-

Talk through design iterations

10/13/2017 at 17:58 • 0 commentsAs I needed to put together a video, which ended being longer than required so I'm posting it here. This is a talk through of the different design iterations and how I ended up with the current design, including comment of limitations and areas that could do with further work.

I do think the original concept could work but requires the right size stepper motor with integral lead screw to be available.

-

Capability testing

10/06/2017 at 16:37 • 0 commentsI've now had a chance to run some coarse testing of the device. This was done by mounting a laser pointer directly to the moving platform, in the case of measuring the rotation angles. And then measuring the distance of deflection of the laser dot on a wall 3m away. In the case of measuring translation of the platform, the pointer was supported at one end so that, when the platform translated the pointer was rotated and the beam moved.

Measuring the translation showed a good match when moving 0.05mm for both UZ and UX (UY assumed to be equal to UX). For the rotations there was more variability but this is likely to be a function of the weight and inertia of the laser pointer with its x2 AAA batteries.

The test results PDF can be found in the files section. Overall I'm pleased with the capability, and i'm sure that the design can be taken further with a better choice of springs for the legs; slightly stiffer, with a varying diameter (wider in the mid-span) so that they are less likely to buckle in compression.

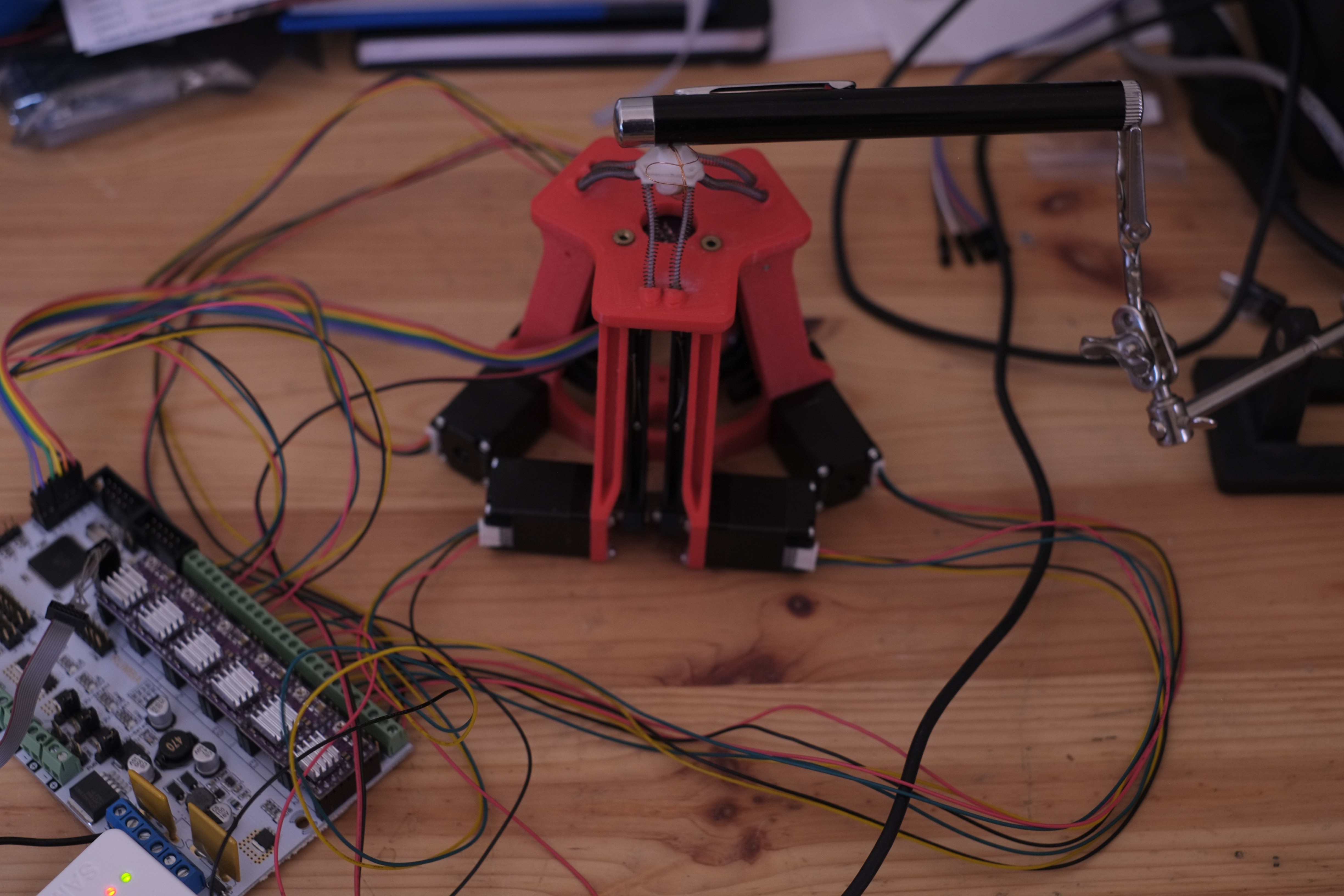

Figure; Laser pointer mounted to the platform (test rotations)

Figure; one end of the laser pointer supported (test translations)

