-

Final Assembly

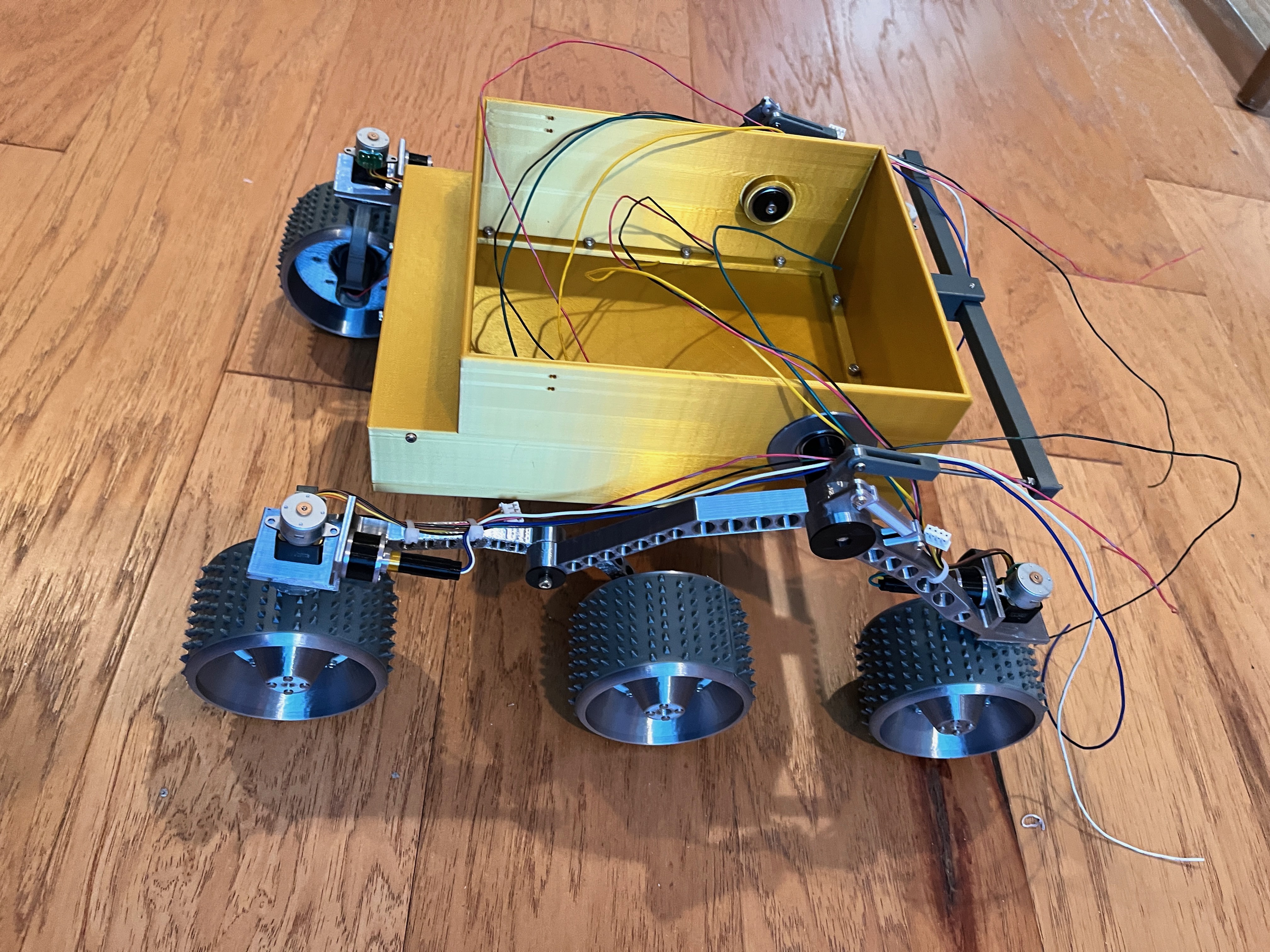

02/15/2025 at 17:34 • 0 commentsThere are a few remaining items to add to the rover. First is the front cameras and laser range finders. The wires are not functional but add a lot to the looks of the model.

