I wanted to start off the documentation of this project by getting into why I think this is worth while and what the general concept is...

THE WHY:

Being on HACKADAY, I think it safe to assume that we all understand the concept of 3D printing and what it represents for us as makers, tinkers, experimentalists, professionals and hackers. It is a gateway to a manufacturing capability that we have never had access to and it gives us degrees and expressions of freedom that we have never enjoyed at home.

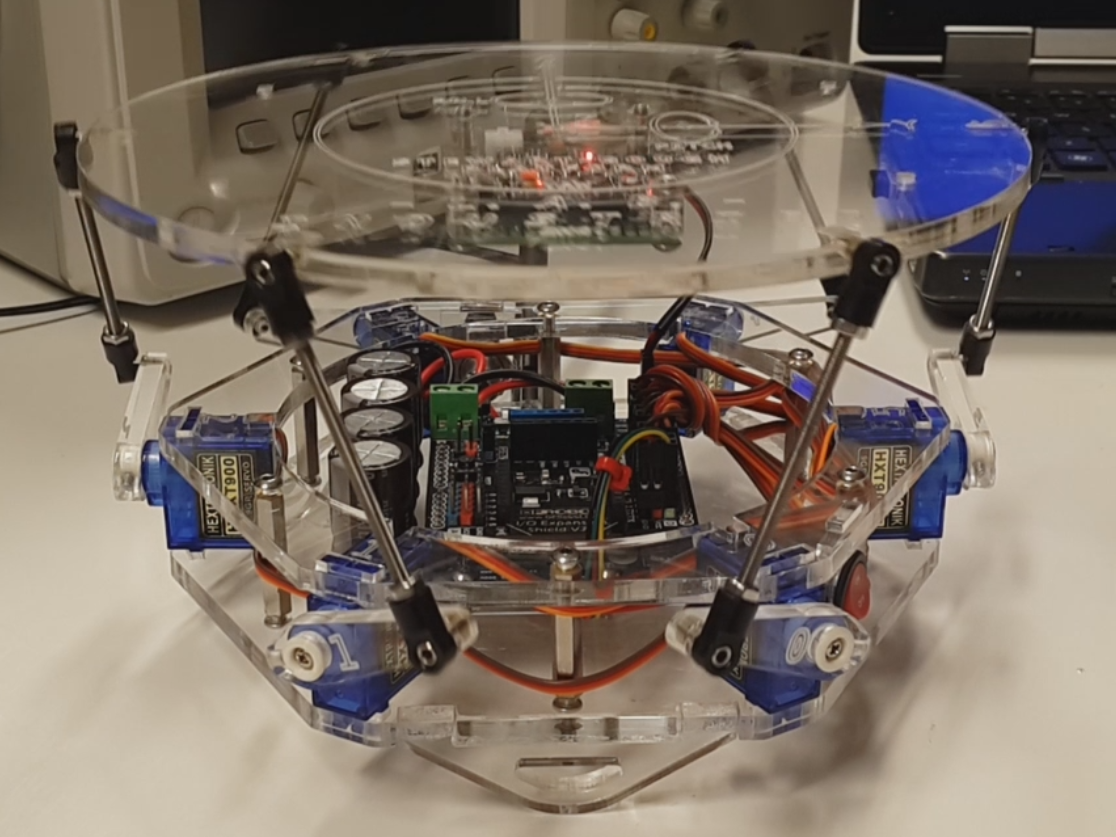

Now, I don't want to bash FDM 3D printing as I think it has elevated possibilities for many people, but for me personally, it just does not cut it - or at least not for the kind of things that I design. In my case I give you an example of a Stewart Platform based proof of concept I was developing. I wanted it to be small enough to sit next to me on a desk so that I could observe it and be accessible without moving from my chair. Stewart Platforms are intricate in certain areas, and therefore the resolution needed for smaller parts was not going to be realized with an FDM printer. I did attempt to produce these parts but I never really got the solution I was looking for.

An example of what I was trying to print for the Stewart platform:

