-

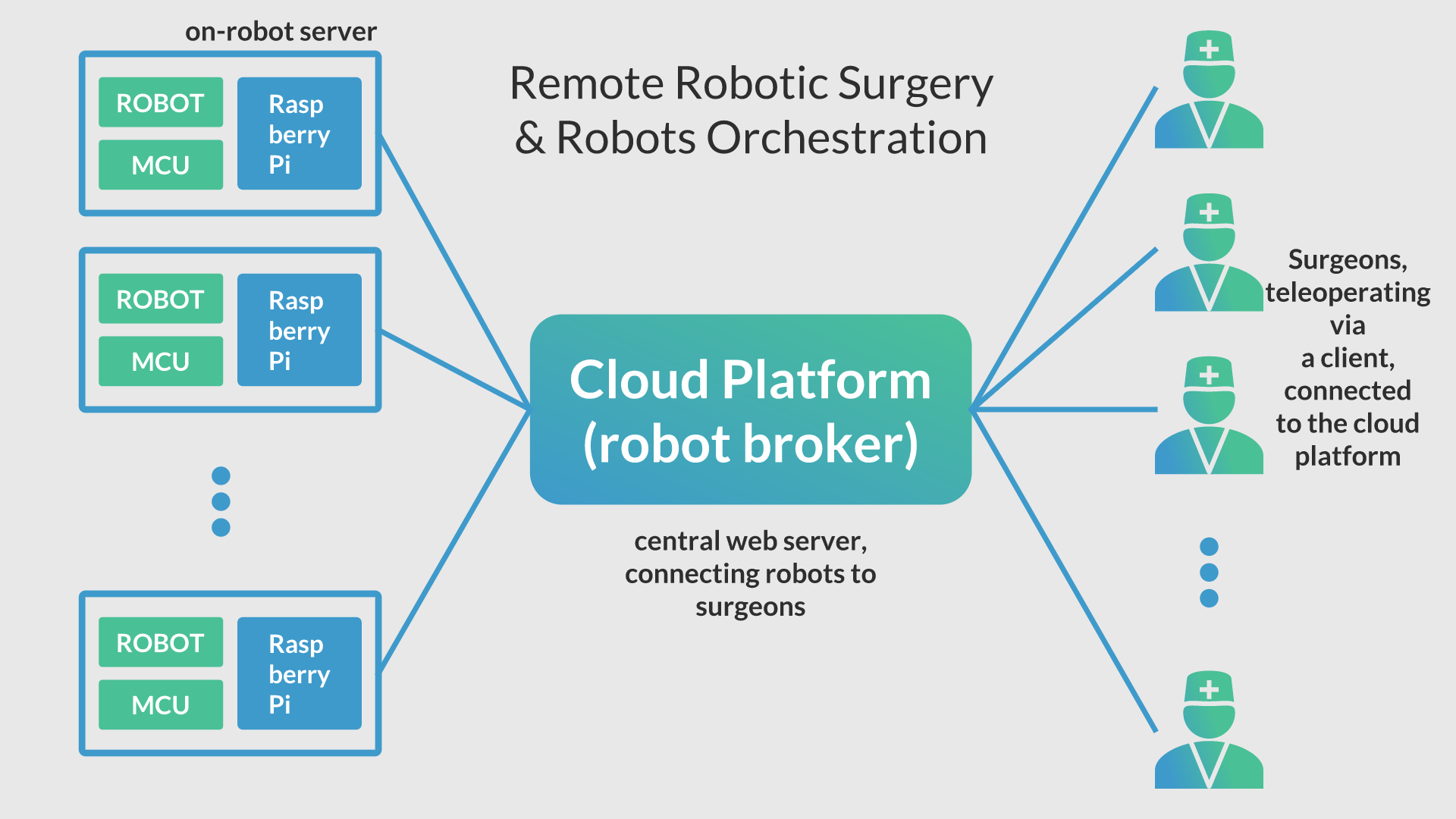

Remote Robotic Surgery & Robots Orchestration

06/03/2018 at 11:54 • 0 commentsThe following diagram illustrates how multiple robotic platforms will be used remotely.

Each robot has a Micro-controller (MCU) and a Raspberry Pi on which there are installed all ROS libraries and code for the micro-controller as well as a small server which communicates with a central server (broker).