-

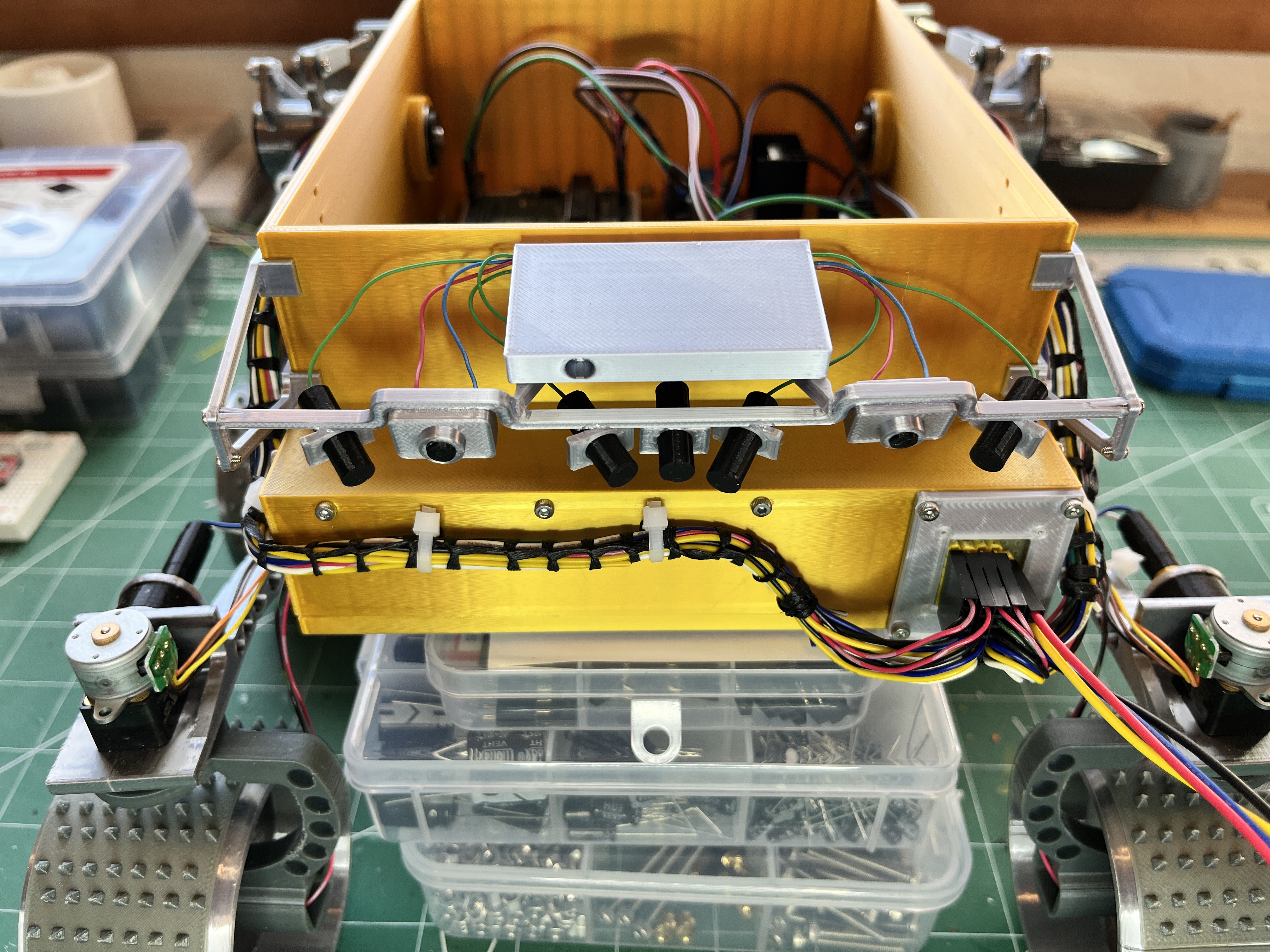

Instruments and Wiring

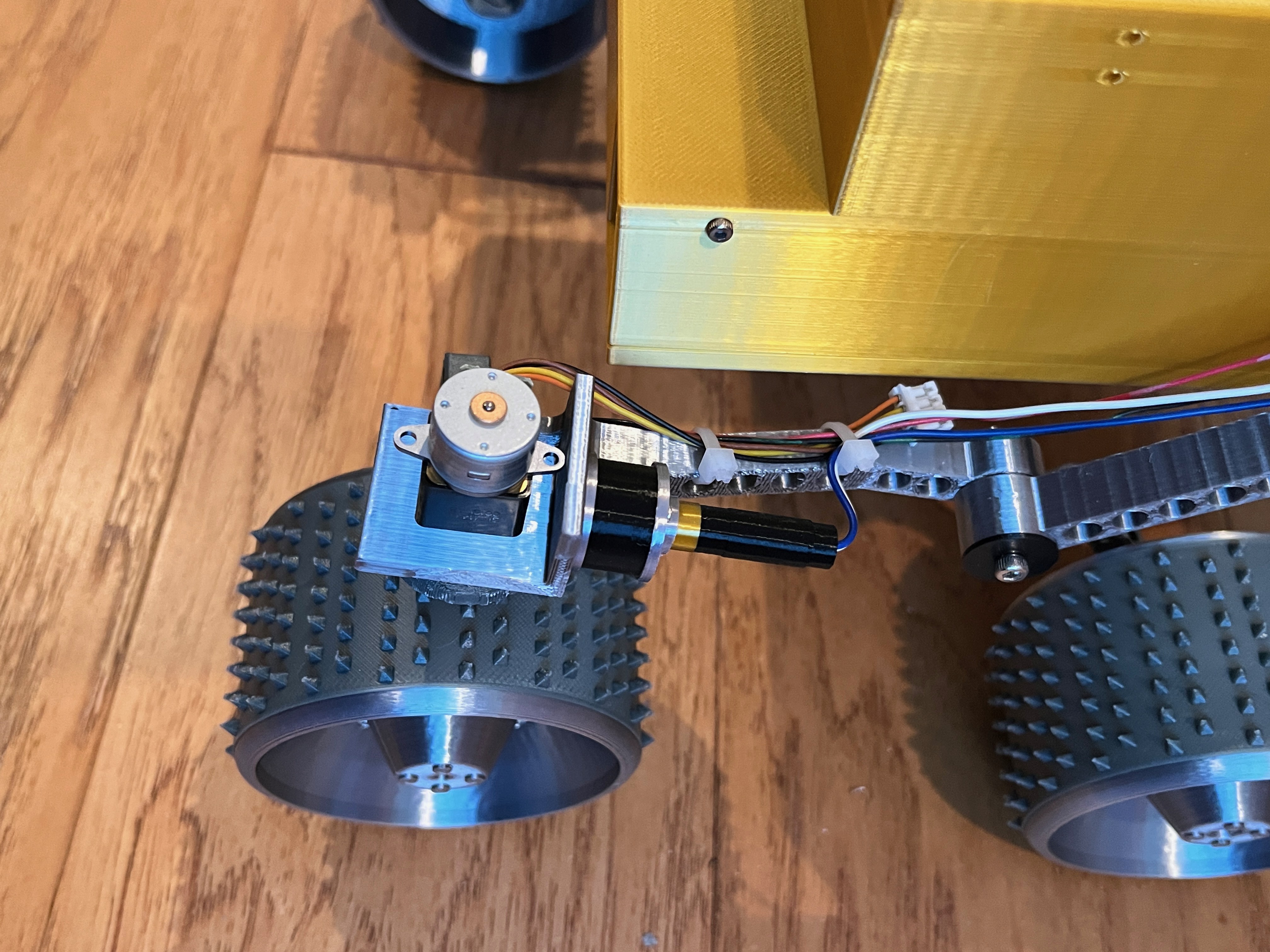

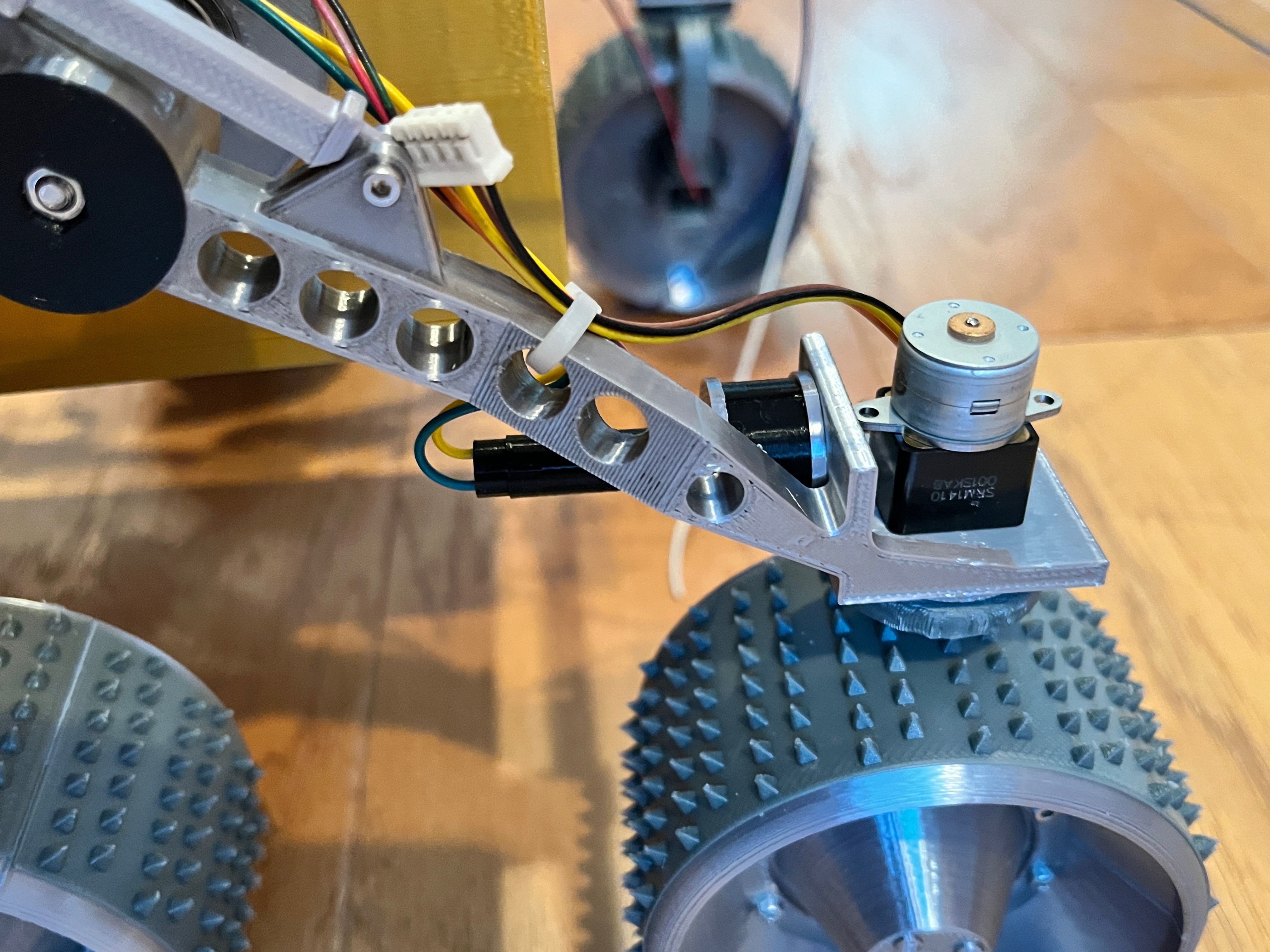

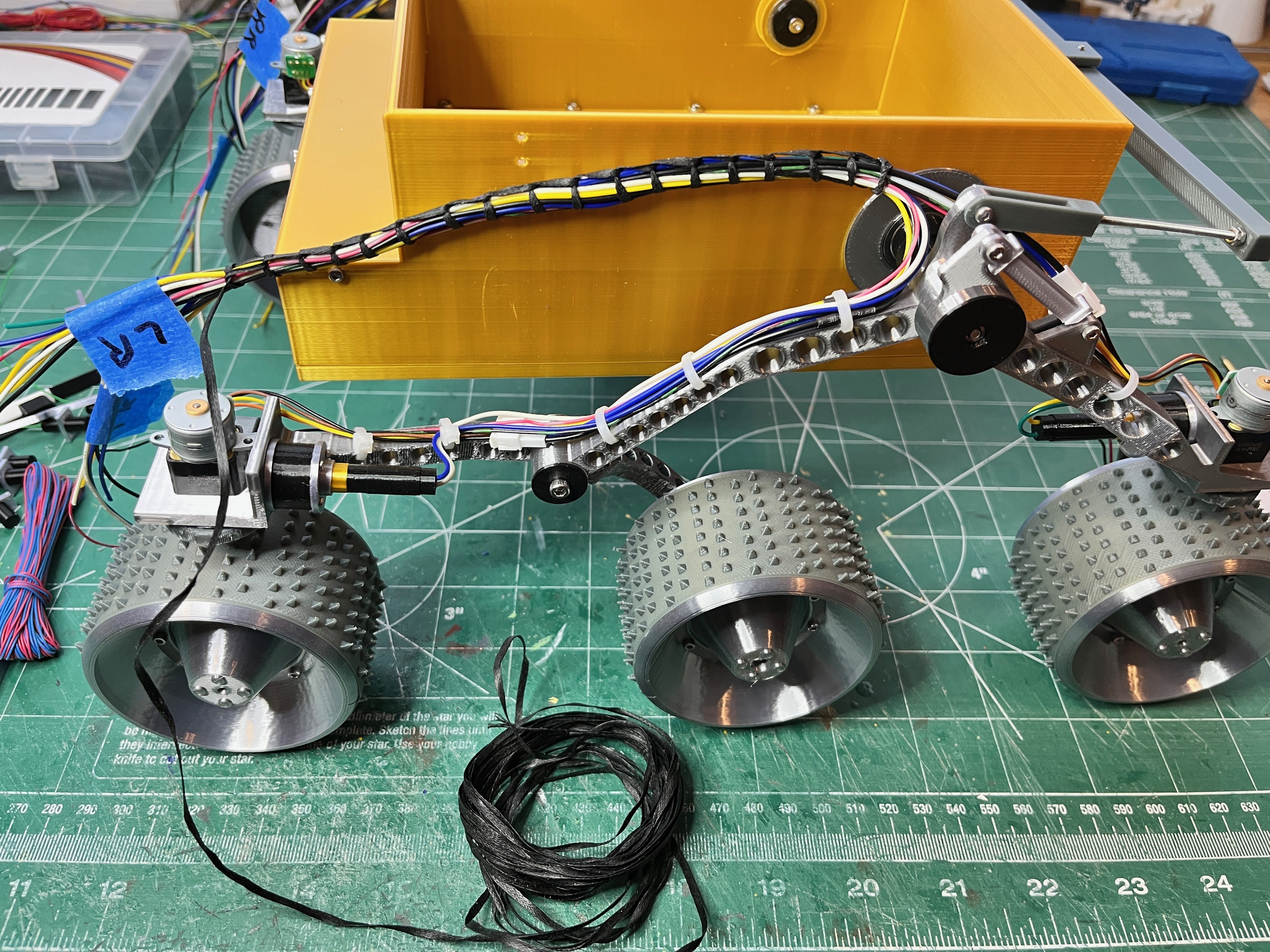

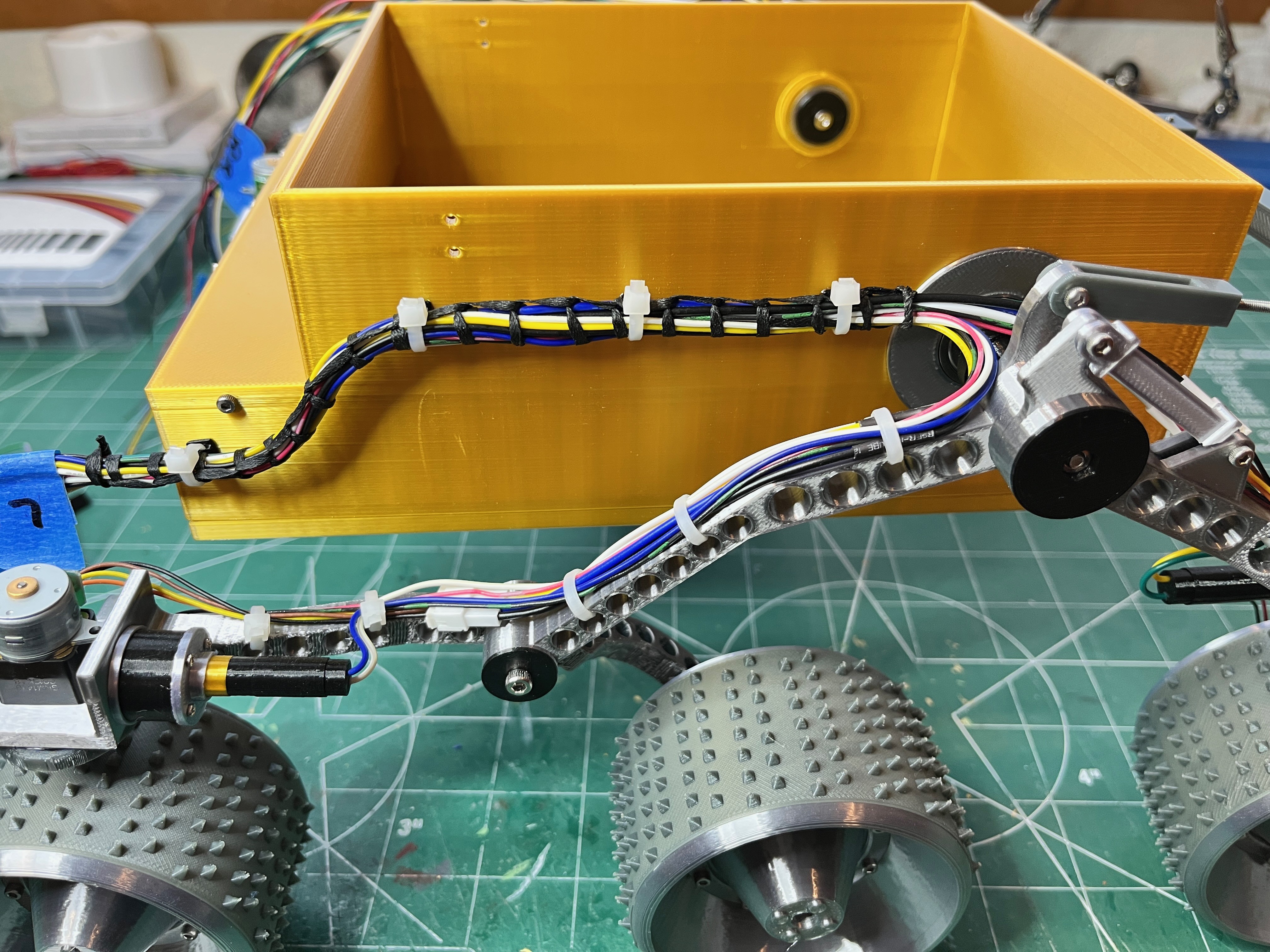

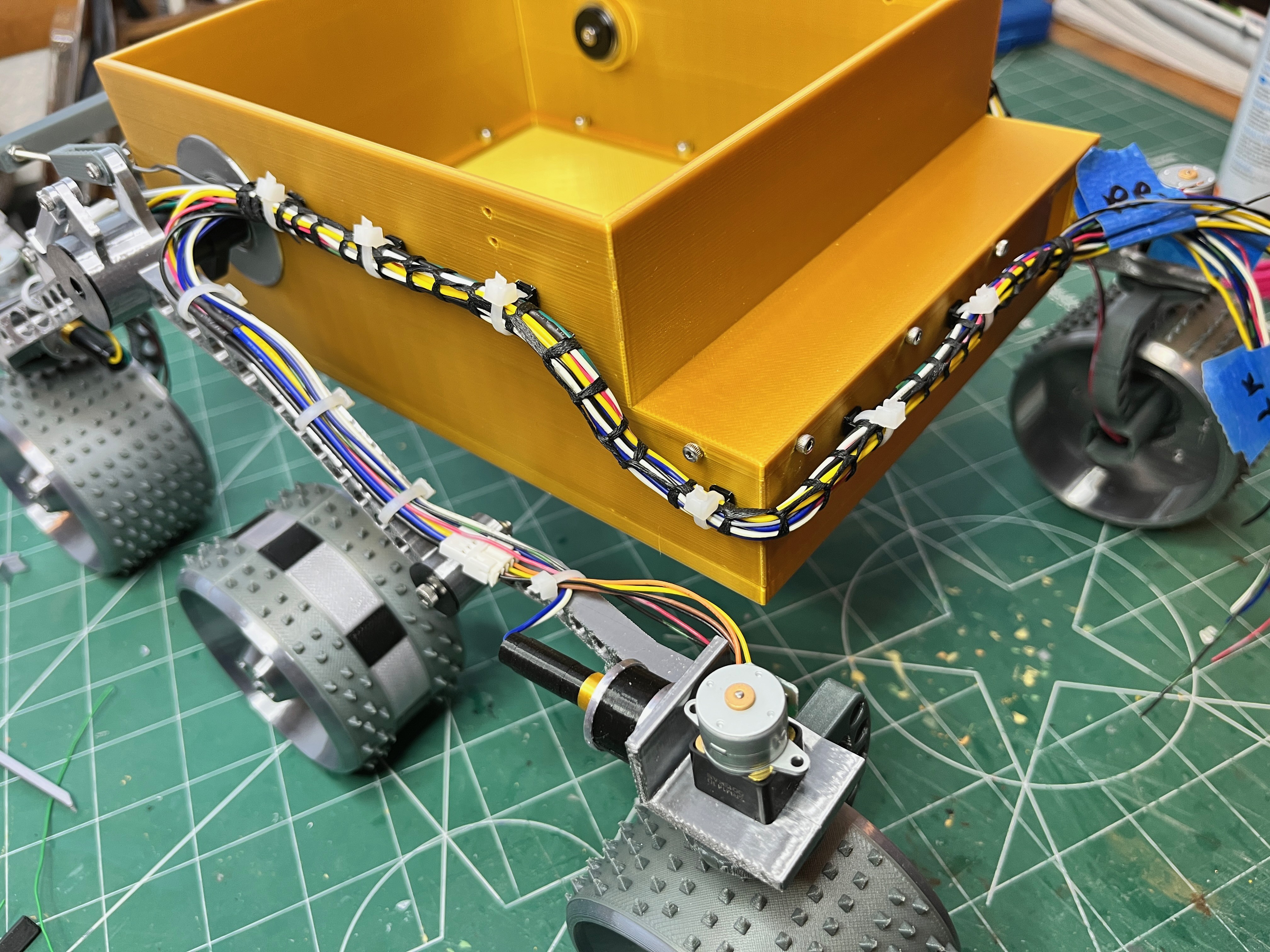

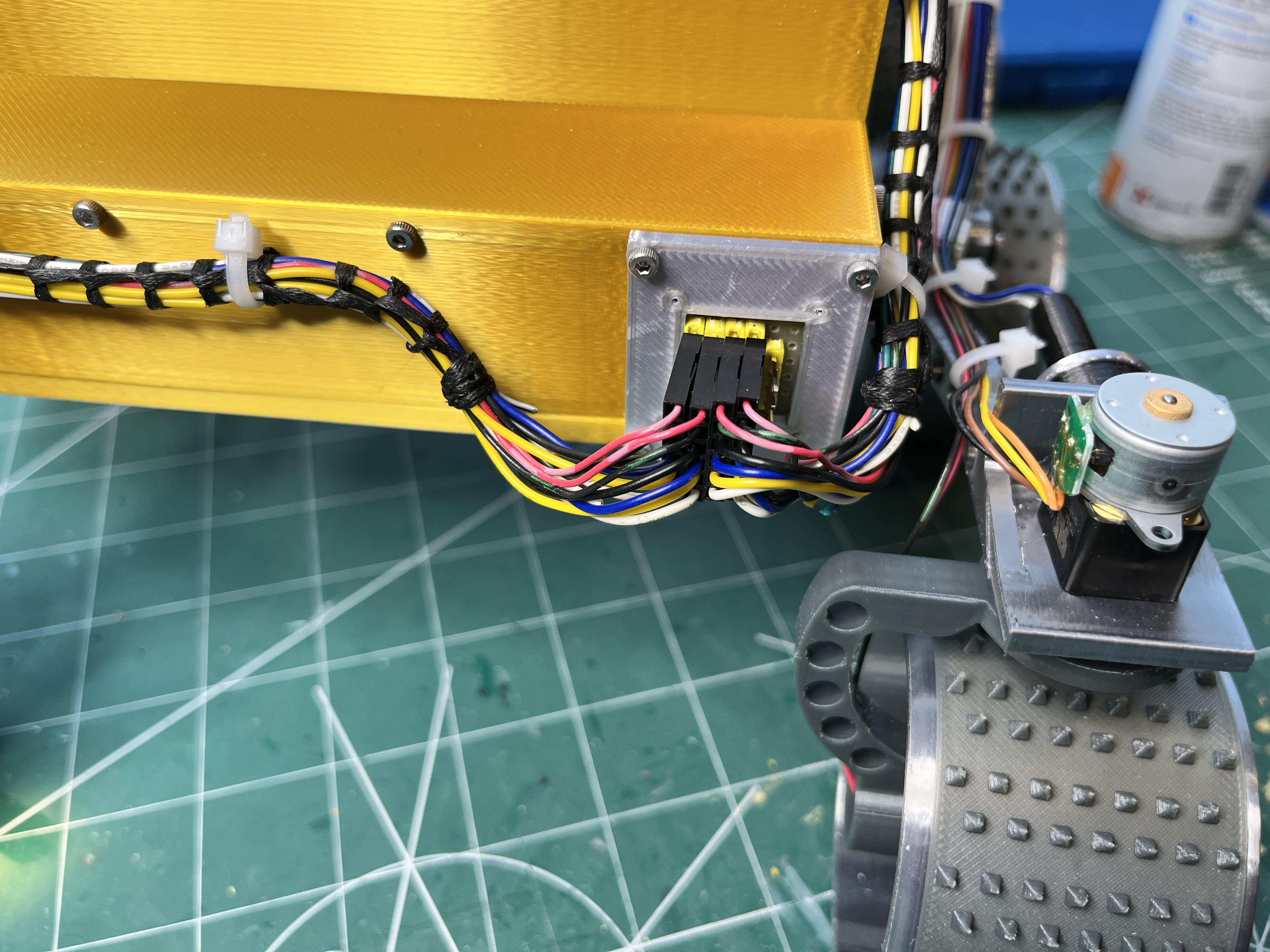

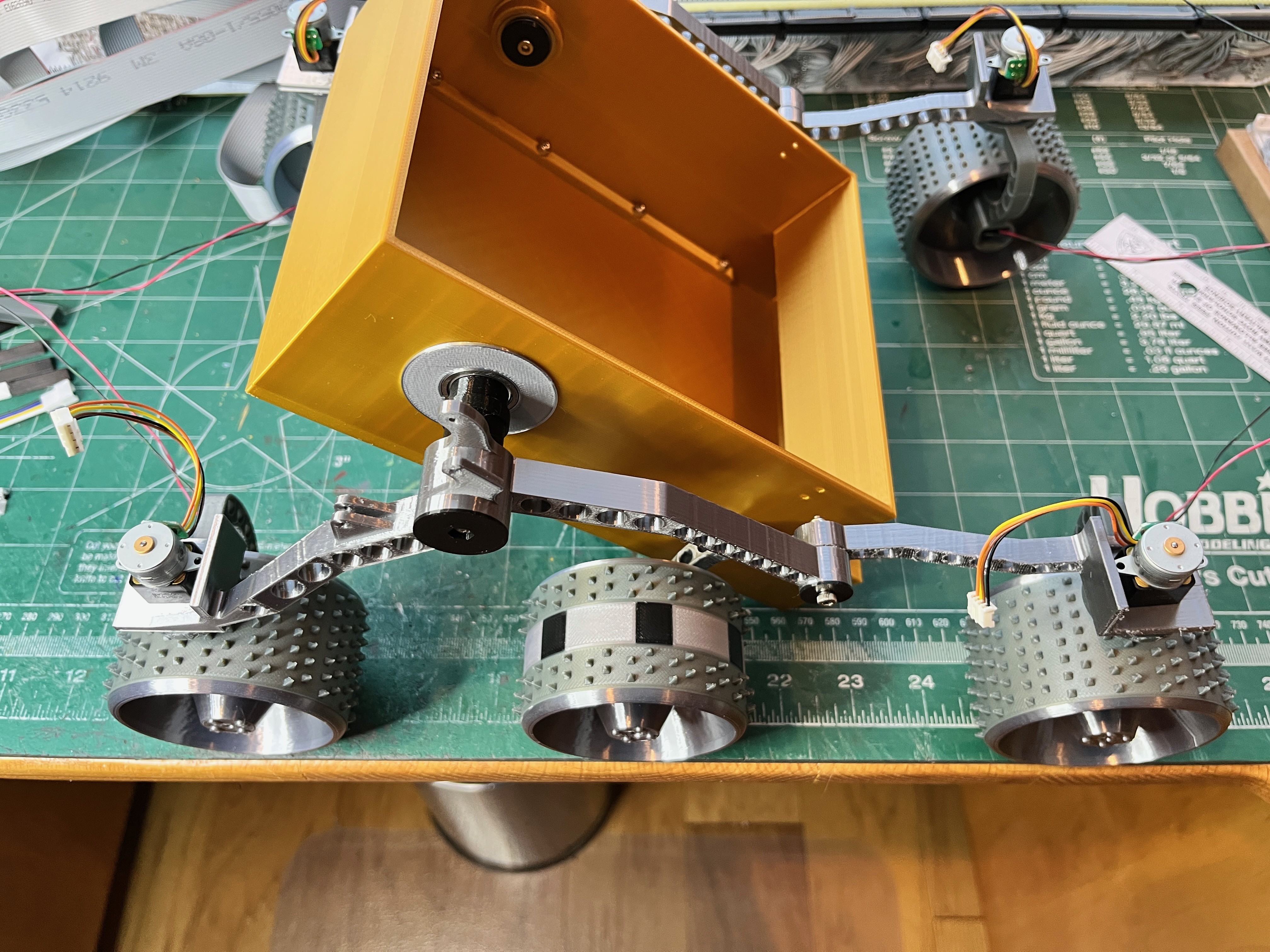

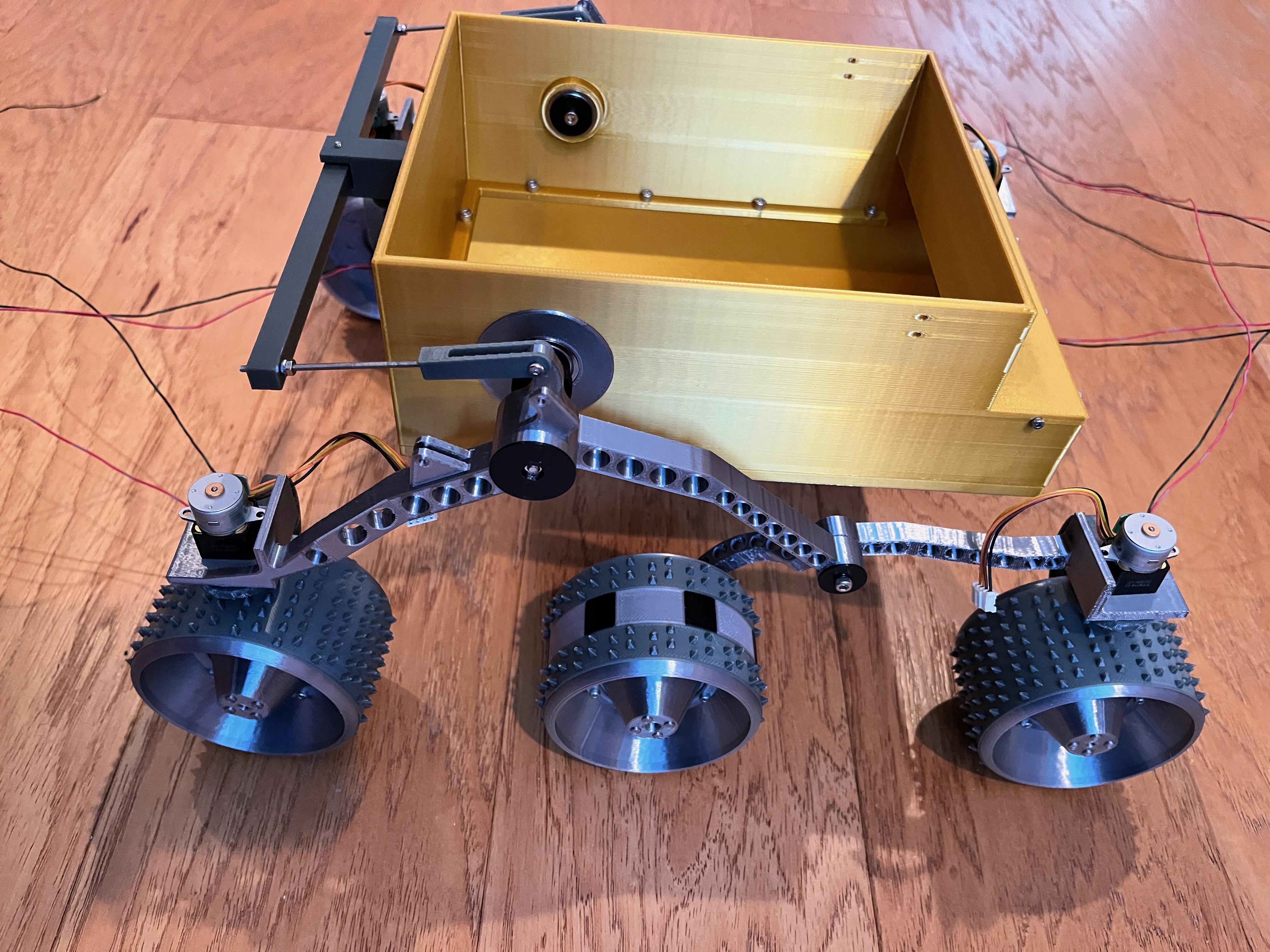

12/05/2024 at 15:24 • 1 commentThe instrumentation has wires running along the outside of the body along with the wiring to run the motors