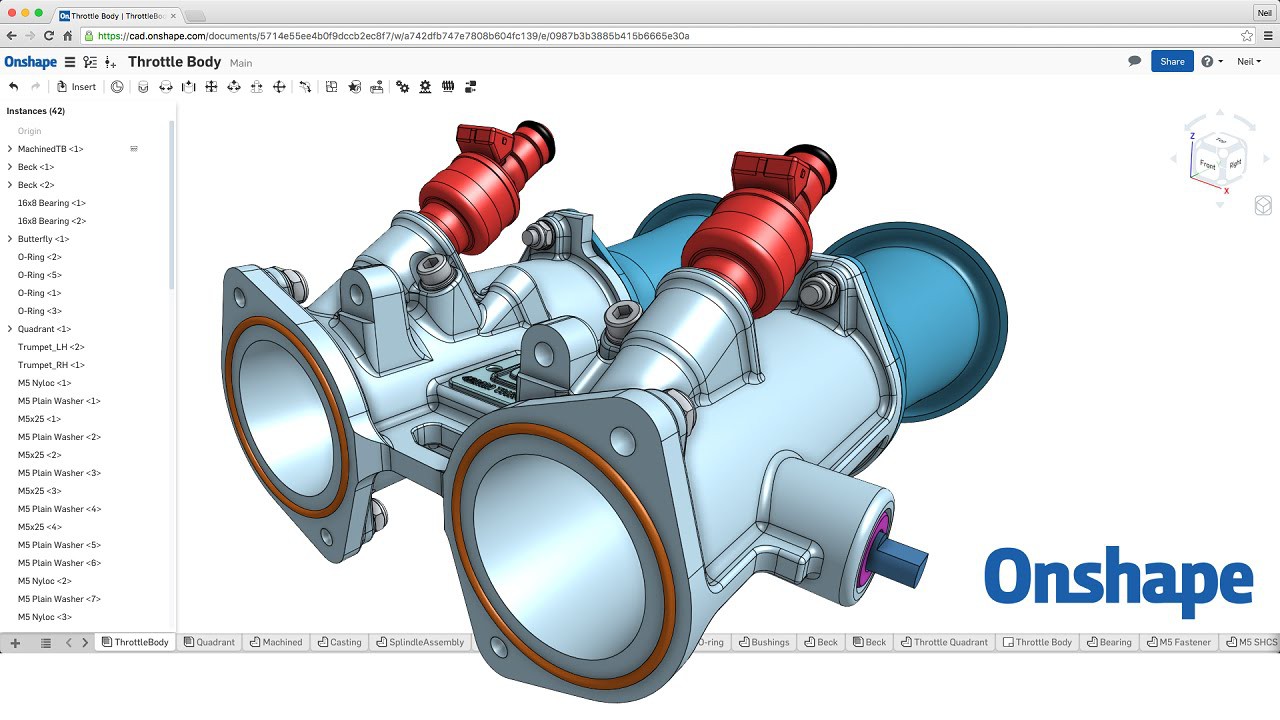

My point is, the more intricate the design and the smaller the part is, the better the resolution of the printer needs to be. The parts I was trying to print in the second picture took about 10 attempts each before I was happy that they were usable. Part of the problem was that the printer would either produce a part that was either bigger or smaller than the CAD, so I had to scale the CAD before every attempt. To my mind a machine is worth its salt when it can accurately replicate what has come from the CAD design. The machine these were printed on was an Ultimaker 2. I have attempted to use a Wanhao Duplicator 4S for other bigger parts but eventually gave up because it was simply not printing to the standards that I needed.

Being an engineer I am also very conscious of time and to me FDM printers waste too much of it. Again, as in the above samples, ten attempts to just get an acceptable specimen, then I still had to print another 20 or so of each (spares included). Okay, I have not experimented with this type of SLA printing, but I am confident that it will not waste the amount of time that an FDM printer do.

The last thing I dislike about FDM printers is the amount of filament they waste!

THE HOW:

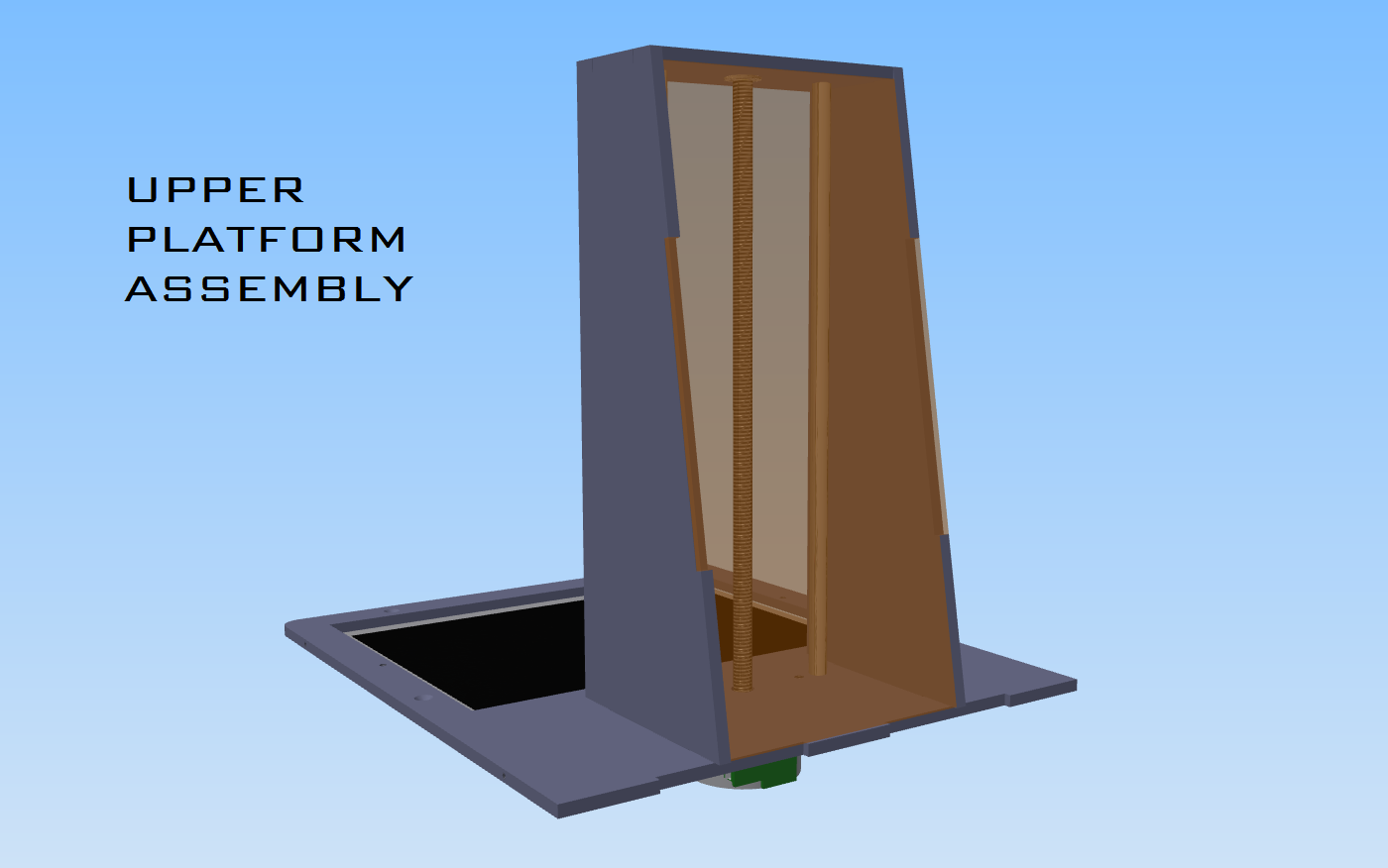

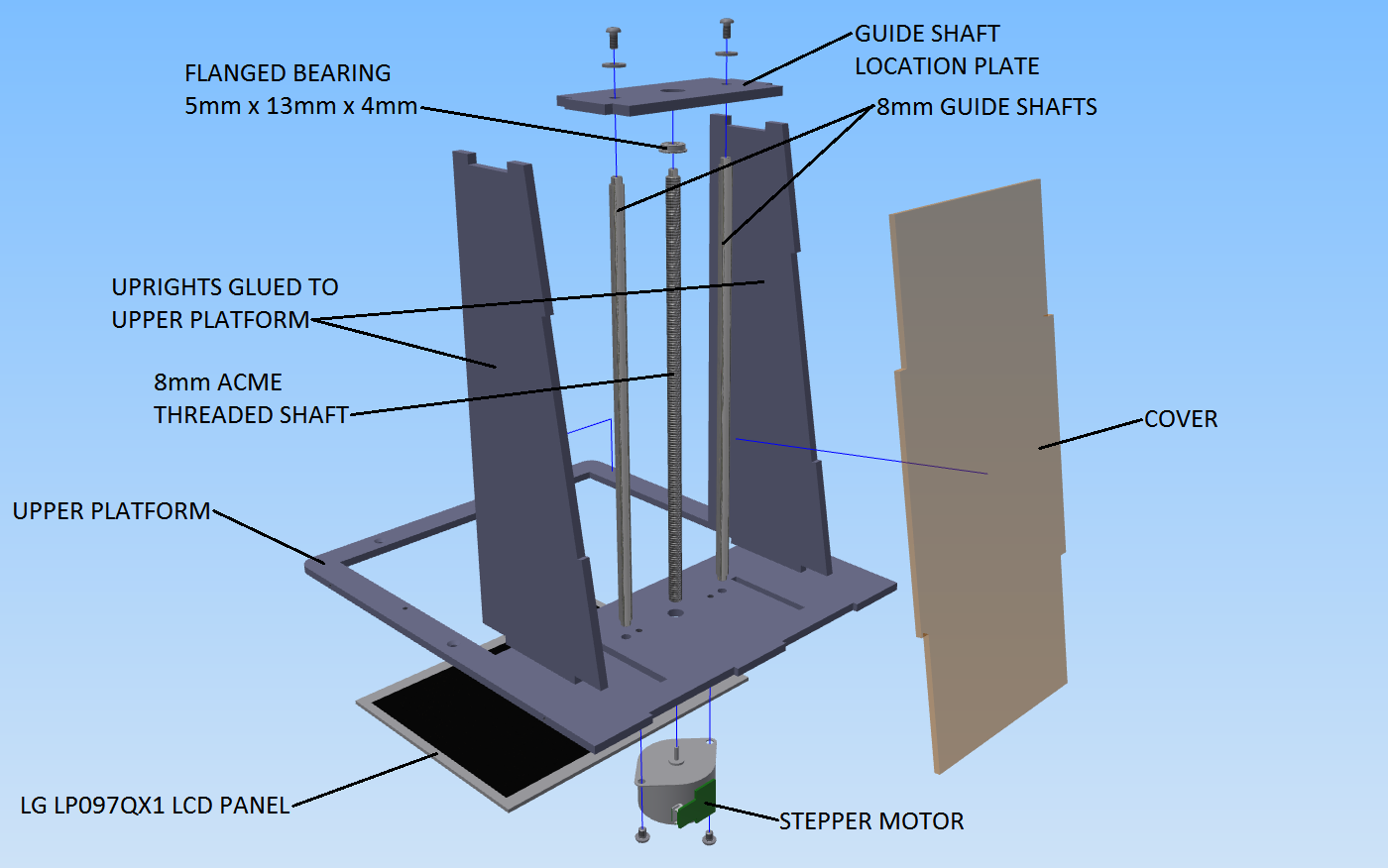

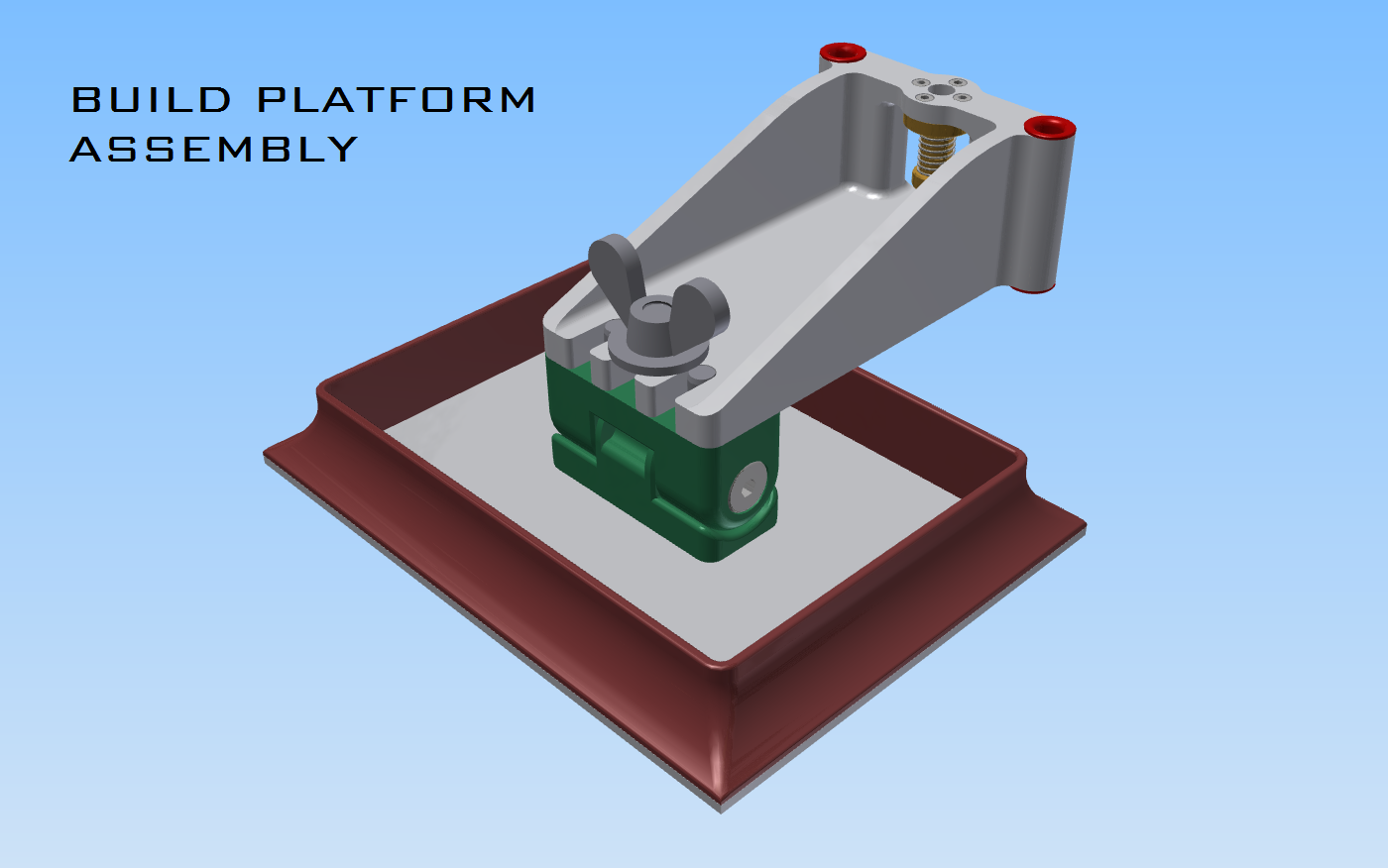

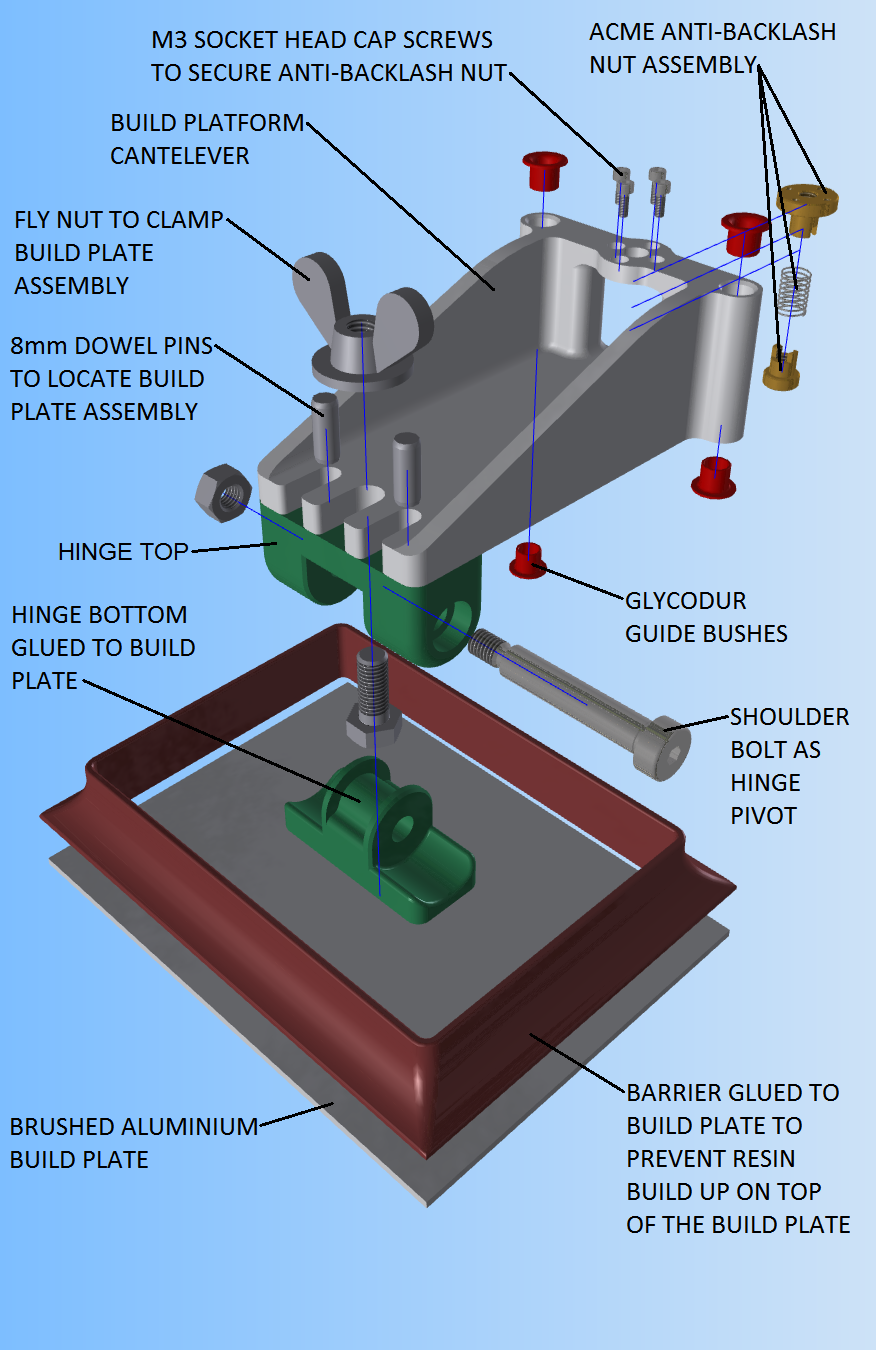

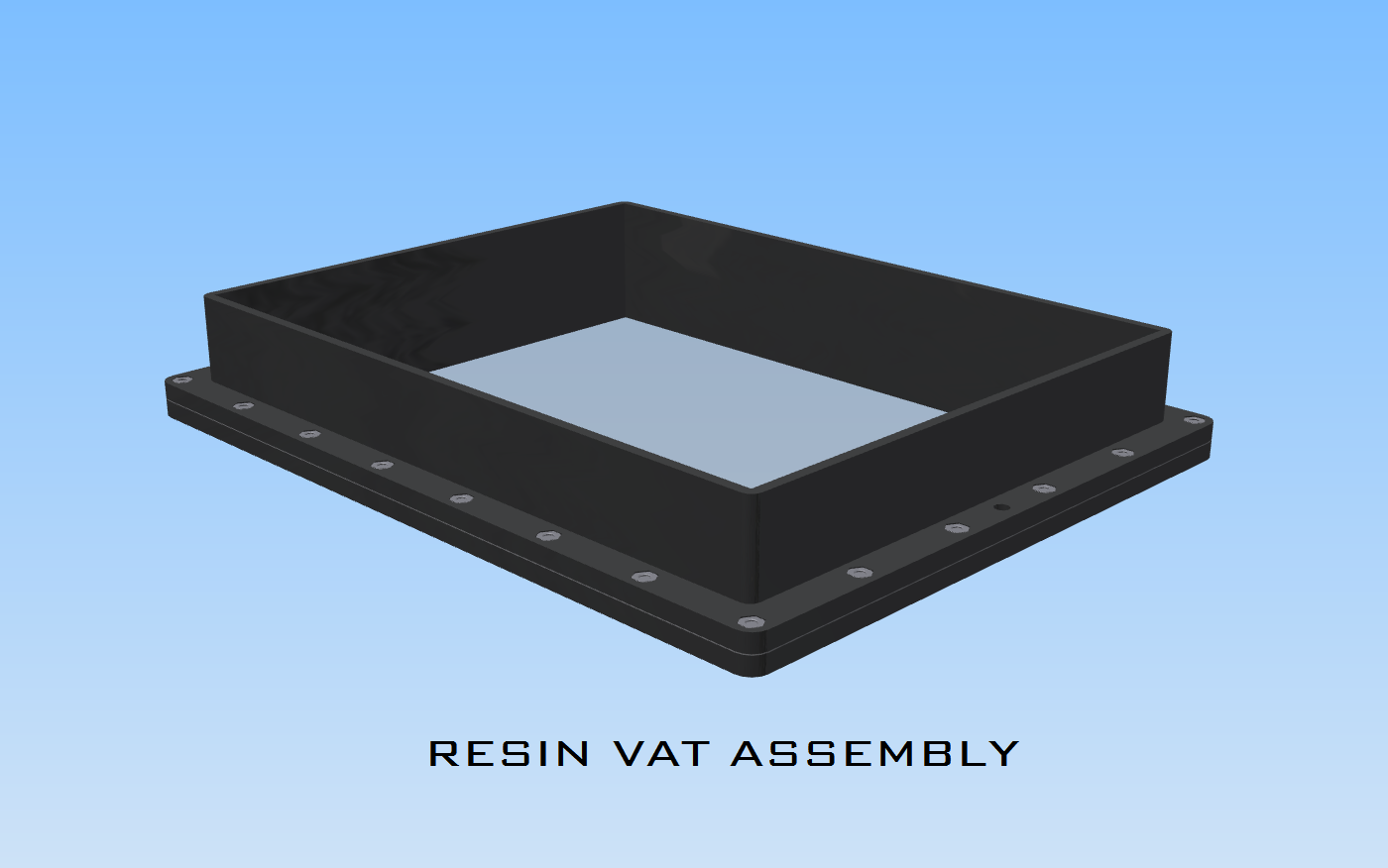