![]()

-

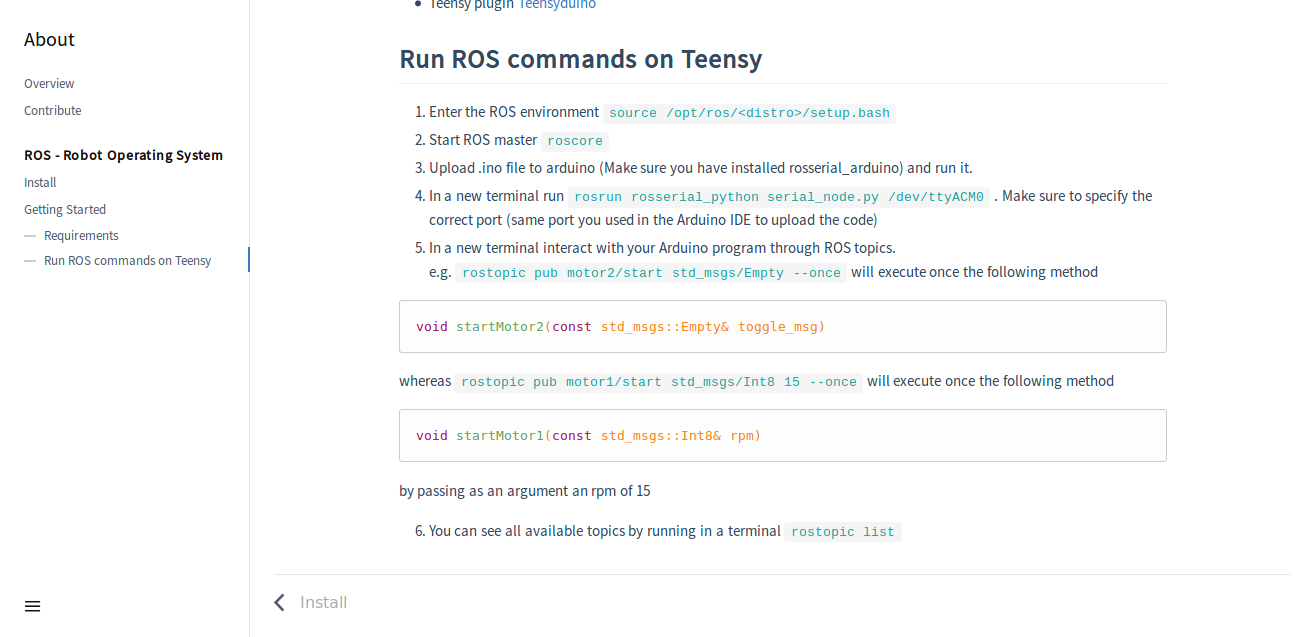

GitHub repository and documentation

05/20/2018 at 13:12 • 0 comments- You can find all of this project's code, relevant files, licenses, documentation at the following GitHub repository https://github.com/ehosp/eHOSP-Surgical

- The repository above also comes with a documentation page which is available here https://ehosp.github.io/eHOSP-Surgical/

(The repository and documentation are in very early stage and in progress)

![]()