and servos so all this is added at the same time. Here are pictures of what look like rotational sensors on the corner wheels. Some of the wiring is starting to be zip tied to the rocker/bogie arms.

![]()

![]()

![]()

I chose to use waxed tape to bundle the wires together.

![]()

The wires are then zip tied to the side of the body just like the real rover. It makes sense to label the bundles of wires, either that or ohm them out later to figure out what goes to what.

![]()

![]()

The rear camera is easy. The front pair of cameras and lasers are a bit more complicated. First test fit the bar that holds them, then glue them on and finally attach the wires to a junction box. I am holding off gluing this rather delicate structure on until I finish the wire interface board.

![]()

![]()

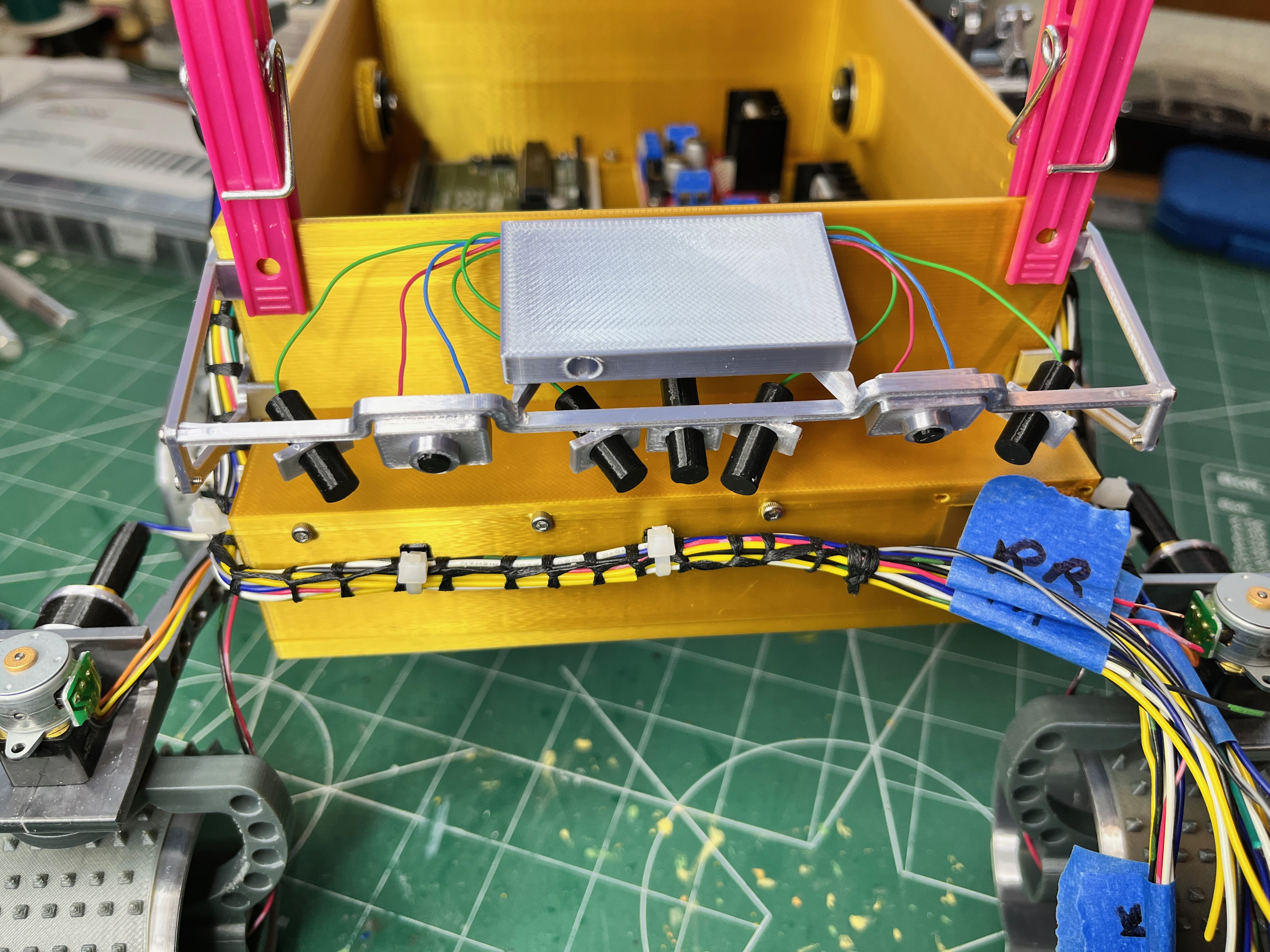

The outer wires go through a plate that has two sided pins. These could have been soldered but I chose to make them detachable. There will be a plate that covers the wires. The inner cable harness attaches to the other side of the plate.

