Shared under the Creative Commons - Attribution - ShareAlike 3.0 license.

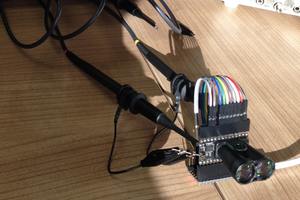

Code for the Arduino and Raspberry Pi now up on GitHub - very much work in progress

Overview;

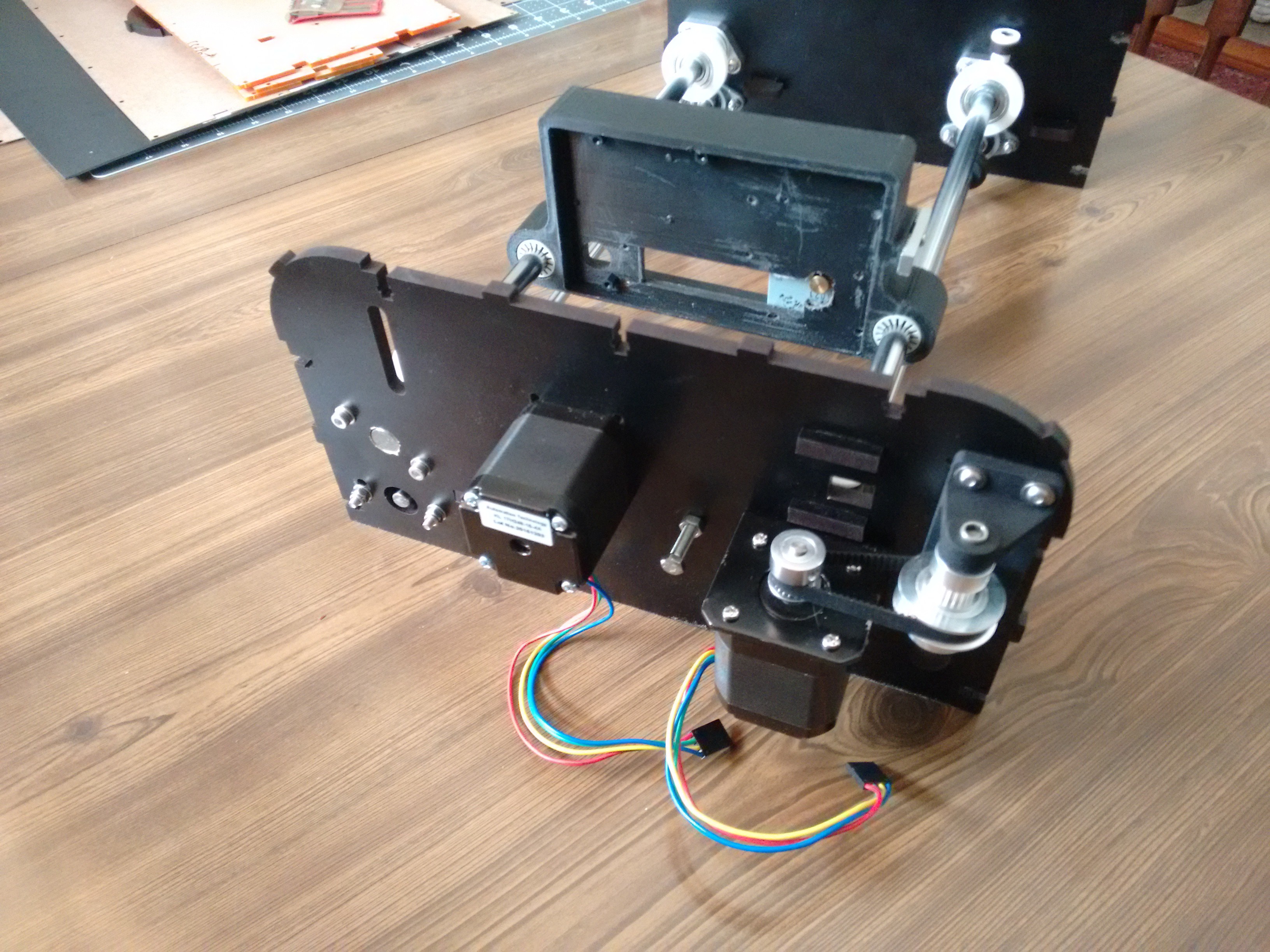

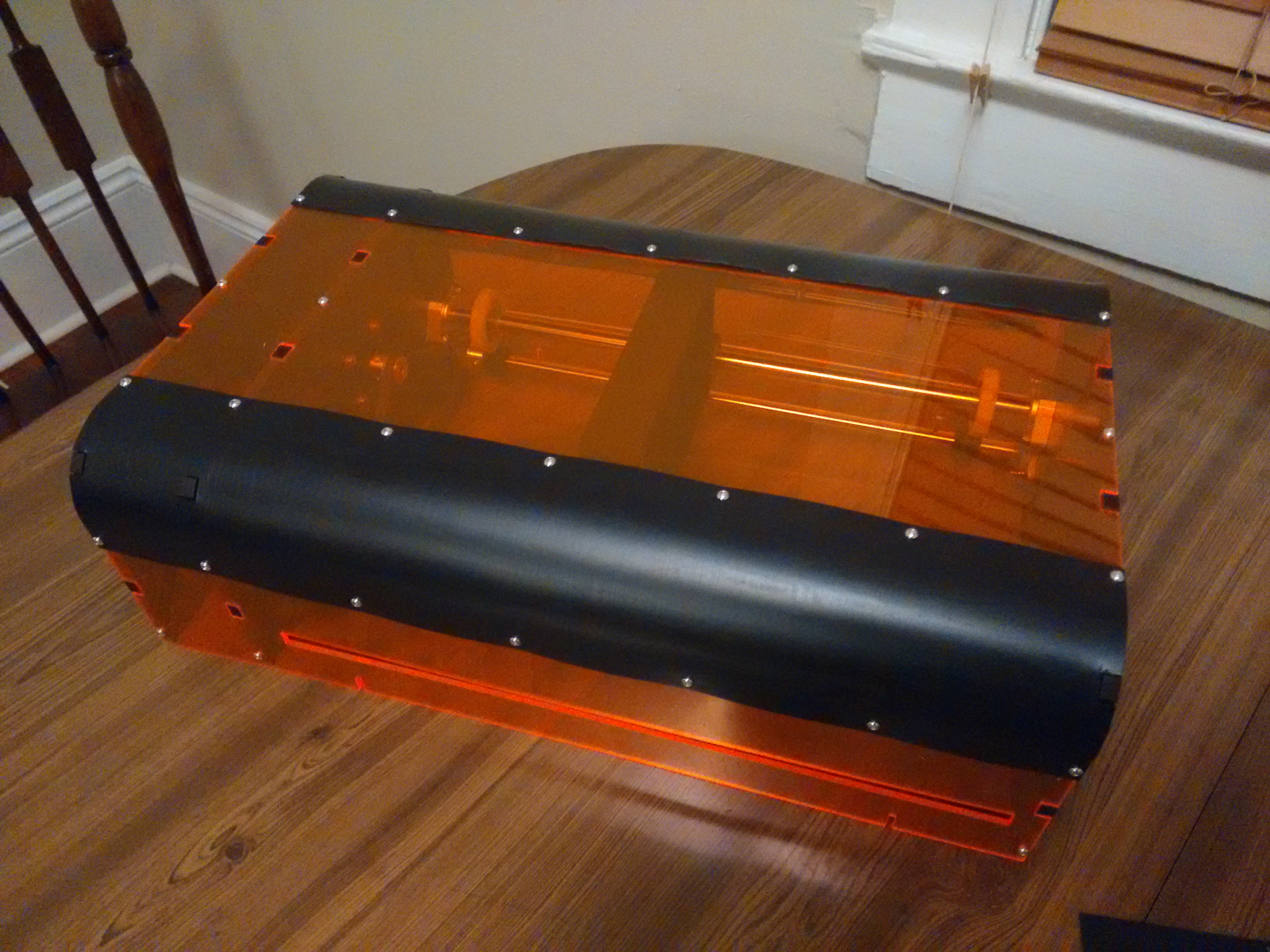

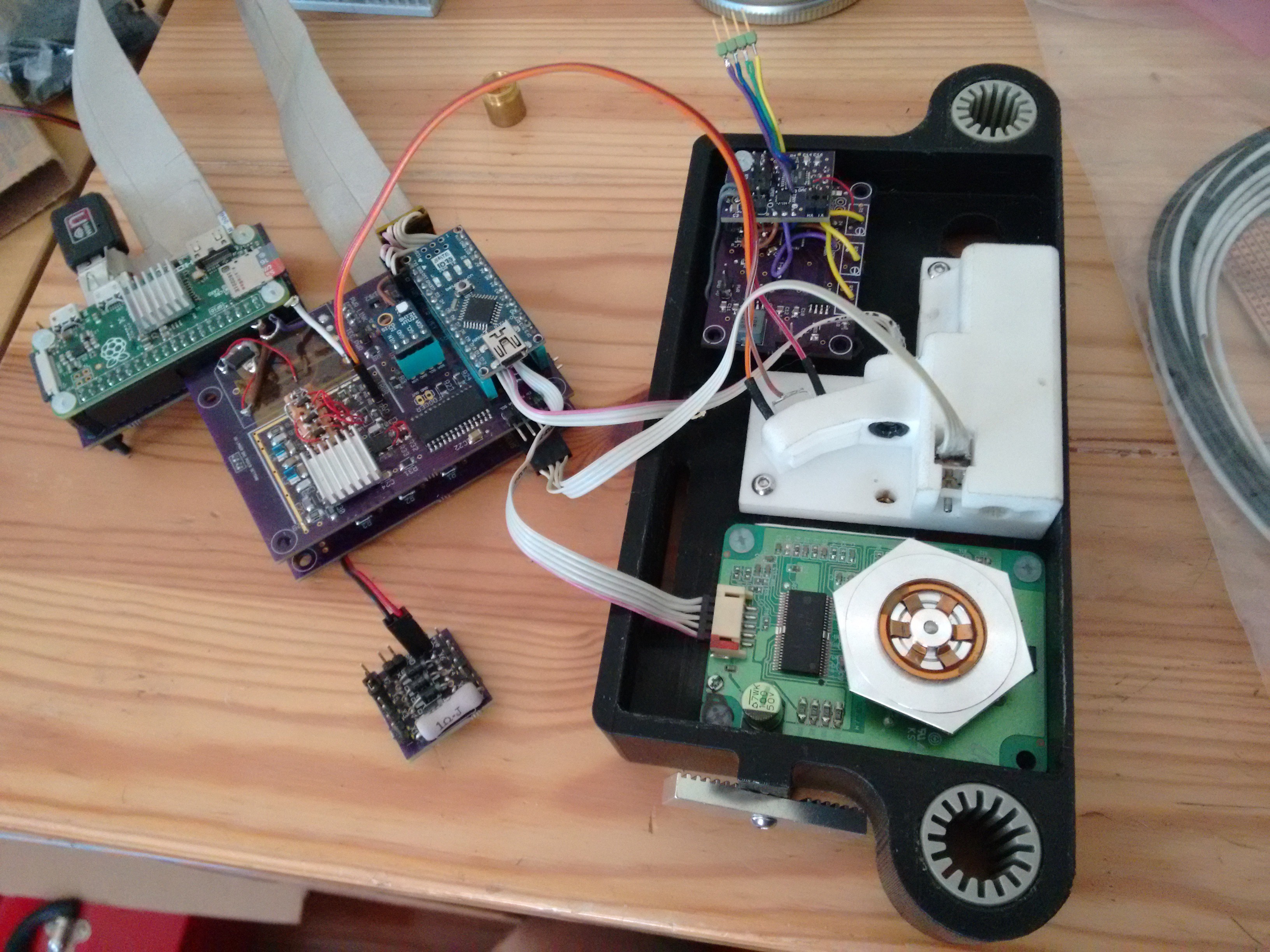