-

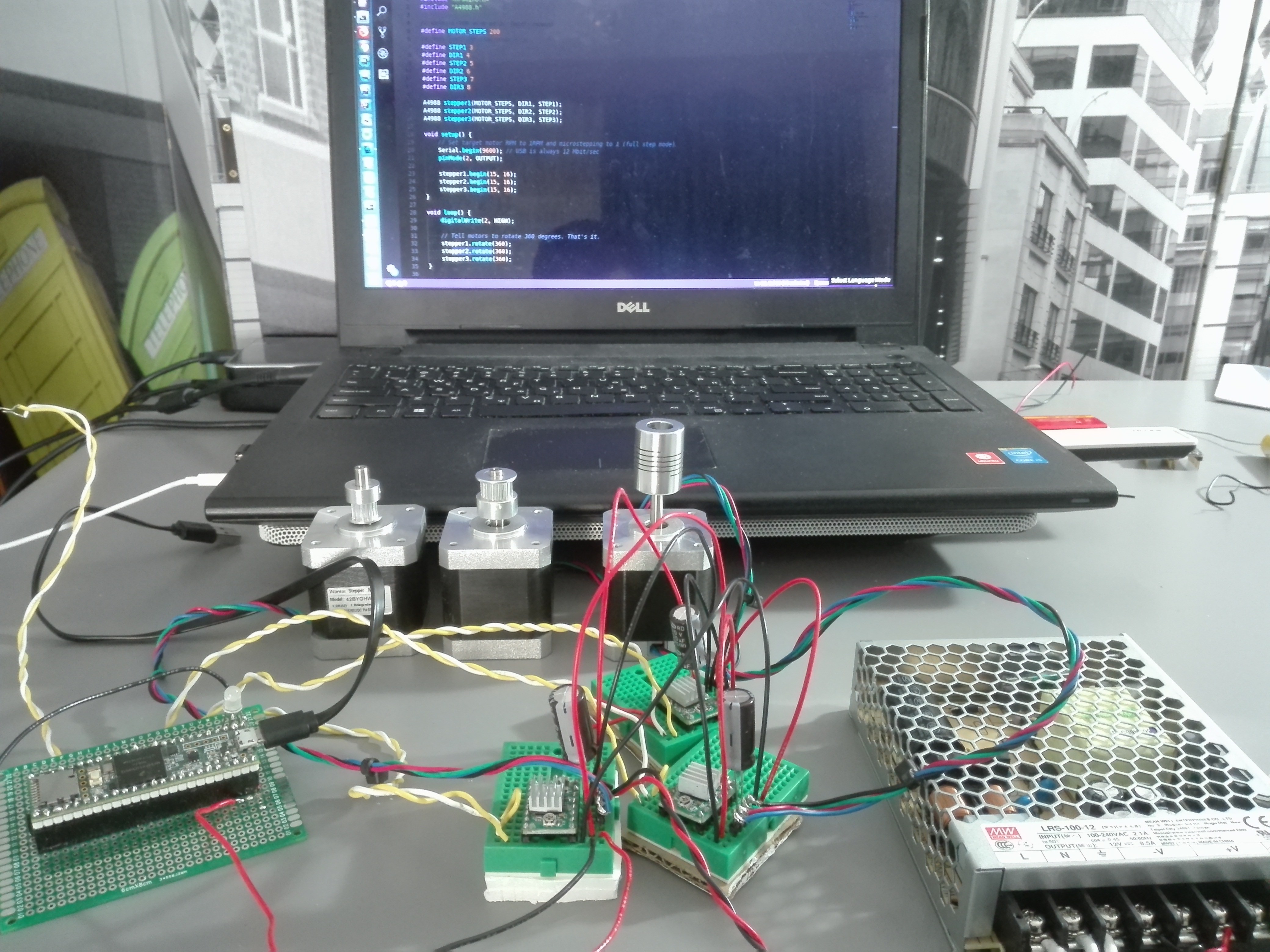

Testing motors for 3 axes

04/21/2018 at 15:58 • 0 commentsWriting simple code to test the 3 axes of the system to simulate a 3D cartesian moving system (like a CNC).

List of components:

- Teensy 3.5

- 3 NEMA 17 Stepper Motors (200 steps/rev)

- 3 A4988 motor drivers

- 12V 8.5A power supply

- 3 100µF electrolytic capacitors

Next step is to control 6 stepper motors at the same time, with a more complicated algorithm to compute the Inverse kinematics of a 6 DOF system. For that I am going to use the rosserial_arduino package, for using ROS with Arduino.

![]()