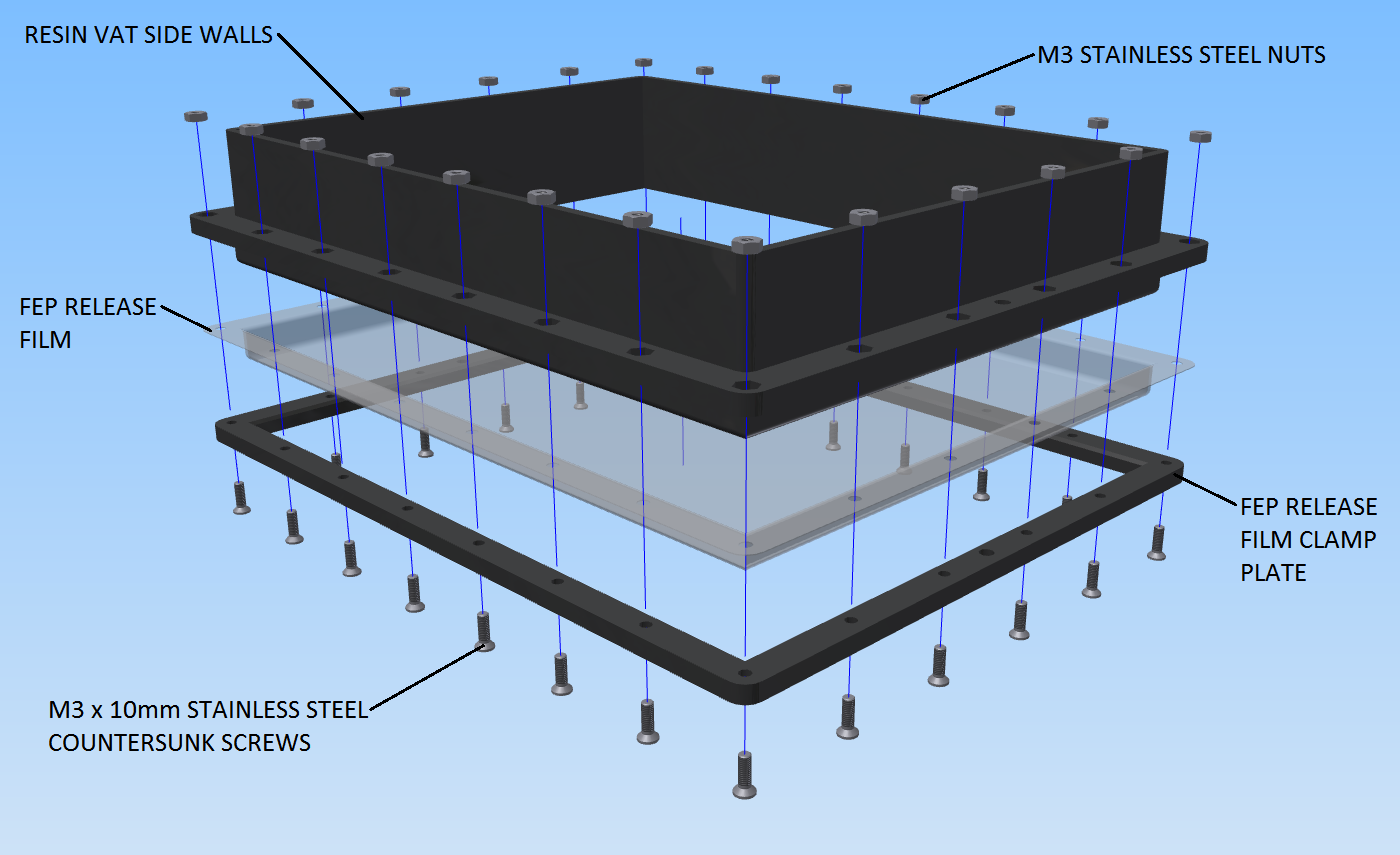

Like all 3D printers, the general concept of this machine is to build up an object from sectional layers. The layers will be projected onto an LCD panel which will then cure the fresh resin layer between the previous layer and the bottom of the resin vat. After each layer is cured, the build platform raises and lowers to allow fresh resin replace the previous layer.

The advantages:

- Less time to produce a singe layer

- Less waste of raw material

- Fewer moving parts to the machine

The disadvantages:

- Resin is more expensive than filament

- Less material choices (this is changing all the time though)

