Results

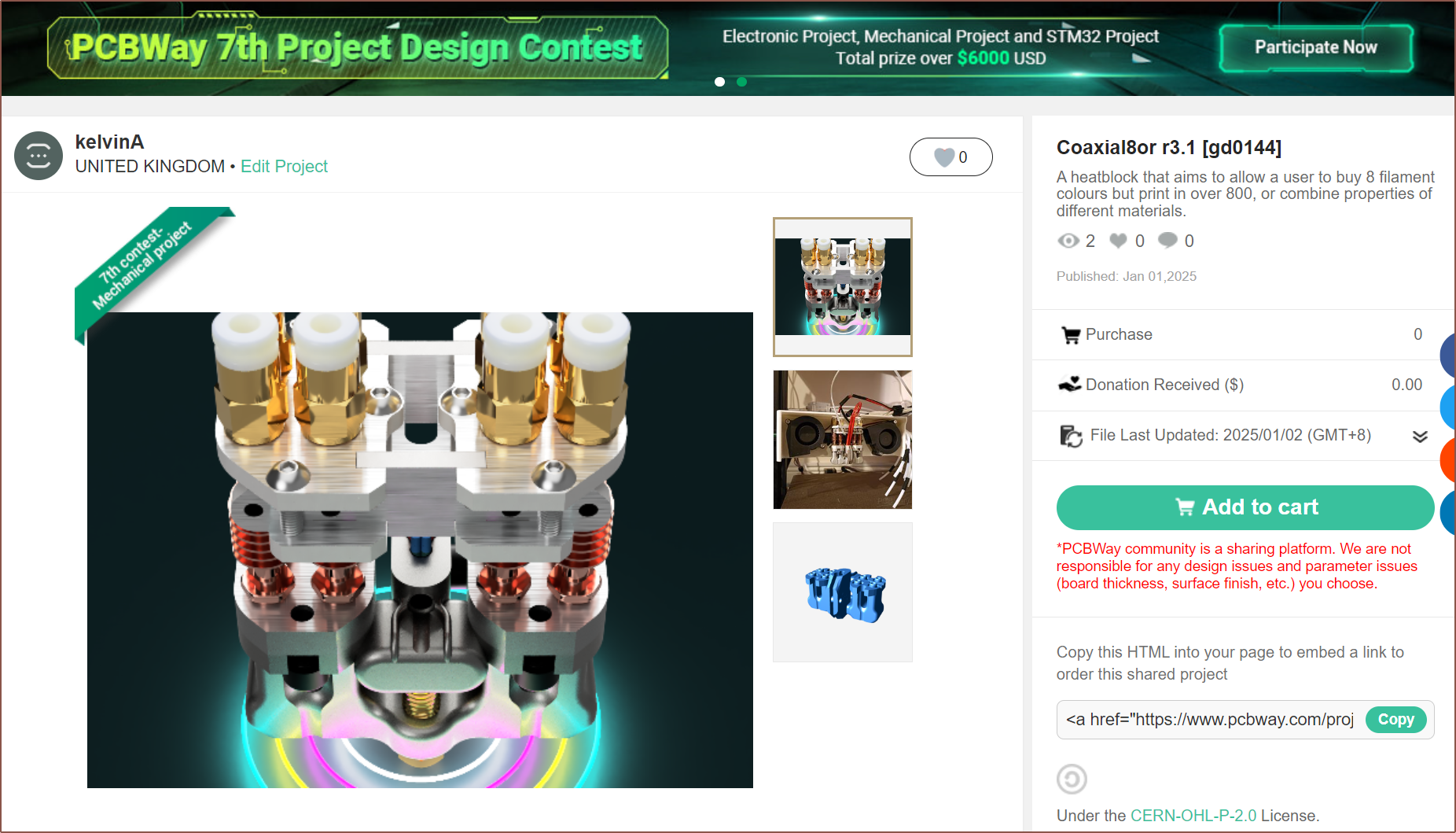

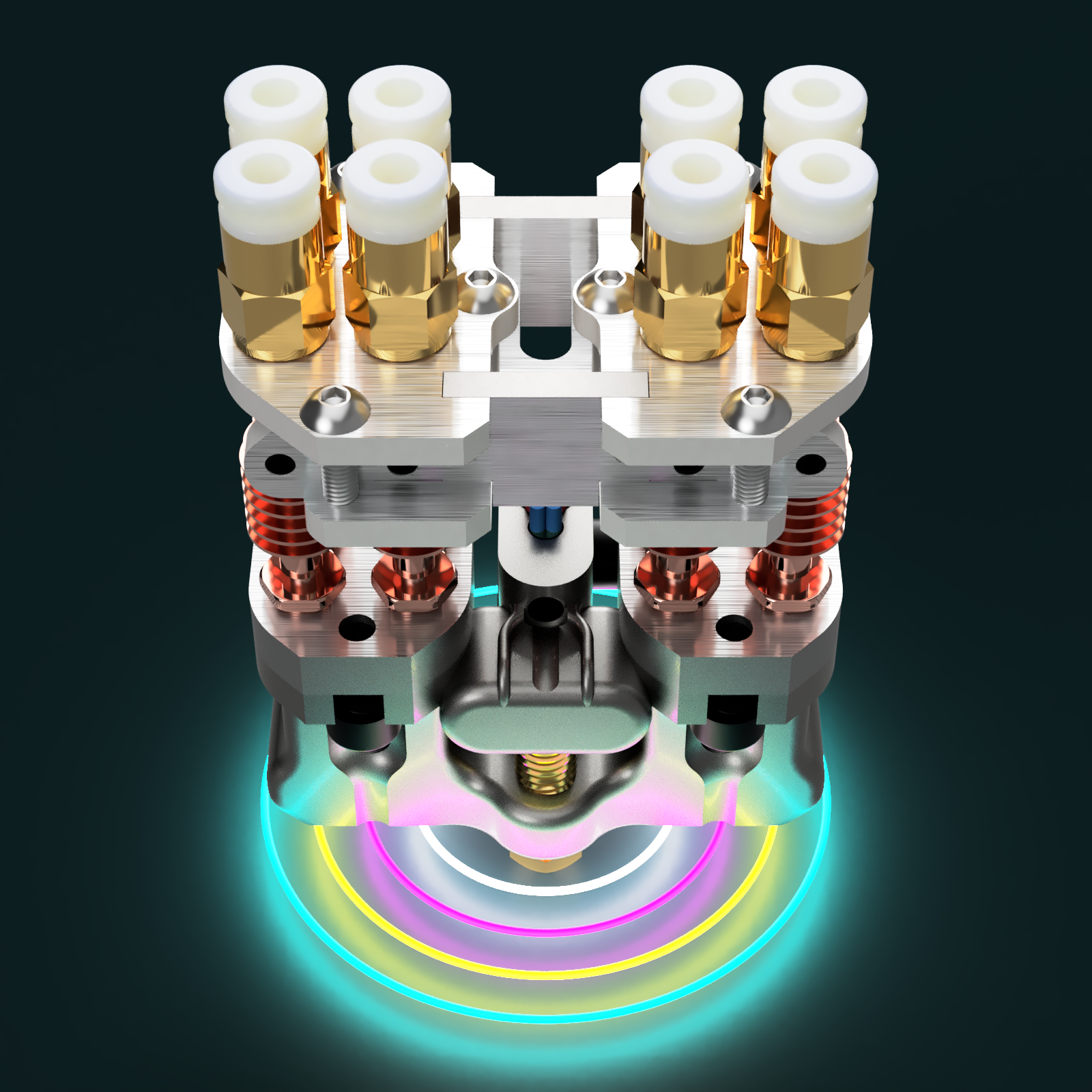

Coaxial8or R3

Coaxial8or R2

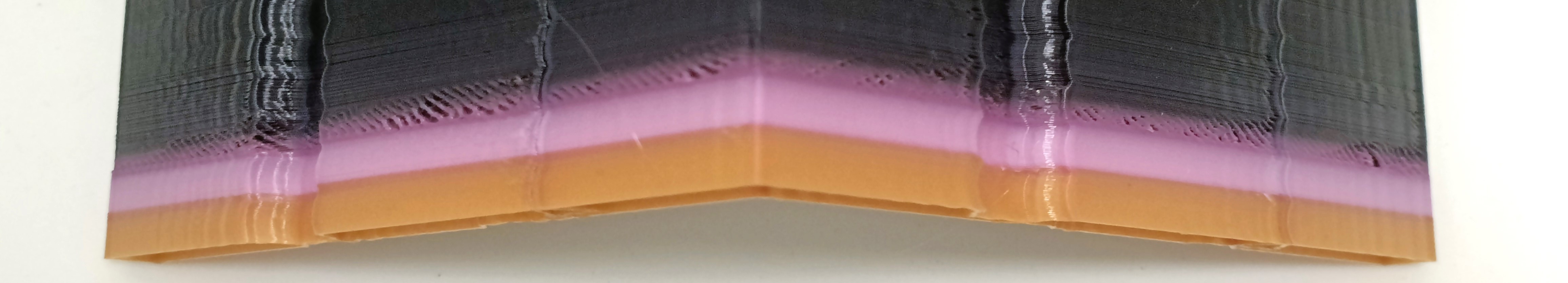

Middle: White around magenta

Bottom: Yellow around magenta

Coaxial8or R0

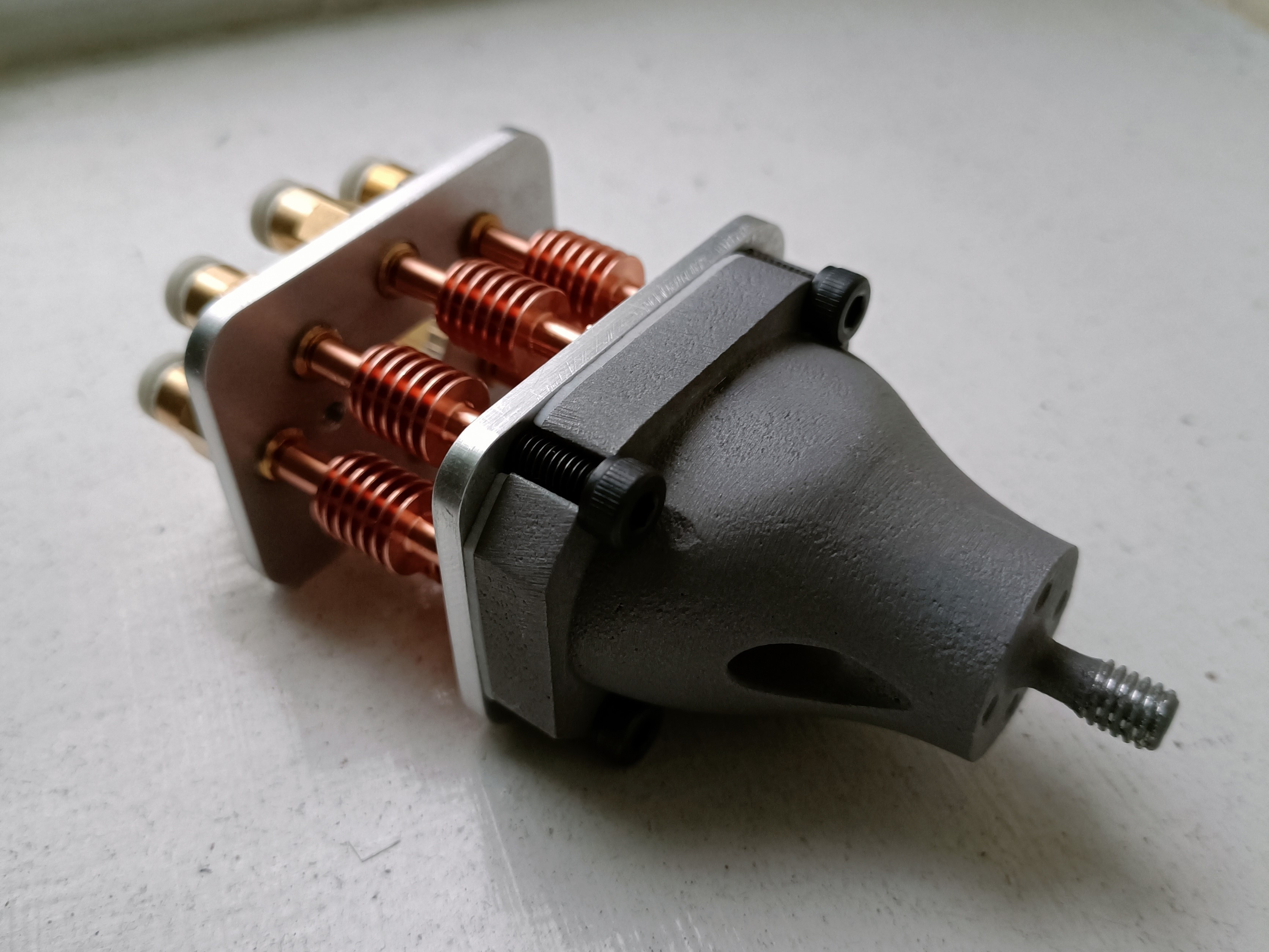

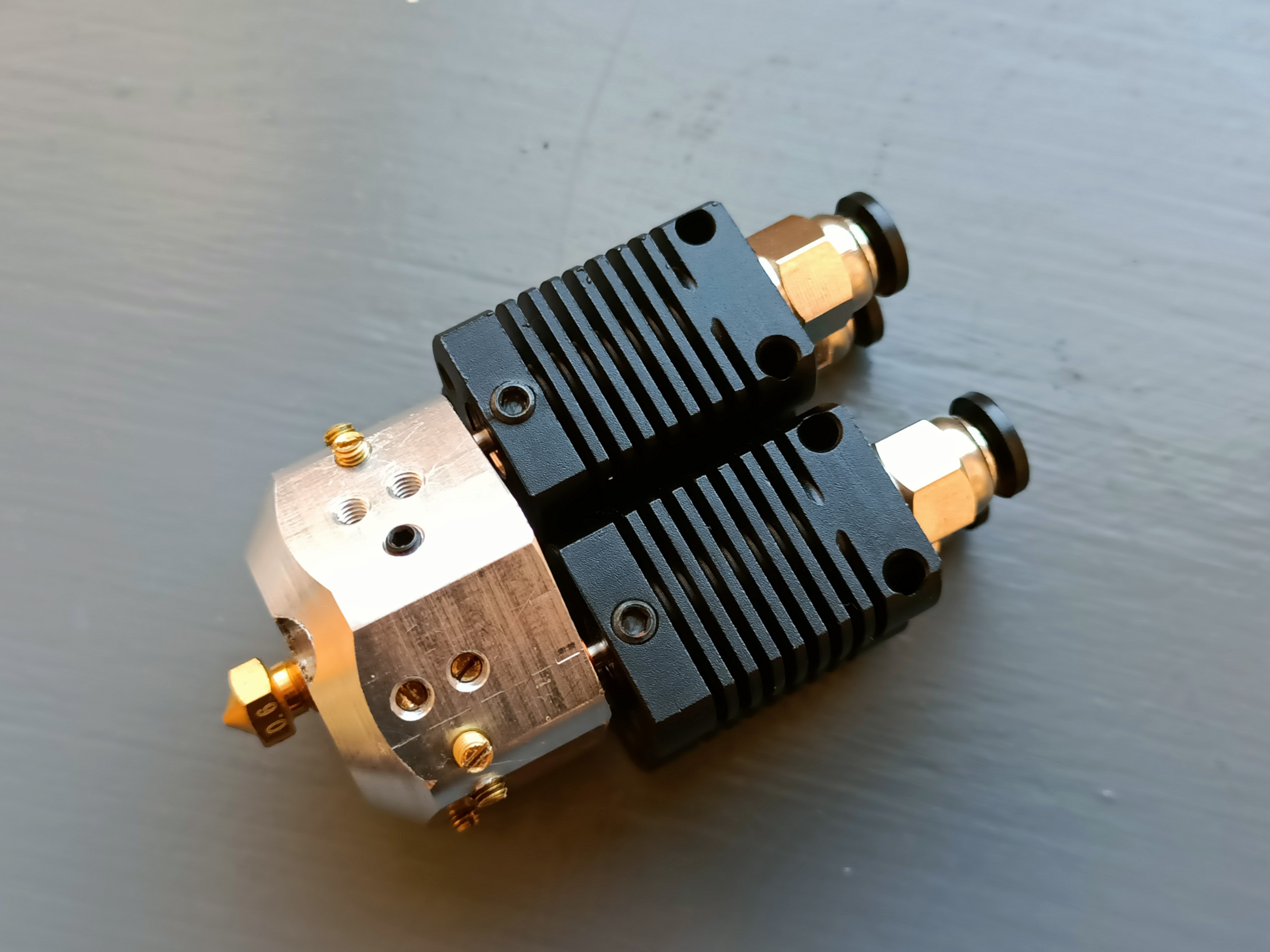

4-in-1-out Coaxial Hotend

Inspiration and/or examples of working principle

Navigation

The title tag system is explained here, and the table is updated when a change occurs. Notable logs have bold L# text.