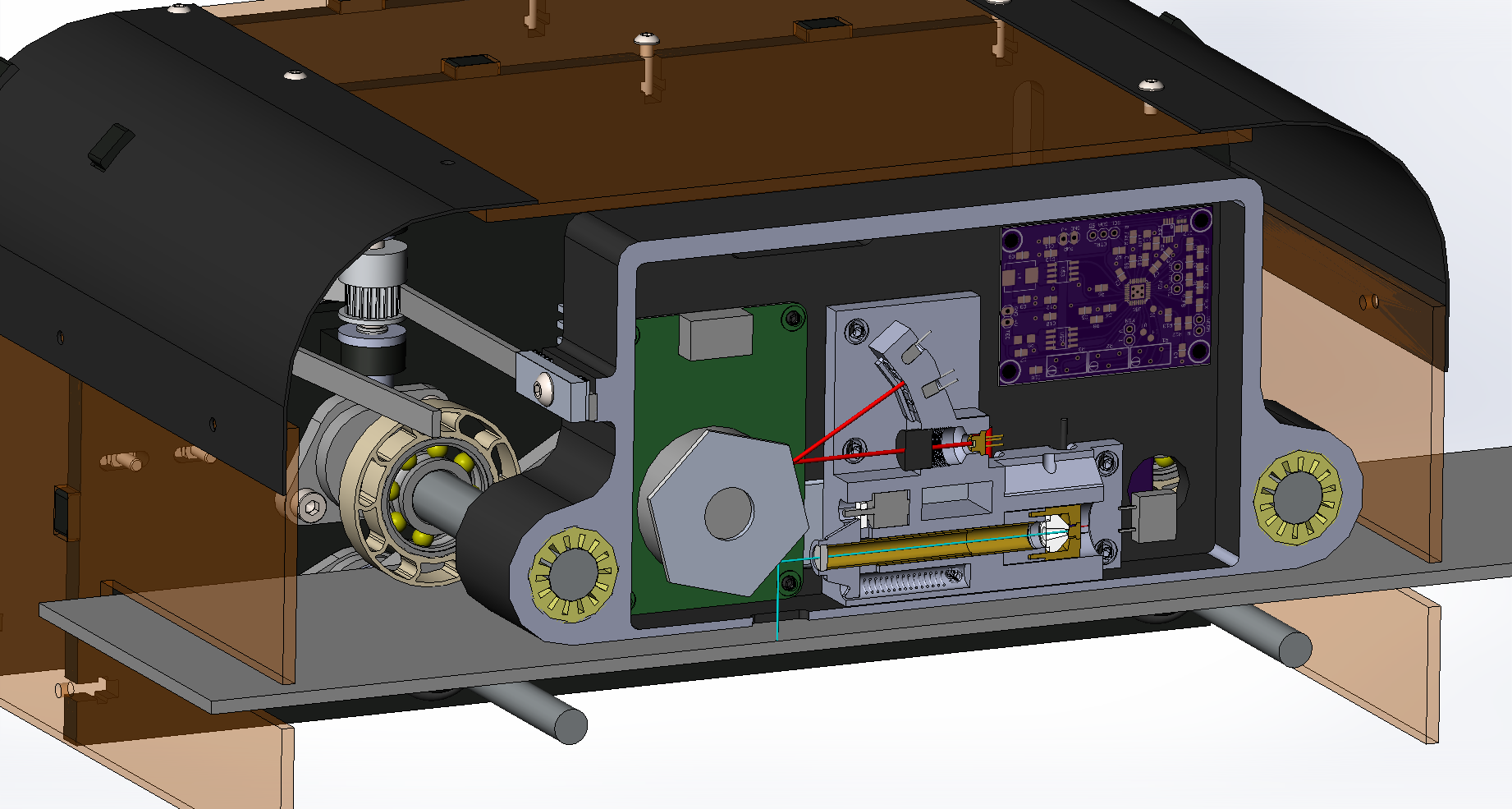

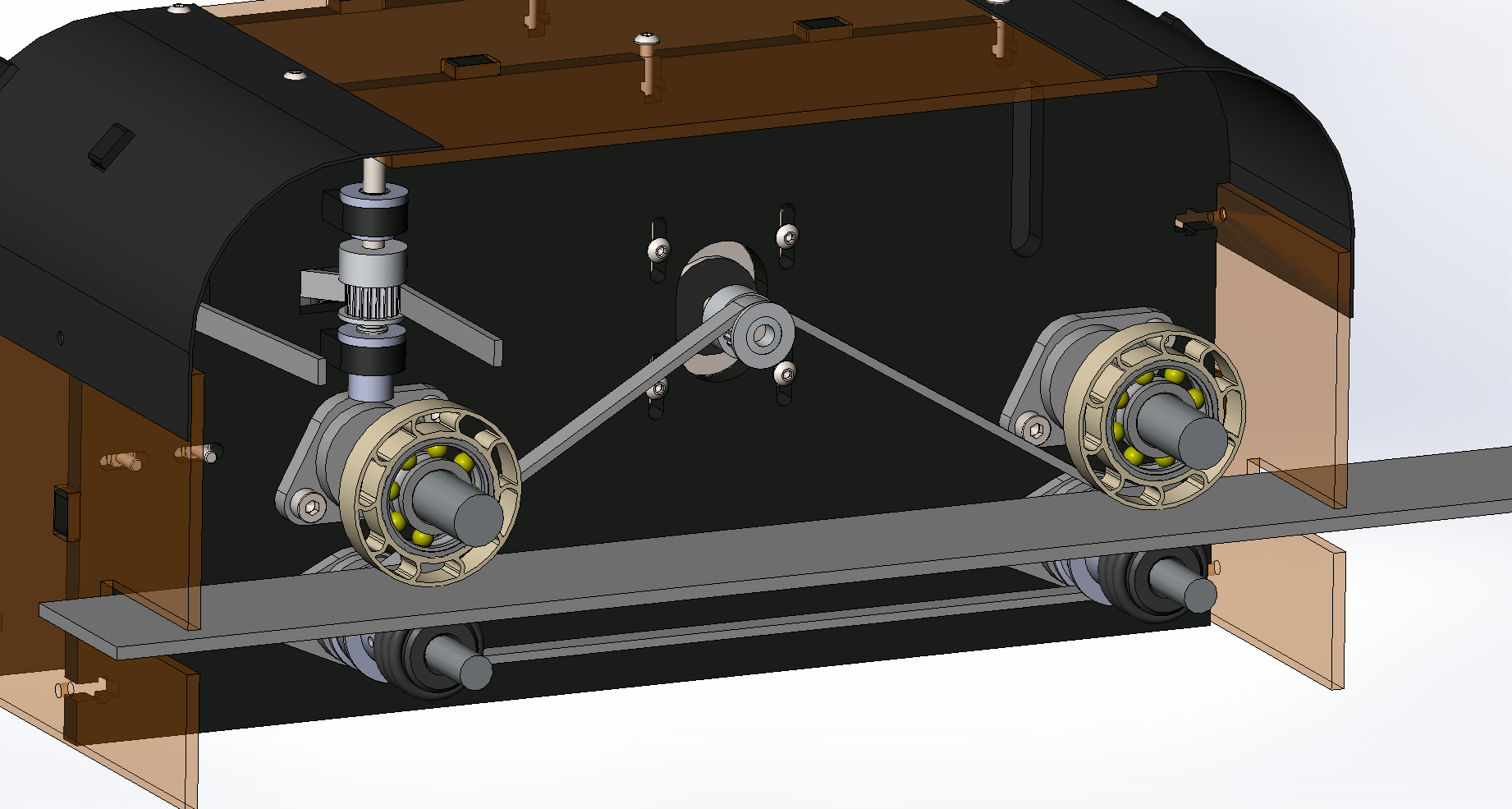

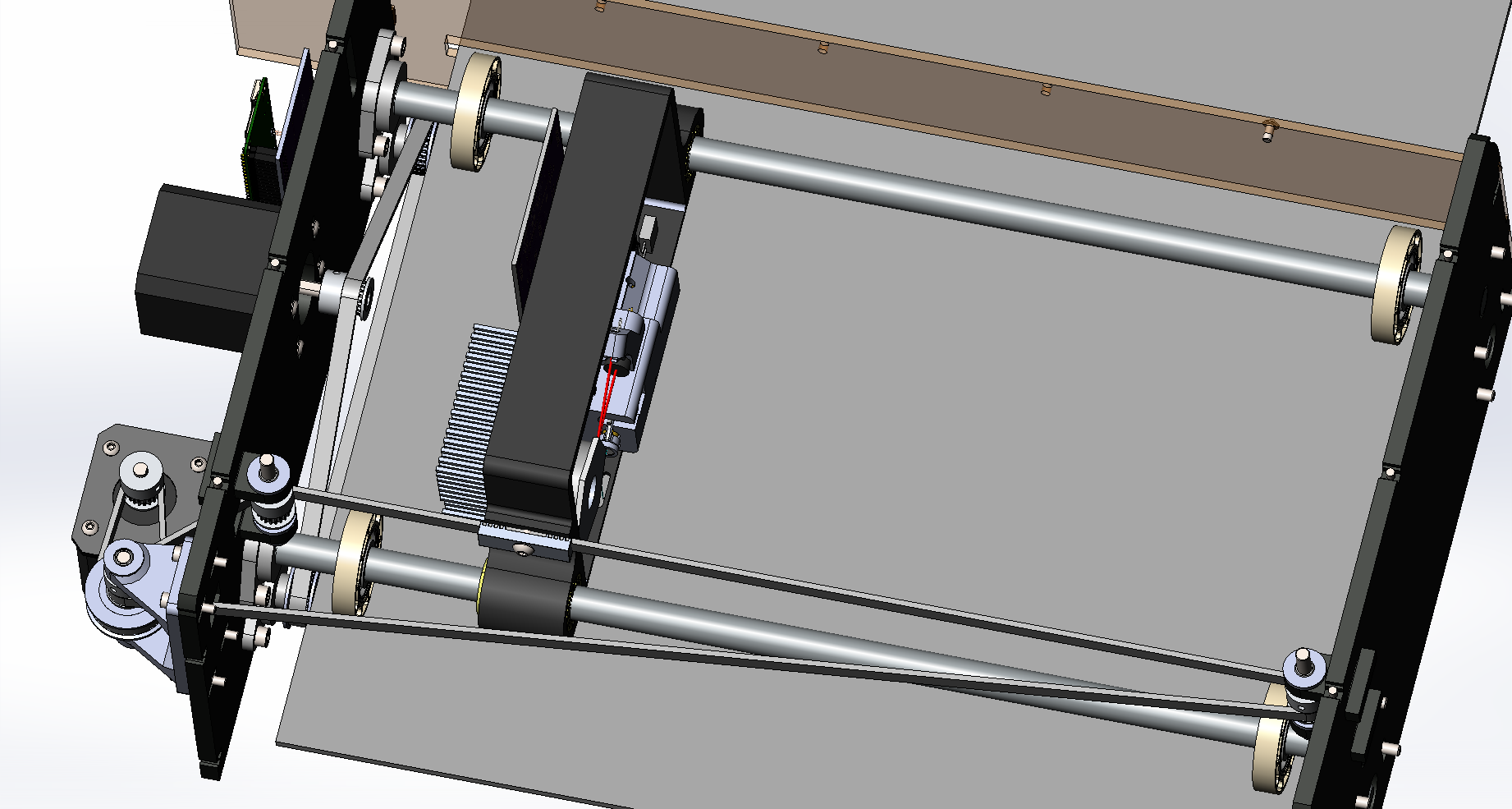

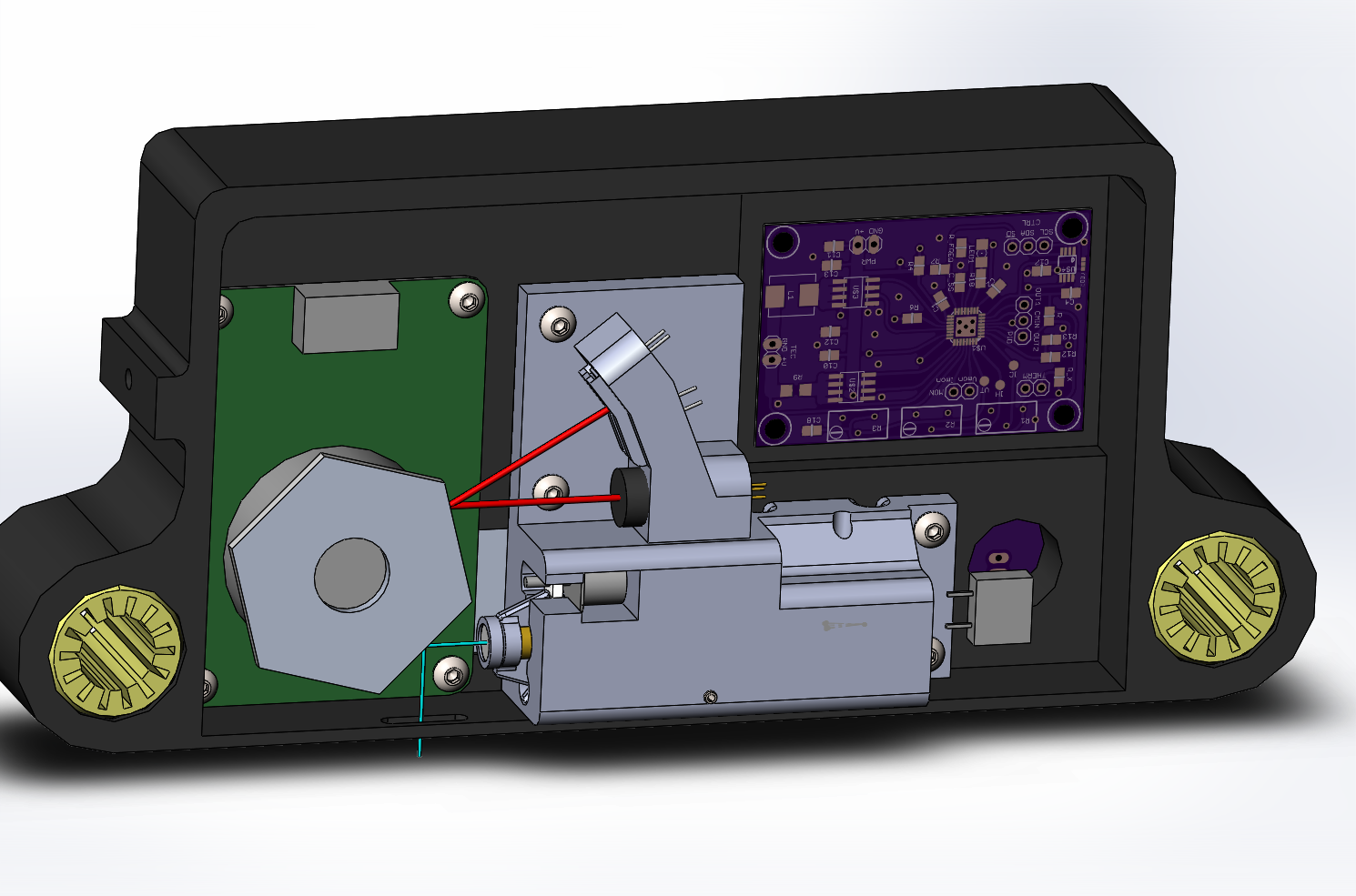