-

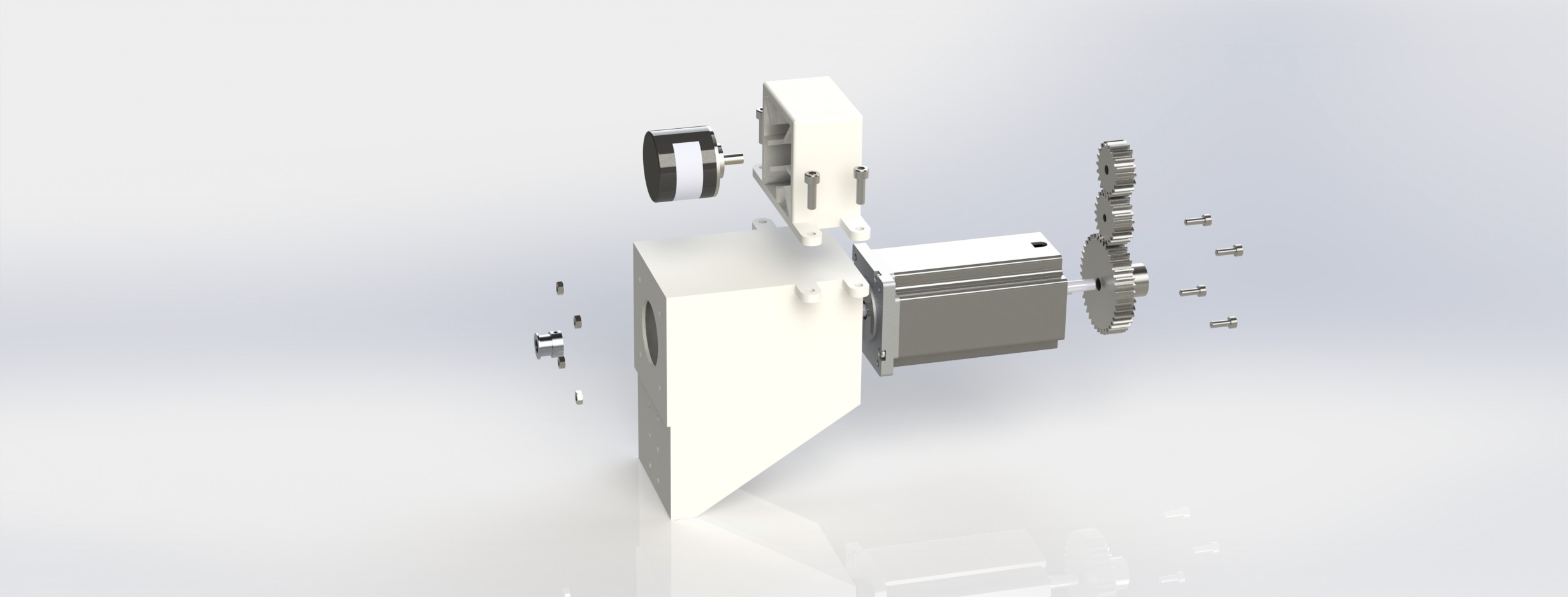

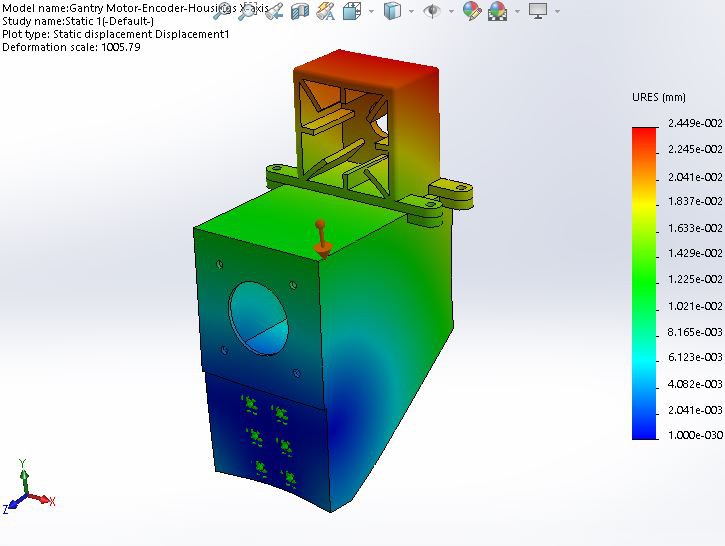

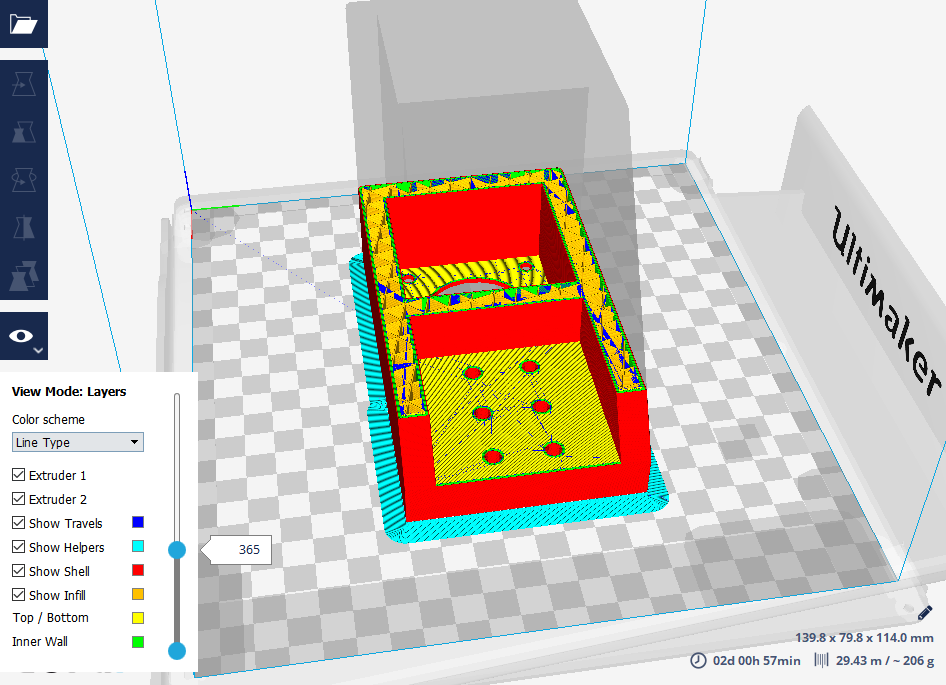

Custom Motor-Encoder system

04/19/2018 at 20:13 • 0 commentsIn Surgery Robotics, the most crucial thing is precision of about 0.5 micrometers and also repeatability. Stepper motors are very precise motors but in order to make sure that these always work as programmed and measure each step correctly we also need an encoder. For each stepper motor (double shaft) we use an optical encoder which will measure the shaft's rotation, from the back side of the motor, via a set of gears.