Read more » kelvinA

kelvinA

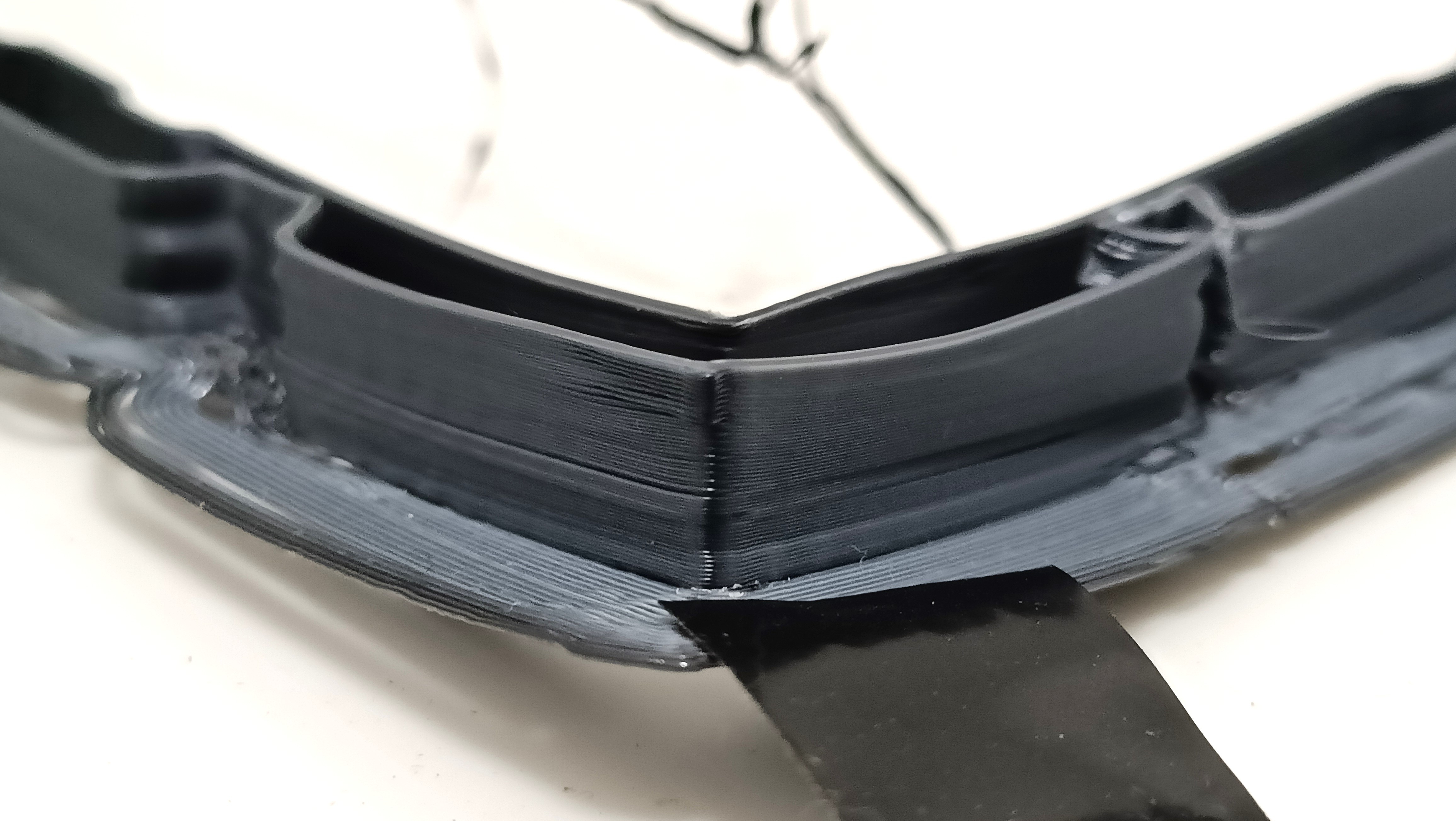

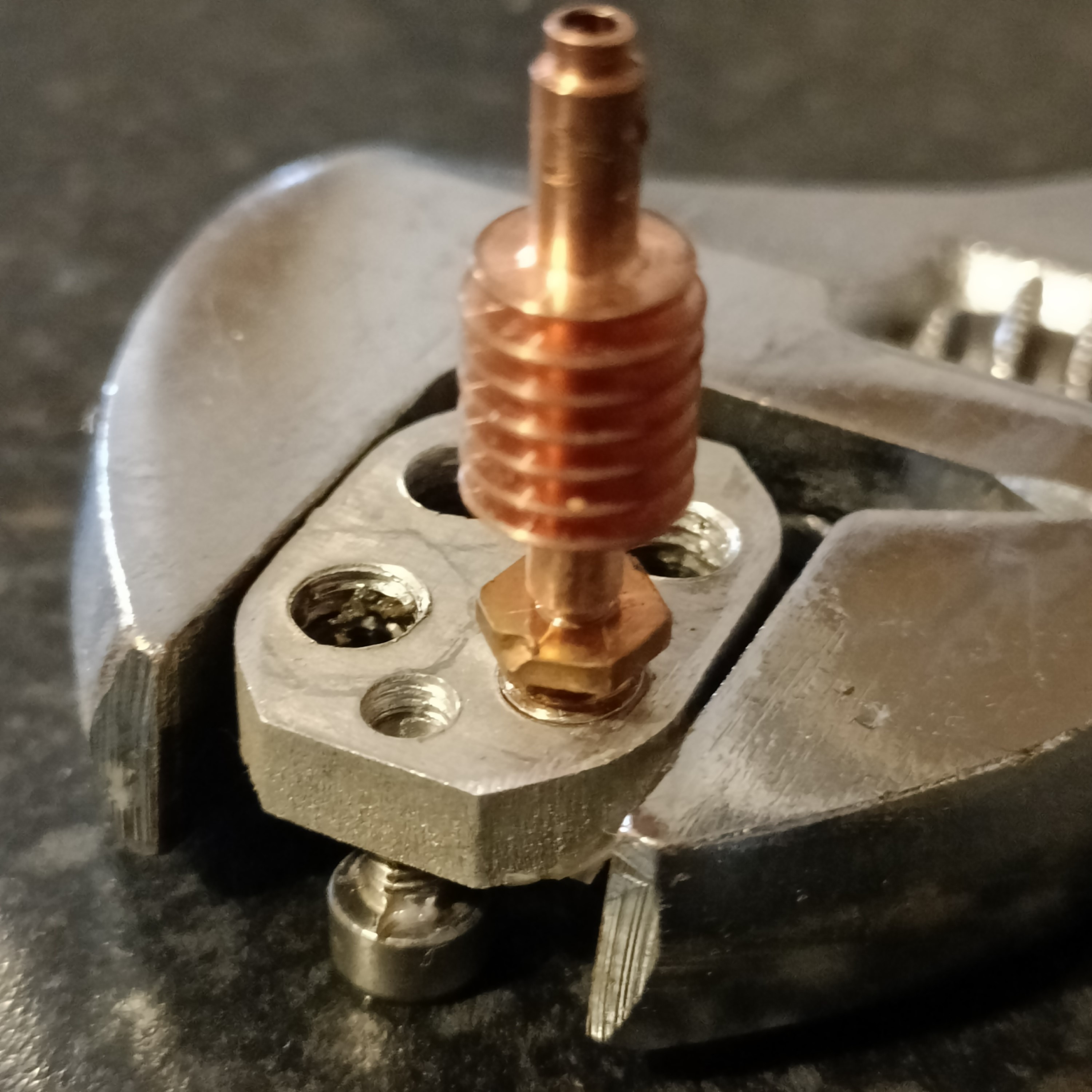

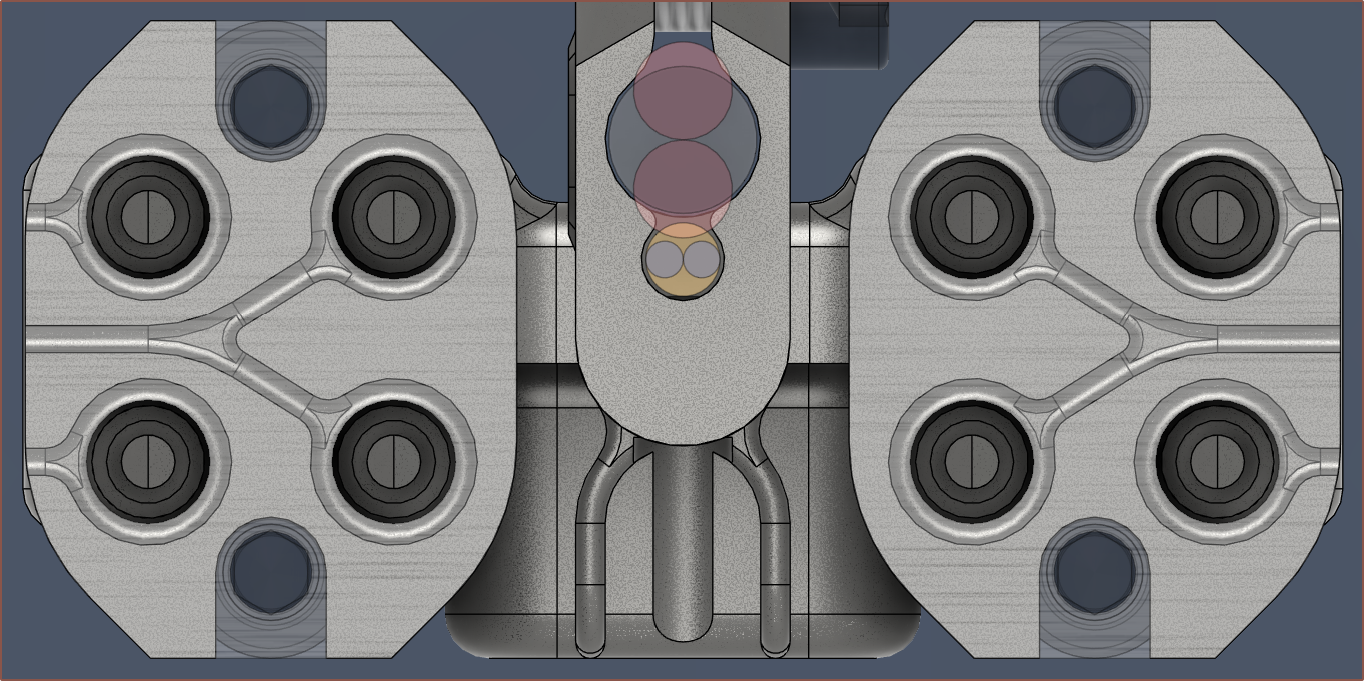

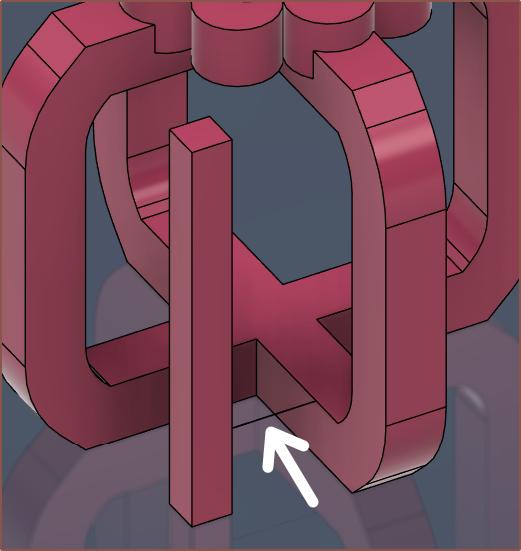

I've been tuning M592 and the amount of leaking is dramatically reduced. With more experience on how the leak propagates, I now feel that it's possible to minimise the shielding of the grub screw and make it look more streamlined. Fusion complained about my fillets so this simple change took multitudes longer than it should've.

I've been tuning M592 and the amount of leaking is dramatically reduced. With more experience on how the leak propagates, I now feel that it's possible to minimise the shielding of the grub screw and make it look more streamlined. Fusion complained about my fillets so this simple change took multitudes longer than it should've.