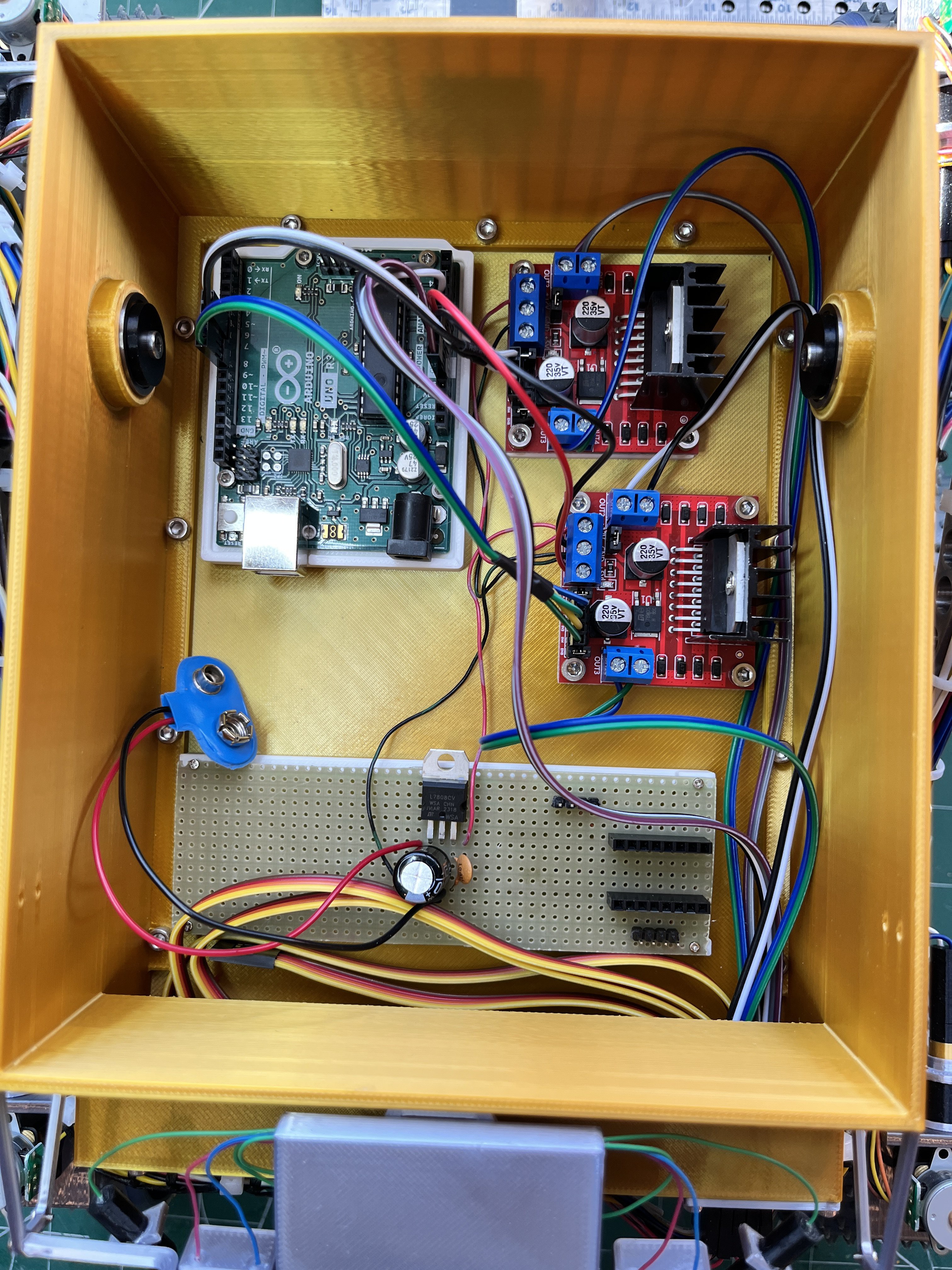

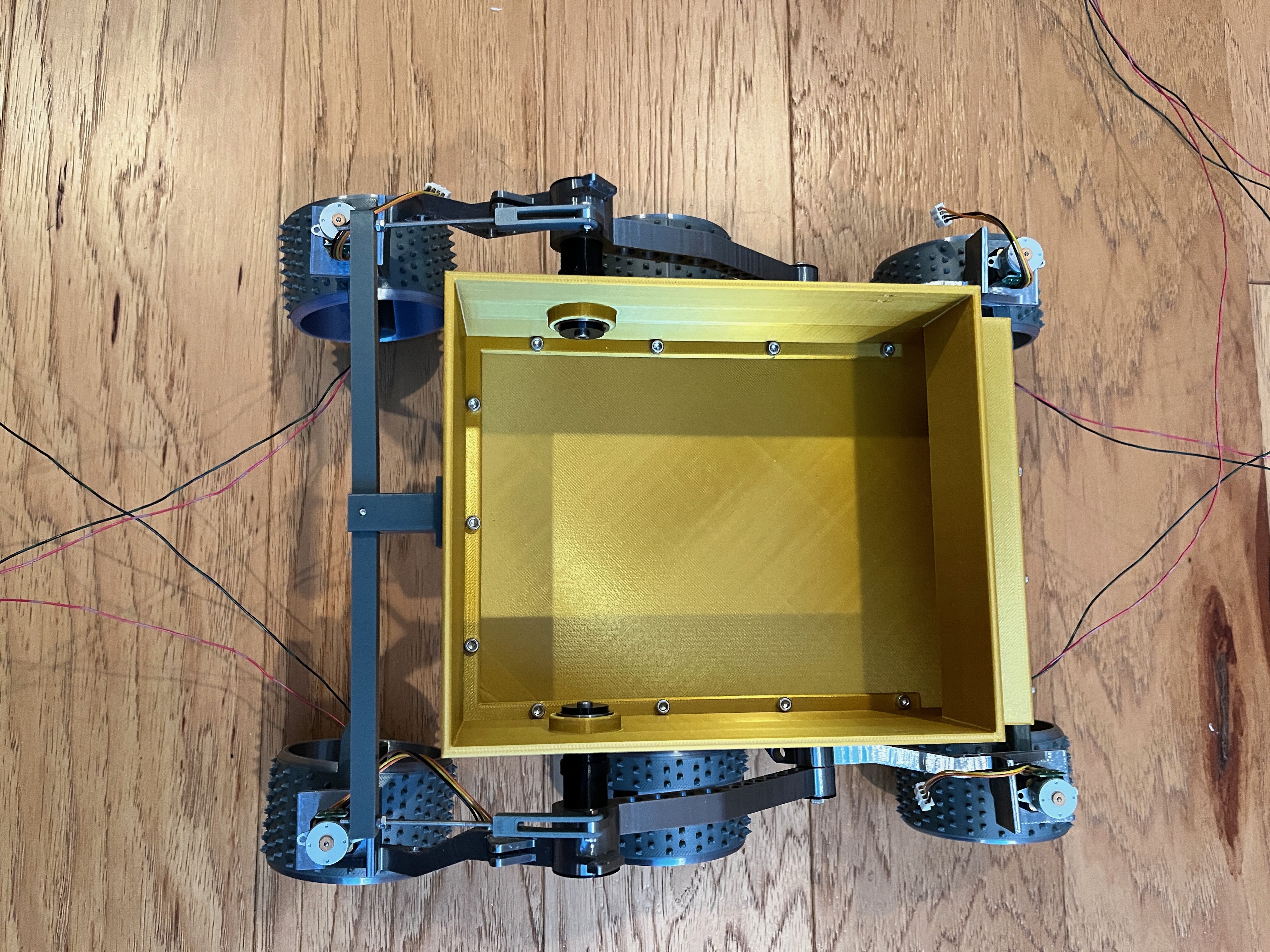

I first tested the joystick and then the wheels moving forward/reverse. The wheel motors are driven by two dual L298N motor drivers. You have to make sure the wires are attached such that all four motors turn in the same direction. After that I tried to get the stepper motors working. They each use an A4988 Stepper motor driver. All this worked fine in a bench test, however on the model these little stepper motors do not have enough power to pivot the wheels. Stepper motors that have enough power to turn the wheels would be way too large and look wrong. At this point I have decided to not implement the turning function. The rover will only be able to move forward and backward. Here is a picture of the interior. There is plenty of room if you want to add additional functionality such as working sensors. I use a L6808 to convert the 9V battery power to 8V which drives the motors.

-

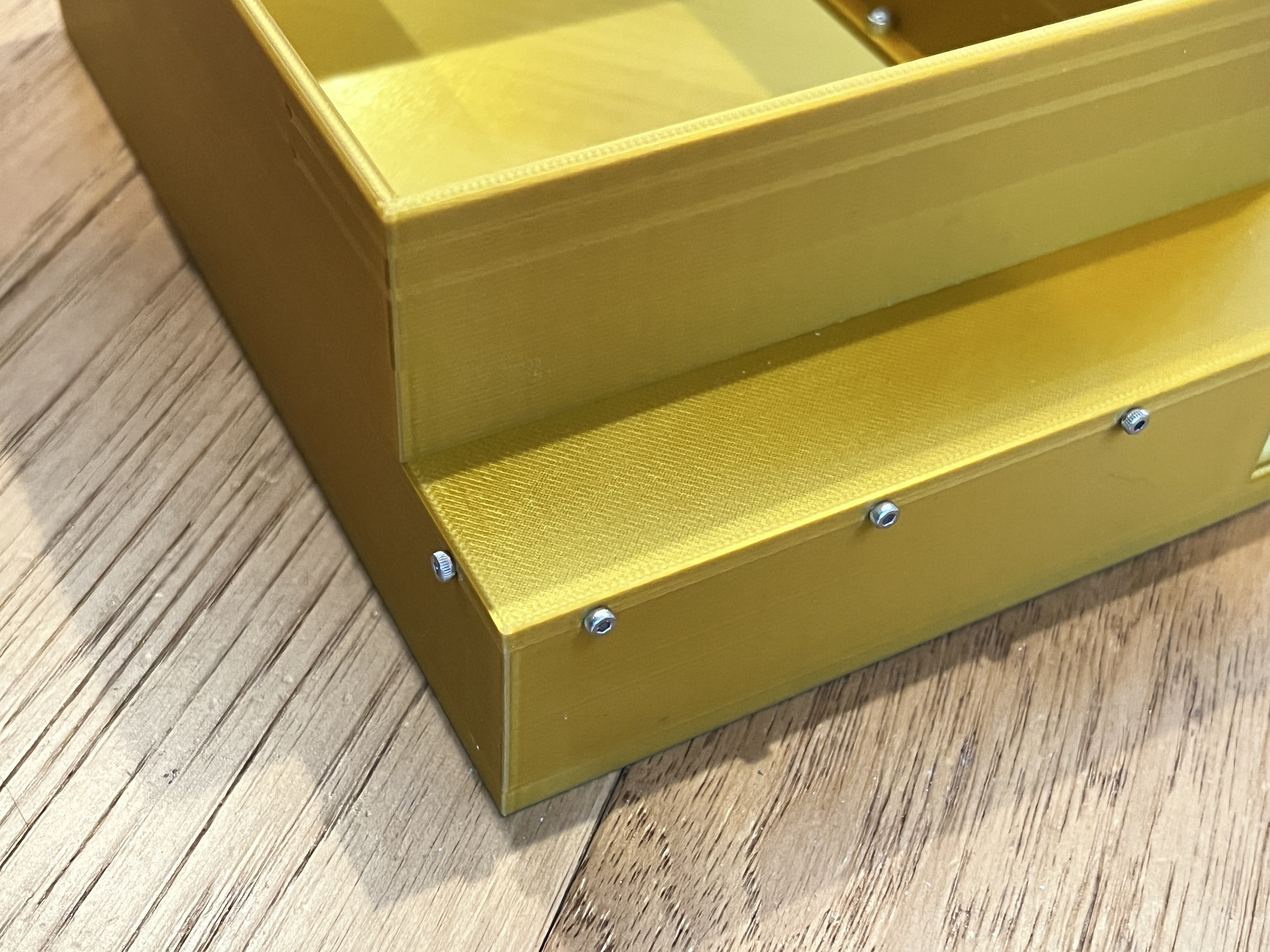

Body

11/26/2024 at 16:14 • 0 commentsThe body was split into three parts; the top part that is attached to the solar panel, the main body and the bottom plate. The bottom plate was separated so that the main body can be printed without internal supports.

There are holes around the front to add small M2 screws that do nothing other than to give the model a more realistic look.