-

Prototype taking shape

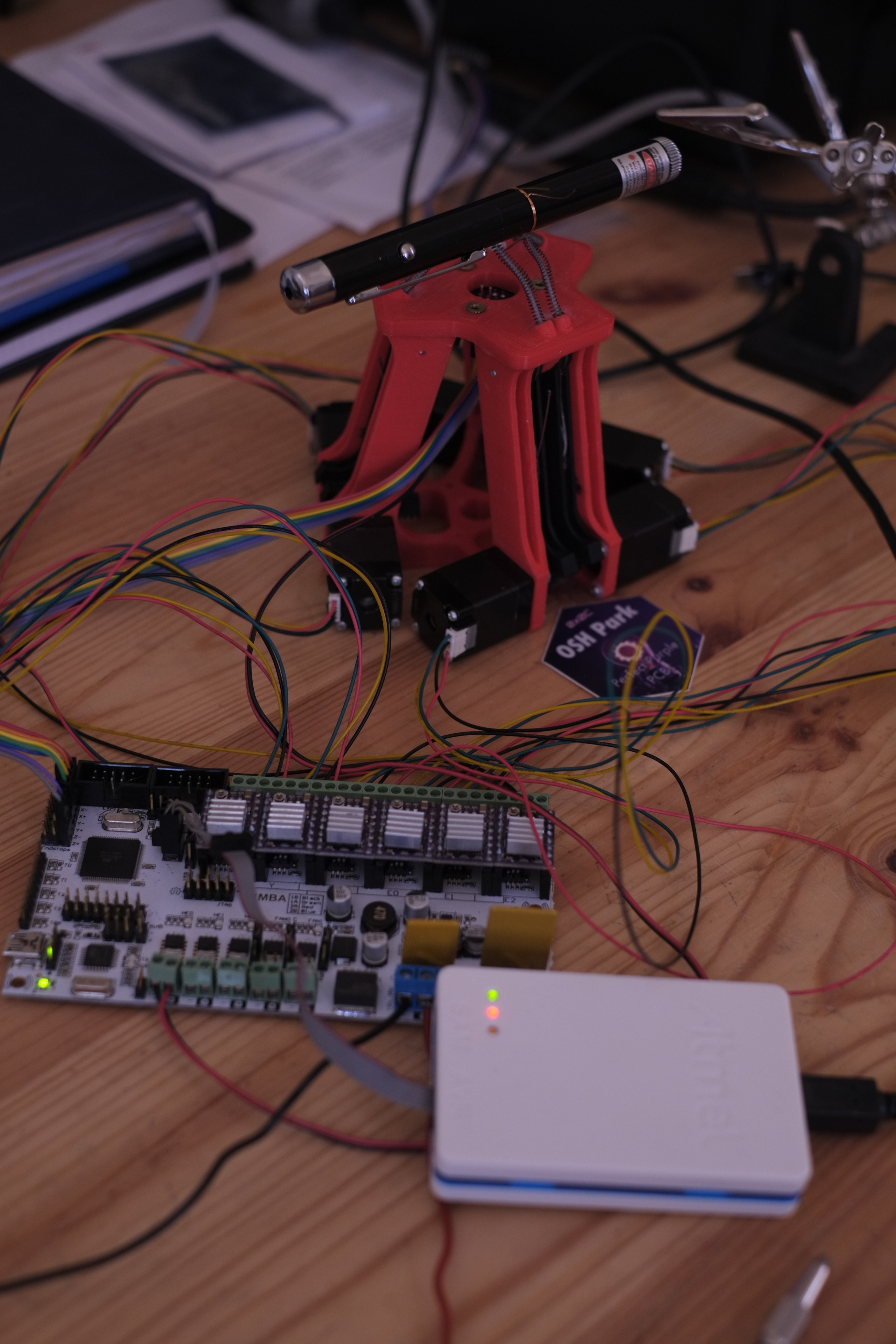

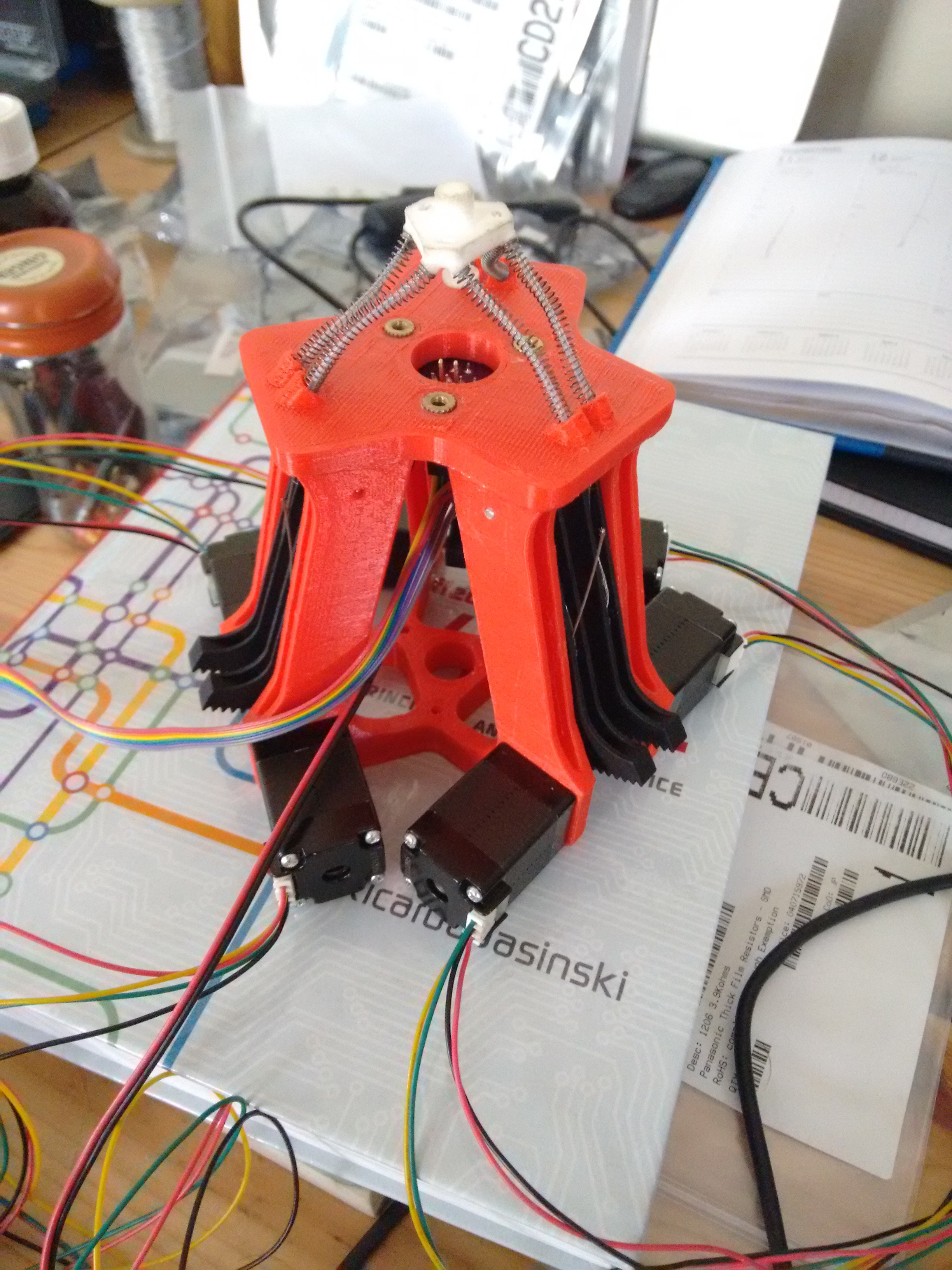

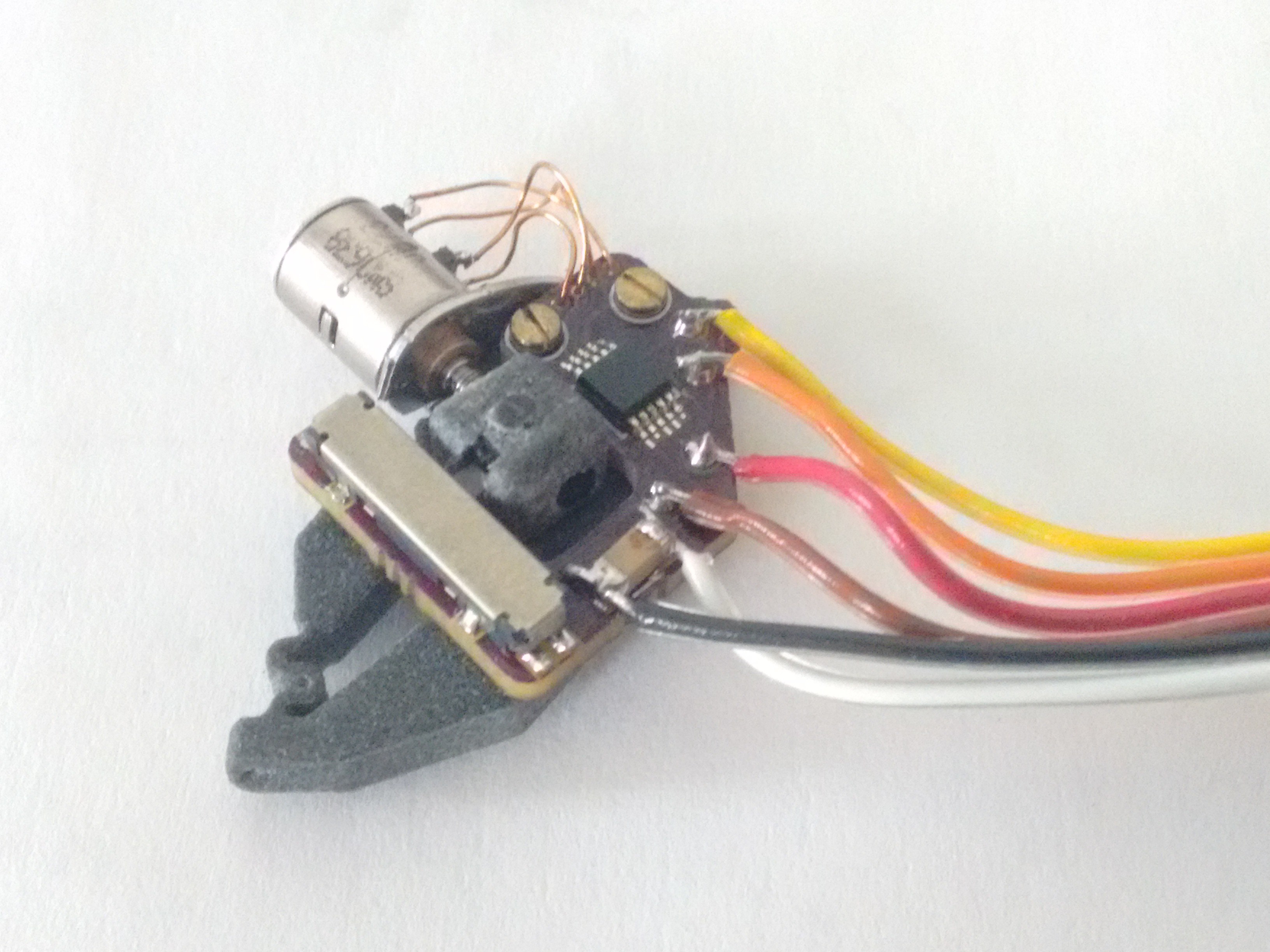

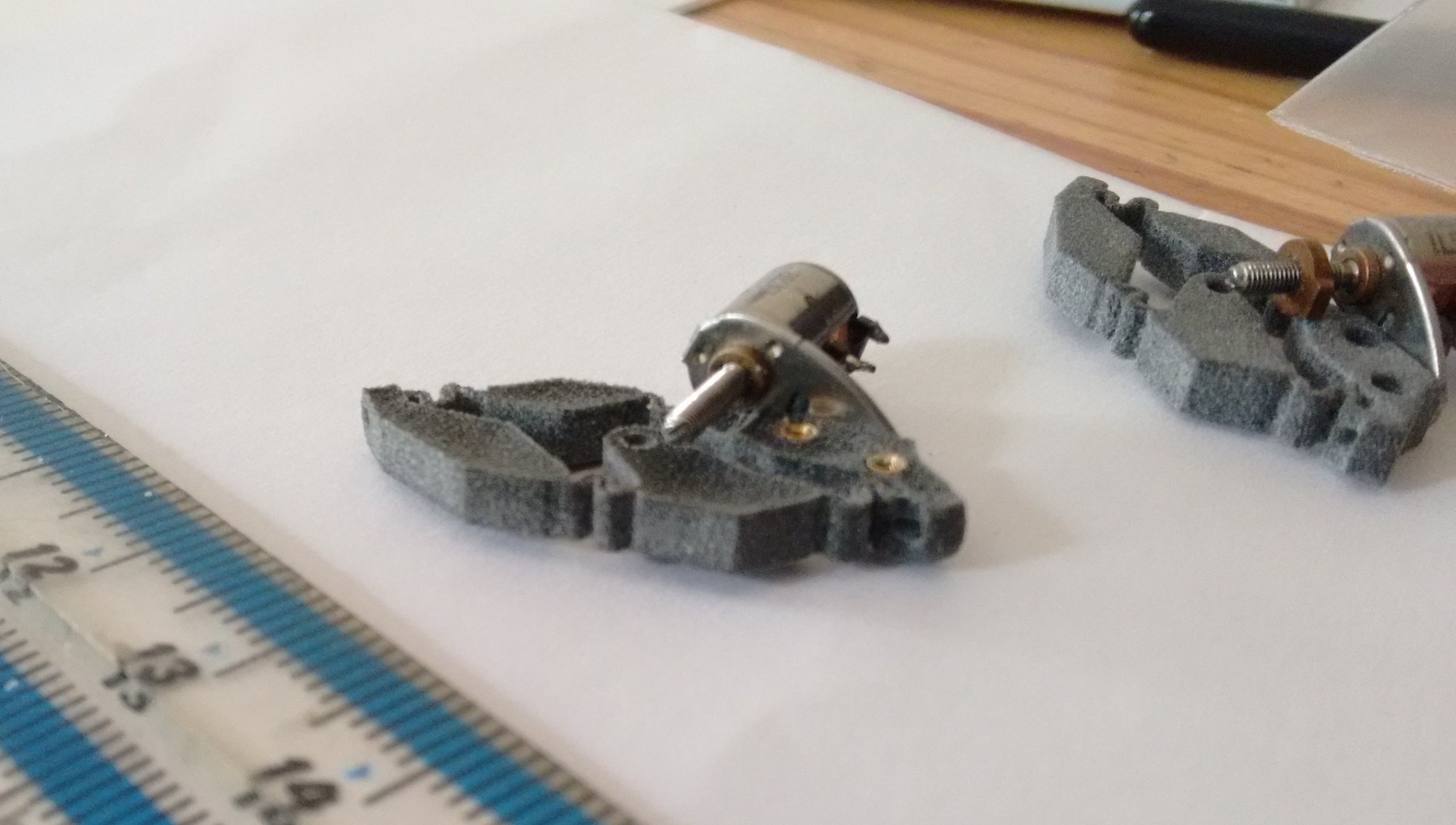

09/03/2017 at 21:27 • 0 commentsSo its been a while since I last posted, some of that was waiting on parts to arrive, such as the SLS printed nylon gears and lever arms. And some of it learning how to use a 3D printer and get it setup correctly, along with other sub-projects.