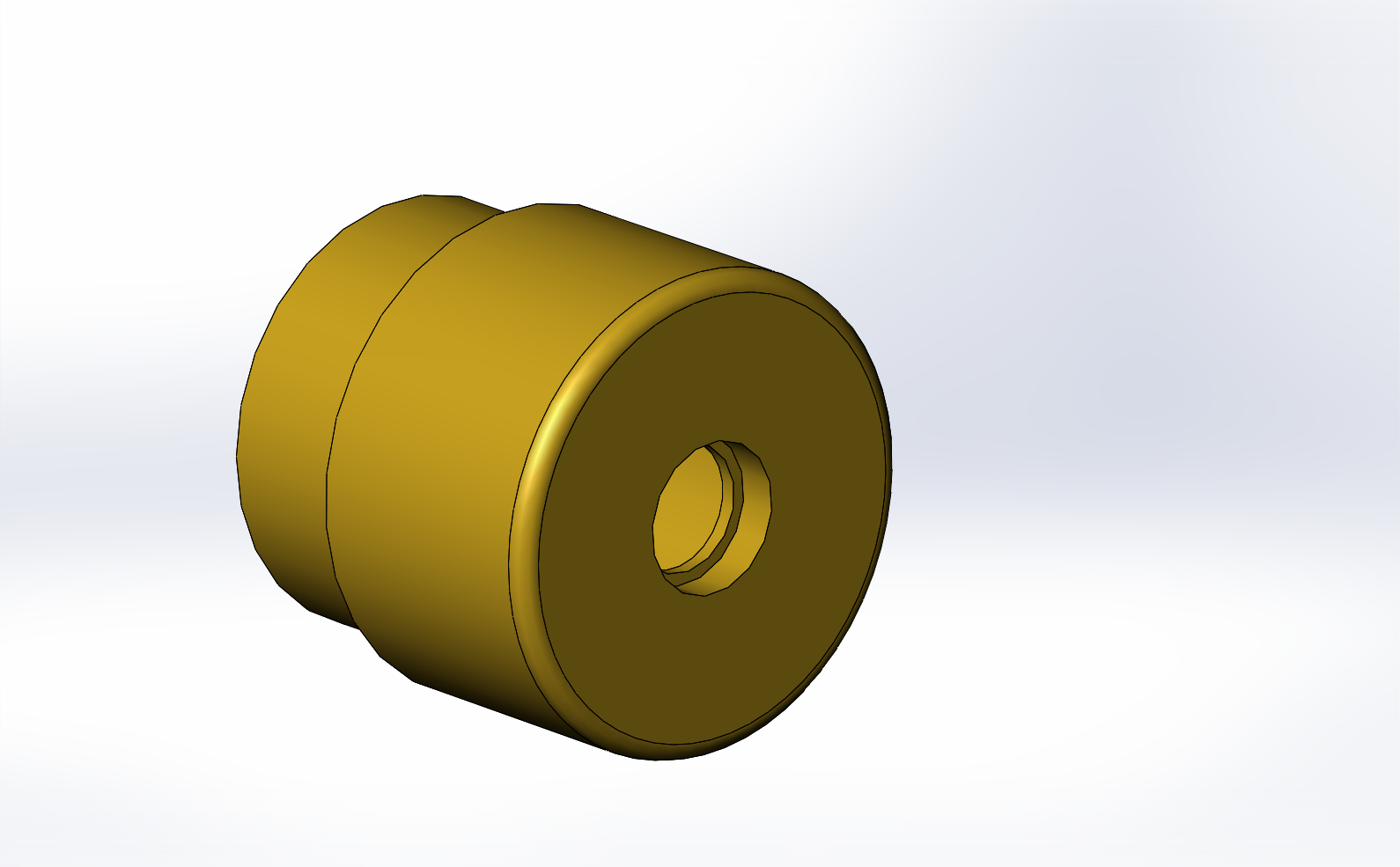

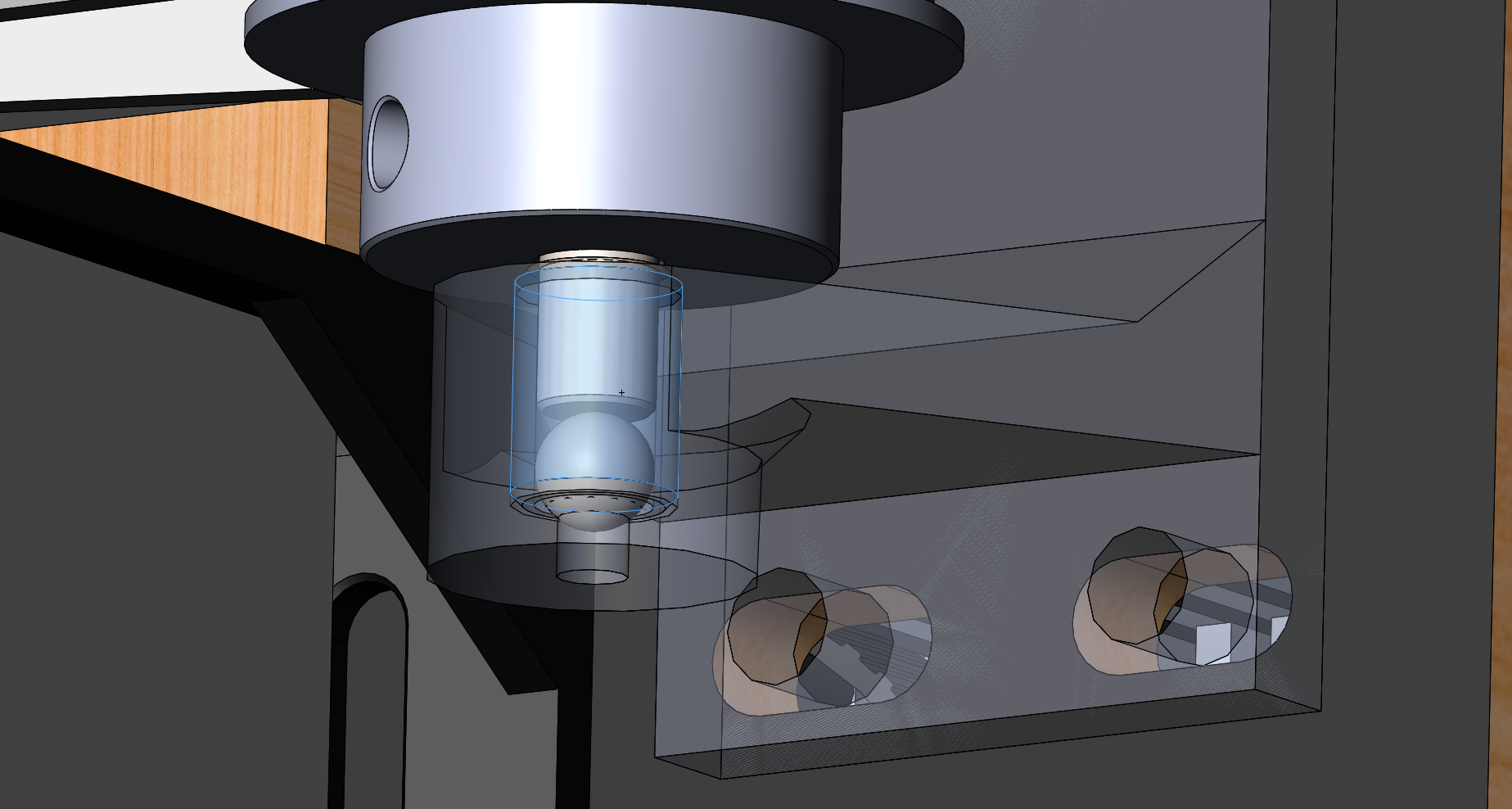

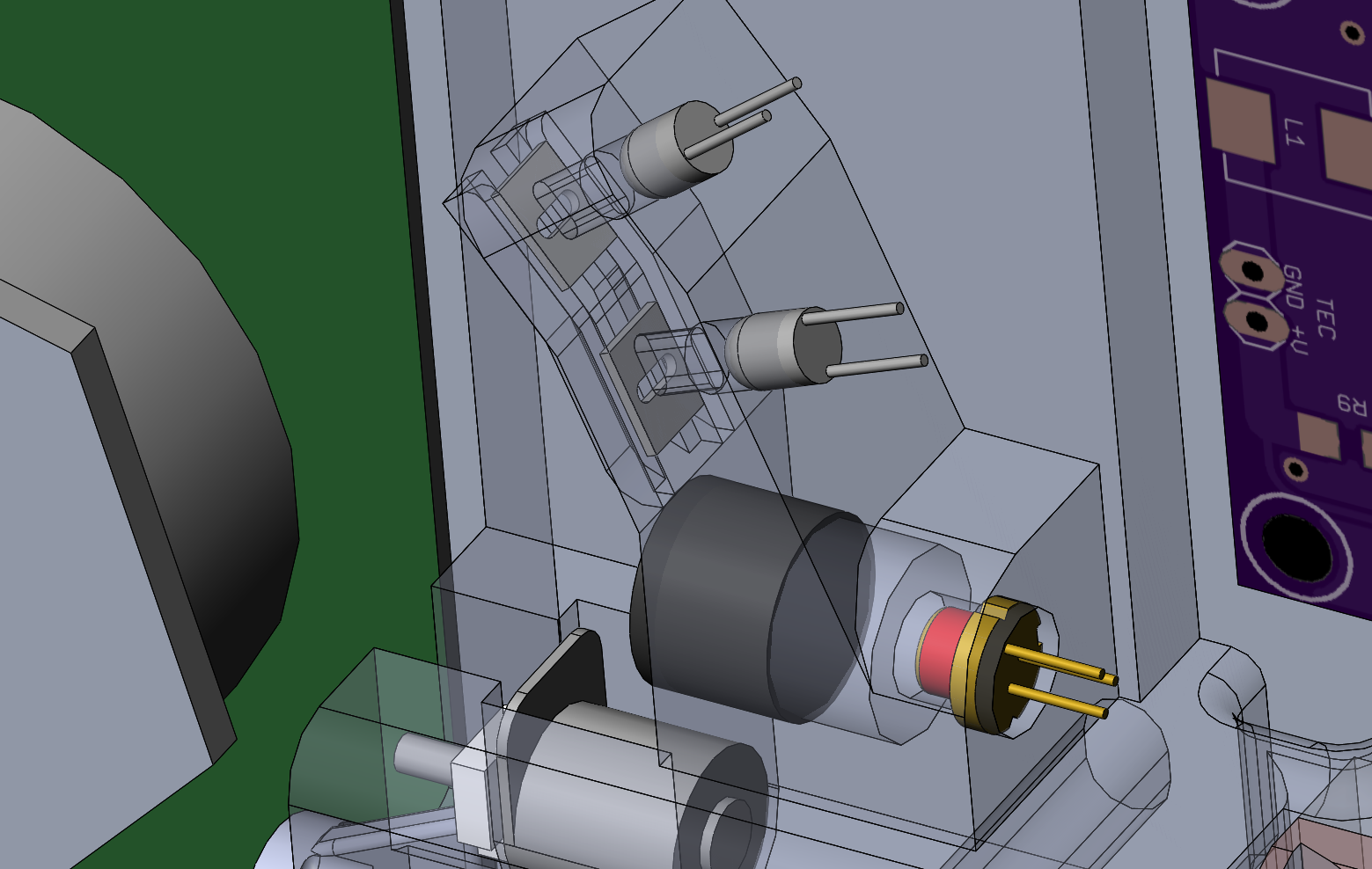

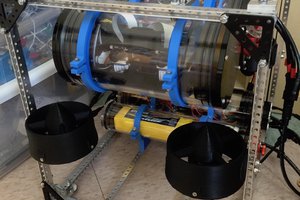

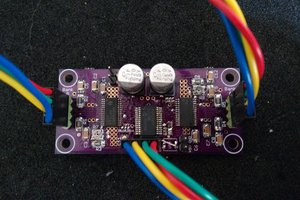

The printer consists of the following parts; Data processing & overall control, a pair of stepper motors to control paper feed (rigid base board carrier) and print head translation and finally the print head itself. In order to attain the desired image resolution, the print head spinning mirror will scan a width of roughly 5mm, to generate a strip similar to that from an inkjet printer. The strips are then built up to form the completed image.