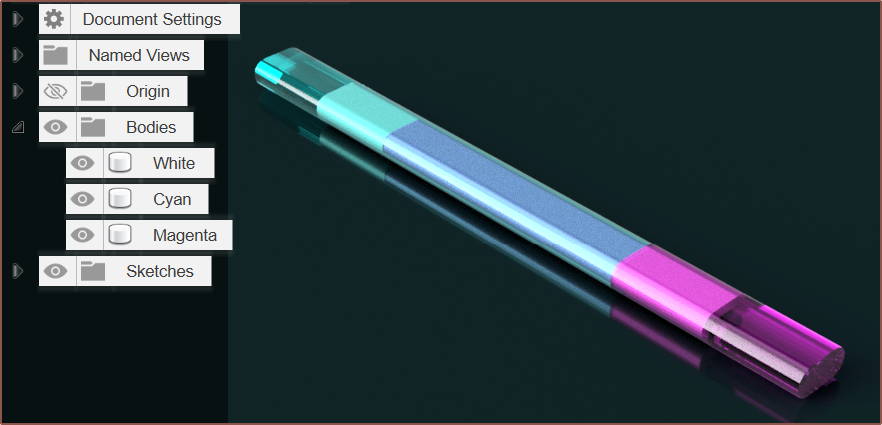

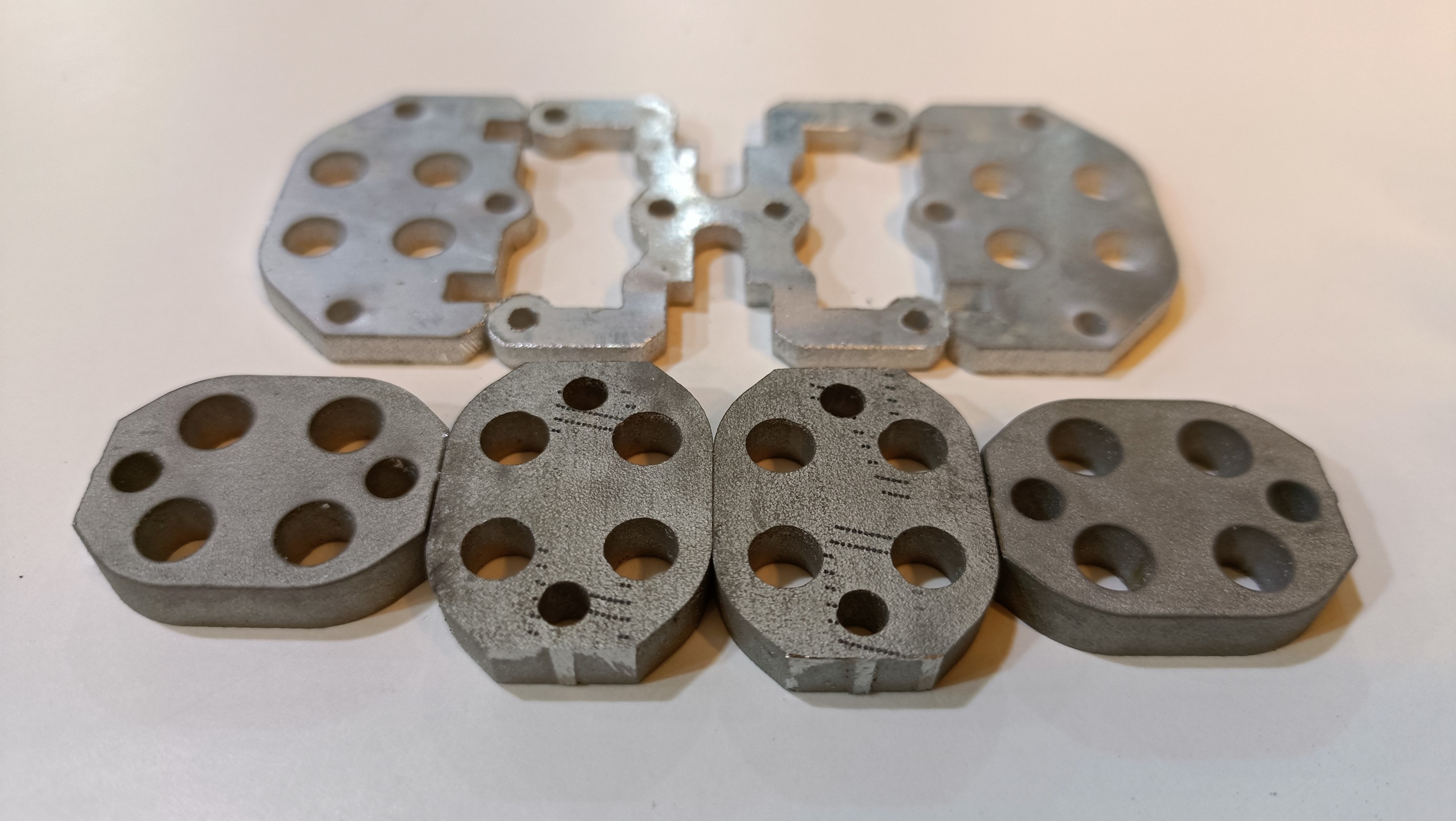

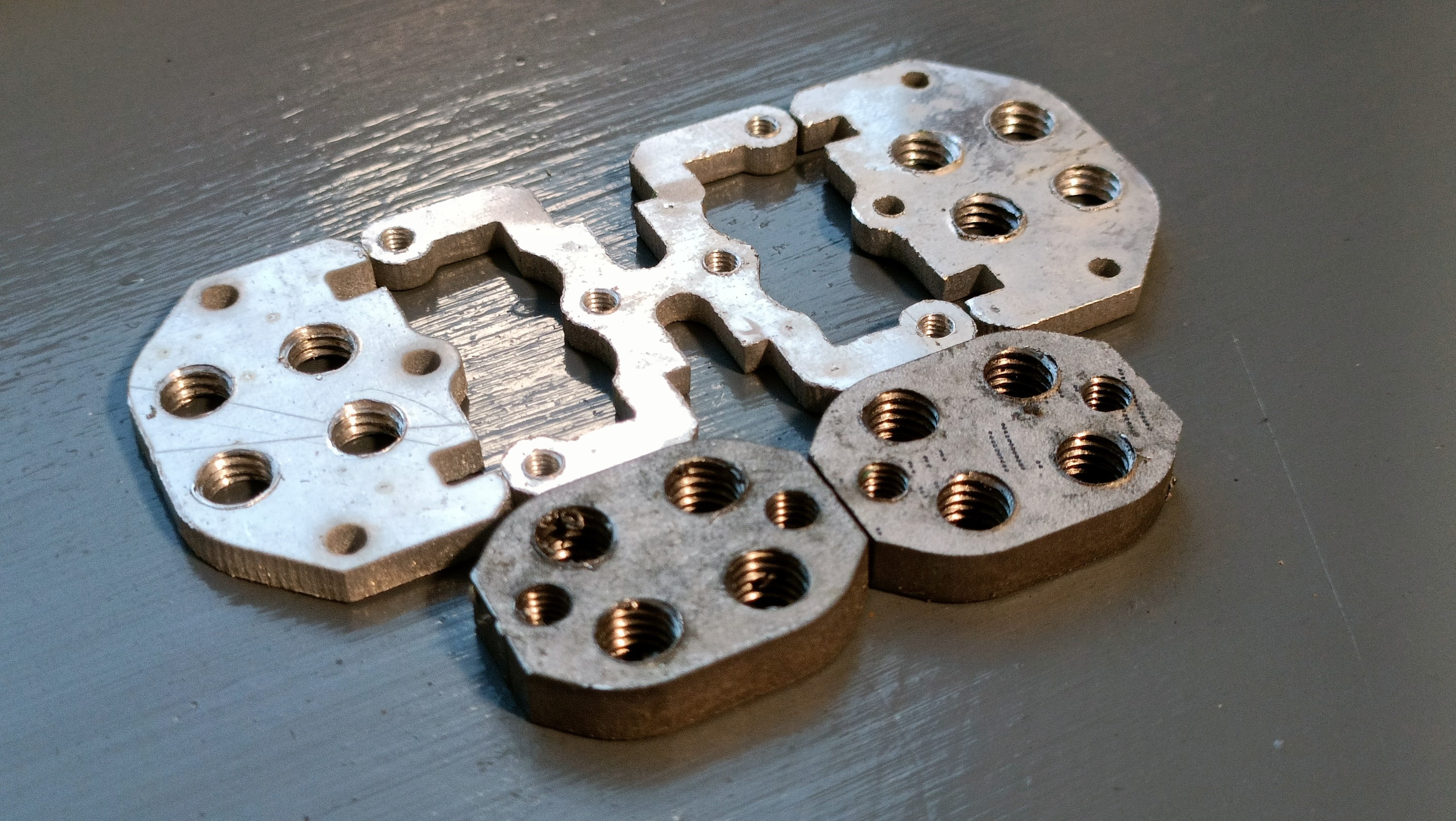

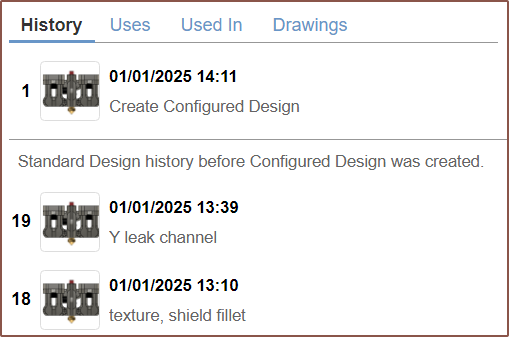

Some of the limitations I found was that you can't edit in place, nor do things like change checkboxes (Eg. "Keep Tools" in a combine feature). But now, I can quickly toggle visibility of certain components:

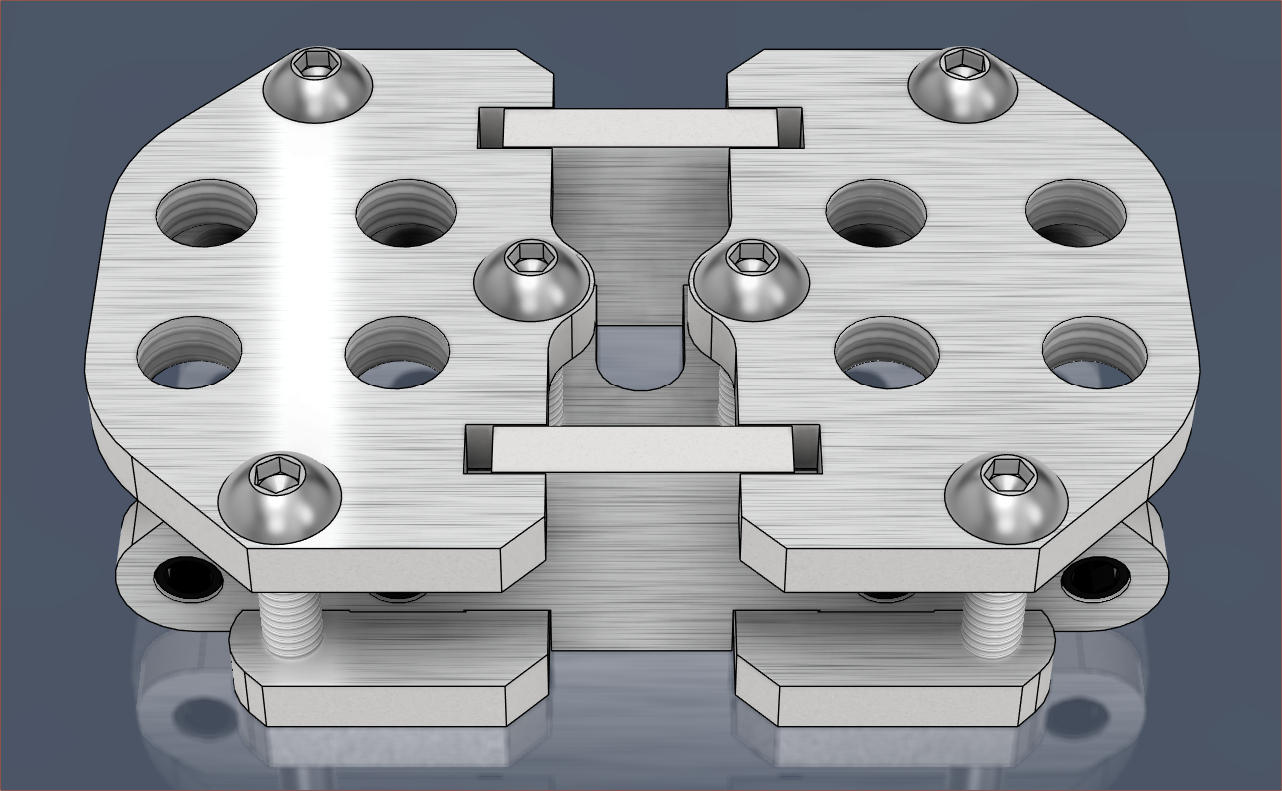

Some of the limitations I found was that you can't edit in place, nor do things like change checkboxes (Eg. "Keep Tools" in a combine feature). But now, I can quickly toggle visibility of certain components: I've also exported the .step of the hotend holder, partially because the odds that I need to continue revising it are not insignificant. Additionally, it's tangled in the rest of the "Coaxial Hotend" file and trying to "Save a copy" gave me an exploded file:

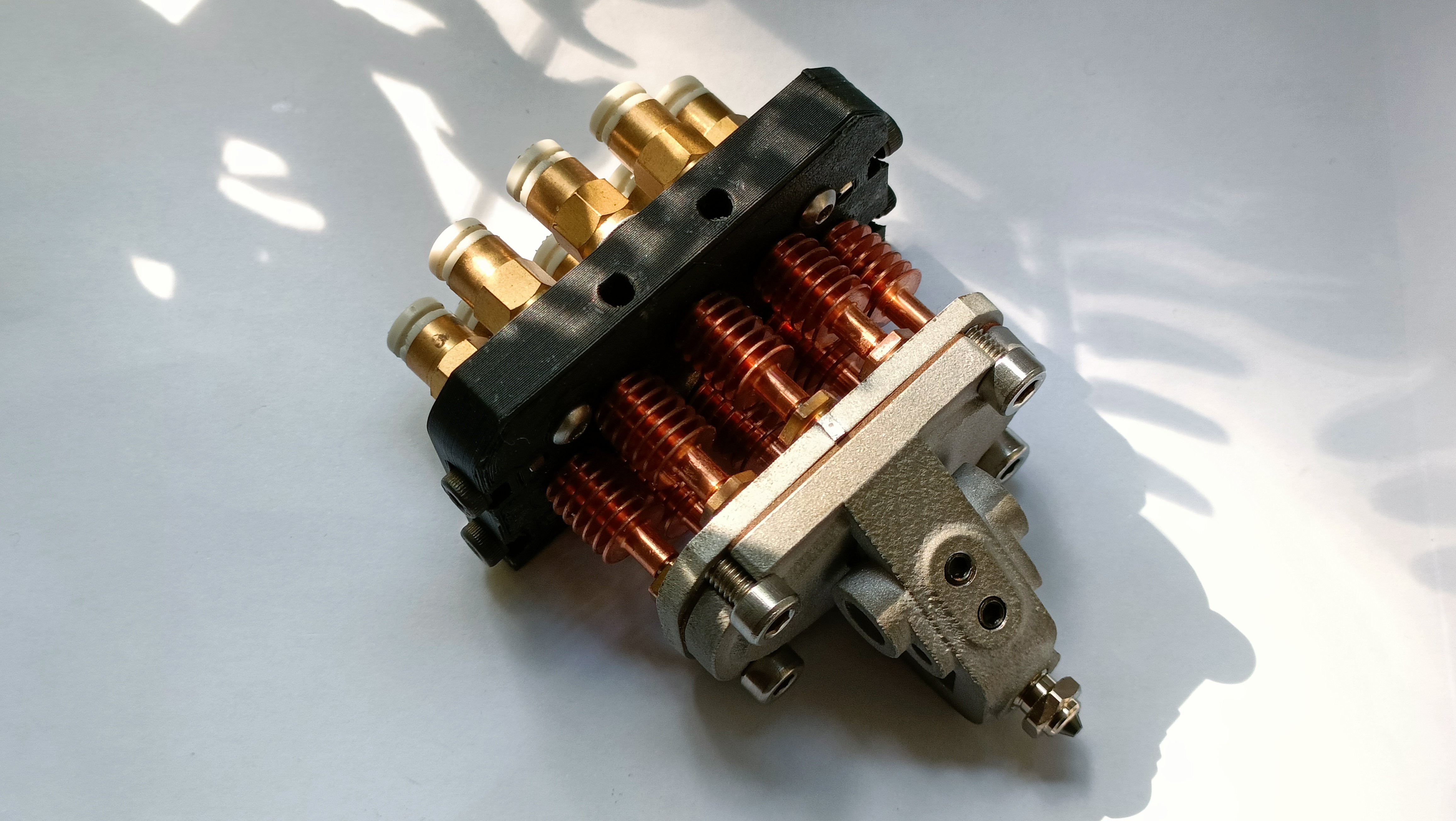

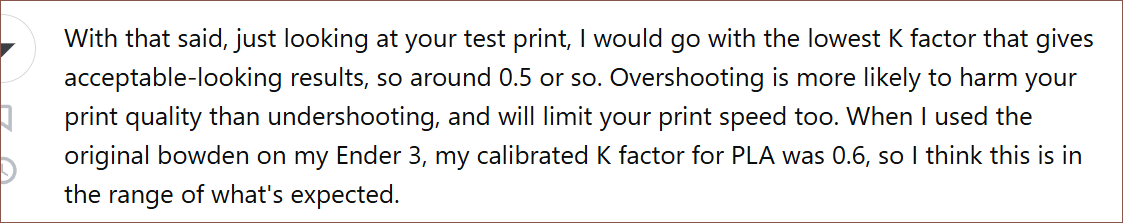

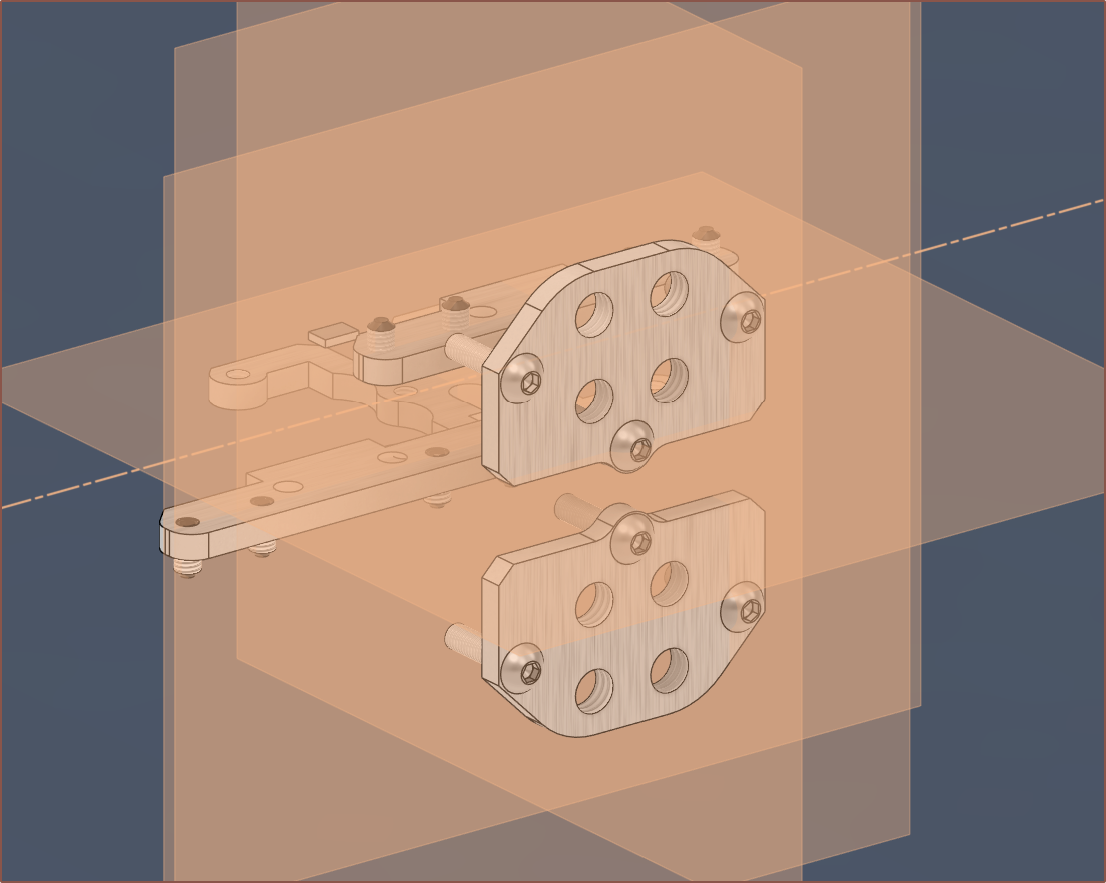

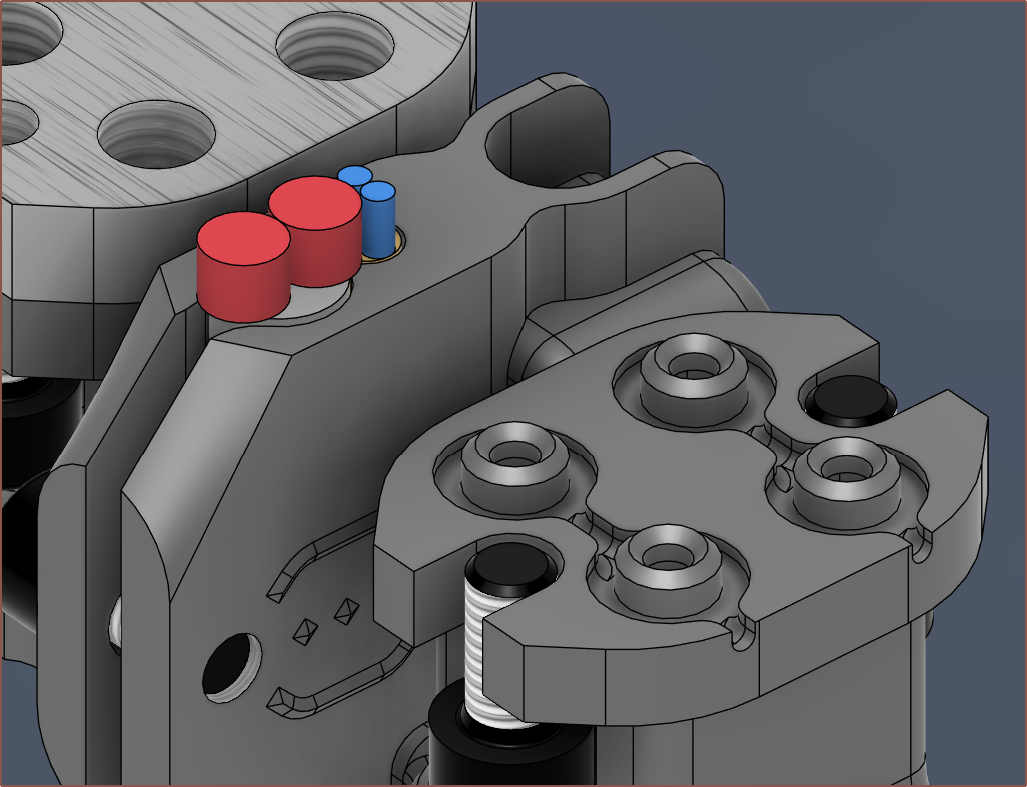

I've also exported the .step of the hotend holder, partially because the odds that I need to continue revising it are not insignificant. Additionally, it's tangled in the rest of the "Coaxial Hotend" file and trying to "Save a copy" gave me an exploded file: I've also rendered the latest heatblock and holder:

I've also rendered the latest heatblock and holder:

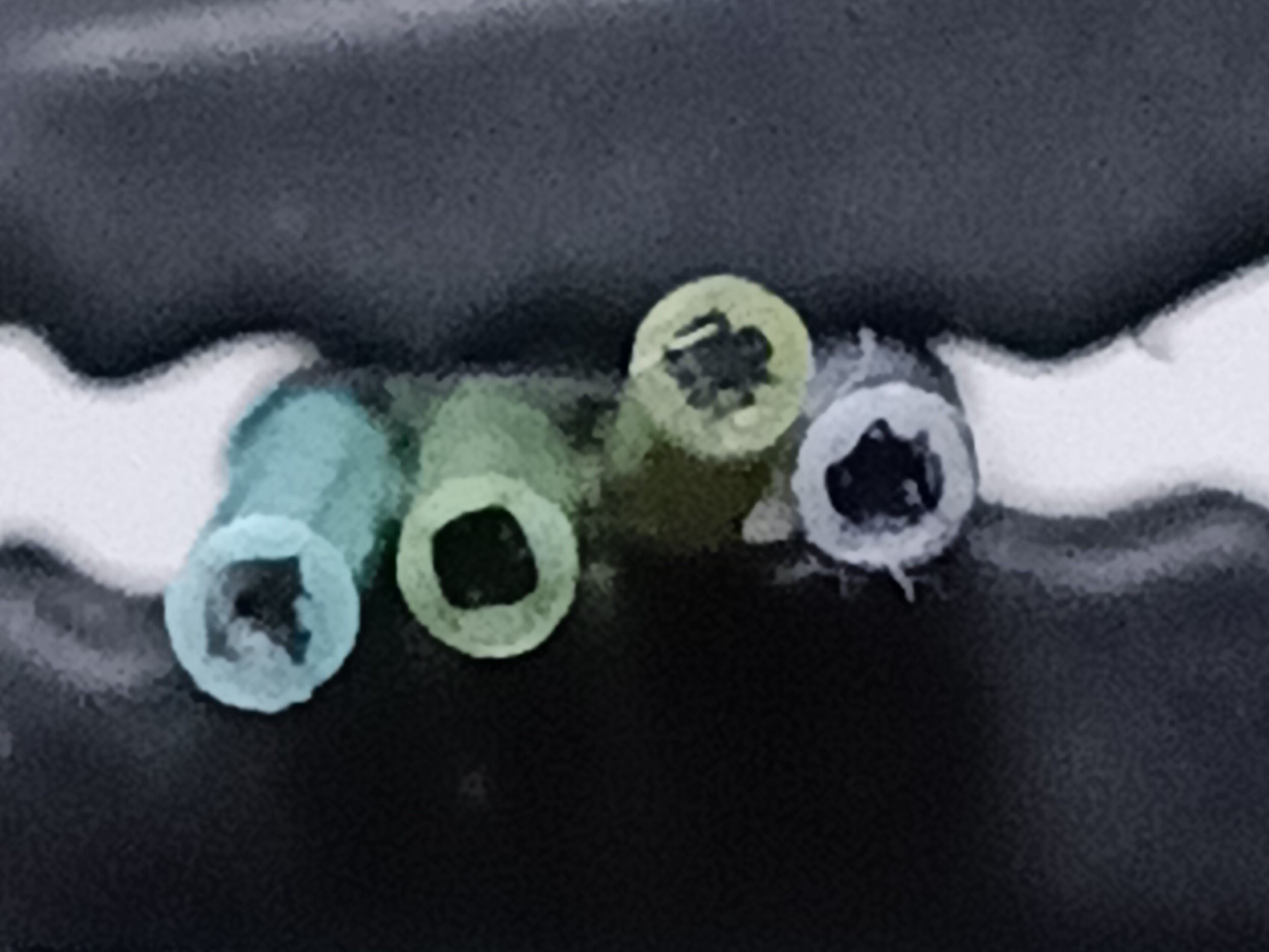

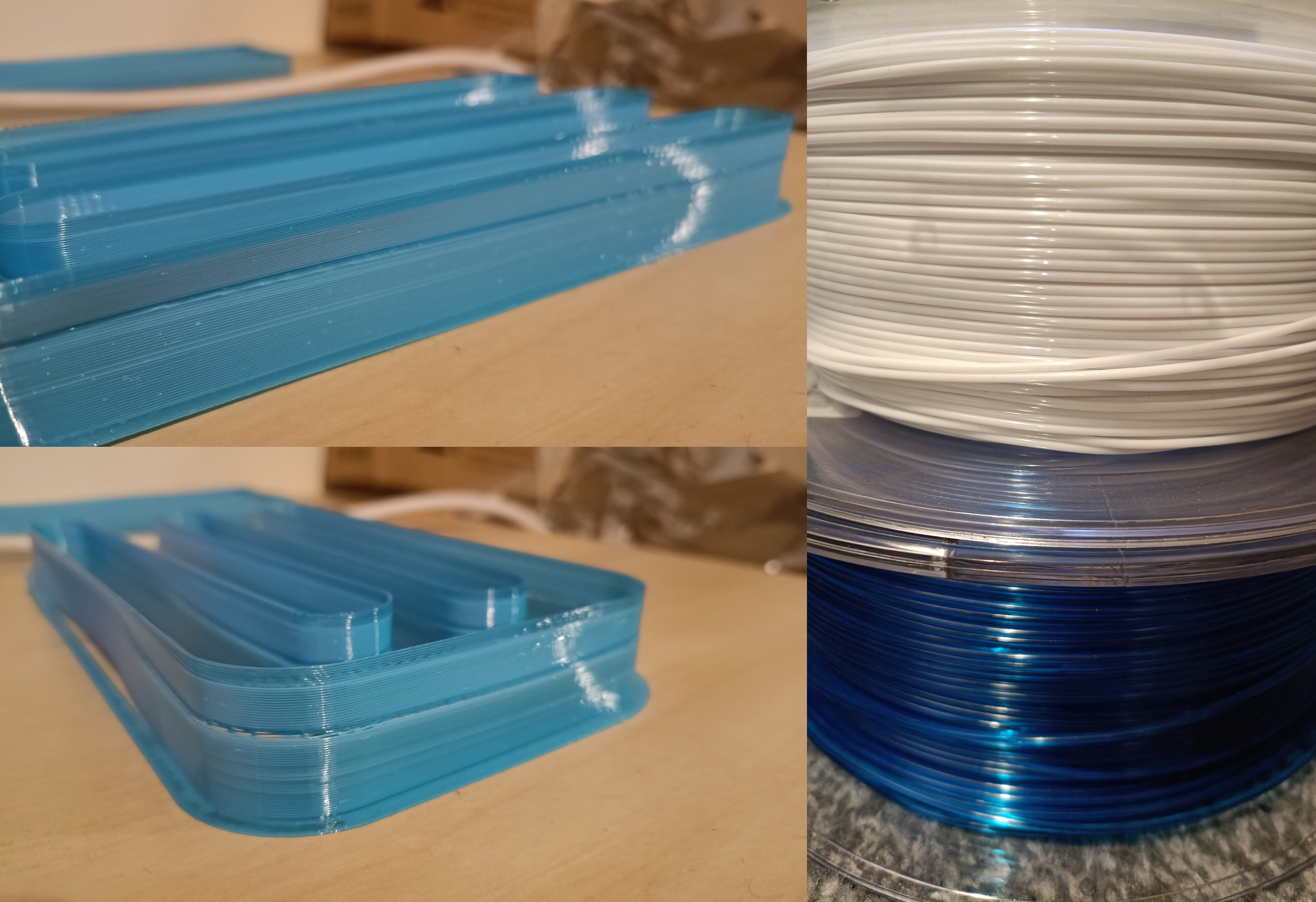

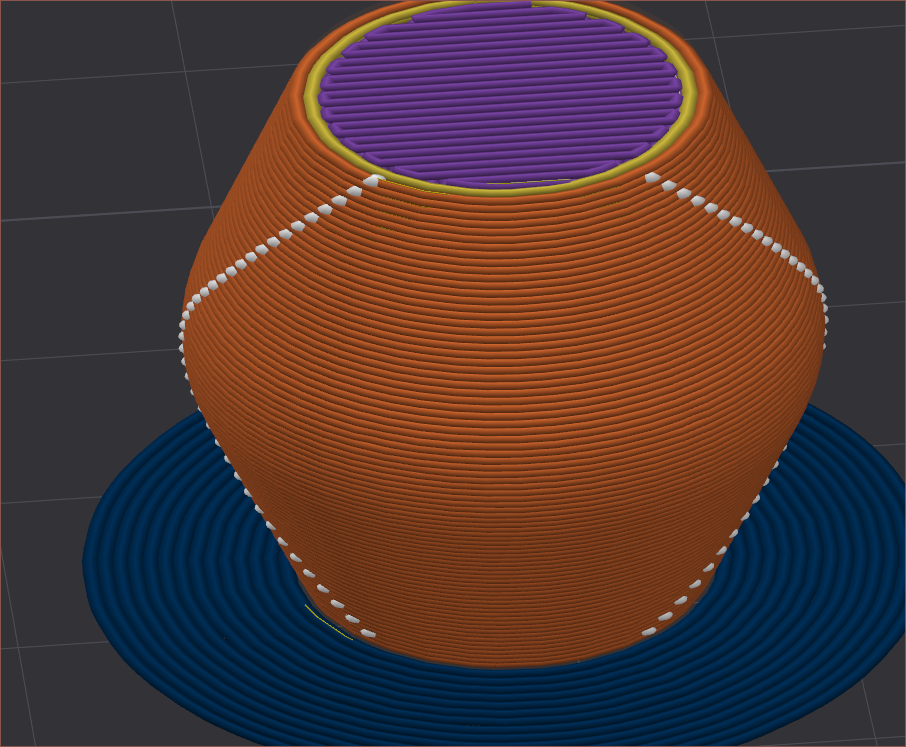

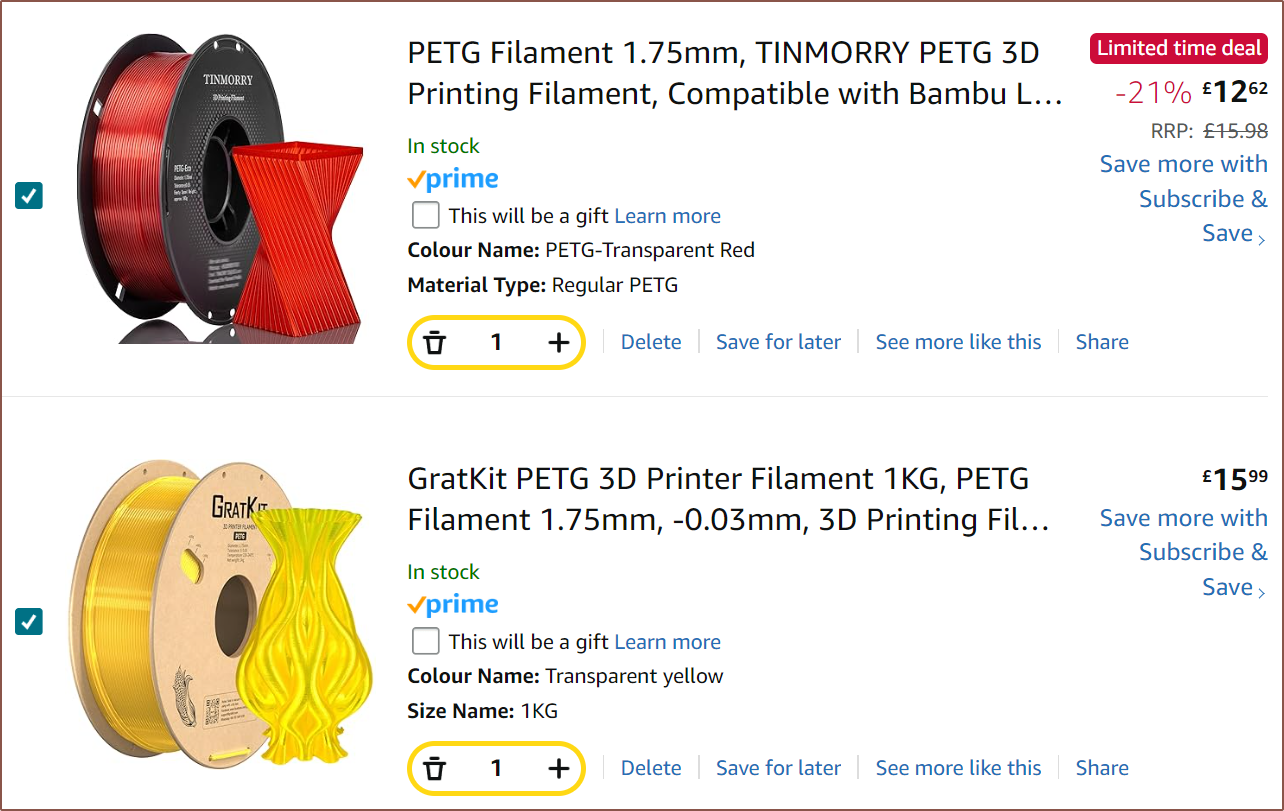

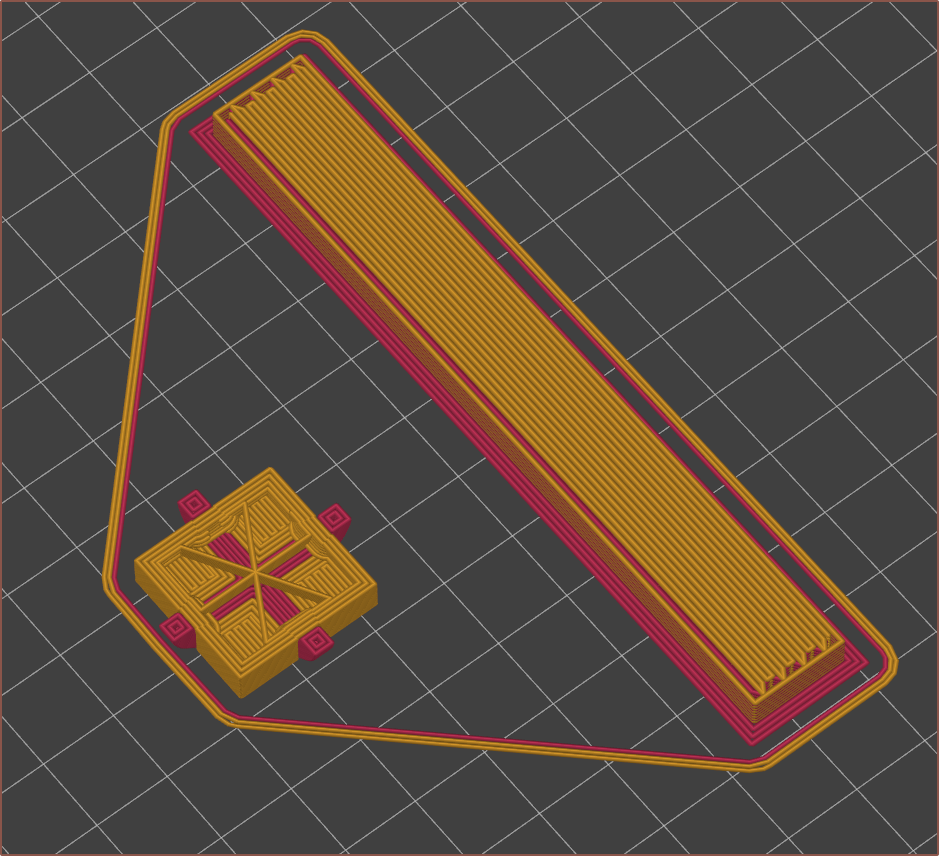

The above is the Mint PETG I have, and my workflow is to:

The above is the Mint PETG I have, and my workflow is to:

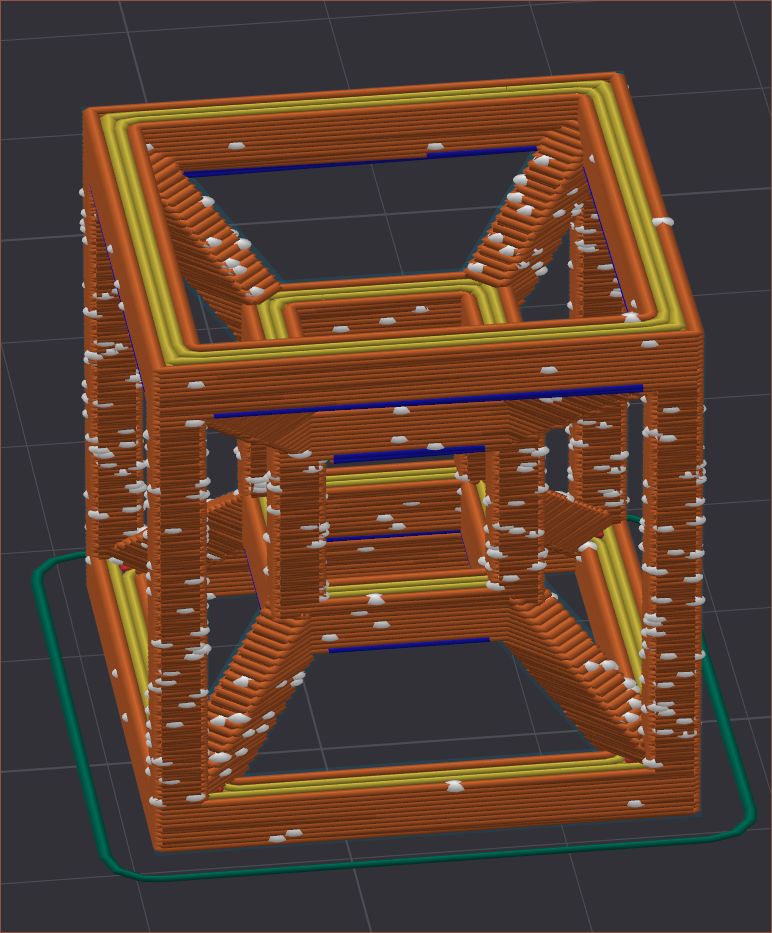

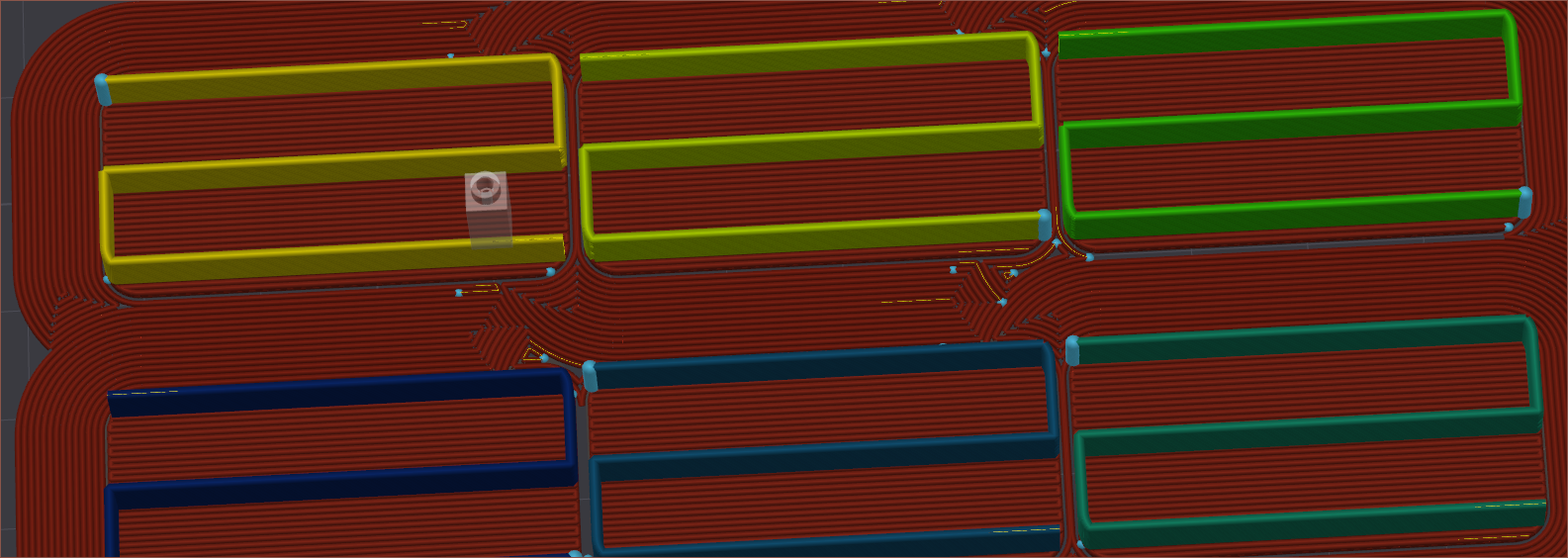

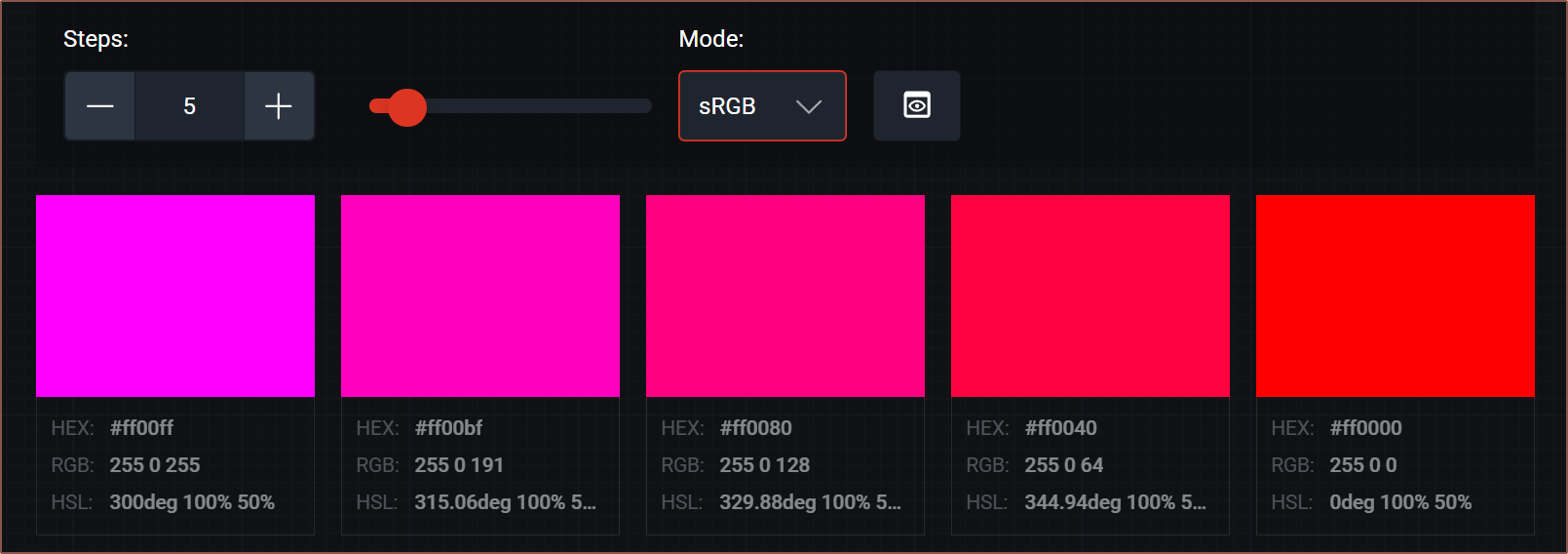

Obviously, to celebrate years worth of calibration cubes, I modelled a ribbon-wrapped 20mm cube with an 8-sided flower-bow on top. I also added a little pillar so that I could mark orientation (because this is still a calibration cube at the end of the day). I joined the pillar with a very narrow (0.001mm) extrusion so that it and the ribbon counts as a single body:

Obviously, to celebrate years worth of calibration cubes, I modelled a ribbon-wrapped 20mm cube with an 8-sided flower-bow on top. I also added a little pillar so that I could mark orientation (because this is still a calibration cube at the end of the day). I joined the pillar with a very narrow (0.001mm) extrusion so that it and the ribbon counts as a single body: It should also be of no surprise that the ribbon has filleted chamfers.

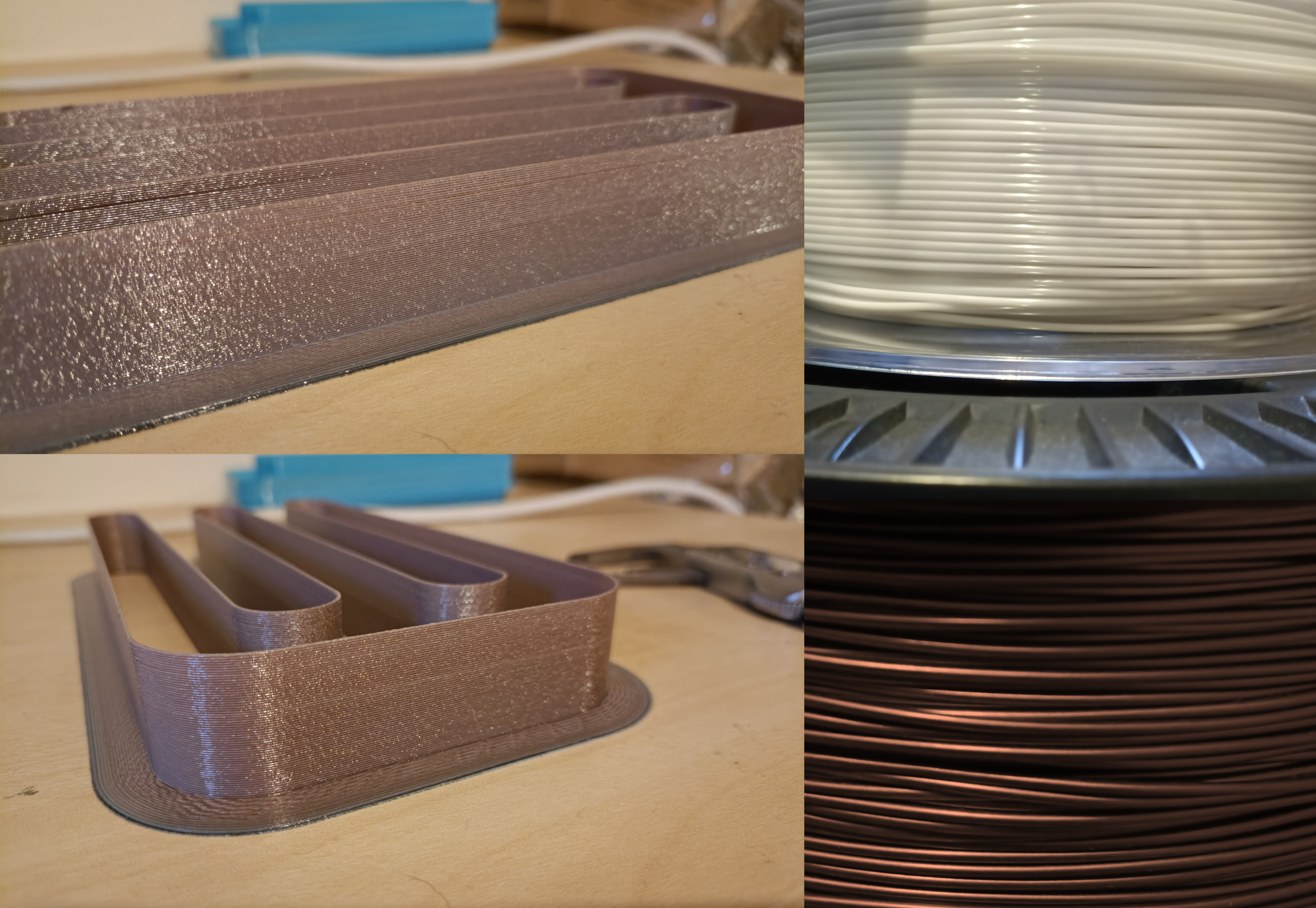

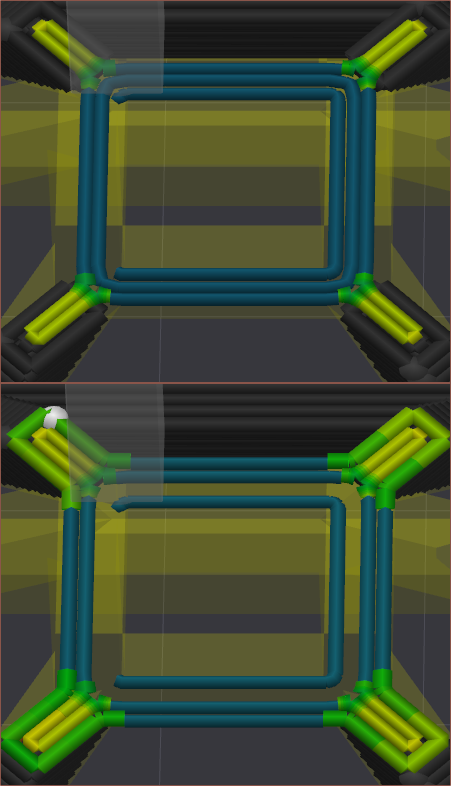

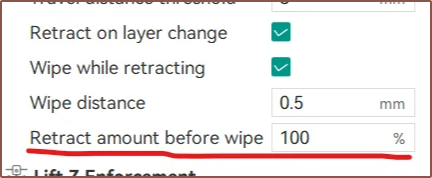

It should also be of no surprise that the ribbon has filleted chamfers. So I was doing things like setting up a decent purge volume and looking at the (failing) prints to see that I really needed to work on retraction settings. What I found that it seems best to