-

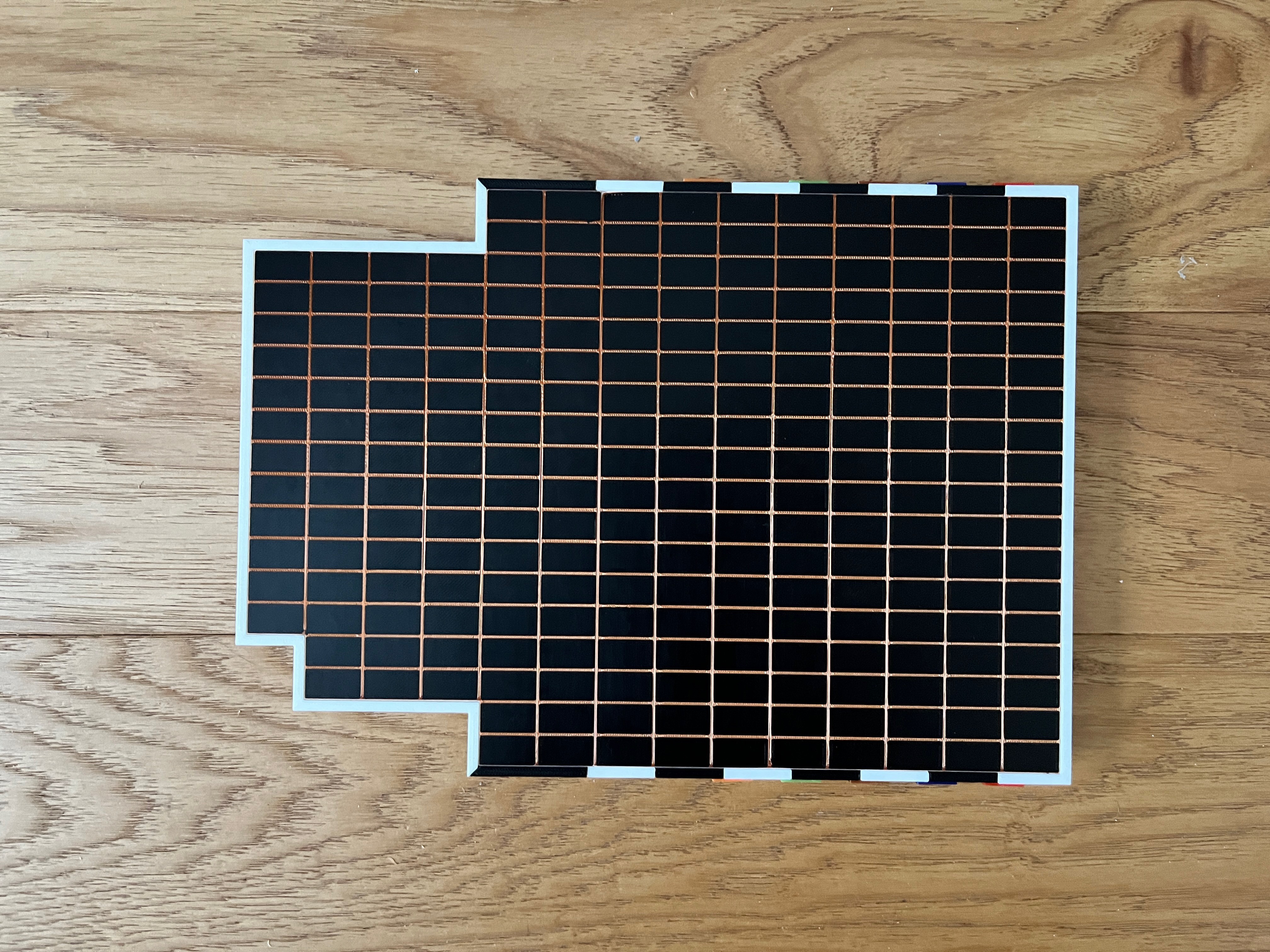

Solar Panel

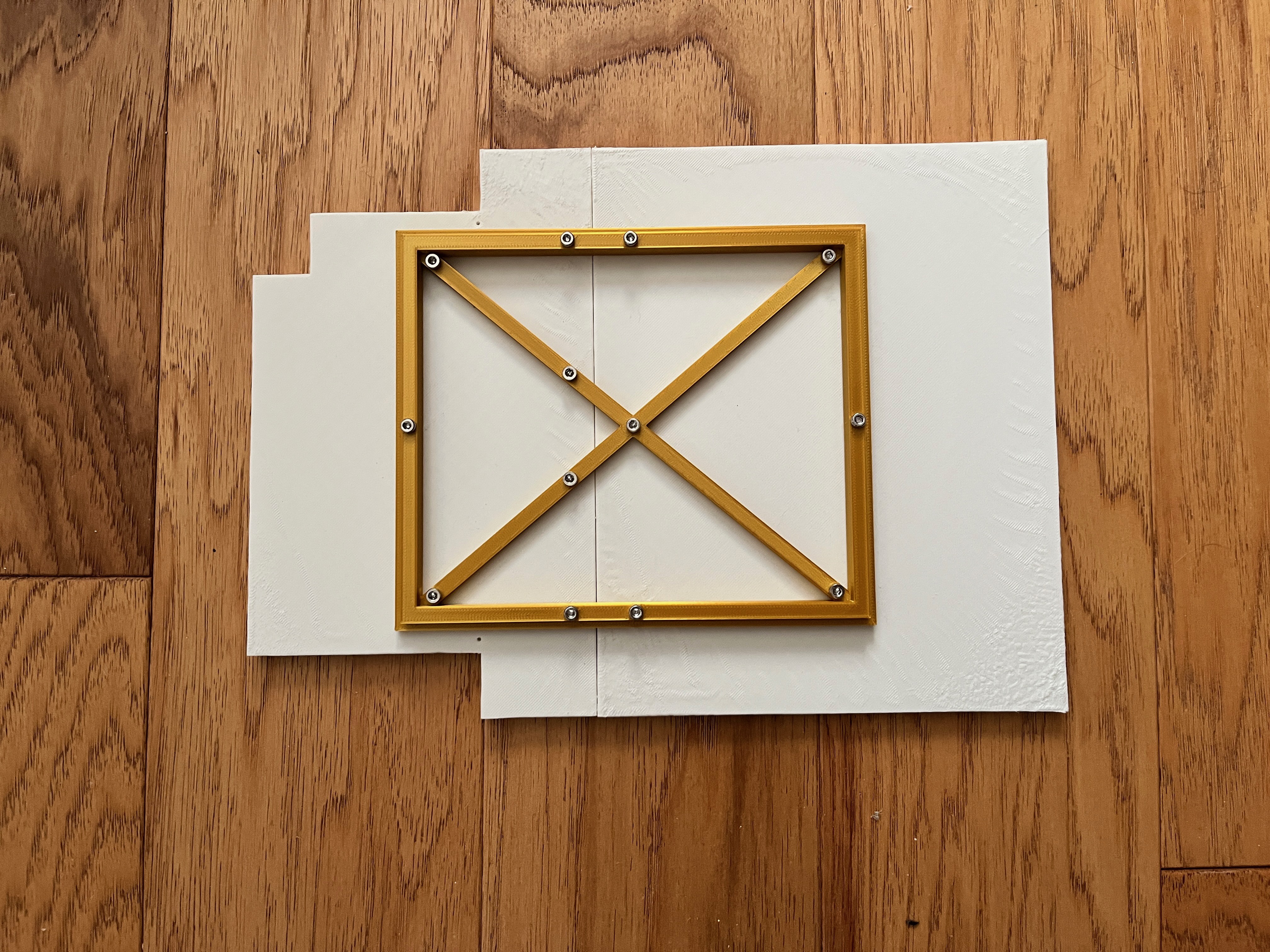

11/24/2024 at 17:15 • 0 commentsThe main part of the solar panel is complete. Since the scale is 1/2 actual size, this is the one part that had to be split in two to fit on a standard 3D printer surface. After trying a print right side up I decided to print the two parts upside down, i.e. the top (good side) on the print surface. These are three color prints. The first layer should be black. Then switch out the filament for copper and print the next two layers. Finally switch out for white filament and let the remainder print in white. No supports are needed because the printer easily spaned the 1mm gap between the black rectangles. On the sides I beveled the edges at a 45 degree angle that go in 0.5mm. After the two solar panel parts are printed, print the body interface in gold and use M3 screws to anchor the top halves together. You could choose to glue these parts if you want but the screws work well at aligning the parts perfectly so you can't tell they are two parts. The solar panel is the most important part since it takes up the entire top.

![]()

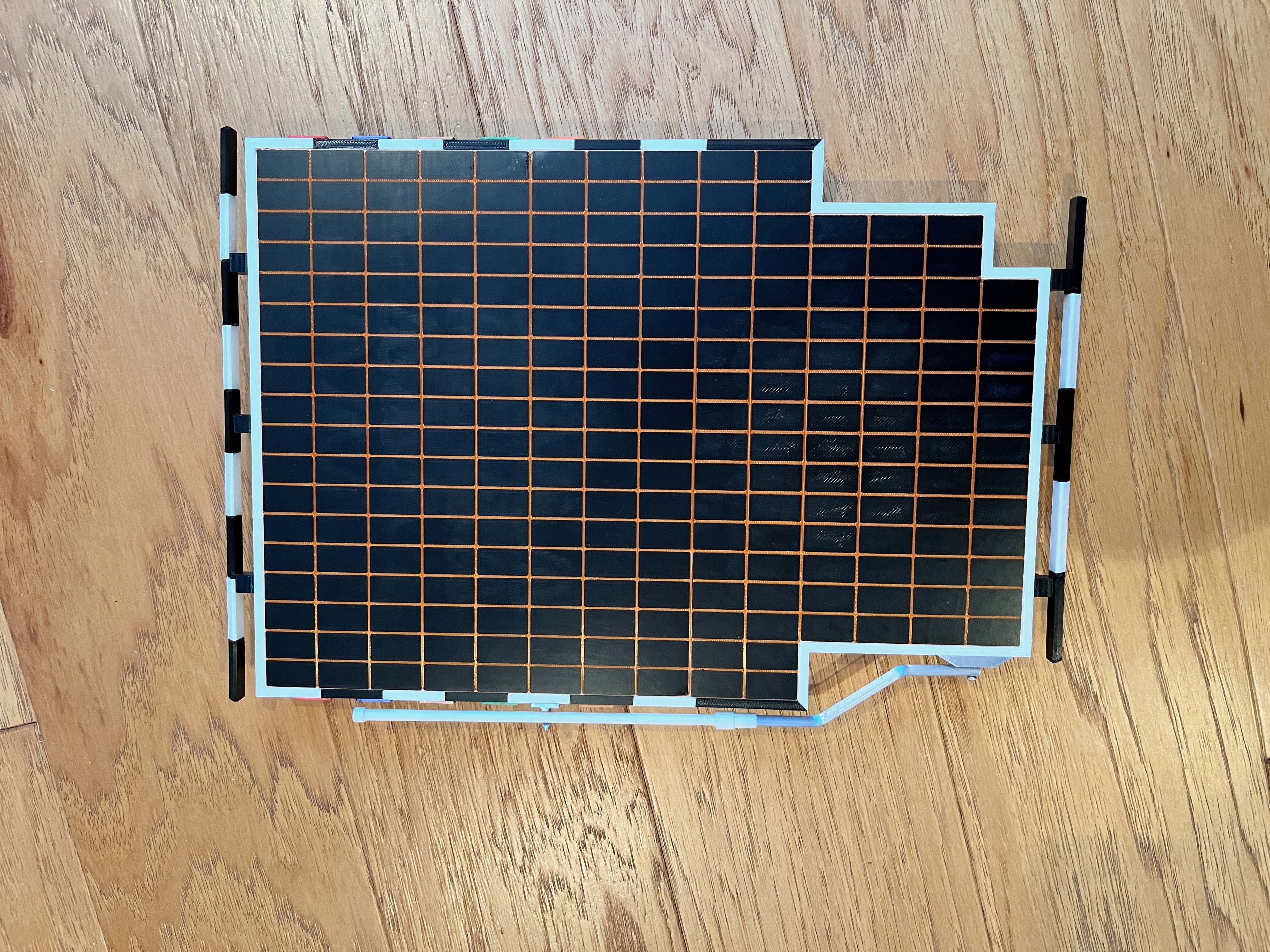

The sides of the solar panel are printed and glued on, first the two end white parts and then the sides alternating black and white. Work from the back to the front so the last parts glued on are the long black parts with the angled ends. For me one side fit perfectly and the other side was a bit long. A little sanding of the end of the last part and it fit just fine. Now print and glue on the colored strips (what I call badges). There is a specific order. On one side make sure you leave enough gap for the antenna park mount to go.