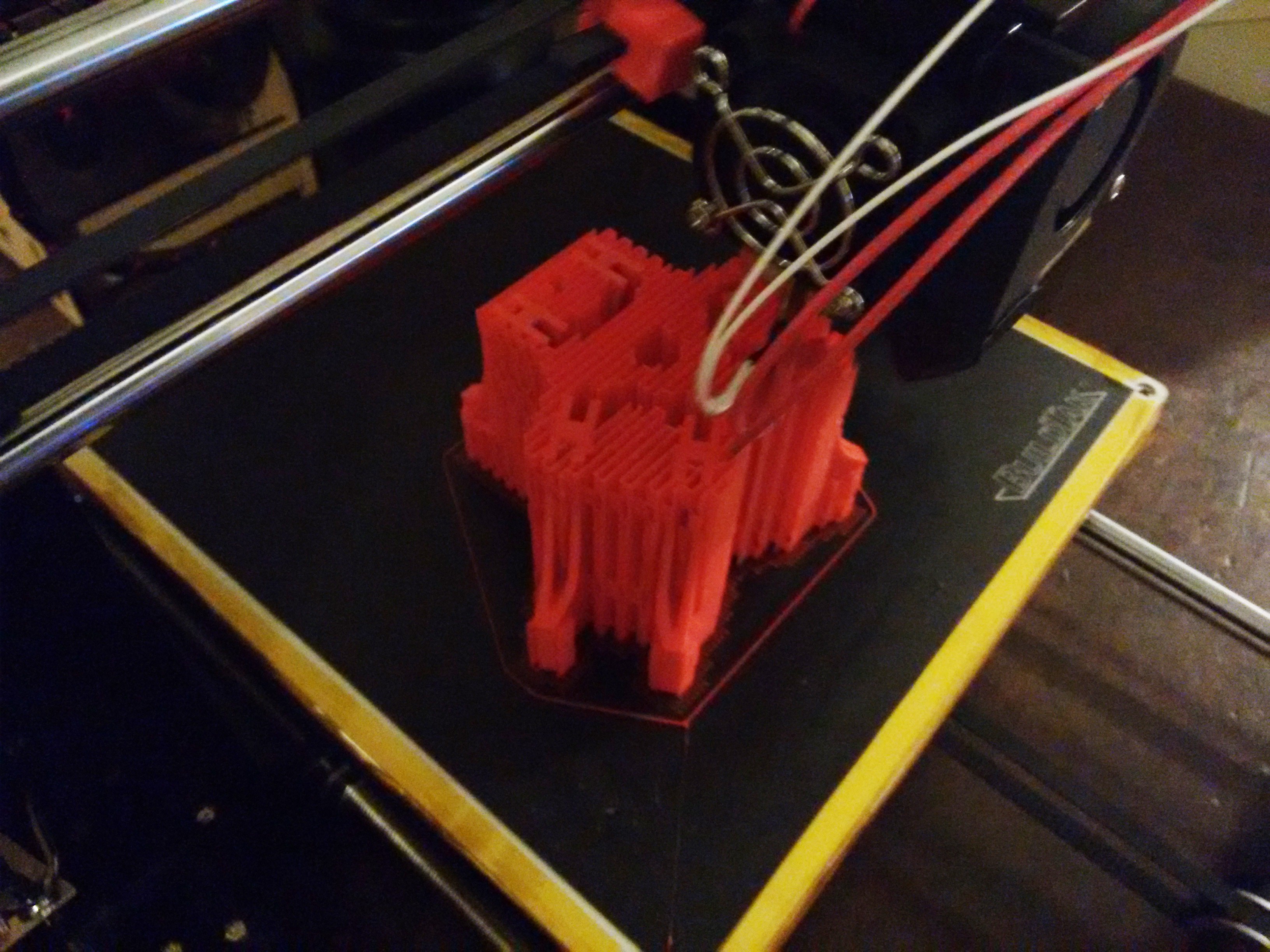

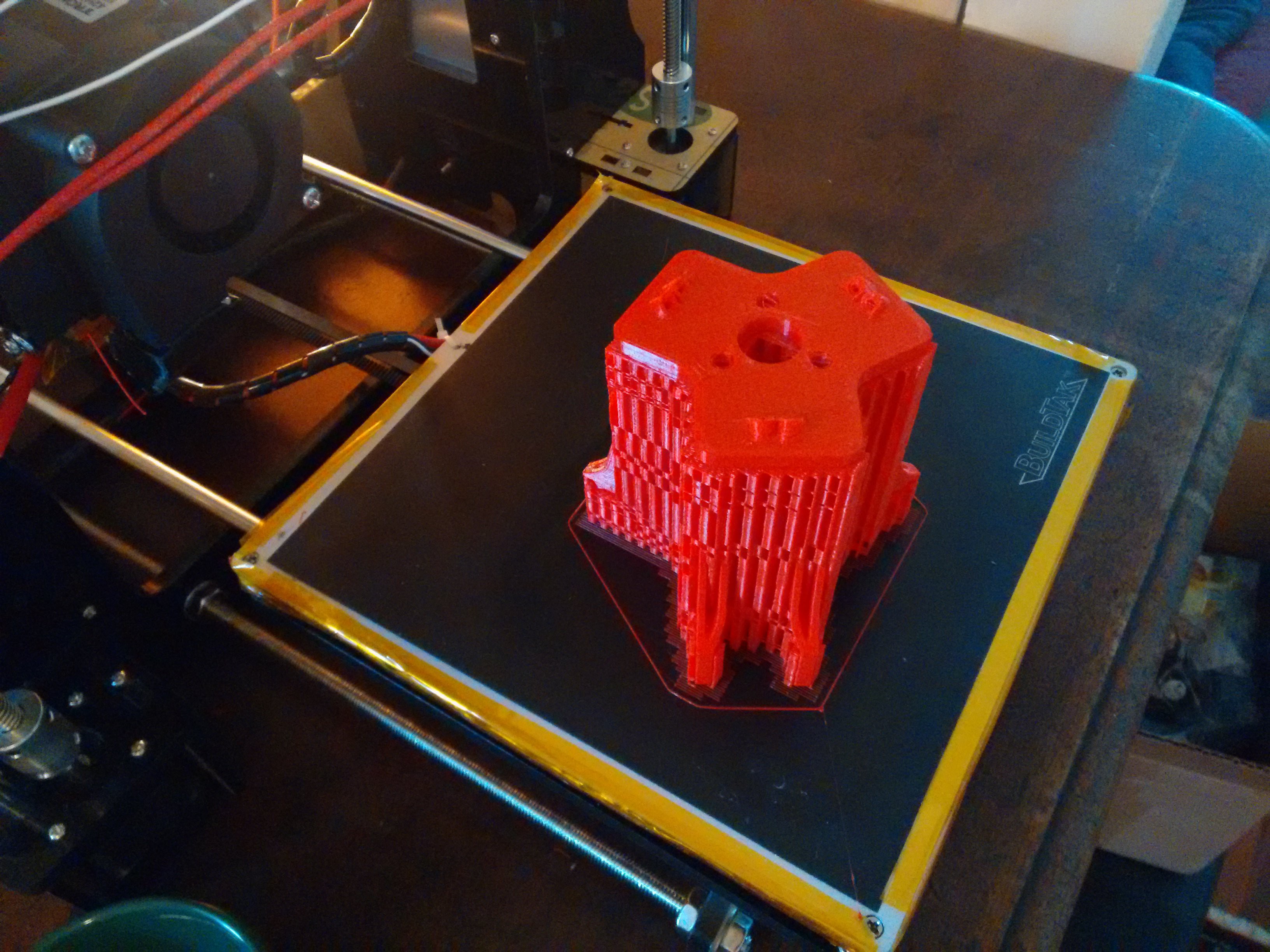

![]() The print of the frame took 15 hours and i was pleased with the quality, given that this was using the $150 printer with all stock nozzle, etc. I'll post up the models for the parts shortly. More after break below; ---------- more ----------

The print of the frame took 15 hours and i was pleased with the quality, given that this was using the $150 printer with all stock nozzle, etc. I'll post up the models for the parts shortly. More after break below; ---------- more ----------![]() By using the printer the cost was probably $5 of filament and 15hrs of time, versus $68 if i had used shapeways. So the printer will pay for itself in short order.

By using the printer the cost was probably $5 of filament and 15hrs of time, versus $68 if i had used shapeways. So the printer will pay for itself in short order.I used shapeways for the motor gears and lever arms as i needed the higher resolution to get a good resolution for the involute teeth. The lever arms are bushed with PTFE tube with 2mm ID (used as bowden tube for 1.75mm filament).

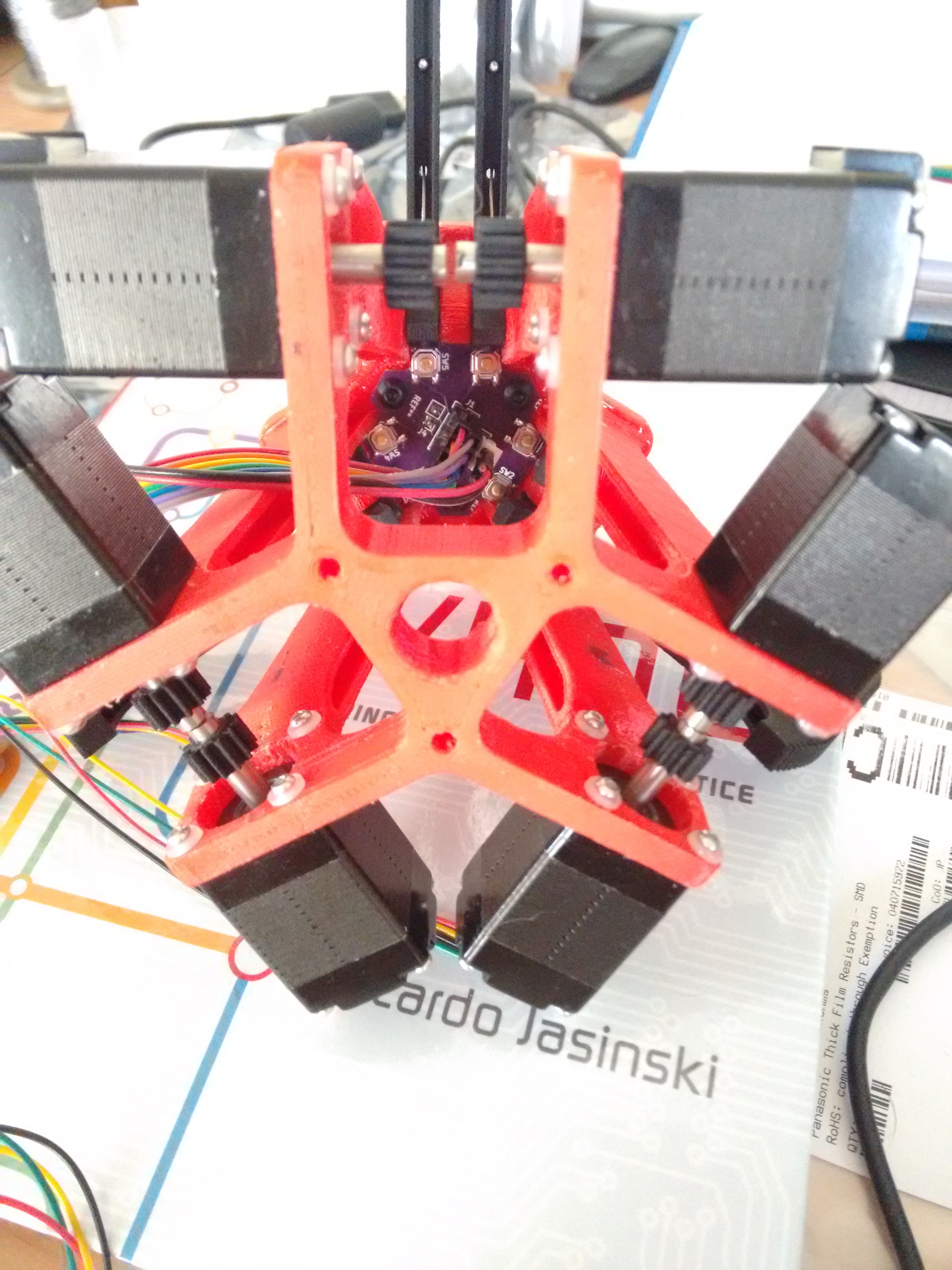

![]() You can see the PCB in the base with the end stop switches that allow the lever arms to be set to a known position.

You can see the PCB in the base with the end stop switches that allow the lever arms to be set to a known position. ![]() The platform end is also SLS printed nylon and I drilled out the doles for the wire cables using a 1mm drill bit.