To make that possible we need a component to house the motor, the encoder and the gears. The housing will be 3D printed.

-

Athens Mini Maker Faire 2017

04/19/2018 at 20:01 • 0 commentsIn May 2017, I presented my proof of concept to the makerfaire community and received very valuable feedback, from the open source community, robotics enthusiasts as well as professors and discussed the next steps of the project (mainly for the mechanical design)

![]()

![]()

-

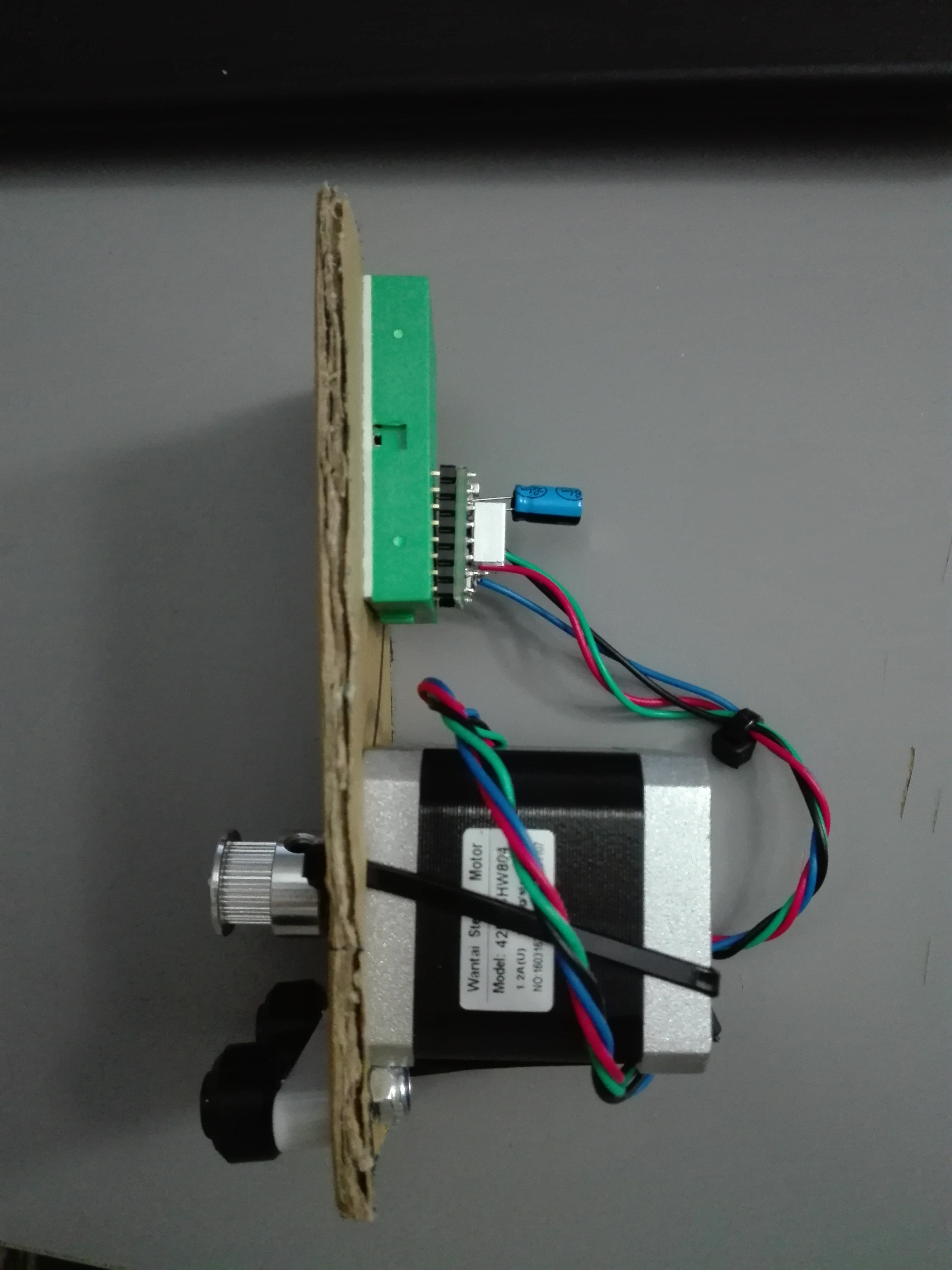

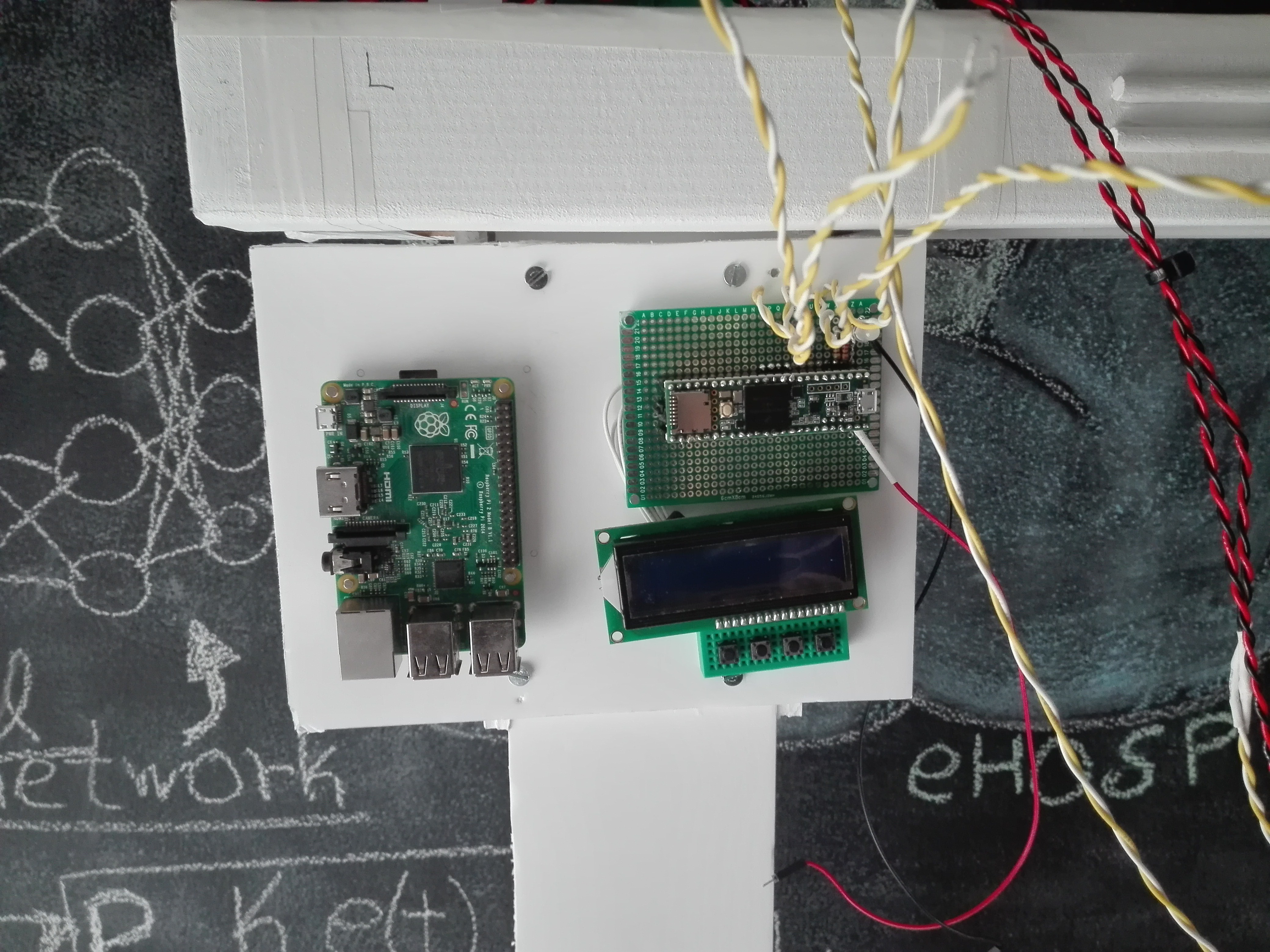

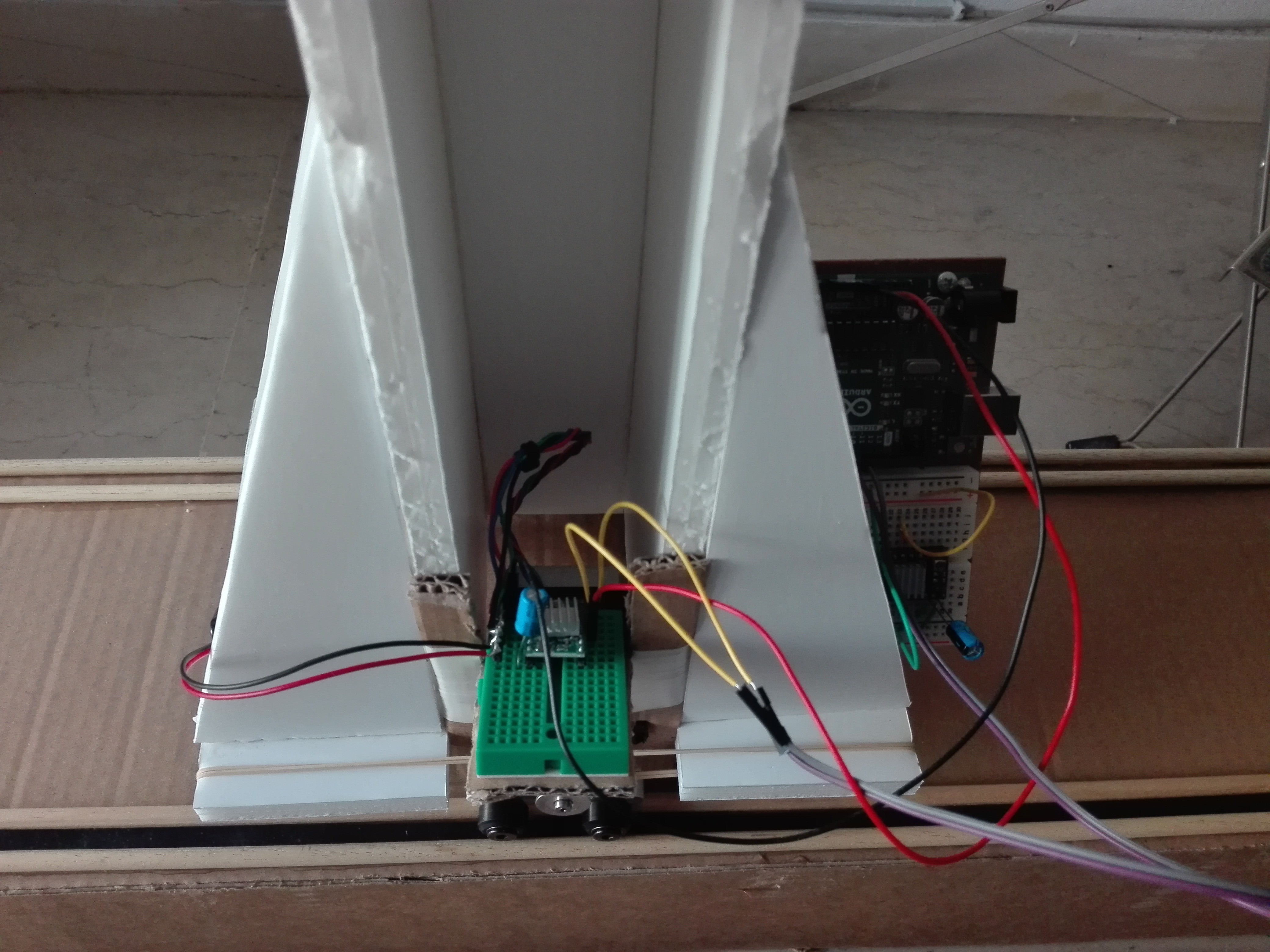

Proof of concept, v2.0, 2017

04/19/2018 at 19:55 • 0 commentsAfter the first trivial proof of concept I started working on a proof of concept with bigger dimensions and better electronics. I still didn't use any expensive aluminum hardware as I didn't have a final design for my robot.