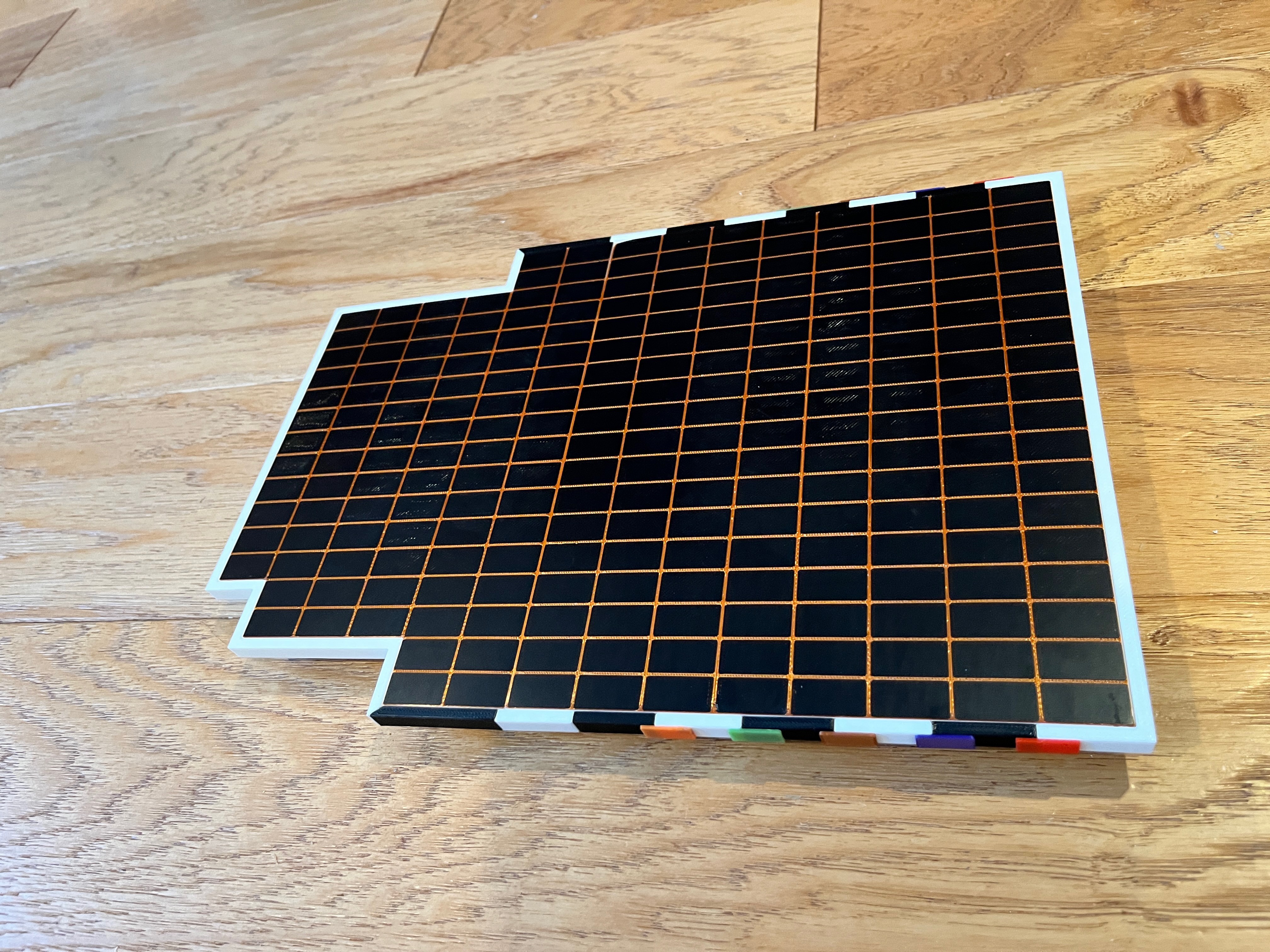

Here is the competed solar panel. I am happy with the result. You can't tell where the two halves meet. The other parts will go on later.

![]()

![]()

The antenna is printed and installed.

![]()

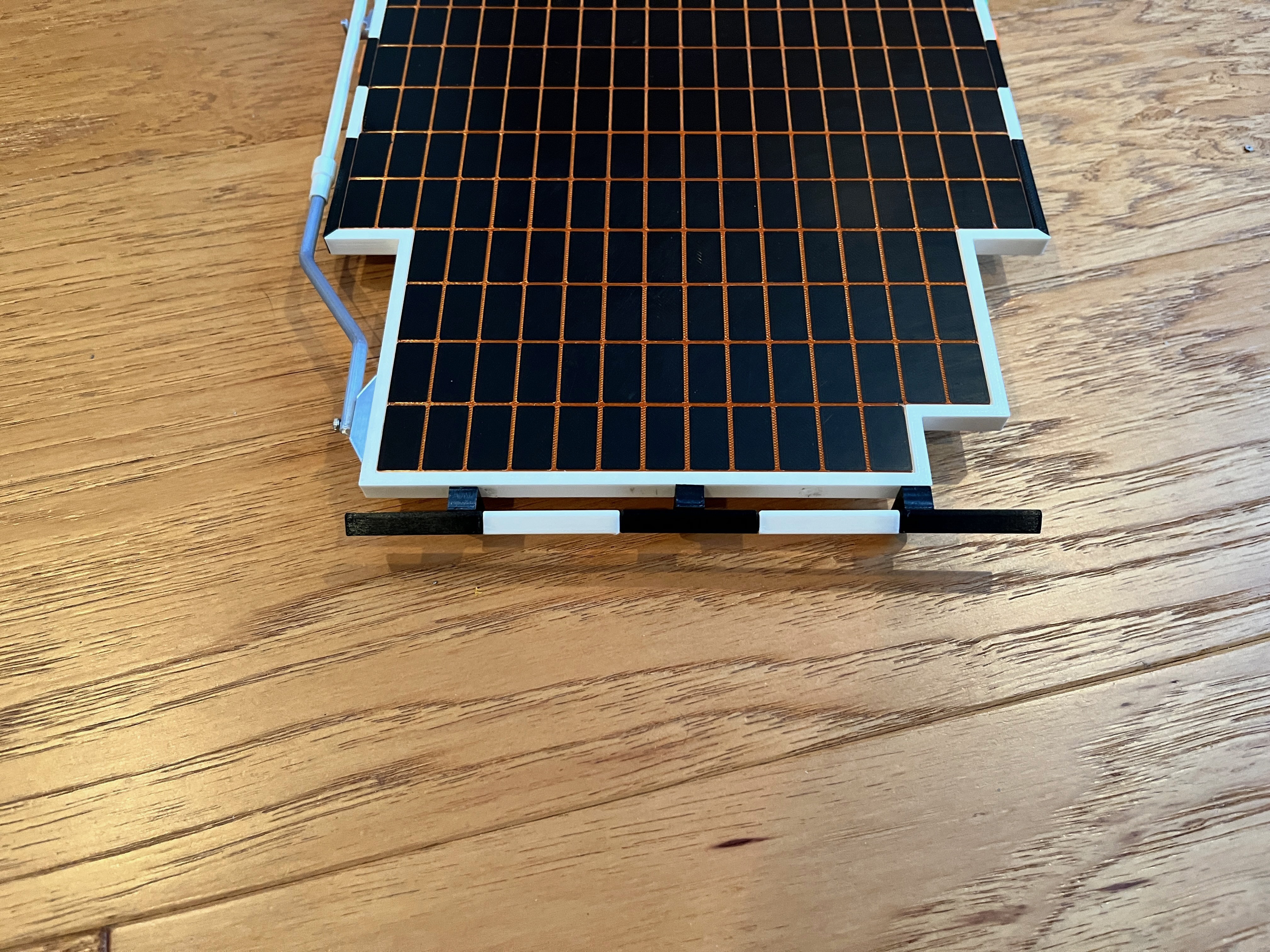

There are bumpers front and rear on the solar panel. They consist of black and white parts that are glued together.

Here is the completed solar panel assembly from the top.

![]()

-

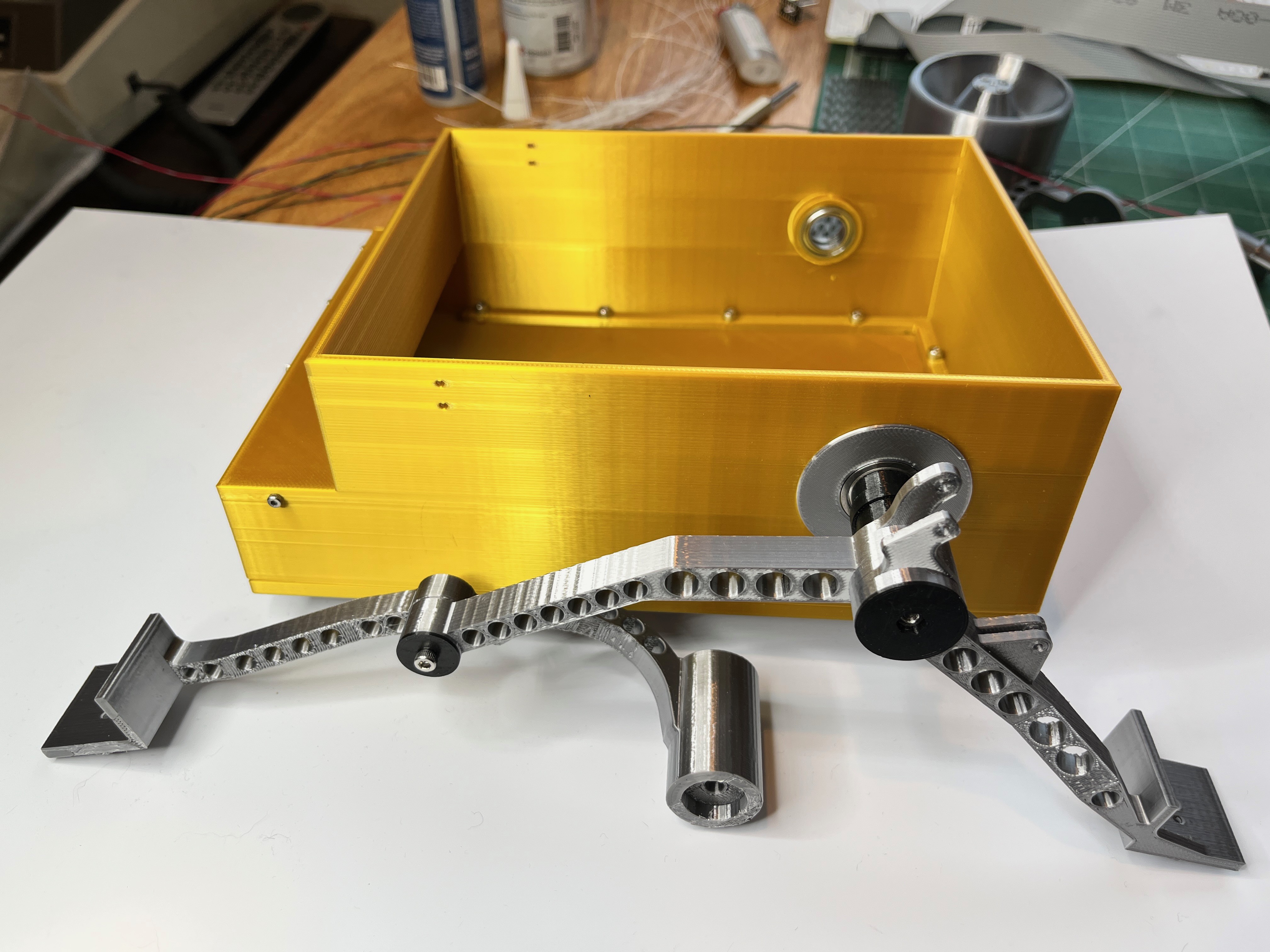

Suspension

11/18/2024 at 15:40 • 0 comments---------- more ----------Most of the 3D parts have been created and are being verified versus available hardware parts. Here is the rocker and bogie arms. The real arms are hollow but when doing test prints the arms at this scale are too flimsy so the arms are solid with holes drilled through the appropriate sides. The wires will be zip tied to the outside of the arms instead of being routed through hollow arms. Still waiting for the small servos to steer the wheels. Unfortunately the really small servos have an 18 degree step but this should be OK because the only real steering maneuver used on this rover is to angle the wheels in and rotate in place.

![]()

There are quite a few parts. Here are some of them.

![]()

And here are the two main arms on one side attached.

![]()

The corner wheels will be rotated with small stepper motors. Here is one of these motors in place along with the arm and the small geared motor to turn the wheel.

![]()

The wheels have small screws that simply add to the look.