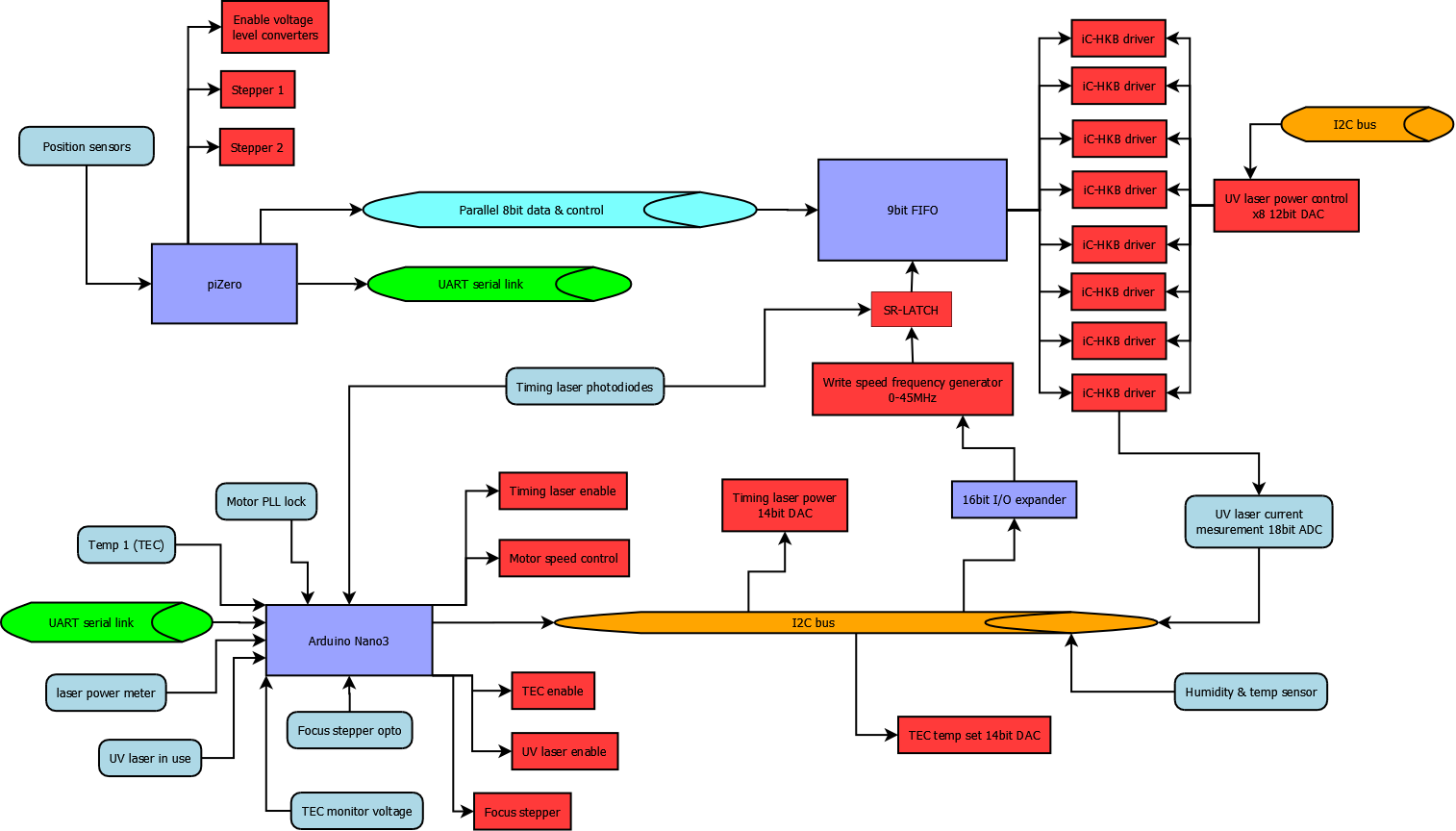

This is the current layout for the various modules (continued below the break).

Figure - System overview (click to expand for more detail)

Background;

The Iron based photographic printing (Siderotype) process dates back to the Herschel Cyanotype, better known as blueprint; which uses the sensitivity to UV light of specific Iron compounds to produce a print. There are numerous other 'alternative' photographic processes many of which should also be suitable.

With the advent of digital cameras it is necessary to print negatives onto transparency film, to allow contact printing, similarly when making enlargements, smaller negatives are scanned and then printed to transparency film.

However printer ink is designed for visible wavelengths and its response to UV wavelengths is variable enough between batches to require repeated time consuming calibration. The transparency film and inks are also fairly costly. The aim for this project is to remove them from the equation, and thus simplify the process from finalising an image to being able to process it. At the same time, allowing full scope in choice of chemistry and media.

I've had questions regarding using this method with other printing chemistry methods such as tintypes. Any chemistry that is sensitive to UV and does not have a very short life-span (wet plates may be possible with humidity control) should be viable. The more sensitive the chemistry, the faster the process should print, up to the limits of the electronics; laser power/signalling speed trade off.

David Brown

David Brown

Tim Wilkinson

Tim Wilkinson

Owen Trueblood

Owen Trueblood

Laser Developer

Laser Developer

Is this project completely dead? I was excited by the possibilities with this. Any alternative?