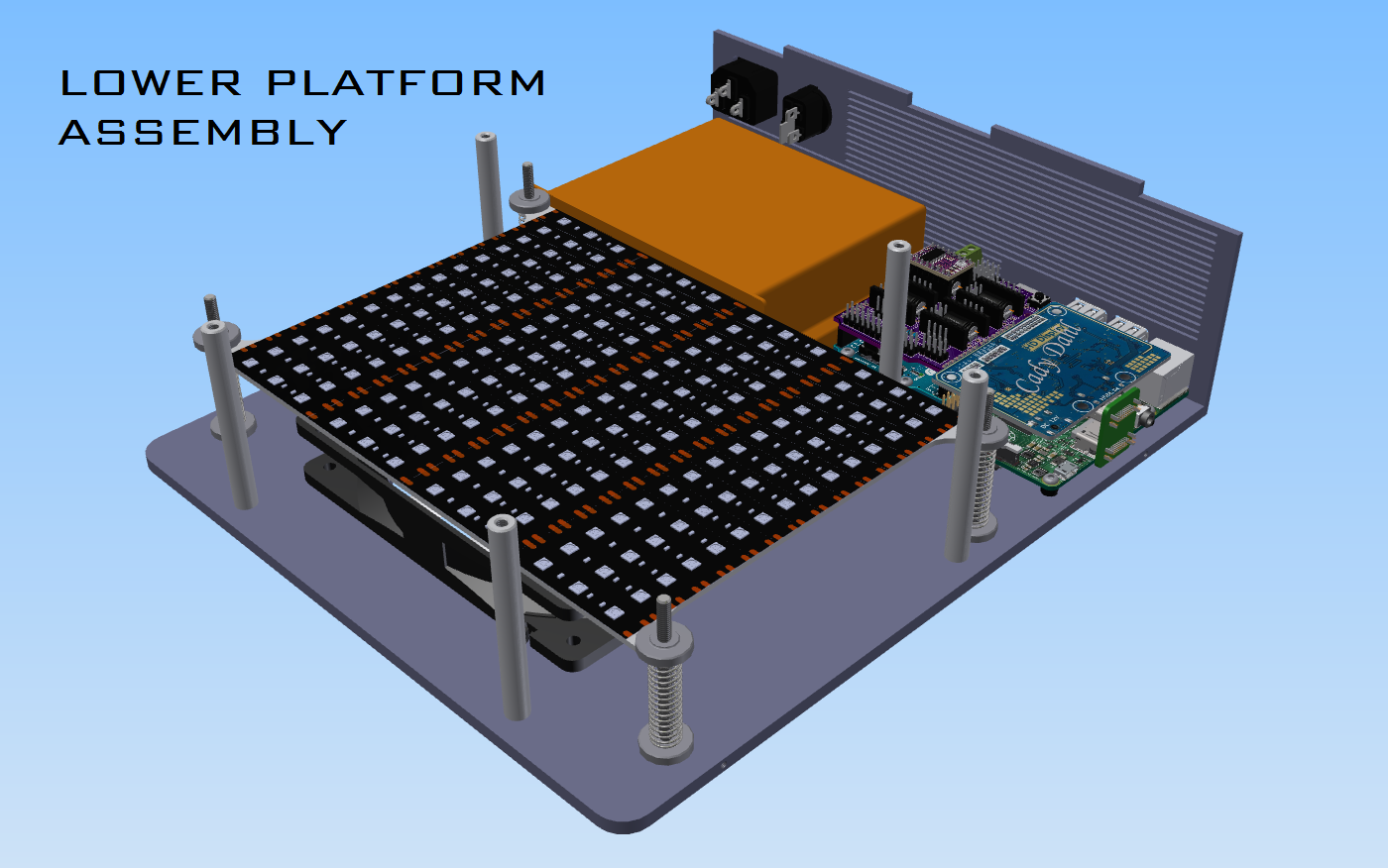

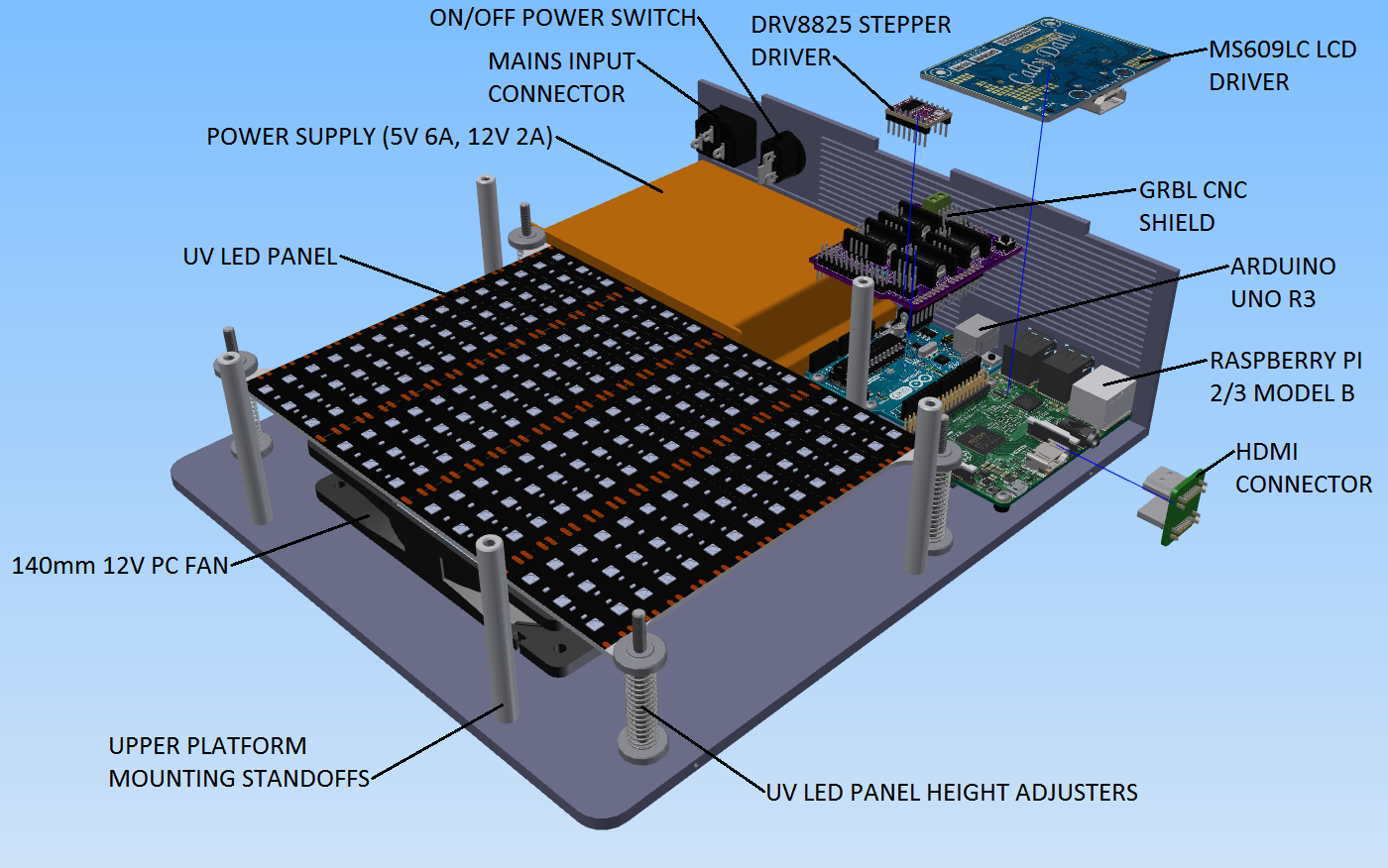

The brains of the operation will be a Raspberry Pi 2/3 Model B running NanoDLP and an Arduino Uno R3 running GRBL. NanoDLP drives the display connected to the Raspberry Pi and also sends the GCODE commands to GRBL. The LCD display used in this project will be the LG LP097QX1 which is 9.7" with a resolution of 2048 x 1536. This translates to a build area of 196mm x 147mm with a resolution of 0.0962mm in the x and y directions and the Z-Axis has been designed to travel 160mm using a 400 step NEMA 17. All this is powered with a dual 5V 6A and 12V 2A switch mode power supply.

I'm excited by this project and I think it will be a great adventure! I know this has been tried and done (I don't think perfected though), but I feel that the main goal of this project is to produce a machine that is open to people interpretations and their wallets. I feel that with collective thoughts we can produce a machine that has industrial capabilities!

TTN

TTN

Benchoff

Benchoff

Can you release the CAD files?