Project Status: Version 2 (In Development)

This project page documents YEAH Robotic Hand , formerly called Rebelia Robotic Hand V2, the next iteration of our open-source robotic hand.

Our commitment to open-source hardware remains unwavering.

The previous version, Rebelia V1, is officially certified by OSHWA (Open Source Hardware Association).

The licenses for the project are as follows:

- Hardware:CERN-OHL-S-2.0

- Software: GPL-3.0-or-later

- Documentation: CC BY-SA 4.0

Once Version 2's development is finalized and stable, we will submit it for a new OSHWA certification under the same set of licenses. This ensures that both versions of the project are fully recognized, compliant, and protected open-source hardware.

From Prototype to Product: Forging the Rebelia Robotic Hand

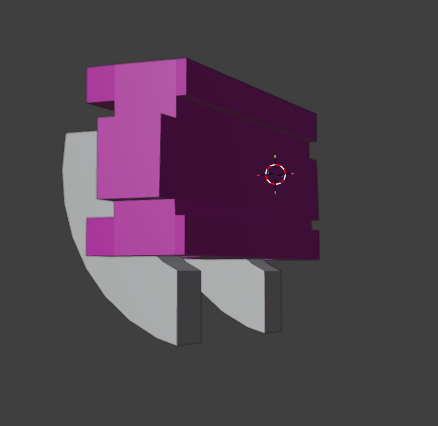

The Rebelia Robotic Hand works.

We've moved past the concept stage and have a functional prototype that has proven its basic reliability.

But now comes the hard part: transforming this prototype into a robust, consumer-ready product that can handle real-world tasks, and we need your help to do it.