The platform end is also SLS printed nylon and I drilled out the doles for the wire cables using a 1mm drill bit.

So far I have put together code that takes the position requested and calculates the required leg lengths (sprung sections), and then moves the levers the appropriate distances. The code is likely not optimal, but should be readable and understandable, i've used atmel studio C++ AVR, but again it should be easy to port the key sections to arduino syntax.

-

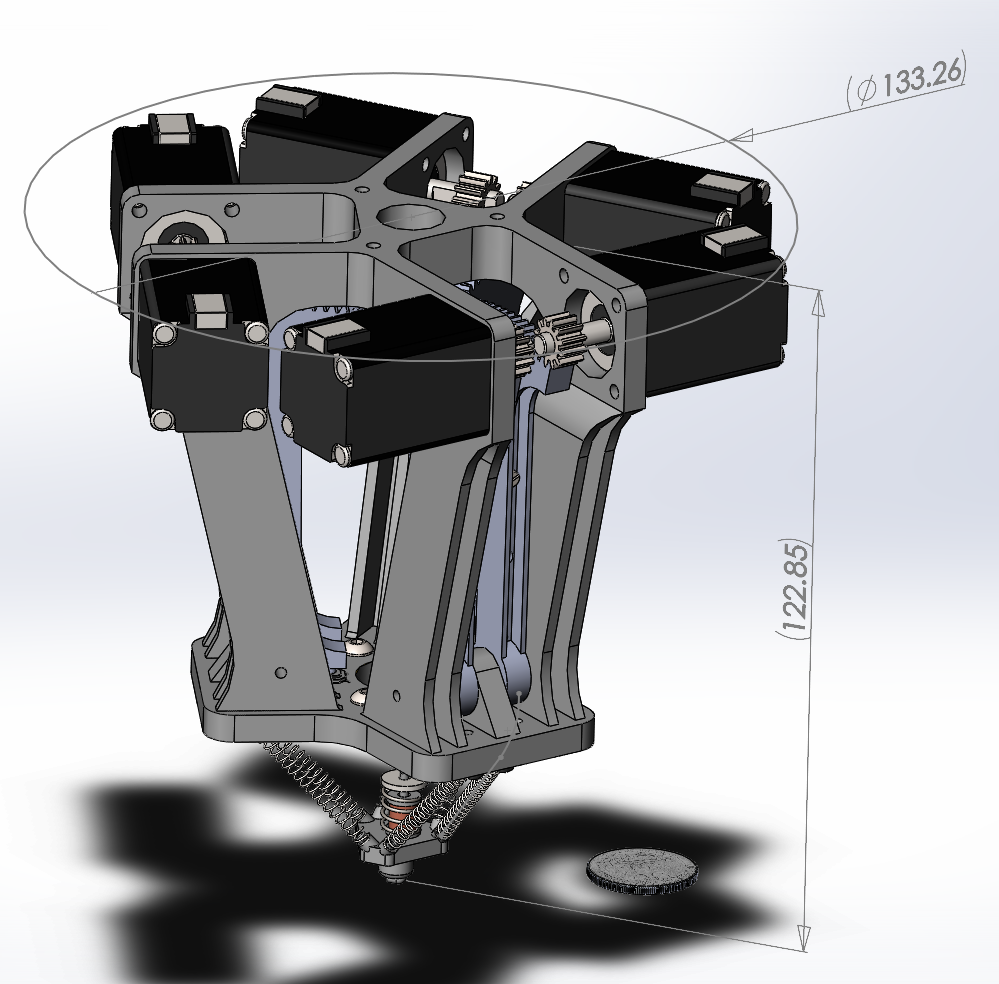

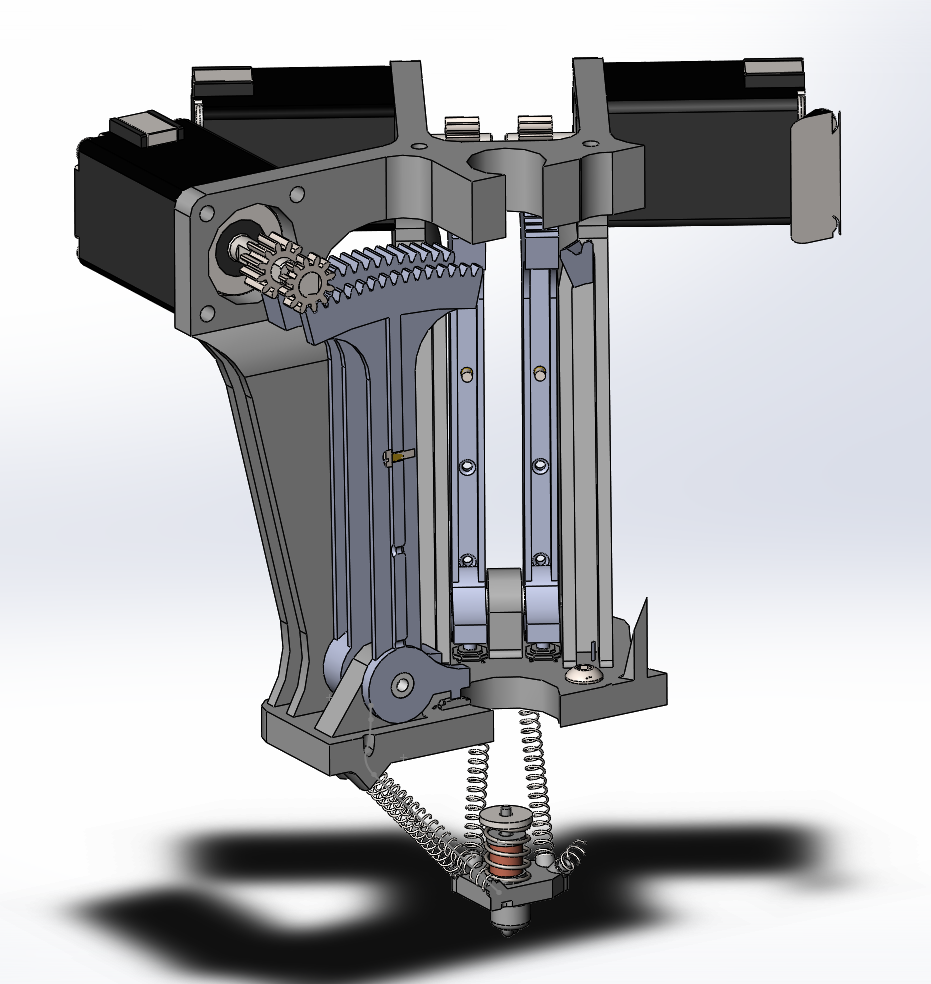

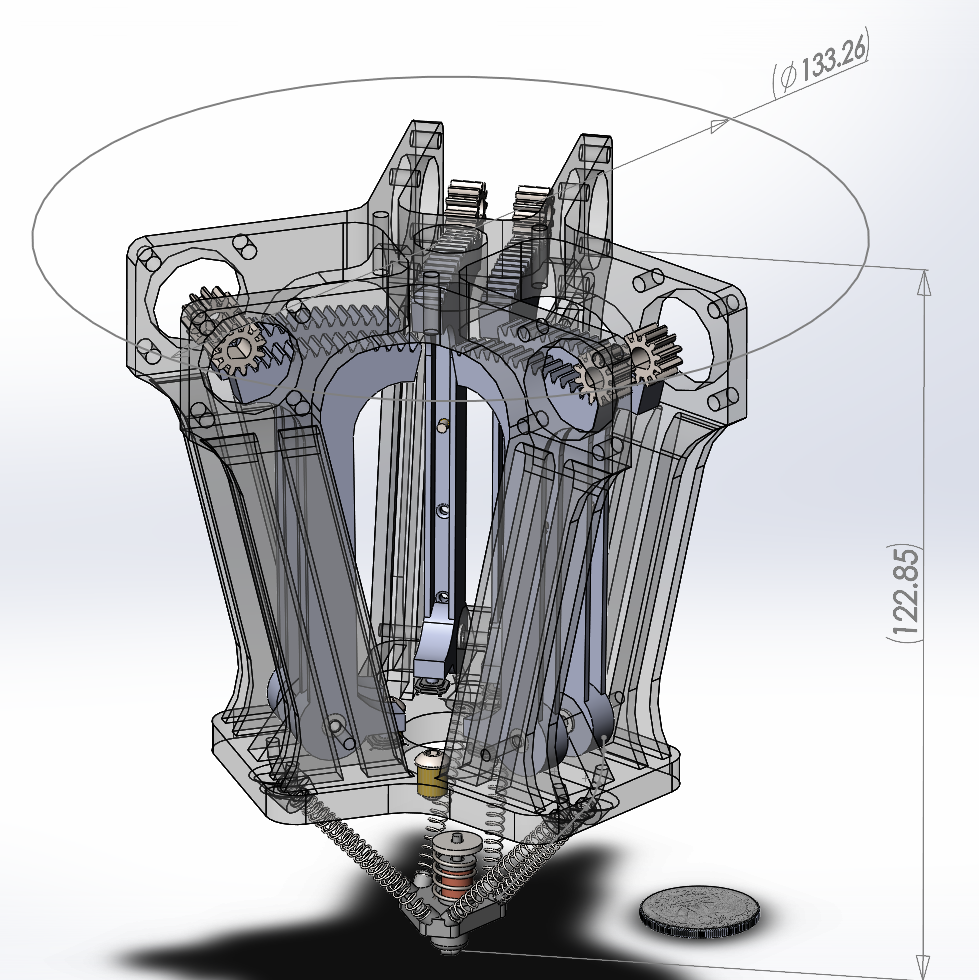

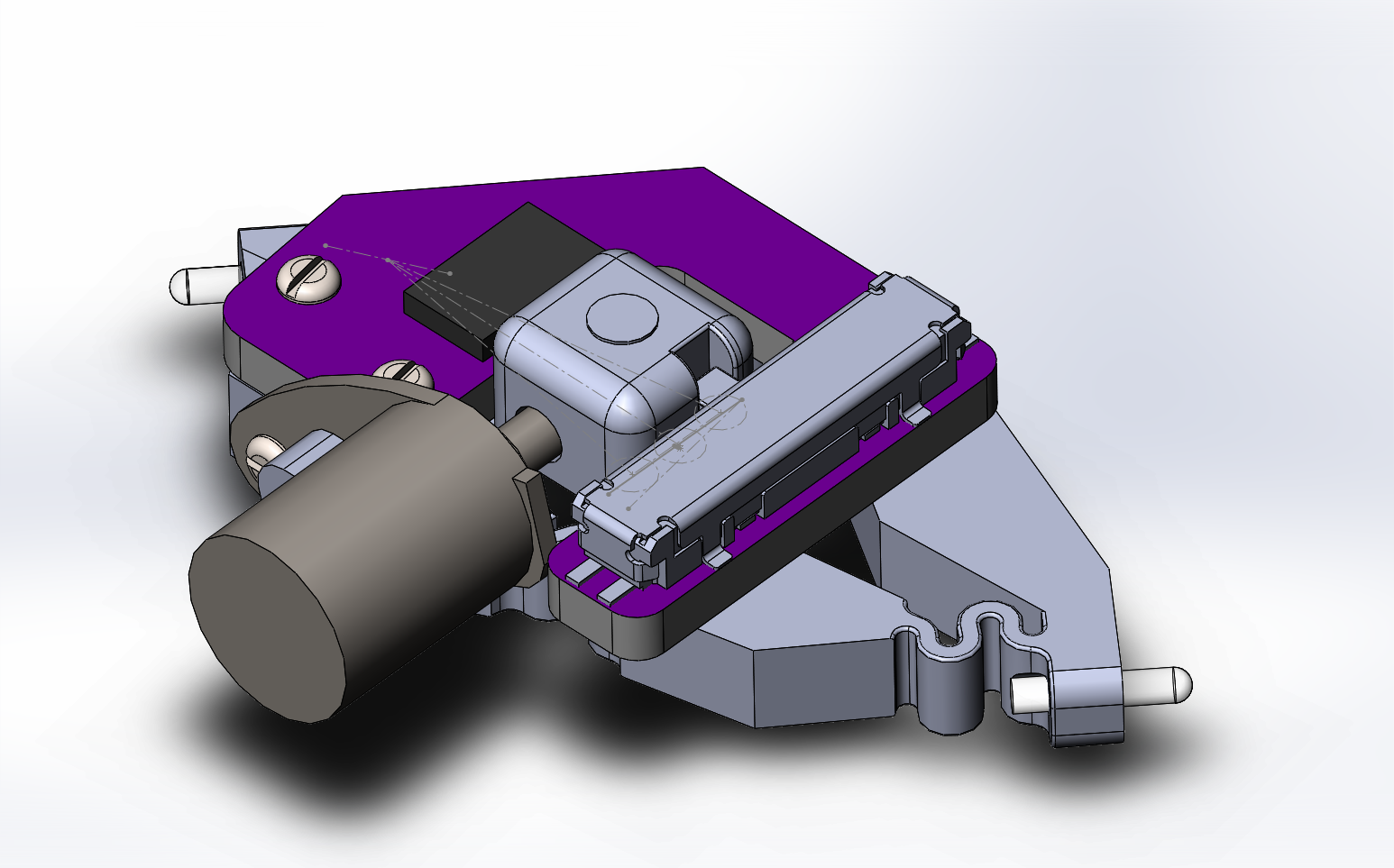

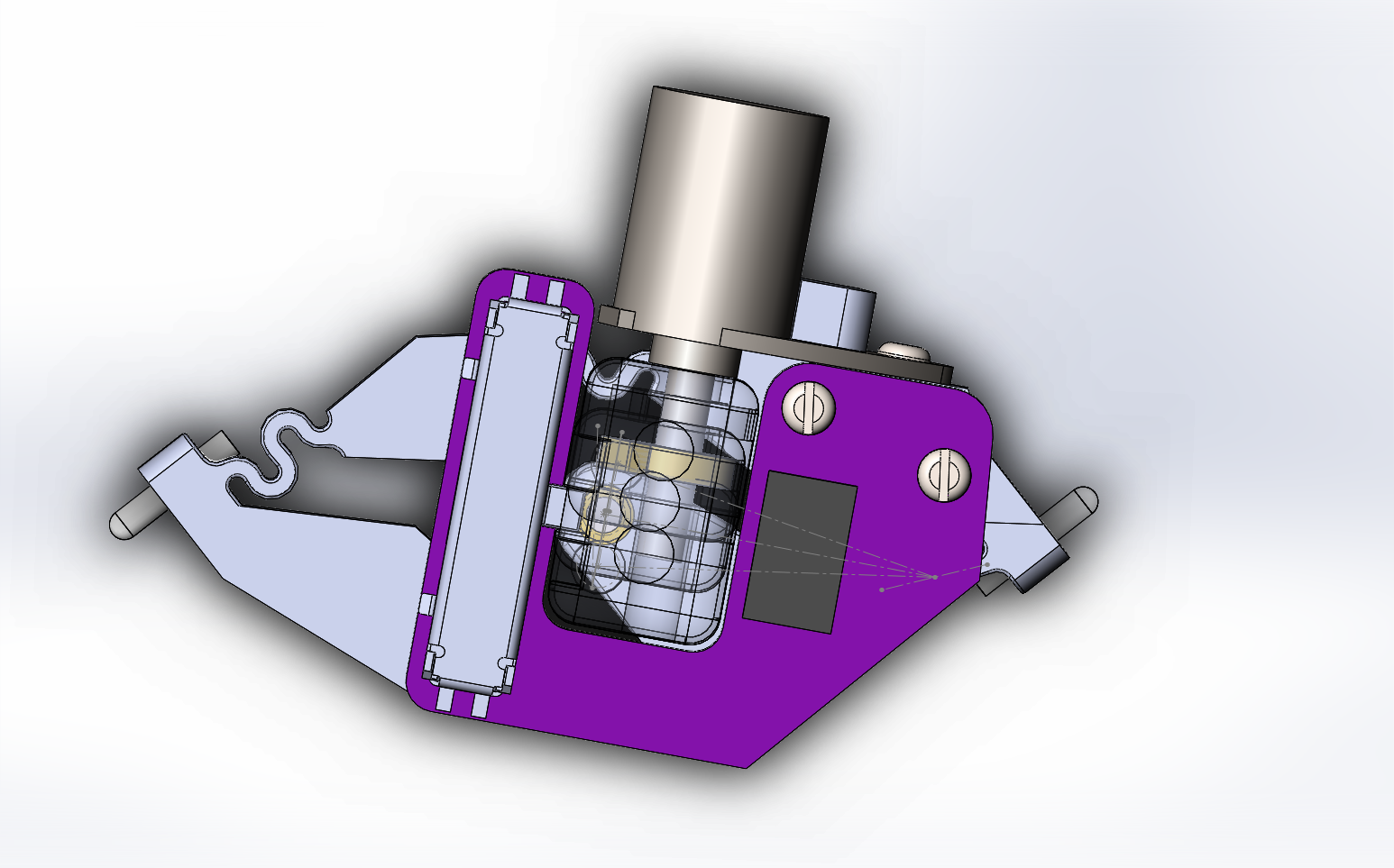

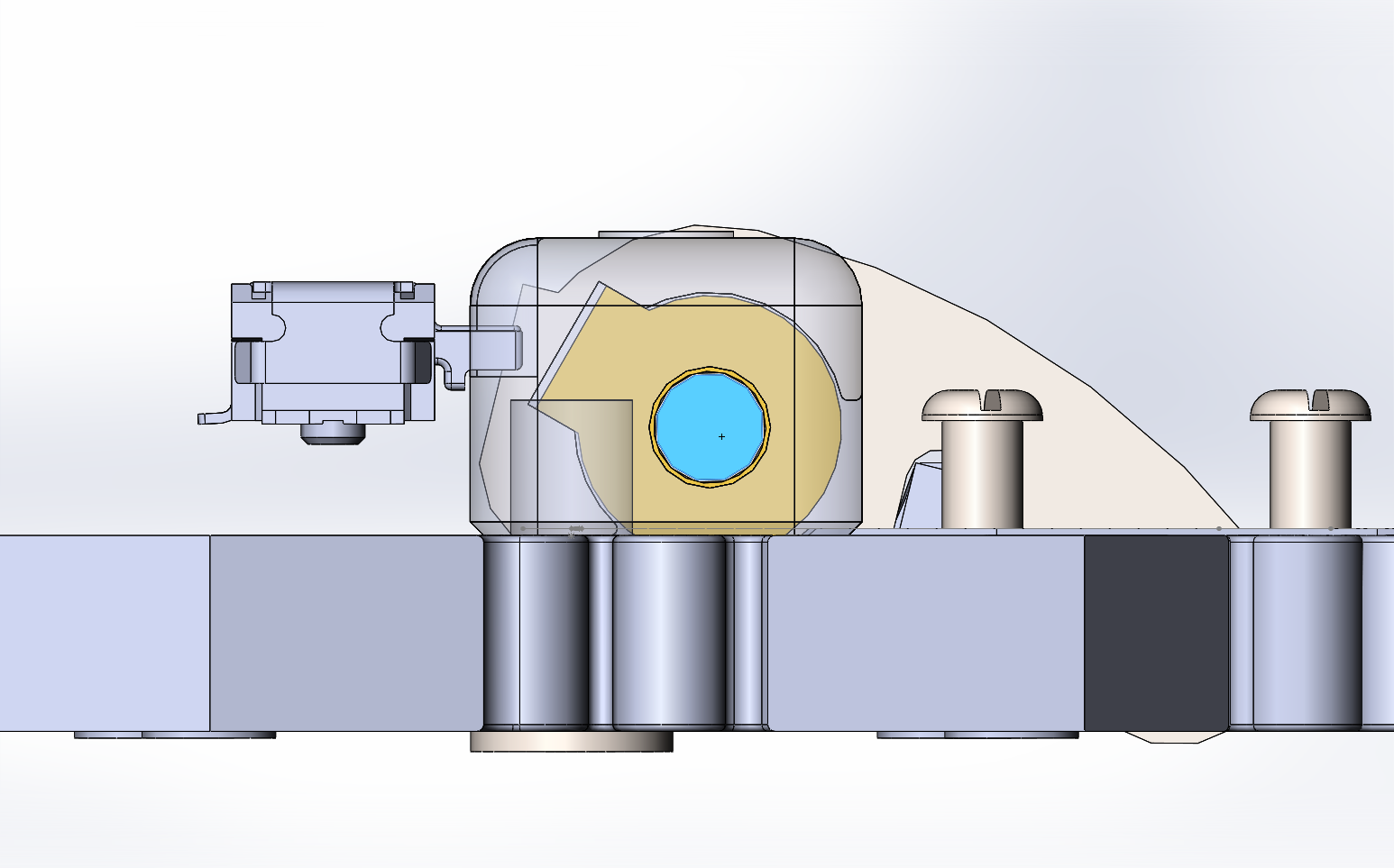

Iteration A4

08/08/2017 at 20:23 • 3 commentsSo after a few iterations of re-design to work with NEMA-8 sized stepper motors which whilst not the smallest available are the smallest in the sub $20 bracket. In this case $12ea.

With the increased size comes the headach of deciding on an arrangment to pack them as close together whislt having a viable mechanism to allow the small dislacement and high resolution with minimal backlash possible. More after the break below...

units = mm

---------- more ----------The design i've ended up with is an arrangement of small gear on the motor driving a large gear, with a fine wire wrapped around a small hub. As the gear rotates the wire is pulled or released off the hub. In this case the large gear takes the form of a leaver with only a small section of the total circumference. As can be seen in the section below;

The 0.5mm wire passes through a PTFE tube through the base and down the centre of the leg spring to the actuator platform. Beacause the overall displacement is small there should not be issues with not having discrete universal joints at the ends of the actuator legs (springs). The wires are tensioned and held in position by the small screw placed in the lever web.

At the centre near the base there is a PCB with six push button switches that allow the levers to be set to a known home position at startup.

Whilst the whole assembly is substantially larger than my initial plans, i'm hopeful that with its more robust design that there will be fewer teething issues. The resulting actuator head still occupies the same volume as the initial design.