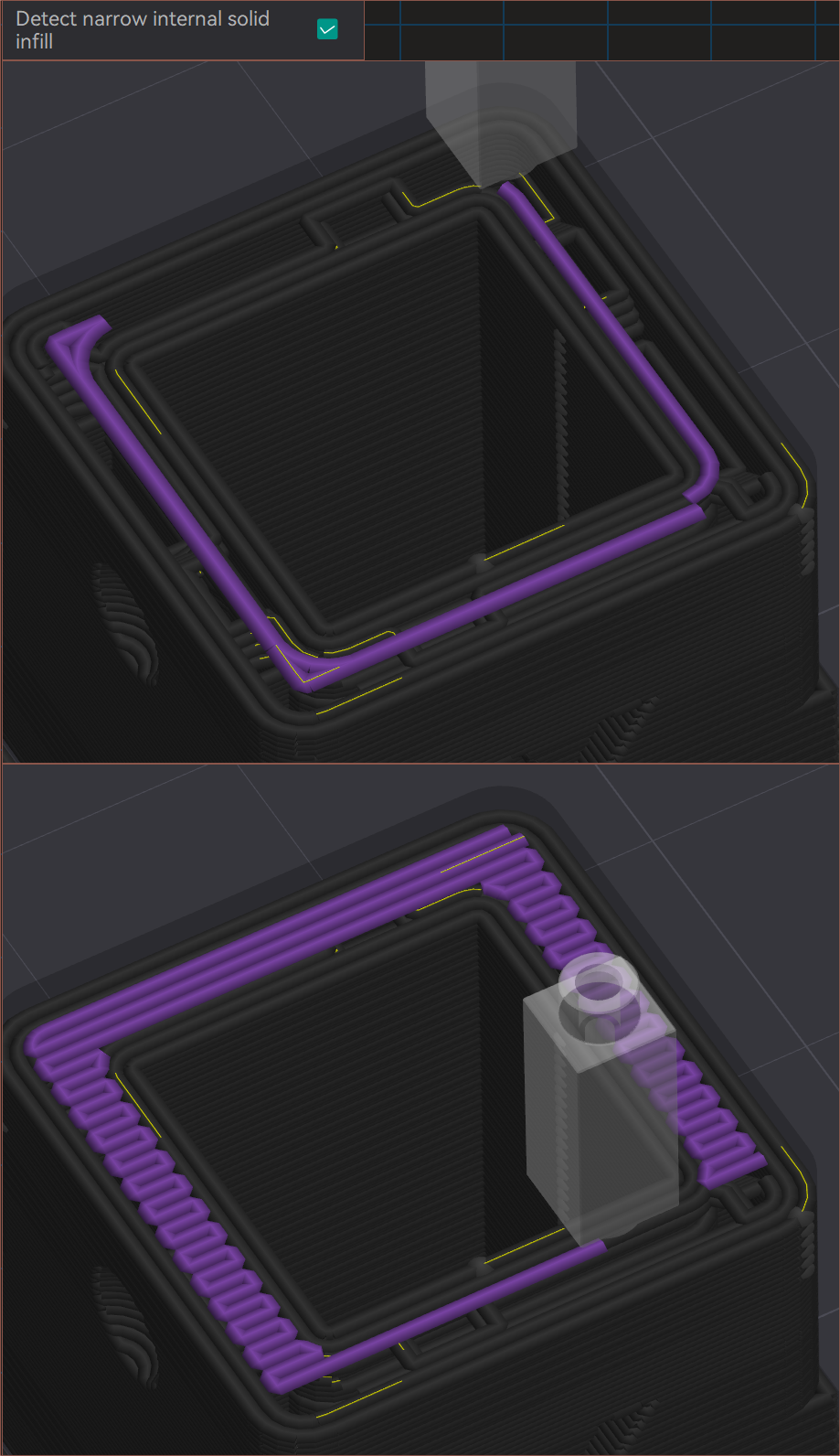

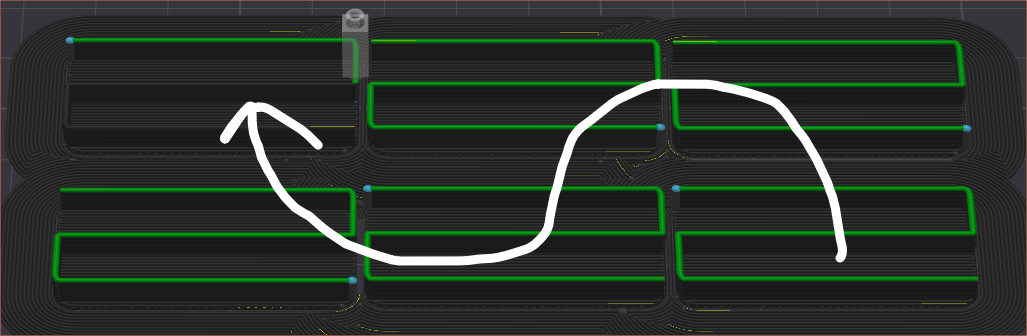

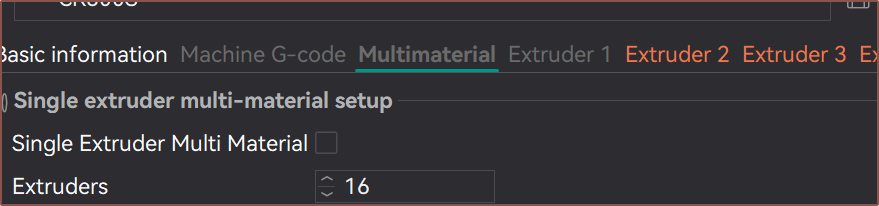

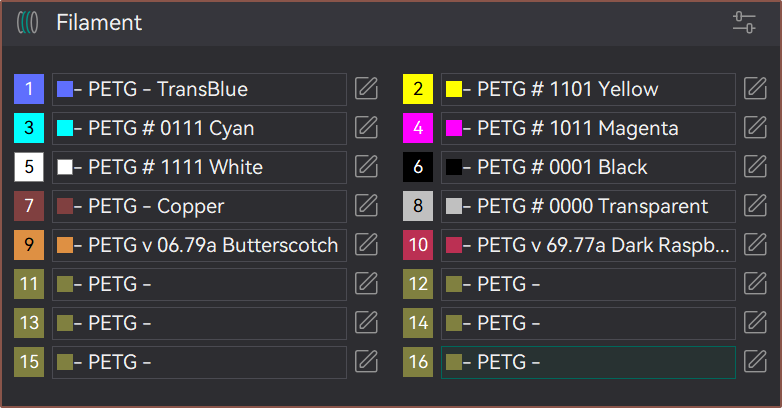

So I was doing things like setting up a decent purge volume and looking at the (failing) prints to see that I really needed to work on retraction settings. What I found that it seems best to Earlier in the year, I didn't use this slicer because it only supported single-extruder-multimaterial options. I can now report that it now supports multiple extruders! The only caveat is that, to duplicate settings across all extruders, I have to temporarily set Extruders = 1 and then back to = 16. This also resets the filaments loaded to whatever was in the first extruder.

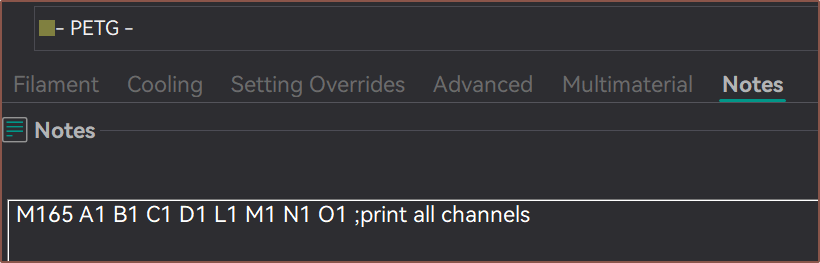

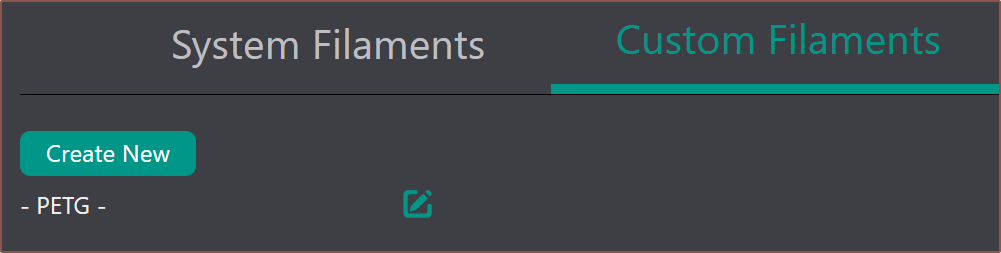

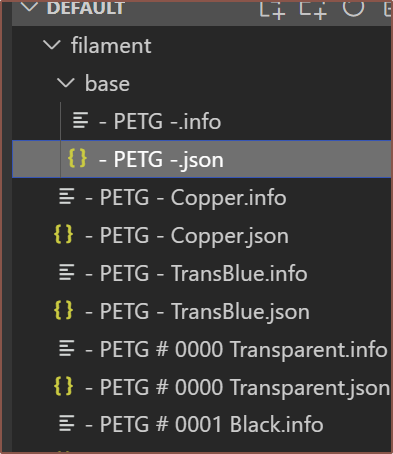

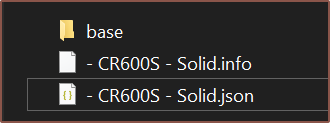

Earlier in the year, I didn't use this slicer because it only supported single-extruder-multimaterial options. I can now report that it now supports multiple extruders! The only caveat is that, to duplicate settings across all extruders, I have to temporarily set Extruders = 1 and then back to = 16. This also resets the filaments loaded to whatever was in the first extruder. The main, exciting thing I was able to (convolutedly) set up was a "master" material, which actually updates other materials inherited by it. This makes things SOOO much more manageable.

The main, exciting thing I was able to (convolutedly) set up was a "master" material, which actually updates other materials inherited by it. This makes things SOOO much more manageable.