Proven Durability: It's Not Just a Demo

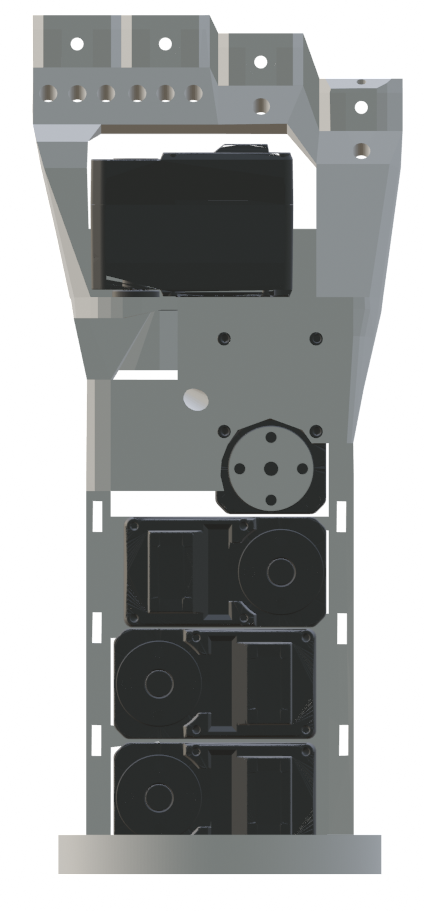

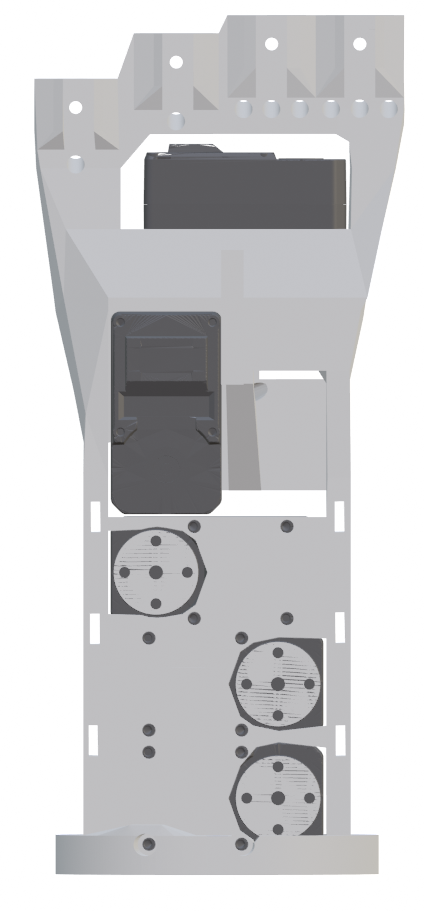

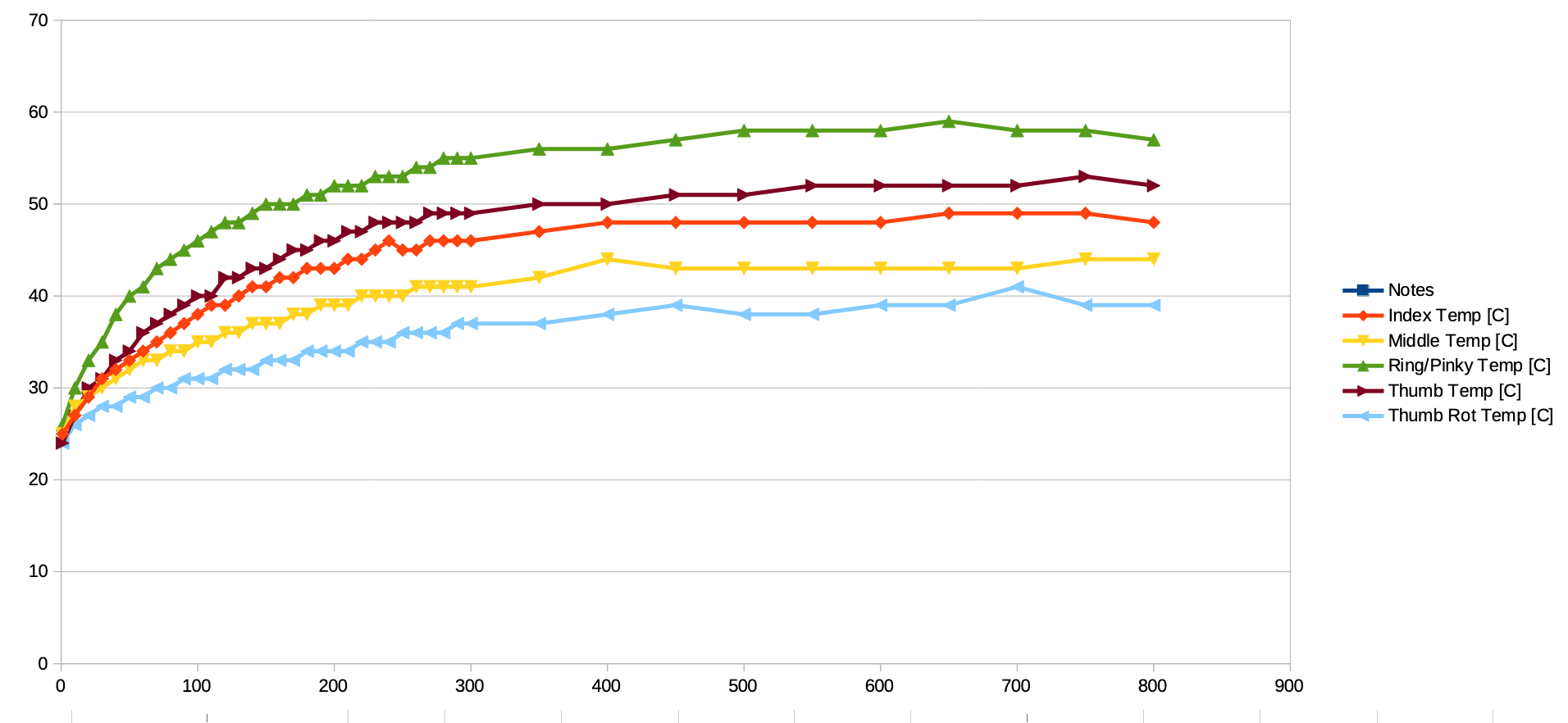

Our latest stress test pushed the hand through 500 open/close cycles of all fingers with a 330 unit force limit.

The result?

The hottest motor stabilized at a cool 58°C. Even after 800 cycles, the temperature held steady, proving the design is stable for continuous use.

This isn't a fragile lab toy: it's a platform ready for refinement.

The Challenge: Beyond the Basics

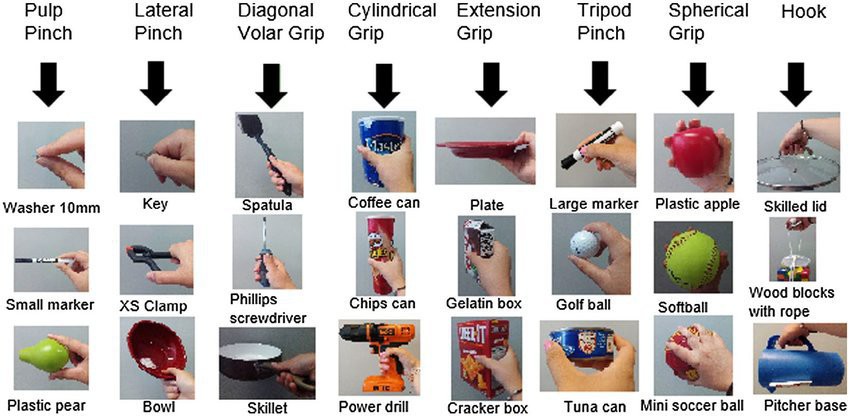

A hand that can just open and close is useful, but a great hand can perform a vast range of manipulations.