-

On to itteration A2

08/02/2017 at 15:16 • 0 commentsSo, time for some more updates;

I recieved the most recent printed parts from shapeways and re-built the test actuator.

![]()

The housing for the lead-screw nut had some dimensional issues as did one set of the actuator bodies. It appears that due to the dimensions of the parts when the print starts or finishes ( I can't tell which) there is significant shrinkage in the initial layer or after cooling that leads to warp/dishing of one of the faces as can be seen;

---------- more ----------![]()

The right most part has a good level surface but the one that was opposite it has a concave surface. [It appears from limited evidence that the 'black' material does not suffer from this defect and that it is only the 'grey' that does so]

Using the ok parts the test actuator went together after application of needle files and sandpaper, but the combination of the friction betwwen the shaft thread and nut (which is not insignificant to begin with), the nut housing and the actuator body or PCB, meant that the motor had barely enough torque to move more than a fraction of a millimeter.

The main issue is that because the core of the motor is only 3mm diameter it is not able to generate sufficient torque for this application. I am sure that with a slightly larger diameter motor and several itterations to compensate for the behaviour of the 3D printer, that this arrangment would be a viable mechanism. The geometry and KiCad PCB files for this version are available in the downloads section for anyone interested.

So time to re-evaluate and change up the design to itteration A2. If say 10mm diameter threaded shaft motors were available then I would do a re-design to suit. Unfortunatly there is a gap in available threaded shaft motors (readily available surplus I should add) between the ~6mm camera lens motors and ~NEMA 23. Another reason to re-think is the wiring required for control and feed back needs to be very flexible and thus far I've been unable to find a reasonably priced candidate.

In order to maintain the required small actuator end my new plan is to move the drive mechanism to be above the 'base frame' as the terminlology for gough-stewart platforms goes. By using an arrangmeent where the actuator is replaced by a 0.5mm wire rope and compressions spring so that the legs of the platform are formed by the wire tendons under tension from the springs.

The end of each tendon will then be pulled by a lever arrangment that divides the displacement at the stepper end by a factor and so allows the small displacements of the platform to be achieved. I'm looking at using PTFE tubing to reduce the friction and capstain loads in the system, with NEMA 8 motors to provide power and also give 1.8deg step resolution. I need to put together the calculations for the lever ratios required and evaluate the tension in the legs to overcome friction/stiction to allow smooth operation.

-

rev2 actuator body

07/14/2017 at 15:47 • 0 commentsSo the initial build of an actuator has allowed me to get a better understanding of the behaviour of the SLS nylon 3D prints and the overall behaviour of the mechanism.

- The HP multi jet fusion printed parts have much better resolution than the older 'strong and flexible' prints.

- Need to minimise the moment generated by the stepper and the actuator pivot point, the motor needs moving as close to the pivot as possible. This also allows the nut to be better captured.

- Slight change needed to allow the control board to be easily installed. The first revision peg has a fully enclosed hole for the resistor slider, as only the lateral force is need, the recess can be open vertically to allow the slider to be dropped into the recess.

- Need to better control the moment about the peg to the body of the actuator, in the first revision a simple drop in cylinder was used as the pivot. Because of the print tolerances and the thickness of the body, there is a degree of movement that helps to bind the mechanism. The cyclinder has been replaced by using a brass insert in the peg and having a screw act as the pivot. This should provide better control of the movement perpendicular to the pivot axis.

I've ordered the new geometry and it will be another few weeks wait for the parts to arrive. Meanwhile I need to sort out how and what the monofilament linkages will be attached and start looking at implementing the algorithm for controling a Gough Stewart mechanism. Images below the break

Updated actuator body and coupling peg showing change of resistor slot to allow easier installation of the control board.

Showing the arc swept by the actuator lever that requires a degree of compliance to be alowed for in the stepper nut housing.End view showing tolerance allowed for the slight lateral movement during the arc sweep. The new design also means that the nut is captive in the coupling peg. If the clearance for the stepper shaft is insufficient then it can be drilled out slightly larger.

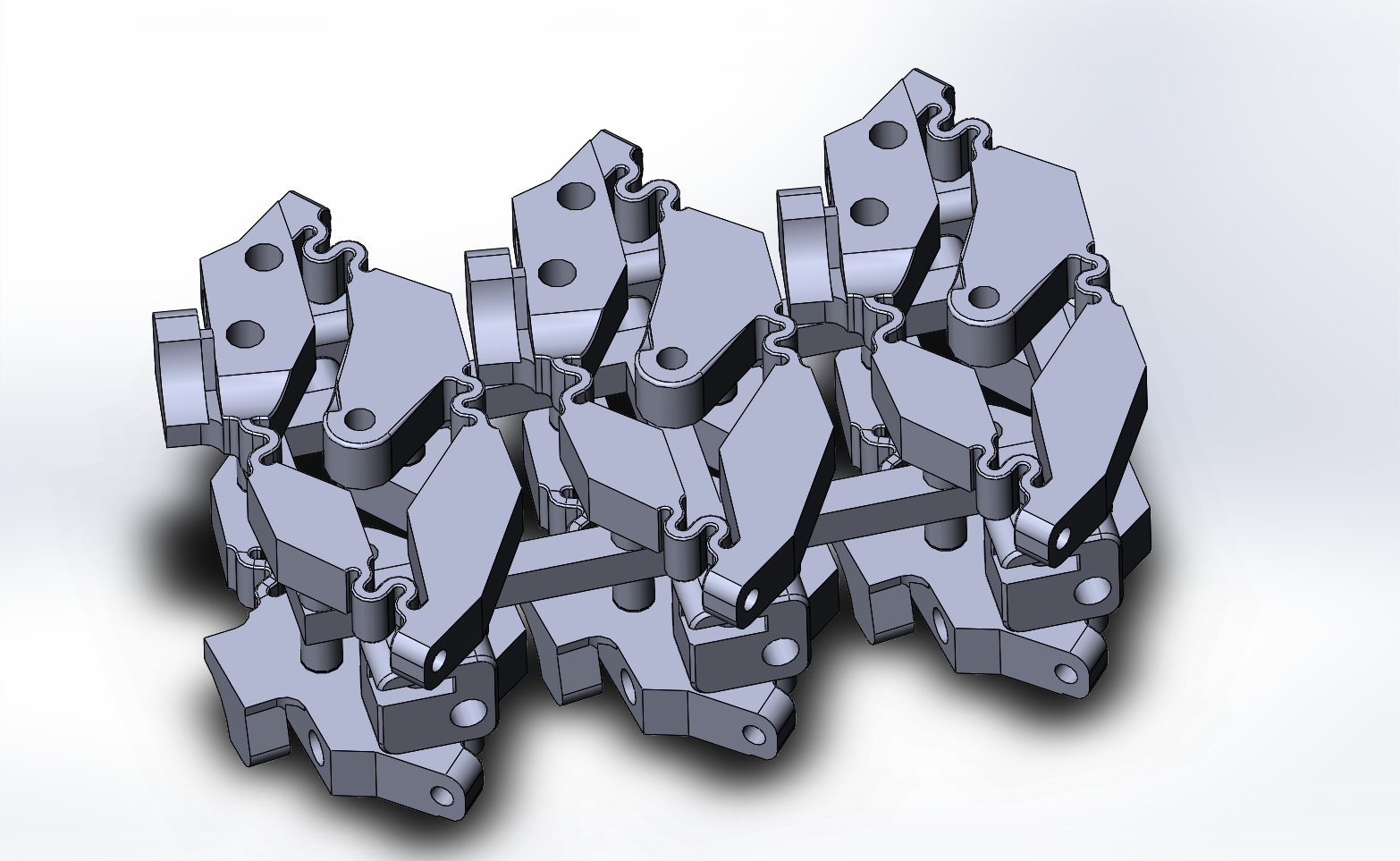

The spru model used to minimise the per item handling costs, so all 6 actuators and coupling pegs mounted on a single spru. This also helps with handling during the cleaning process after printing. -

initial power-up

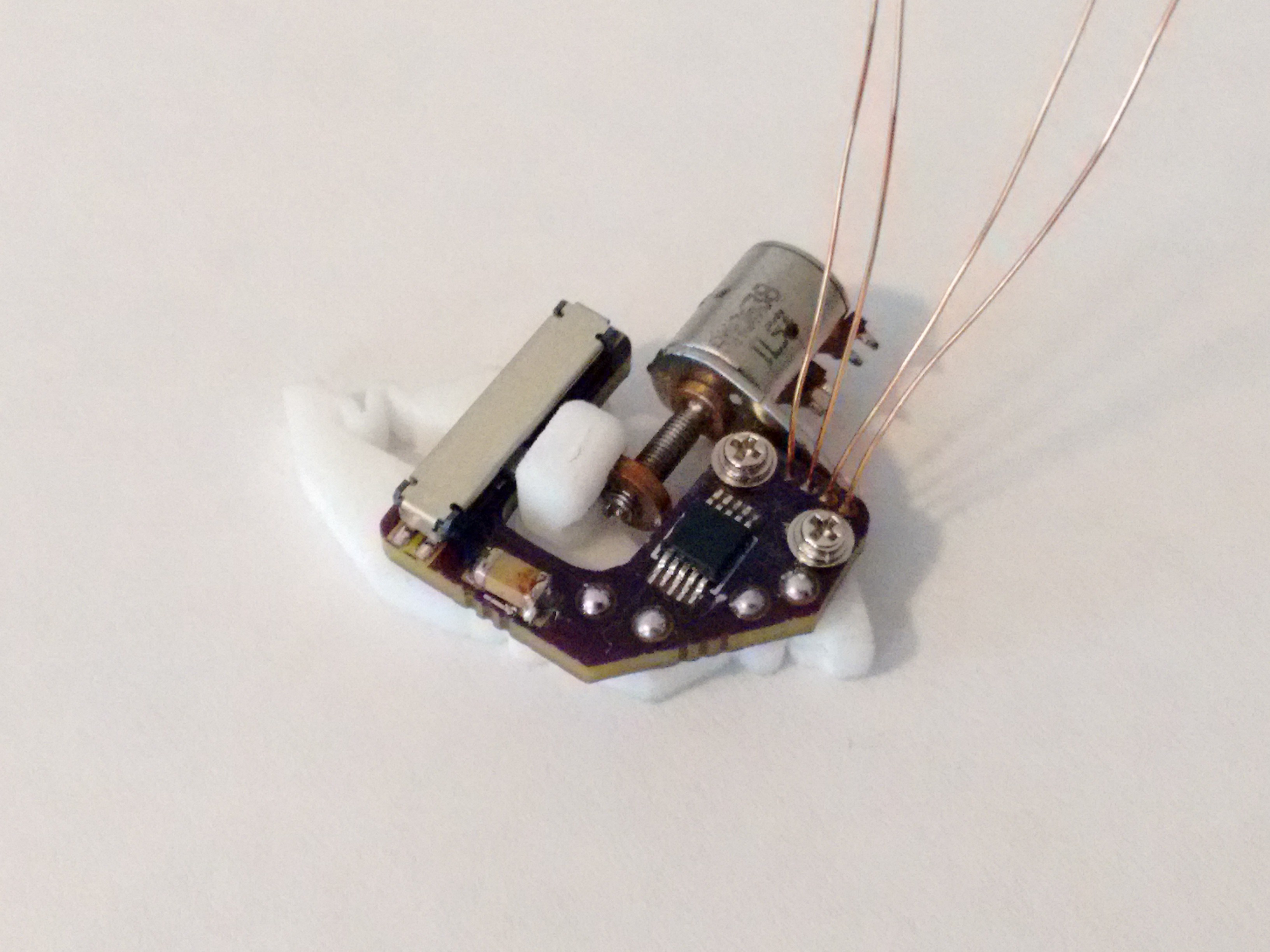

07/12/2017 at 21:55 • 0 commentsAs you can see i've transfered the components to one of the HP fusion printed actuator bodies as these have better definition on the hinges, so require less force to move. The 'strong and flexible' (Shapeways SLS nylon) had too much load on the motor (hinge material printed out thicker). The video below is of the actuator moving back and forwards twice over. This required some adjustment (use of needle files), as the printed nylon has some variation from the design geometry.