![]()

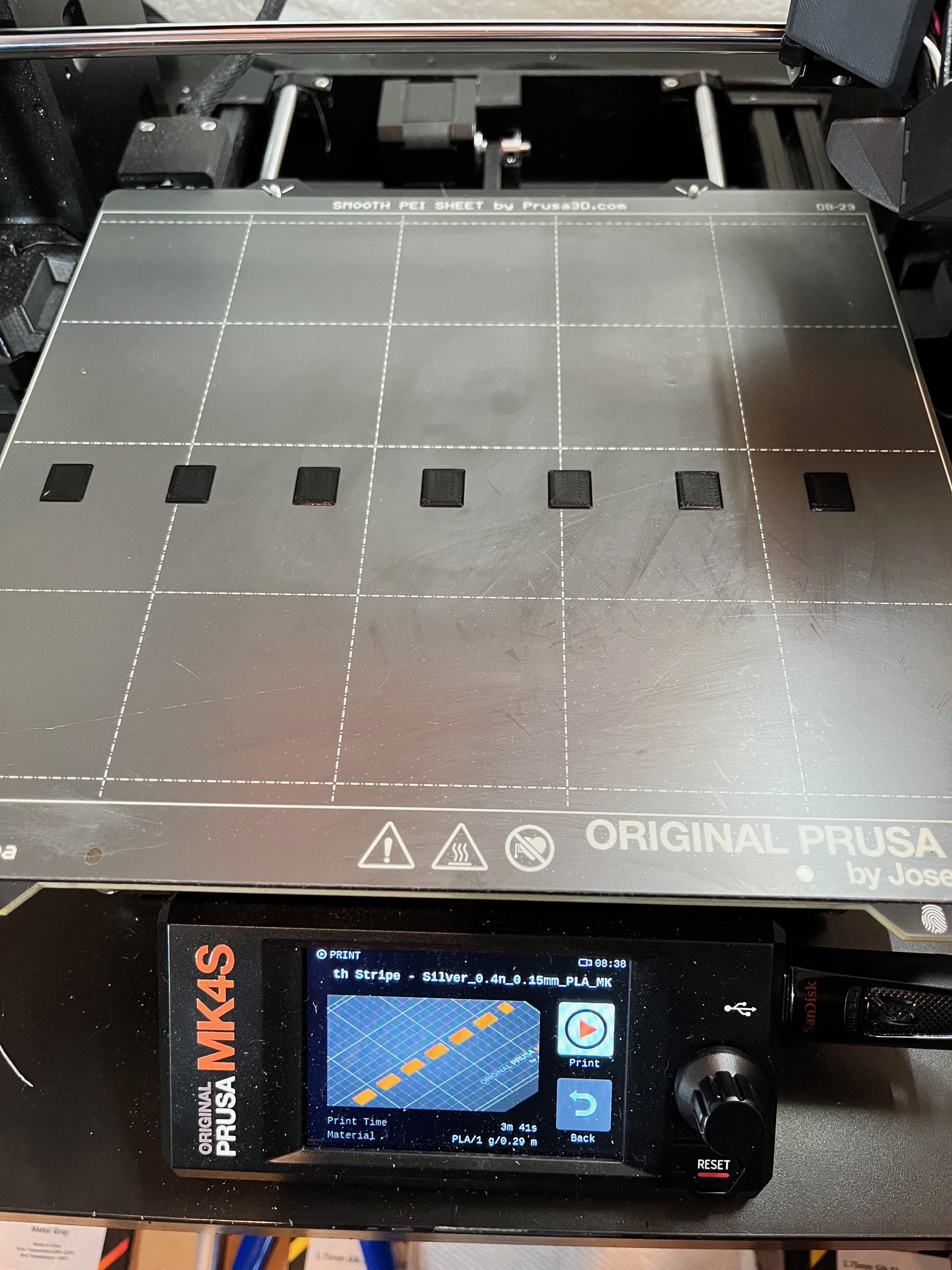

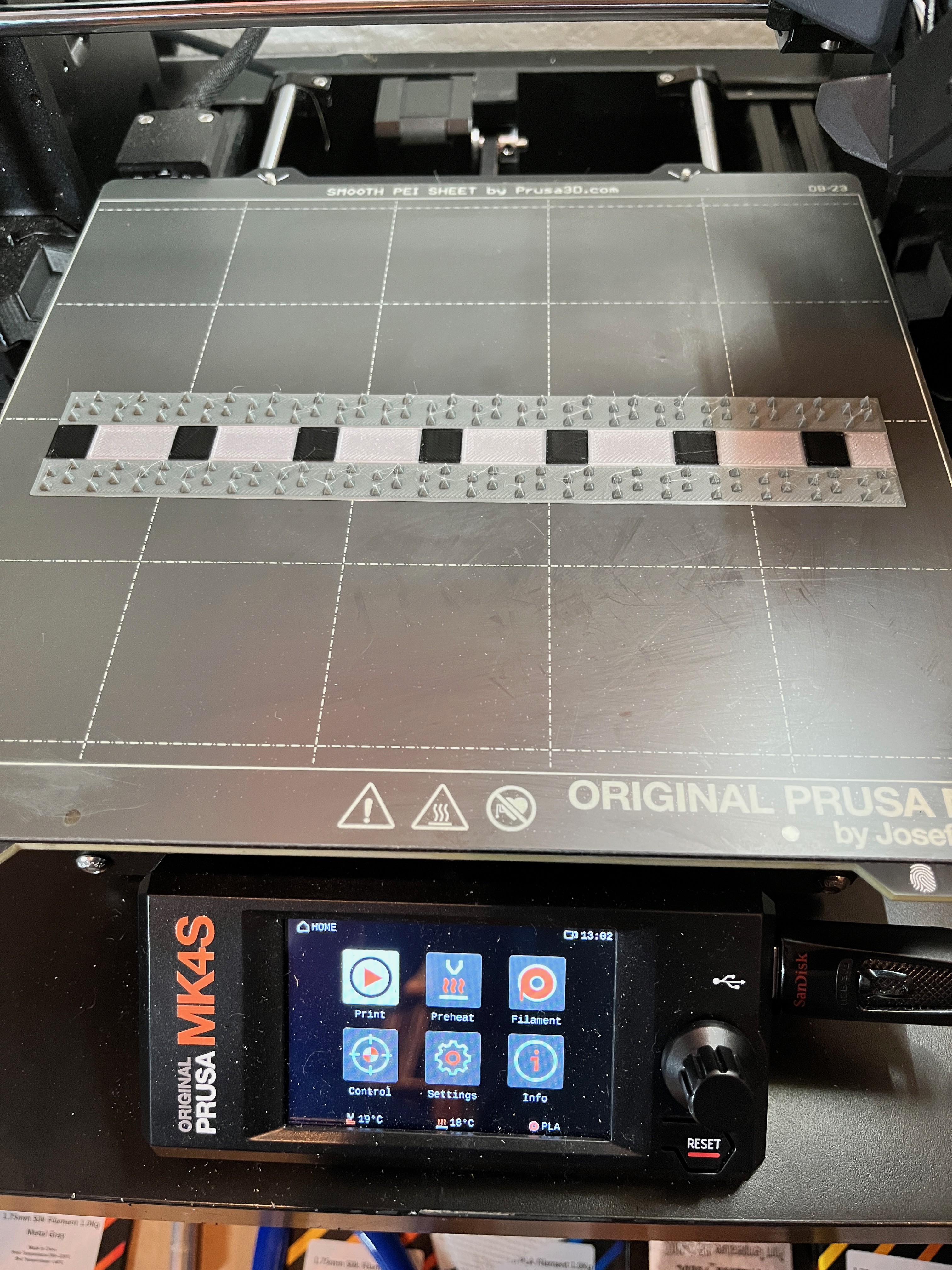

Along with treads that are glued on. They are printed using a different color. The spikes are printed on top of the first two layers that are thin so the tread can be wrapped around the wheel and glued on.

![]()

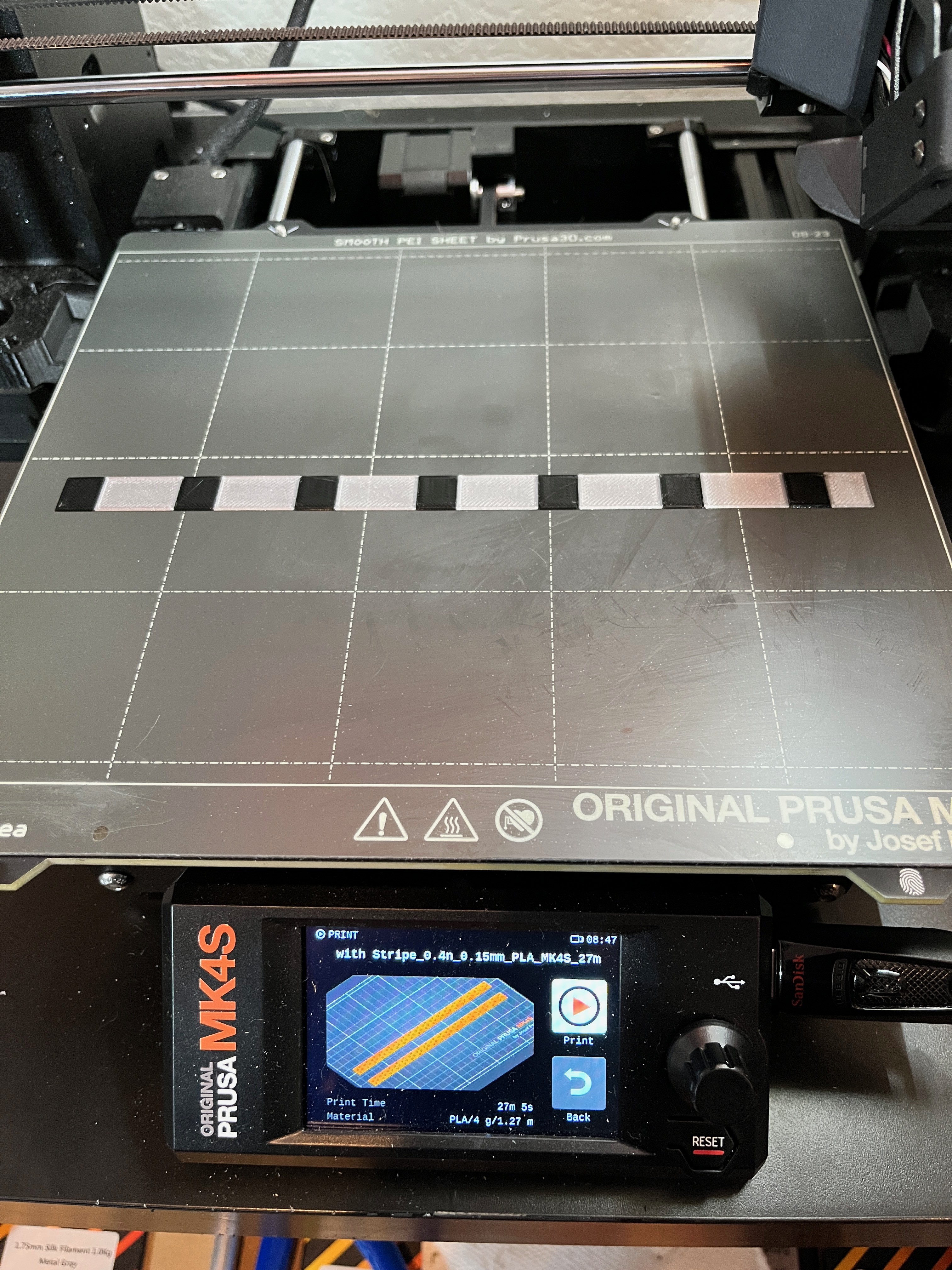

One of the middle wheels has a black and white stripe down the center. For this I overlay three STL files in the slicer to align them perfectly, then one by one remove two and slice the remaining STL, giving three printable files that are perfectly aligned. The key to doing this trick is to disable any elephant foot compensation so that the three prints meld together. You also need to position the STL files such that the center stripe is not going to interfere with the first layer measurements (at least if you have a Prusa printer that creates a plate height map so the first layer compensation is automatic). For other printers this may not be an issue. Start by printing the black parts. When complete change out the filament with silver, leave the printed parts on the plate but remove any initial filament laid down to get the flow started. Now print the silver parts. The parts are only two layers thick so they should not interfere with each other. Now swap out the silver for a grey filament and print the third file. In the end you should have a flexible tread ready to glue on to a middle wheel.

![]()

![]()

![]()

The suspension is on but the body sags down. What it needs is a stabilizer bar. This bar not only holds the body in place but allows one side of the suspension to go up while pushing down the other side. There is some bend to this bar. You should print it with at least 30% infill.

![]()

![]()

![]()