Components:

- cheap materials (cardboard and wood)

- 4 NEMA 17 stepper motors

- 4 DRV8825 Stepper Motor Drivers

- timing belts & pulleys (GT2)

- v-wheels

- Teensy 3.5

- Raspberry Pi 2 Model B

- Power Supply 12V 8.5A 102W

- Precision shaft & Lead Screw T8 1000mm

- Cables, resistors, buttons, switches, capacitors and prototyping boards

![]()

![]()

![]()

![]()

-

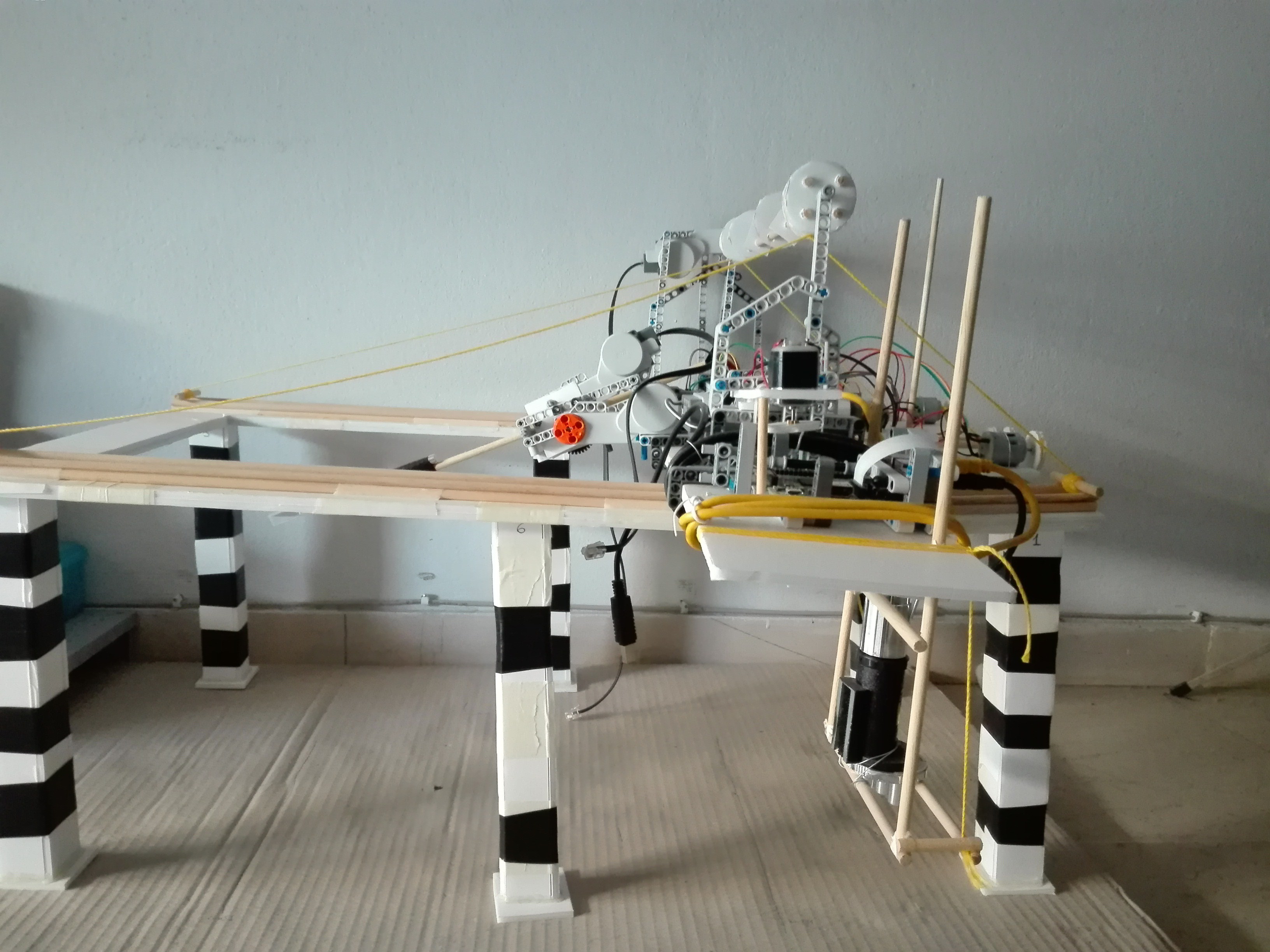

Proof of Concept 2016

04/19/2018 at 19:36 • 0 commentsIn 2016, I made a very trivial proof of concept with very cheap materials and whatever electronics I had back then (Arduino Uno, Raspberry Pi and Lego NXT Mindstorms). I made a robotic platform which could move in one direction and control a scalpel. The Raspberry Pi, served as the main unit, on which there were connected an Arduino Uno and the Lego NXT Mindstorms. On the Raspberry Pi, I installed a simple web server and I was able to remotely via HTTPS download commands to the NXT. Moreover in the backside of the moving platform, I attached a small microscope on top of which there was a Raspberry Pi camera module.

![]()

![]()

![]()

SurgeyOS Robotics platform

A modular Robotic Surgery platform which is a more accessible and inexpensive tool to researchers, students and doctors.

Alex Karadimos

Alex Karadimos