have also managed to properly setup MFG tokens, so the device is properly displayed on HA subpage.

-

Step 3 - Running up the stack

02/09/2024 at 15:45 • 0 commentsLooks like I'm on a good streak!

After many hours of debugging all the stuff, I managed to fix audio issue in external library (https://github.com/schreibfaul1/ESP32-audioI2S/issues/626). Now the audio startup noise is gone.

I've also ordered smart bulb, which paired flawlessly. Check this out!

-

Step 2 - Forming it all up

02/08/2024 at 22:35 • 0 commentsThe application skeleton for ESP32 (main CPU) was built on my ksIotFrameworkLib, which provides some fancy stuff like device configuration portal, MQTT support, LED management etc.

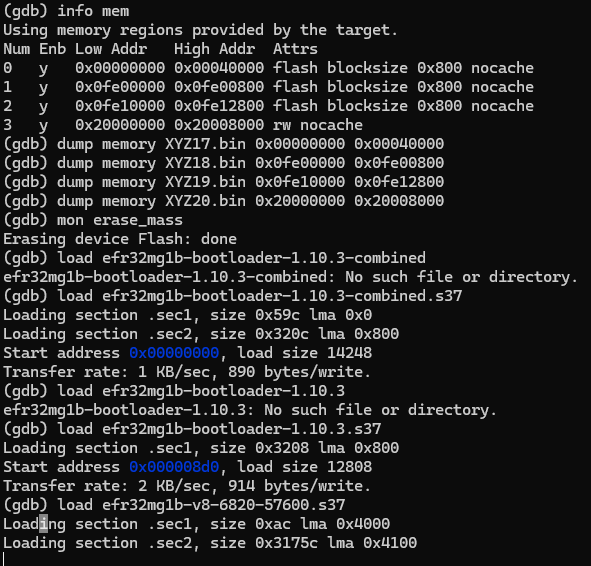

Then the E-180 module has been studied in relation to firmware update. The idea was to use ESP32S3 as a proxy to flash the module. It was challenging since there are a plethora of possible solutions.

After some trial and error, the module was flashed with the help of esp32-blackmagic, which supports the SWD protocol in addition to being primarily used for remote on-chip debugging. It was necessary to change settings to match PCB design IO numbers for SWD IO and CLK lines.

![]()

Here's the link for EFR32 firmware blobs:

https://github.com/cziter15/EZSP-Firmware -

Step 1 - Solder and verify

02/08/2024 at 21:42 • 0 commentsThe board has been assembled to test the circuit's functionality. Zigbee module was mounted on the board right after DAC verification.

The most challenging part was soldering the DAC chip and then, a bit easier was USB-C soldering.

Quick examination confirmed correct voltage generation, DAC functioning, but noise during playback startup.

Here's a little demo:

KS Zigbee Gateway

My own Zigbee Gateway with speaker output for realtime audio notifications, with MQTT support and more

cziter15

cziter15