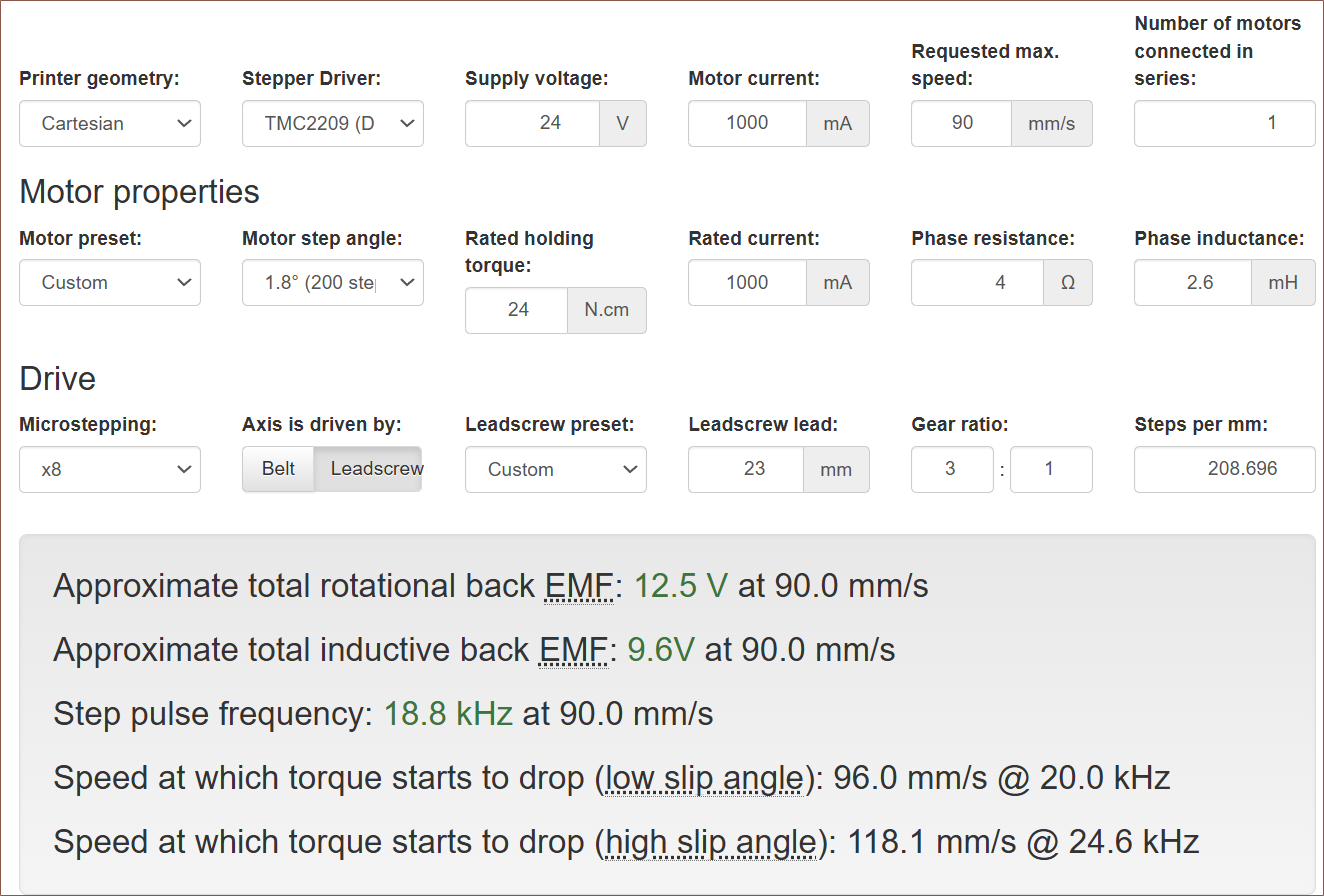

It insists that some "@MyMarlin" thing is added to the end. I went to the

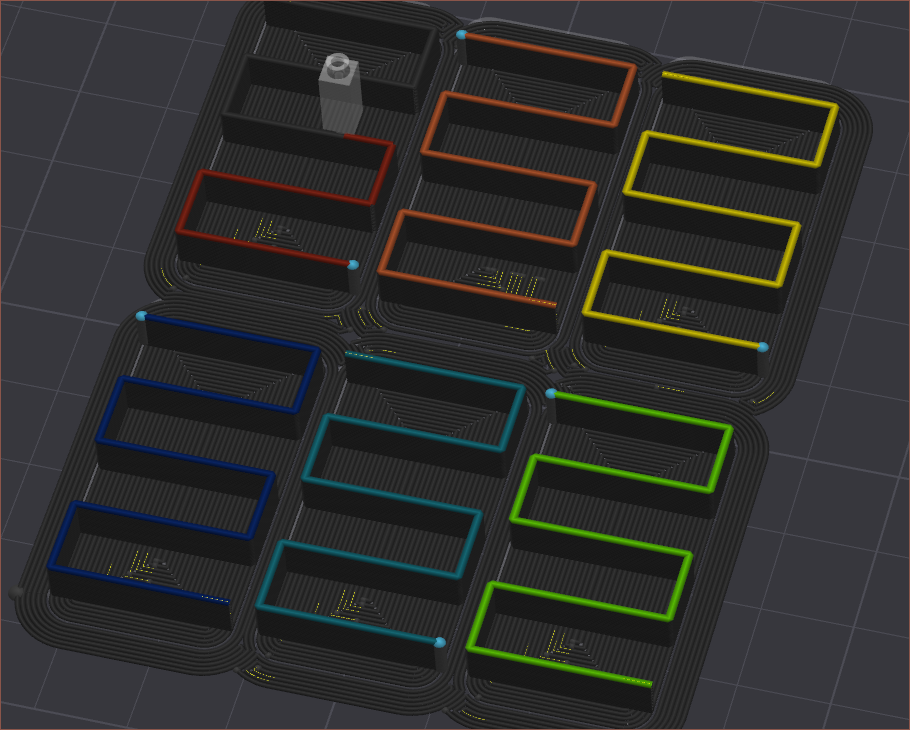

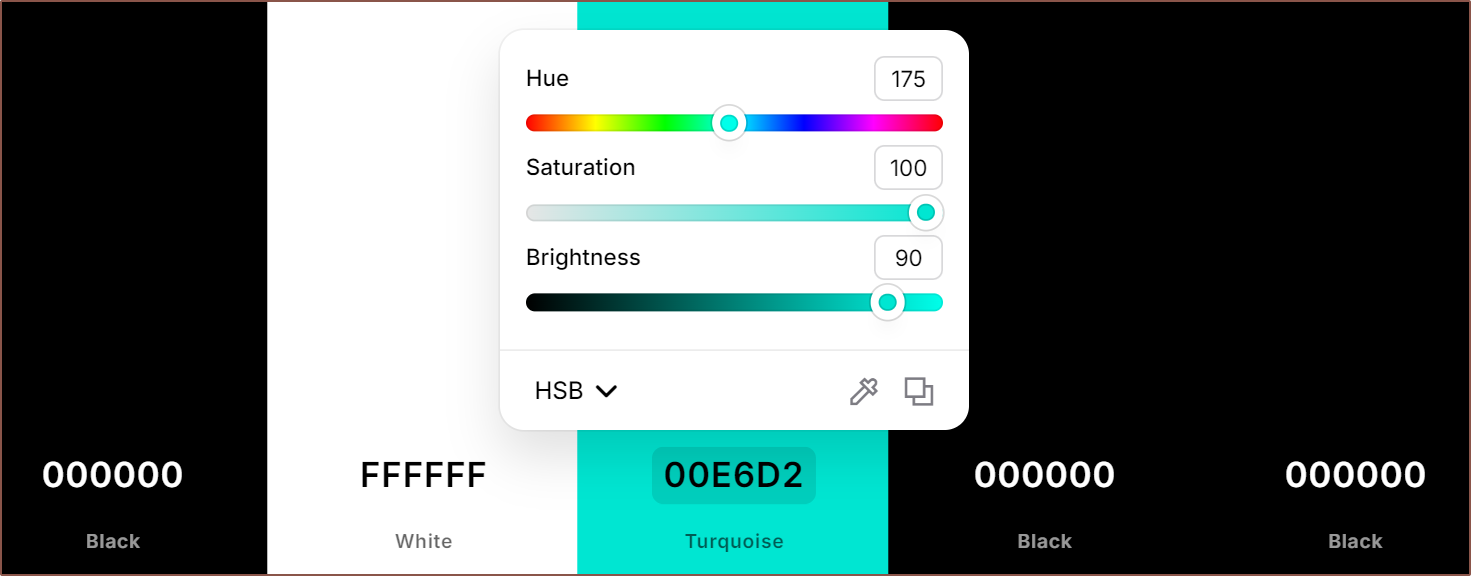

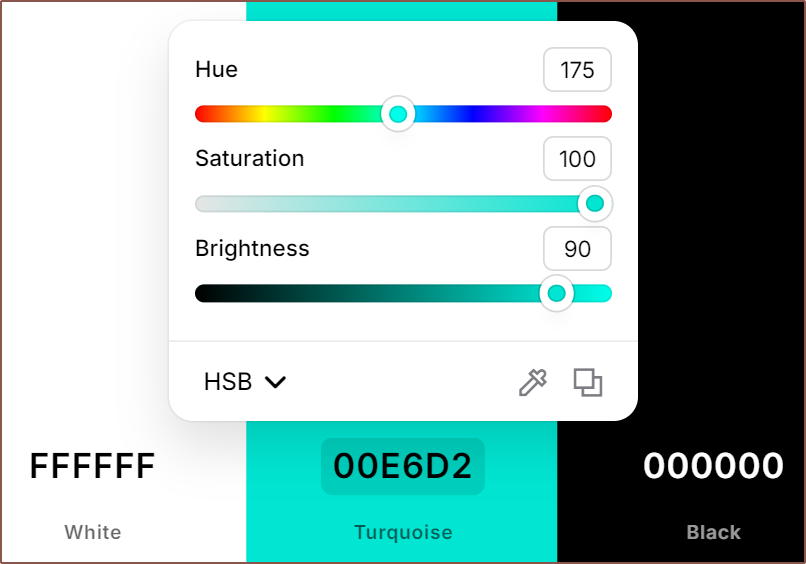

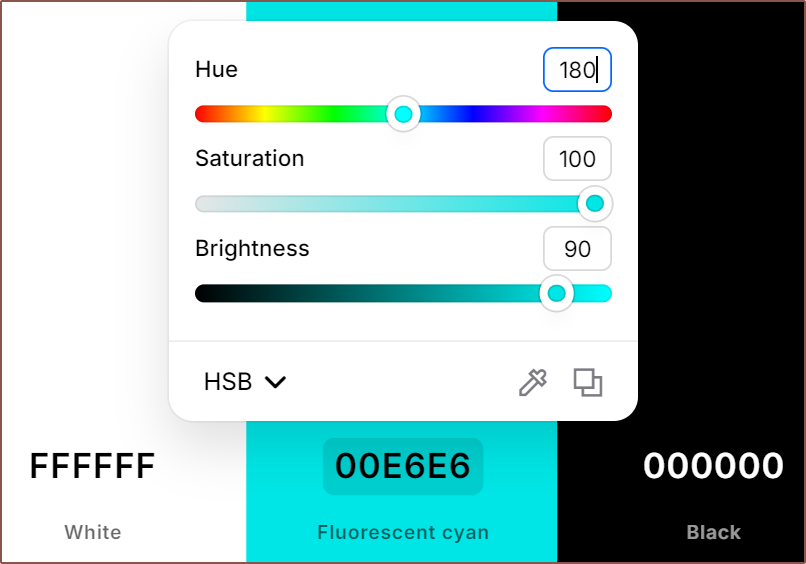

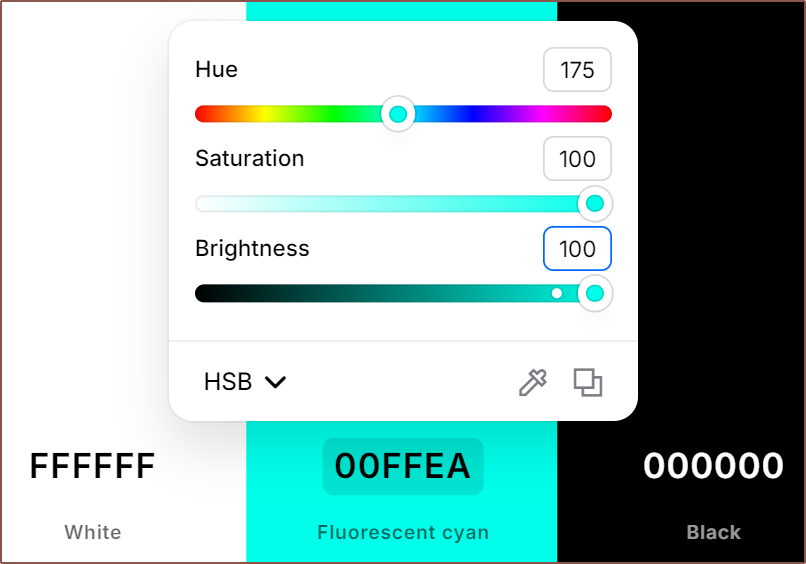

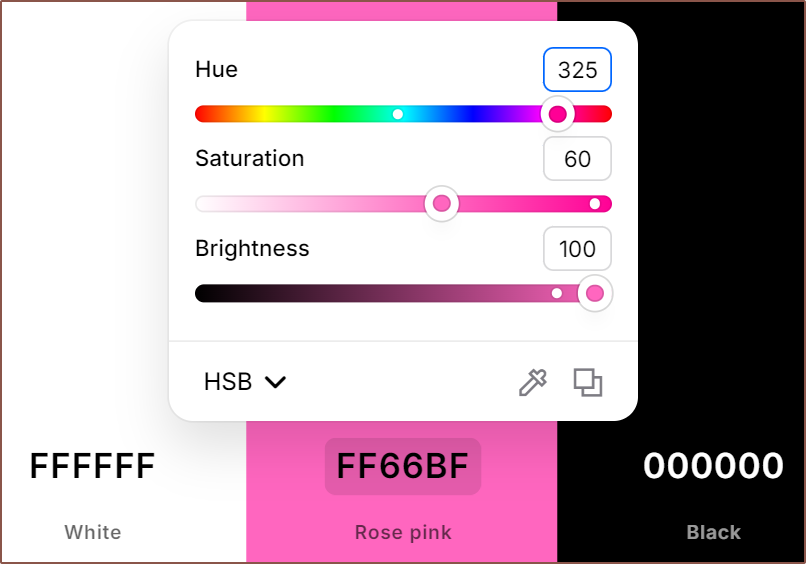

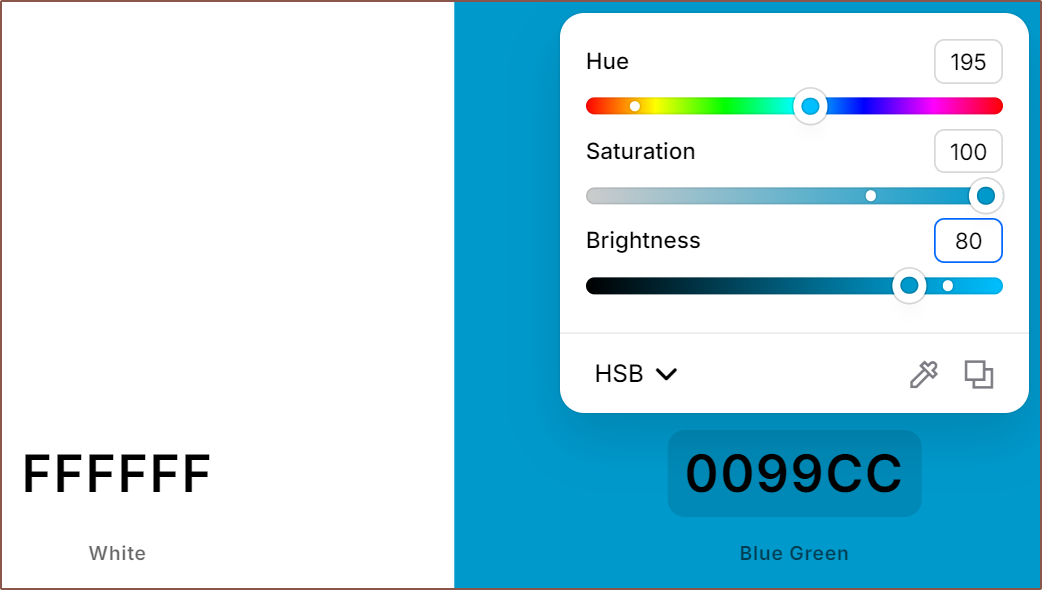

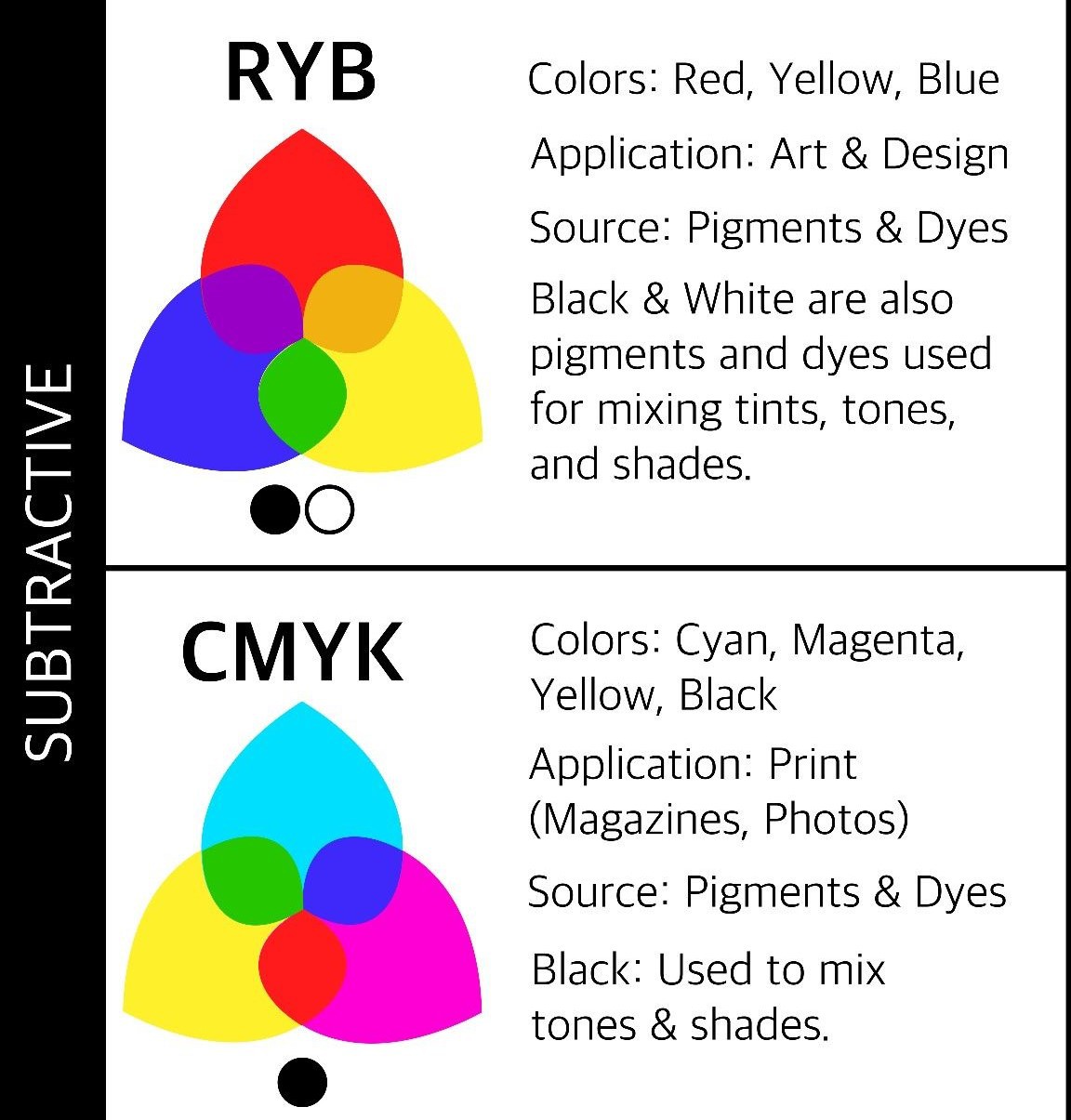

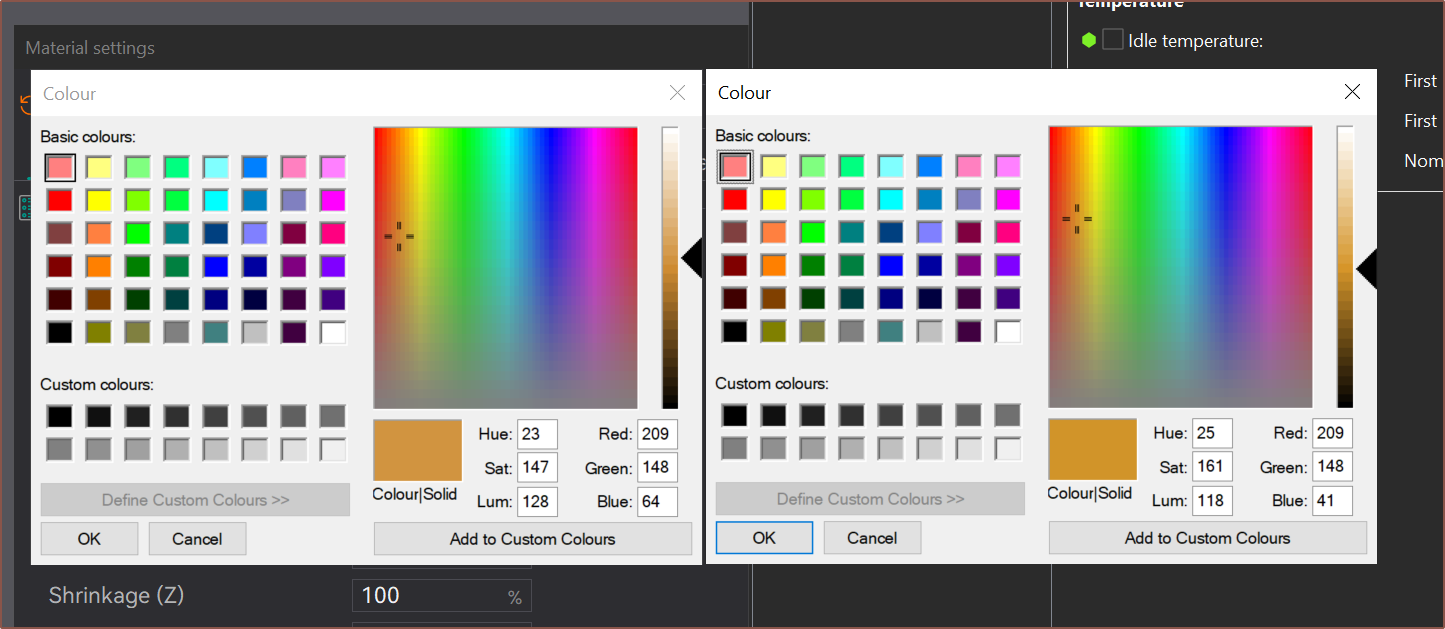

It insists that some "@MyMarlin" thing is added to the end. I went to the  As you can see, I decided to name the block colours with a 4-bit number. So instead of hex of RGBA being FFFF for opaque white, it's 1111, since the block colours are either entirely on or off anyway.

As you can see, I decided to name the block colours with a 4-bit number. So instead of hex of RGBA being FFFF for opaque white, it's 1111, since the block colours are either entirely on or off anyway. Finally, I can have an easily editable master profile! I've been wanting this feature ever since I got into 3D printing. What makes it special is that, if I changed a value in the child preset and I want it to follow the master again, I just need to change the value to whatever it was in master. It's not like Cura where I'd have to open the config file in VSCode and delete the entry.

Finally, I can have an easily editable master profile! I've been wanting this feature ever since I got into 3D printing. What makes it special is that, if I changed a value in the child preset and I want it to follow the master again, I just need to change the value to whatever it was in master. It's not like Cura where I'd have to open the config file in VSCode and delete the entry.