As you may be able to see the black 'peg' that couples the motor, resistor and actuator moves around a fair bit and there is obvious backlash from the motor nut to the peg. I need to investigate a new iteration for the peg geometry to take most of this out.

Getting the motor aligned was also a tricky and required adjustment of the brass insert to get the angles close. This is fine for small numbers, but larger numbers will require a accurate jig for placement.

-

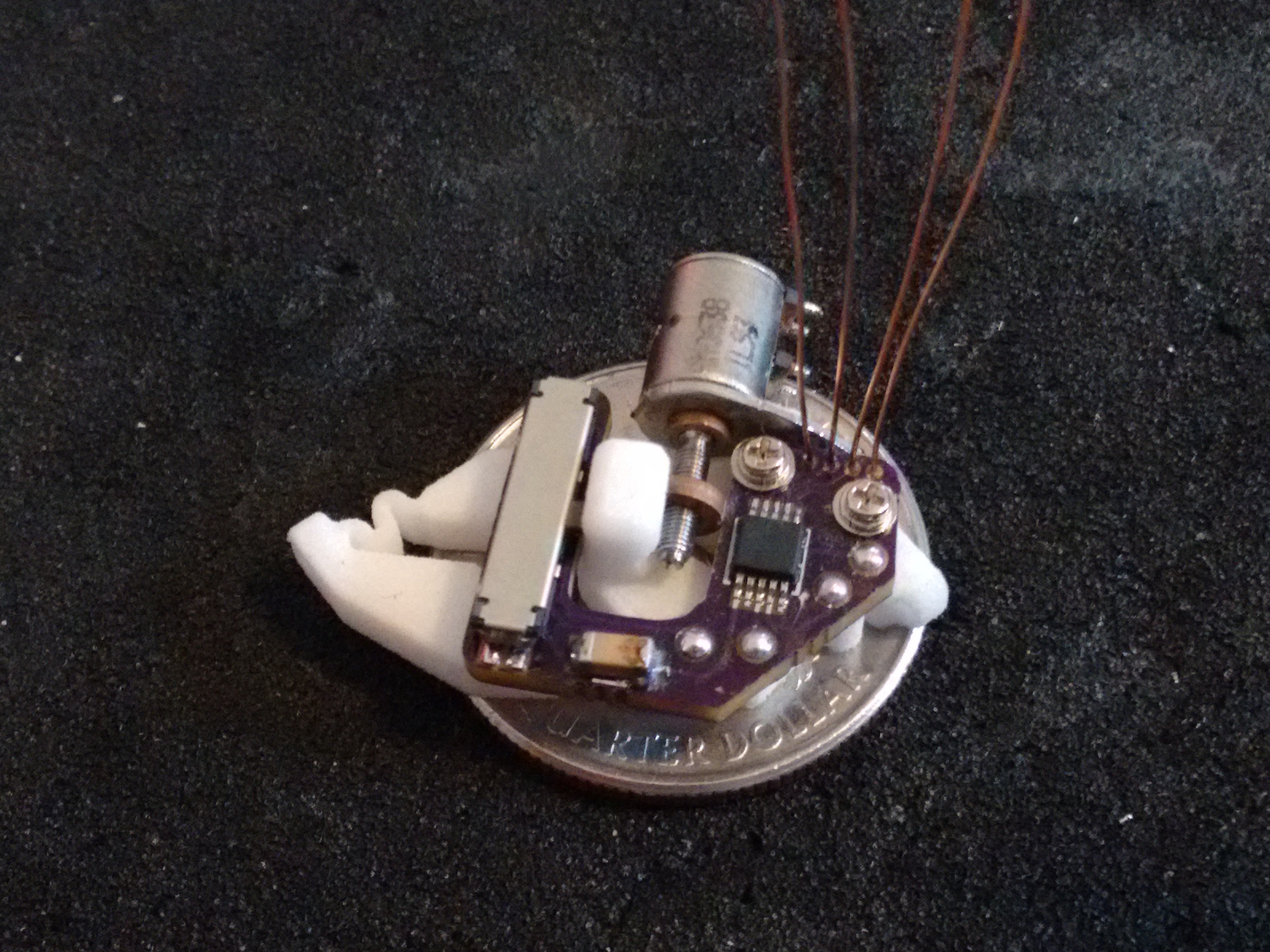

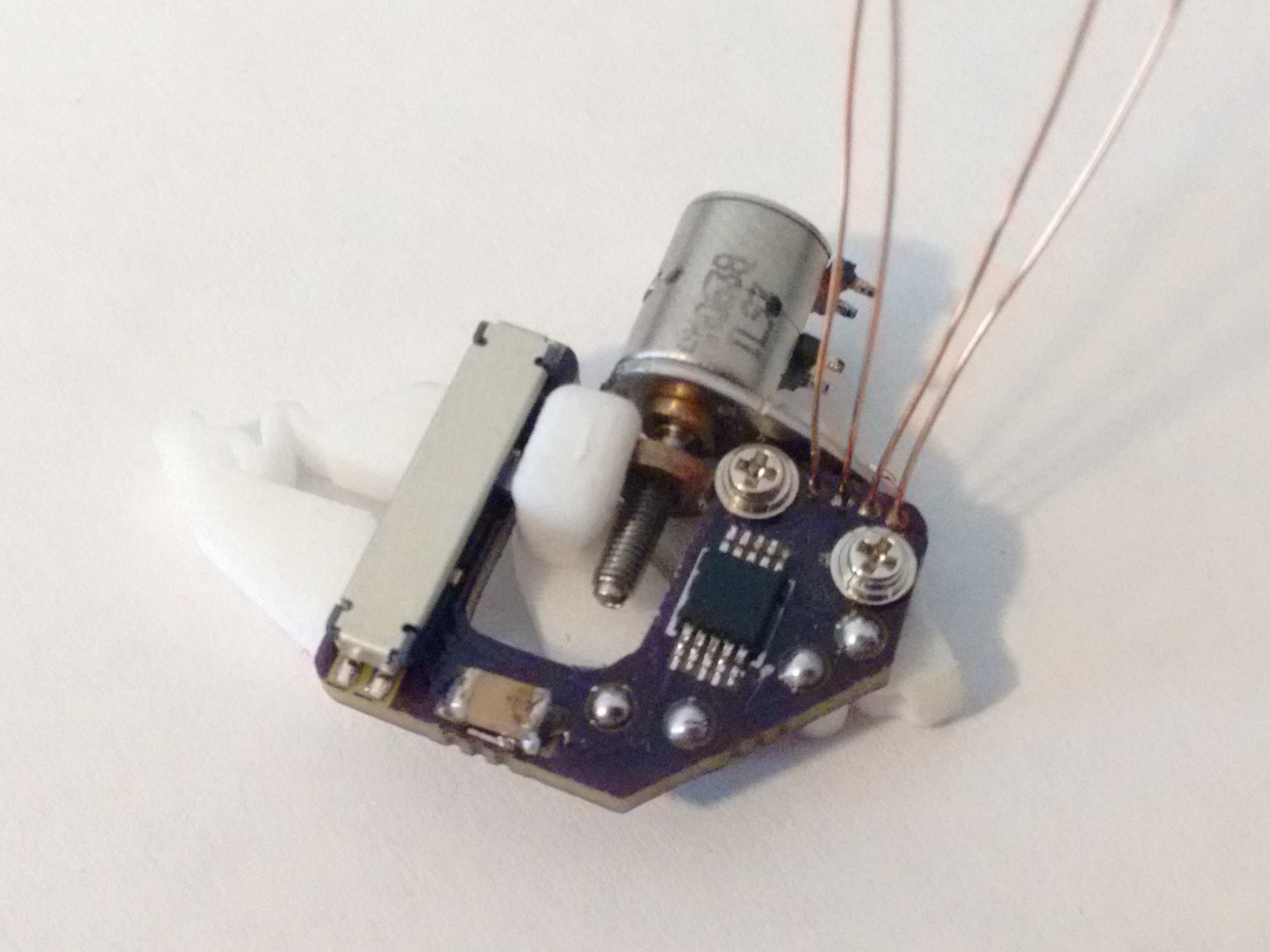

Initial assembly

07/11/2017 at 19:37 • 1 commentSo the SLS nylon parts arrived from Shapeways and i've put together one actuator. unfortunatly the brass screw inserts which were supposed to be M1.2 turned out to be M1.5 so i managed to find x3 M1.5 screws in my bag of tiny screws from dismantled stuff. The others will have to wait another few weeks until the re-ordered inserts arrive, but at least i have one to run tests on, which I'm quite pleased about. More below the break....

![]()

Actuator sitting on US quater (24mm diameter)

![]()

The grey and black parts are from the new HP fusion jet that Shapeways is trialing and the results are certanly sharper (the hinge sections are much closer/thinner to the design) than their standard 'strong and flexible' machine.

I've not yet had a chance to wire up the motor but using the slot in the end of the shaft I've been able to explore the response through most of the range in movement. So for approximatly 5mm nut movement (which is like squeezing the narrow points of a diamond/rhombus) the length of the actuator changes by roughly 1.24mm.

![]()

Full nut retract (actuator extension)

![]()

Full nut extension (actuator retraction)

-

Actuator components

06/23/2017 at 15:20 • 0 commentsSo i've ordered the printed components from shapeways (SLS nylon) but the lead time is quite long, so will see how quick those parts come through.