We've identified key use-cases it needs to master:

But our list isn't exhaustive. What are we missing?

Suggest scenarios we haven't considered. Is it wielding a tool?

Manipulating a delicate object?

Performing a specific task in a workshop or kitchen?

Design Files & Licensing

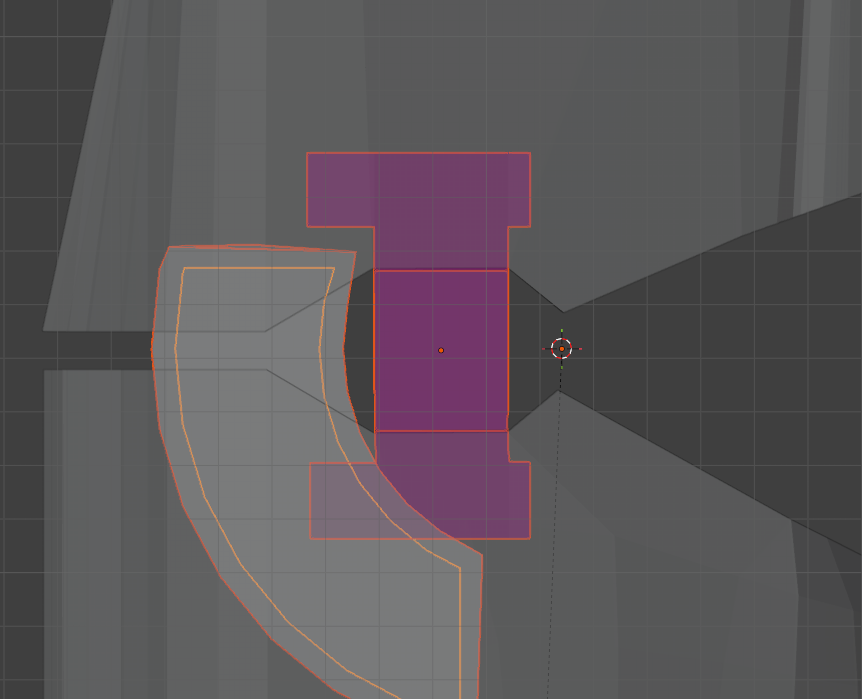

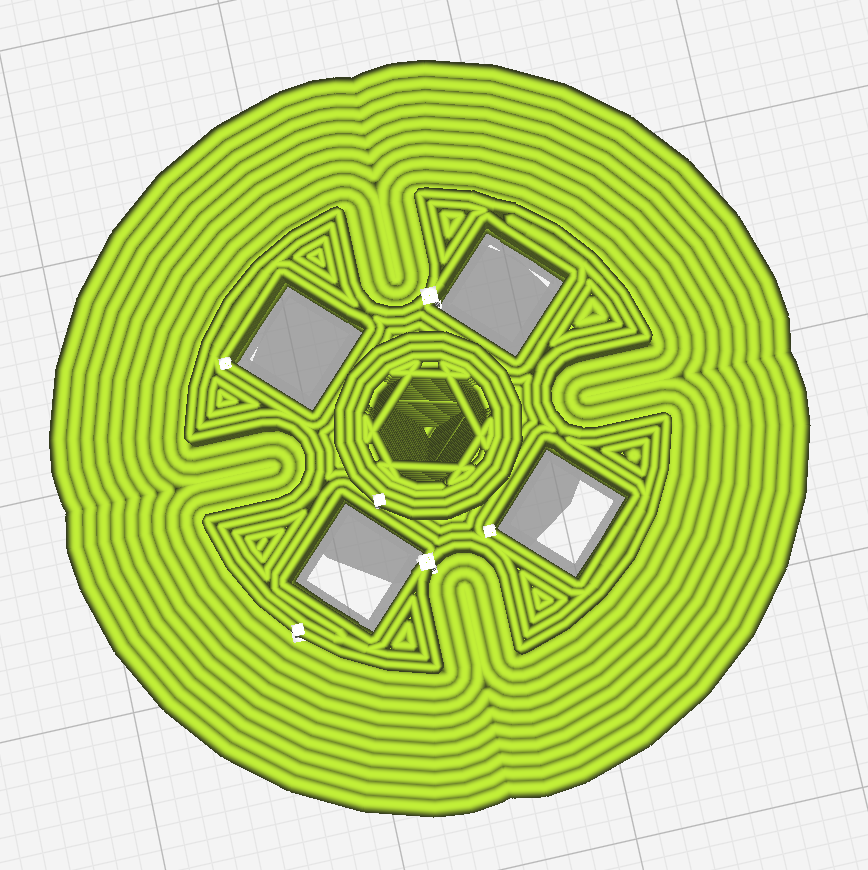

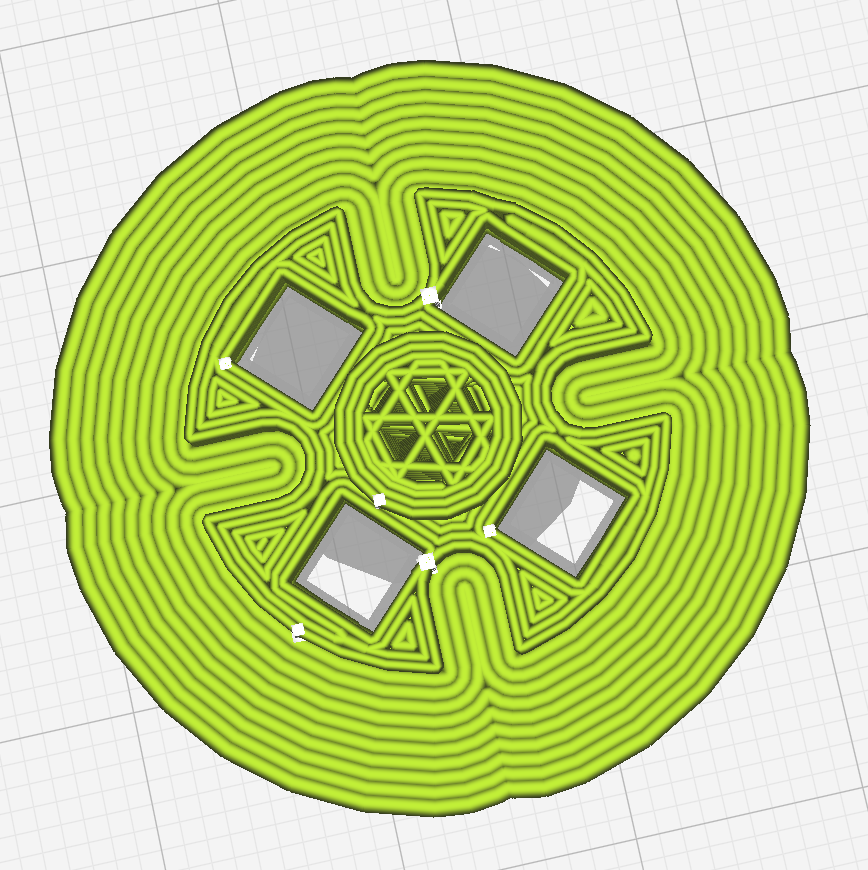

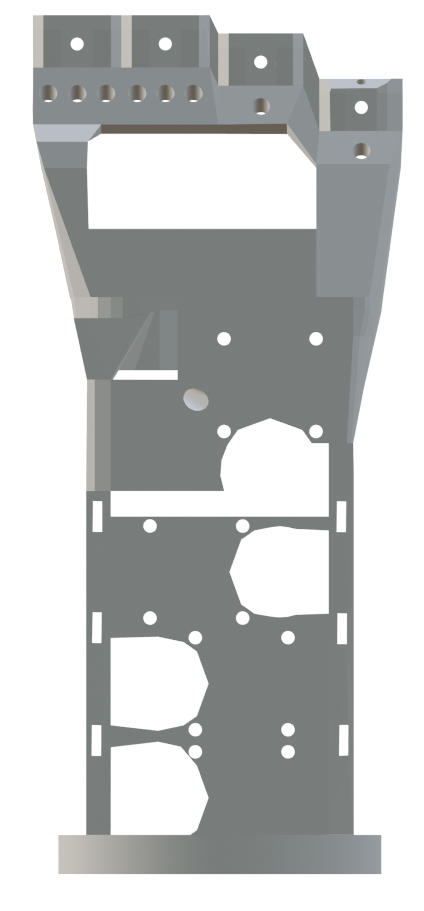

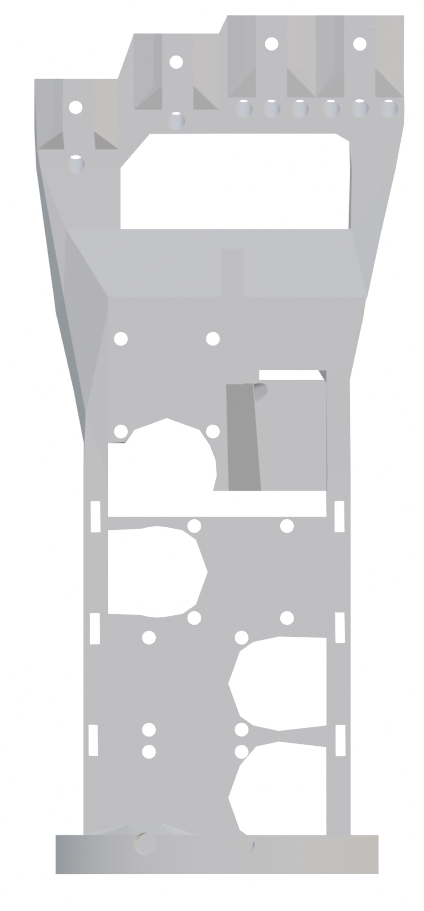

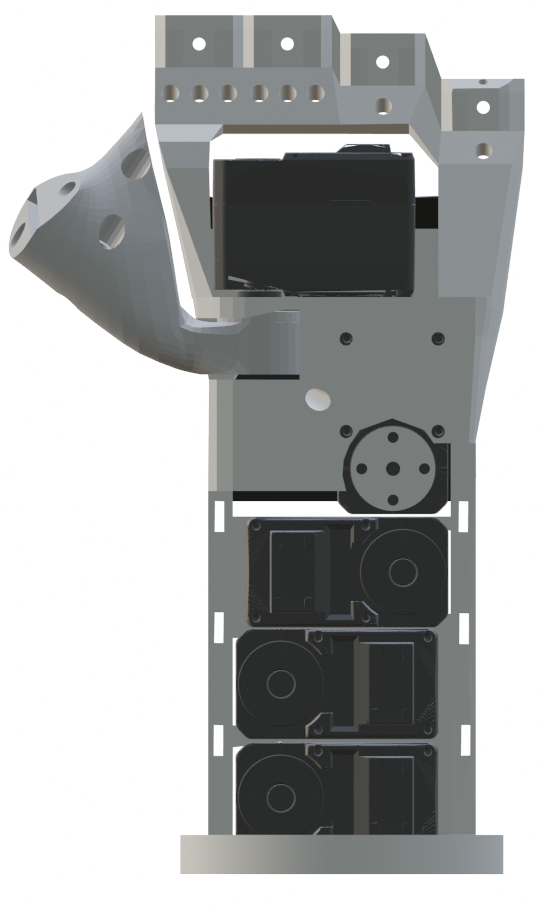

This project is designed using a parametric, modifier-based workflow in Blender. The source .blend files contain the full design history and logic, allowing for powerful non-destructive customization.

- Source Design Files: The native and preferred source files are the

.blendfiles, which use Blender's modifiers to drive the parametric design. - Production Files: The

.stlfiles provided are exported outputs from the source, ready for 3D printing. - Open Hardware License: All hardware design files are released under the CERN Open Hardware Licence Version 2 - Strongly Reciprocal (CERN-OHL-S-2.0). You can find the full license text here: Link to CERN-OHL-S-2.0

- What this means for you: You are free to use, modify, and distribute the designs. However, if you distribute any modified version (a "Adaptation" under the license), you must release the source files for your modifications under the same CERN-OHL-S-2.0 license. This ensures the project remains open and contributions are shared back.

For builders who prefer a ready-to-use solution, fully-tested kits and assembled units are available from my shop.

An Open Invitation to Collaborate

This is a copy-left, open-source project. It belongs to all of us.

The potential technological solutions—from novel grip-pattern algorithms and sensor fusion to new materials and actuation methods—are infinite.

We challenge you to propose solutions, and we commit to implementing and testing the best ideas.

This isn't private, closed tech.

It's an open platform, it's affordable by design, and together, we can make it the best it can be.

Let's build the future of accessible robotics, together.

Vittorio Lumare

Vittorio Lumare