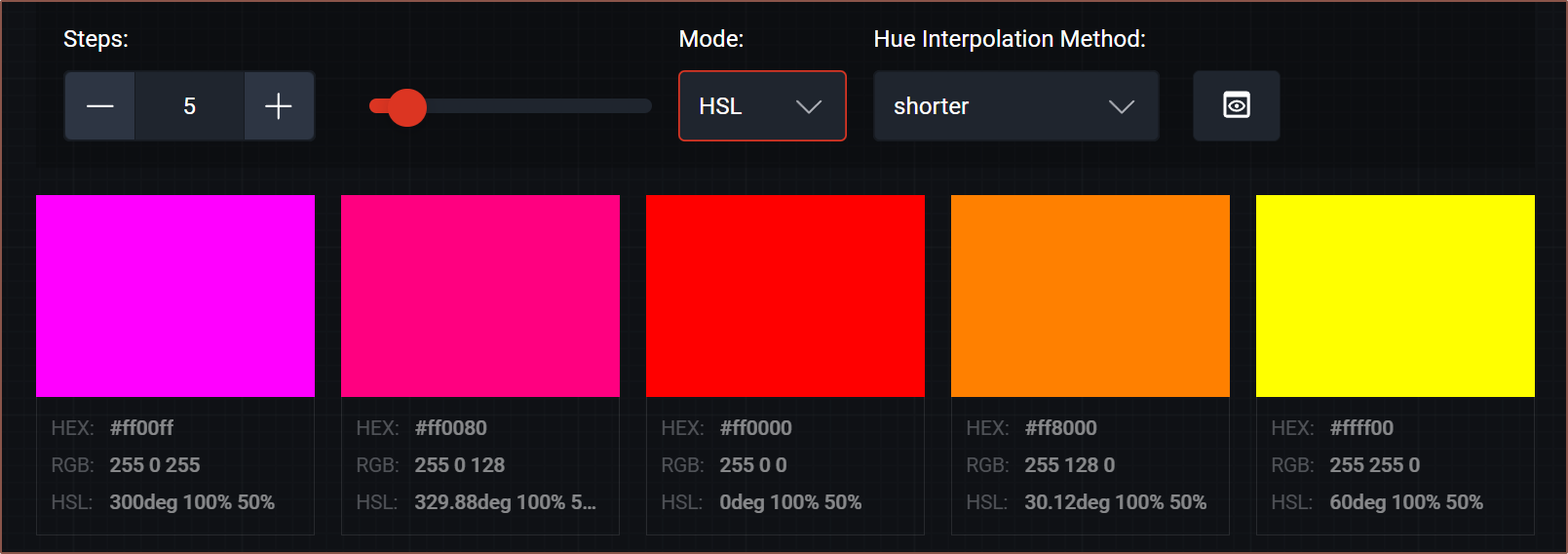

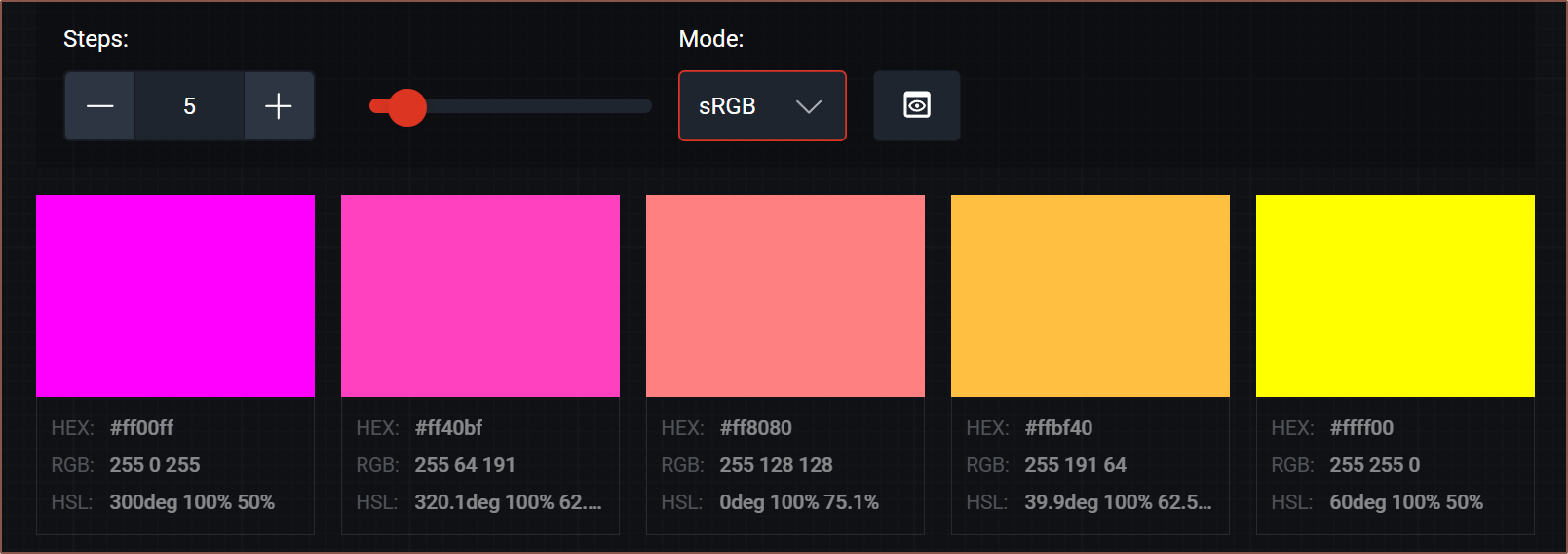

Do you see much of a difference in these colours? I don't, but the blue value is quite a bit different. I then remembered that all these virtual materials are going to be sorted in alphabetical order. If I continued to use RGBA, it'll be all over...

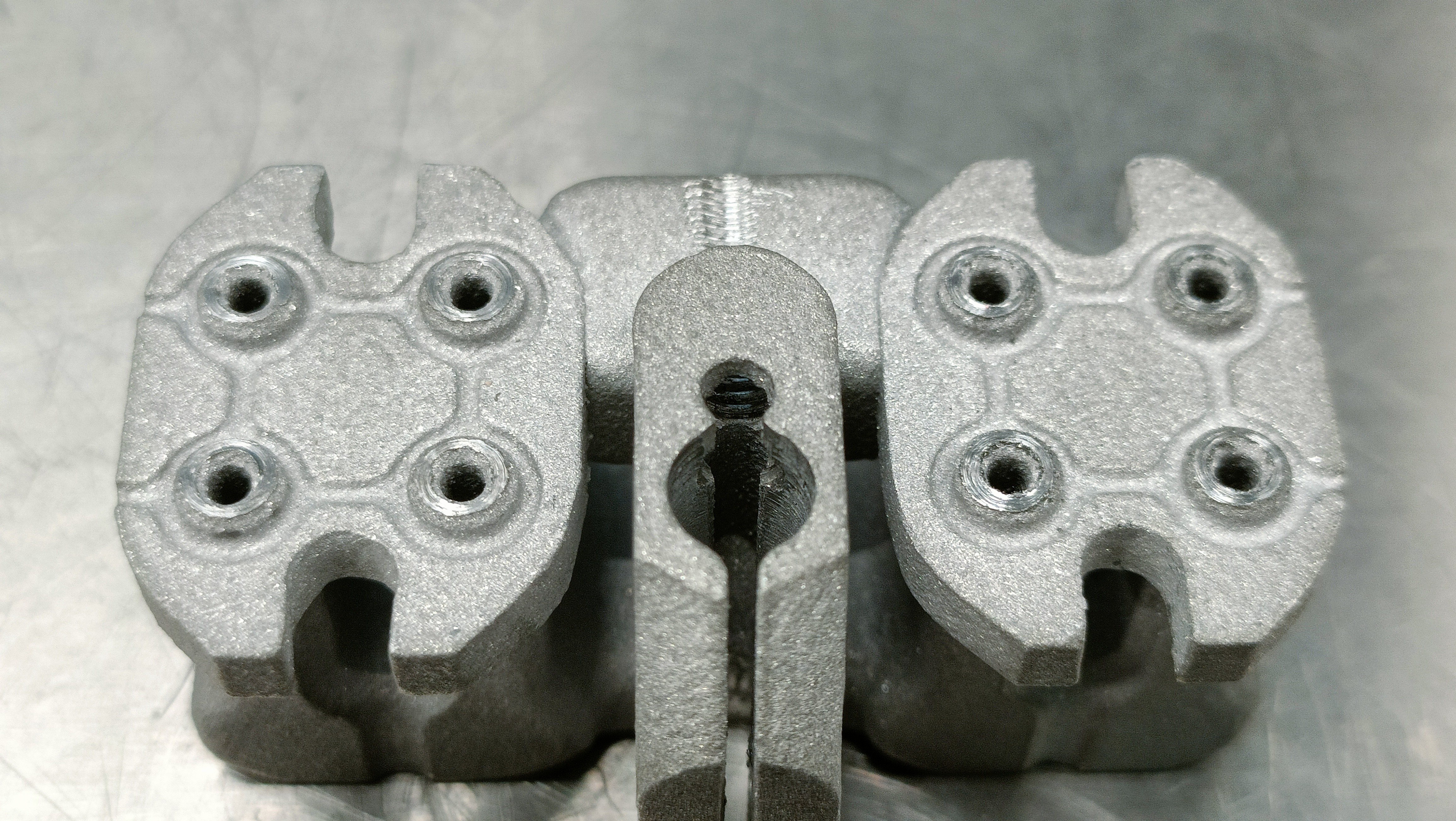

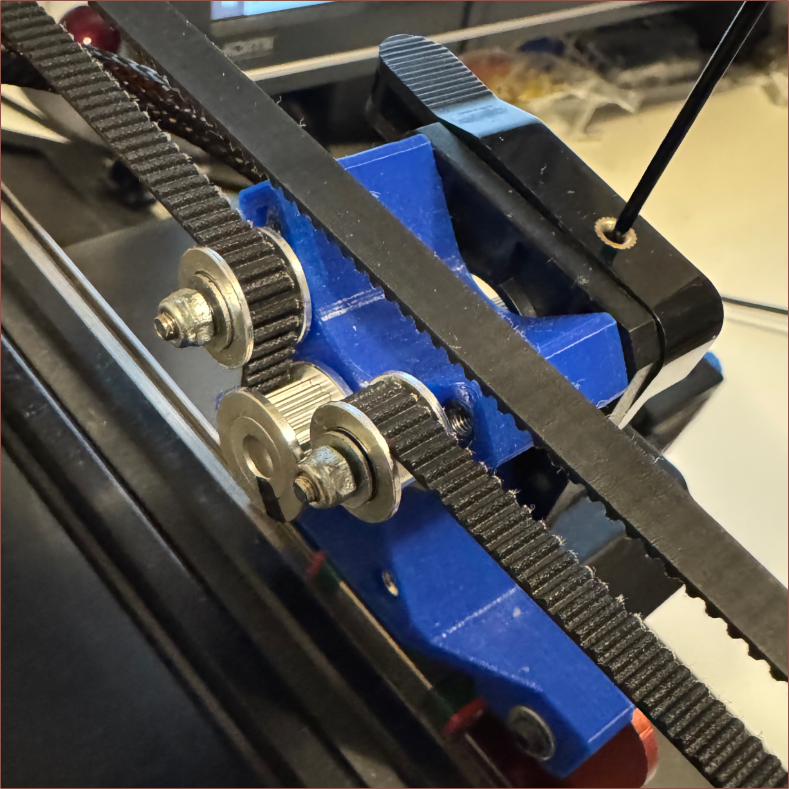

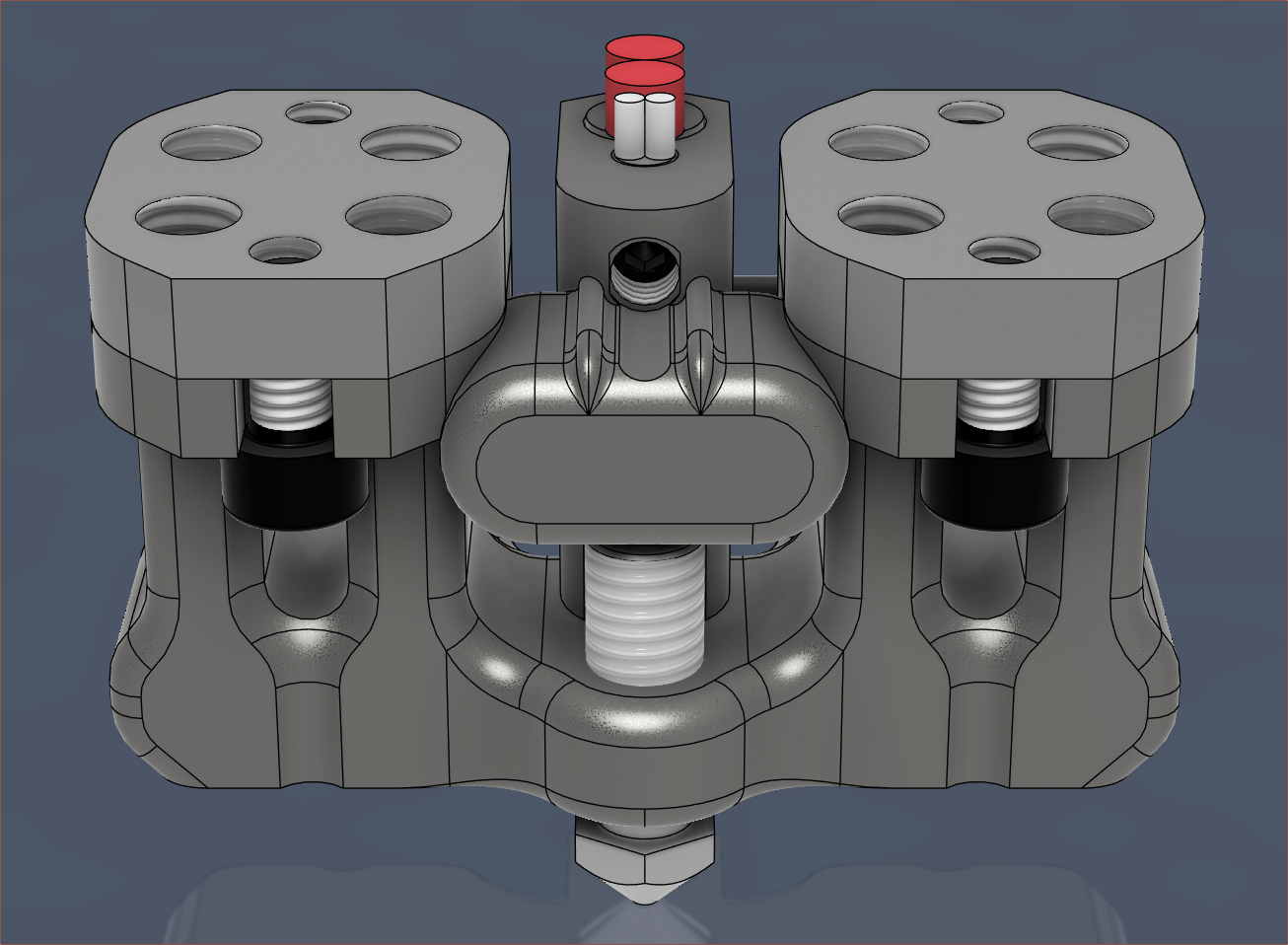

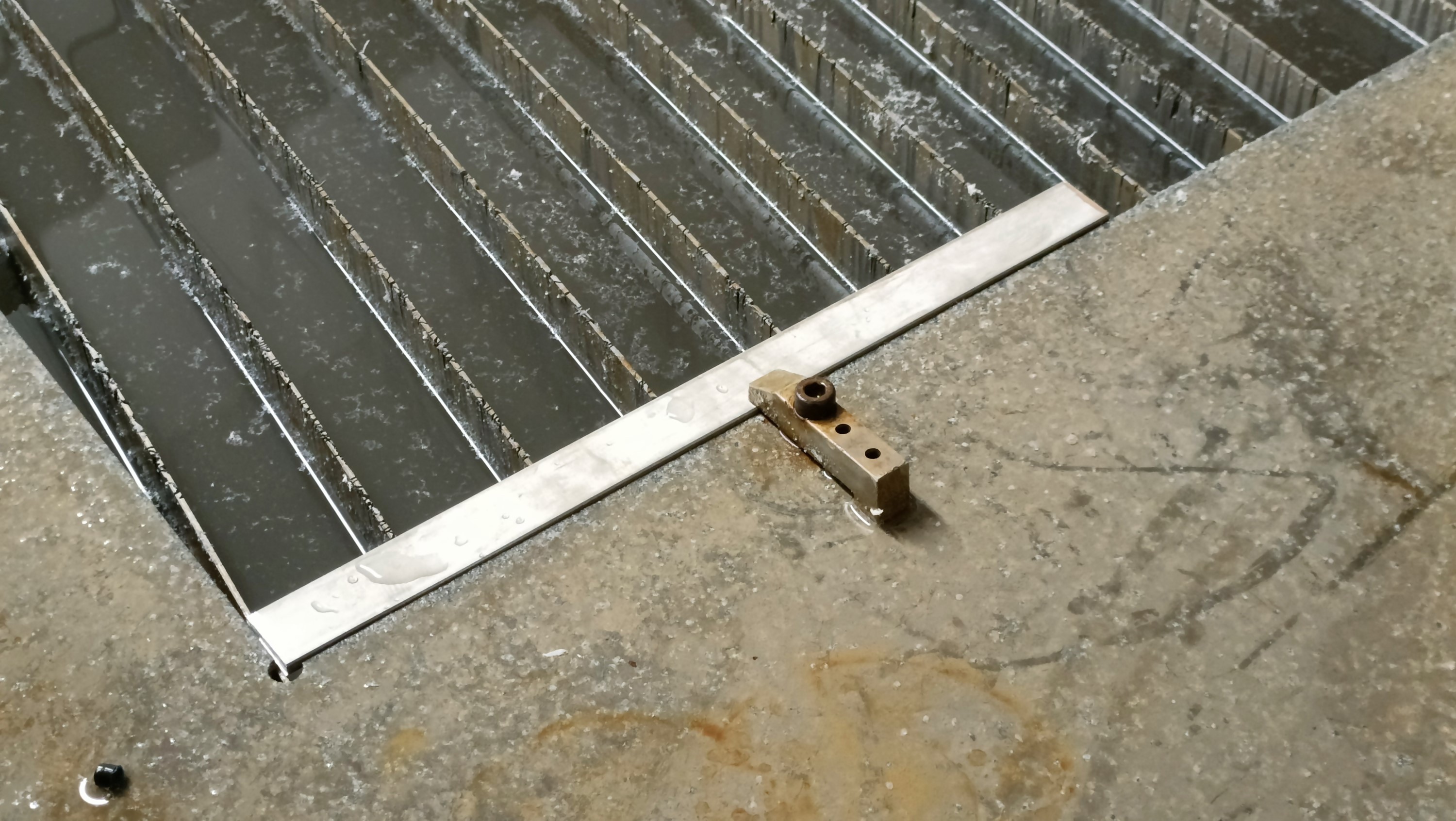

Do you see much of a difference in these colours? I don't, but the blue value is quite a bit different. I then remembered that all these virtual materials are going to be sorted in alphabetical order. If I continued to use RGBA, it'll be all over... I've added a leak shielding to the thermistor grub screw. I've also removed some leak channels and made the remaining ones deeper in depth so that leaks:

I've added a leak shielding to the thermistor grub screw. I've also removed some leak channels and made the remaining ones deeper in depth so that leaks:

P

P

MasterOfNull

MasterOfNull

I have been following this project for months, and it's my go to morning reading when I clock into work, haha