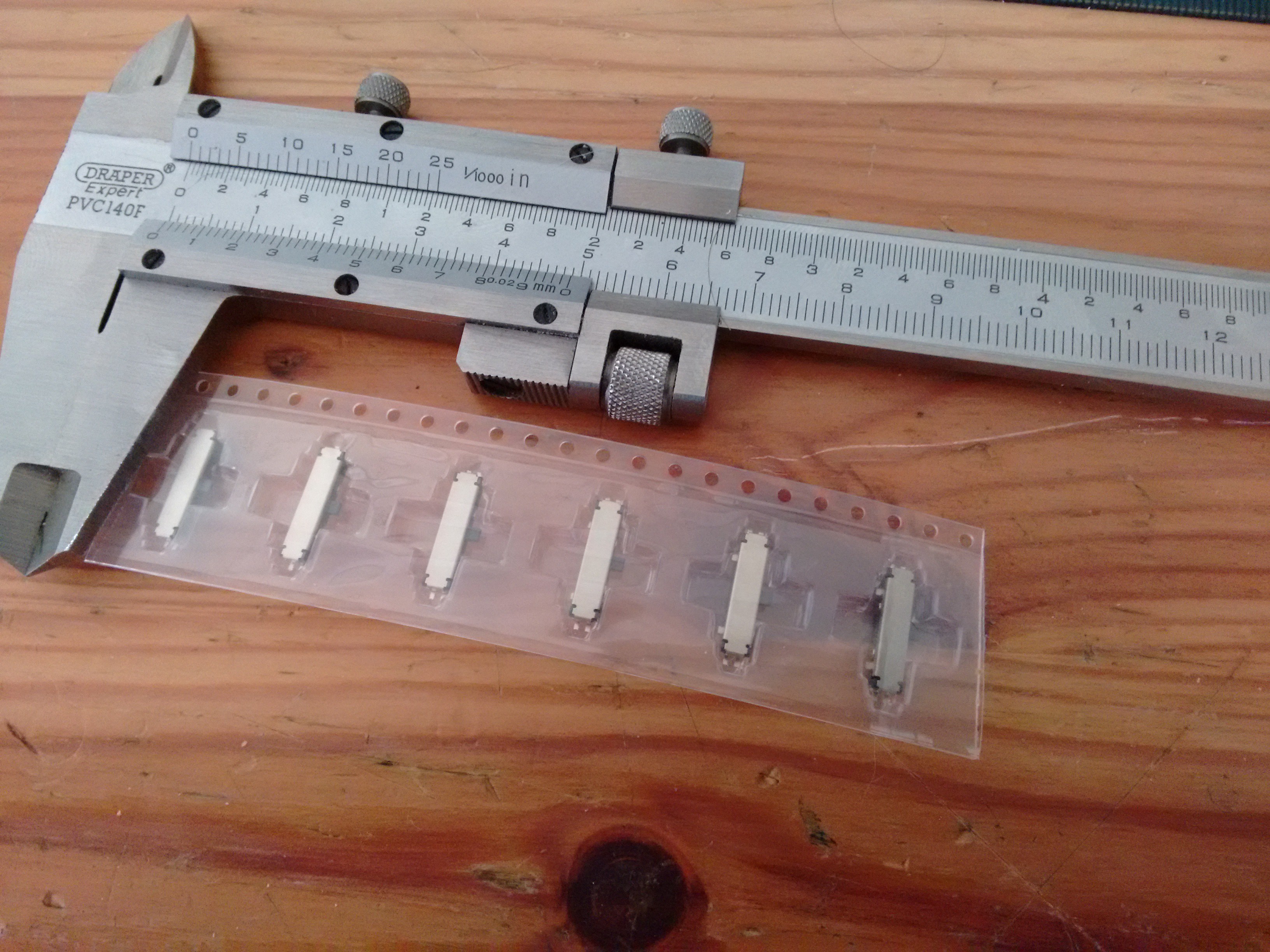

The linear variable resistors (ALPS RS08U11AZ001) have arrived - really small, see below;

![]()

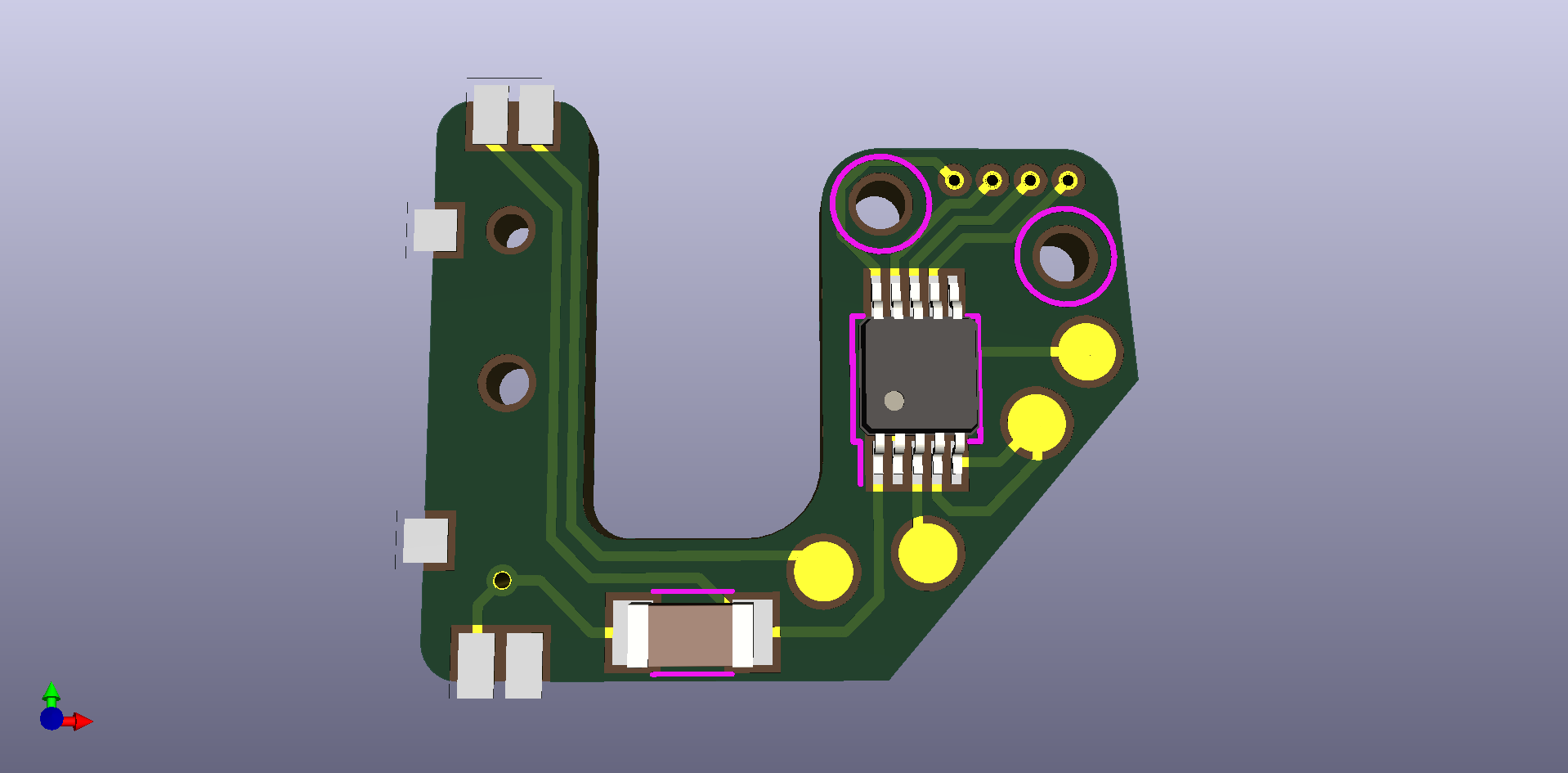

And i've ordered the boards that these mount to from OSH park. Kicad render below;

![]() This has been designed for both the LB1935FA and LB1848MC bipolar motor control ICs, as i've still got a few pieces of the now obselete LB1935FA. There is a single pin difference, so its a case of cutting one of the tracks, depending on which one is being used.

This has been designed for both the LB1935FA and LB1848MC bipolar motor control ICs, as i've still got a few pieces of the now obselete LB1935FA. There is a single pin difference, so its a case of cutting one of the tracks, depending on which one is being used. -

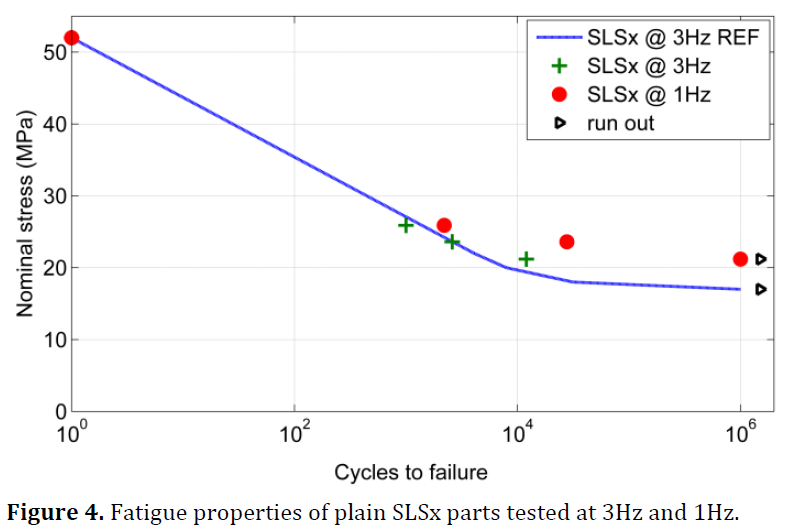

Fatigue design in PA-12 / Nylon

06/21/2017 at 01:05 • 1 commentThe actuator body has now been designed for fatigue and to meet the requirements for Shapeways 'strong and flexible' sintered plastic (PA / polyamide / nylon 12).

Figure: Final design for articulator body.The material data for this is available by searching for PA2200 material data sheet. The stress limits come from a paper I found [ref. High cycle fatigue properties of selective laser sintered parts in polyamide 12] the key findings of which are;

- The building orientation of the SLS specimens has no influence on the fatigue properties, due to high percentage of fusion.

- The fatigue life is significantly influenced by cyclic softening if the sample temperature reaches the glass transition region, leading to brittle fracture.

- Where the print machine employs contour scanning the outer surface is of higher quality, damge to the surface by machining reduces fatigue life as cracks nucleate from unmolten powder particles and these are not present on the unmachined surface.

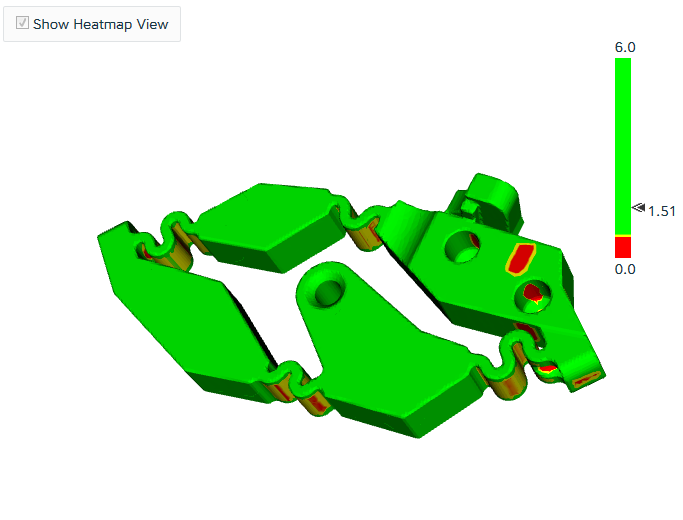

![]() The design followed an itterative process from the initial design, extending the length of the thin hinge material. Initially simply, but when I found the fatigue data a more radical solution was needed to get the stress below 18MPa for a 1.5mm deflection. This necessitated meandering the thin hinge material to fit the length between the attachement points.

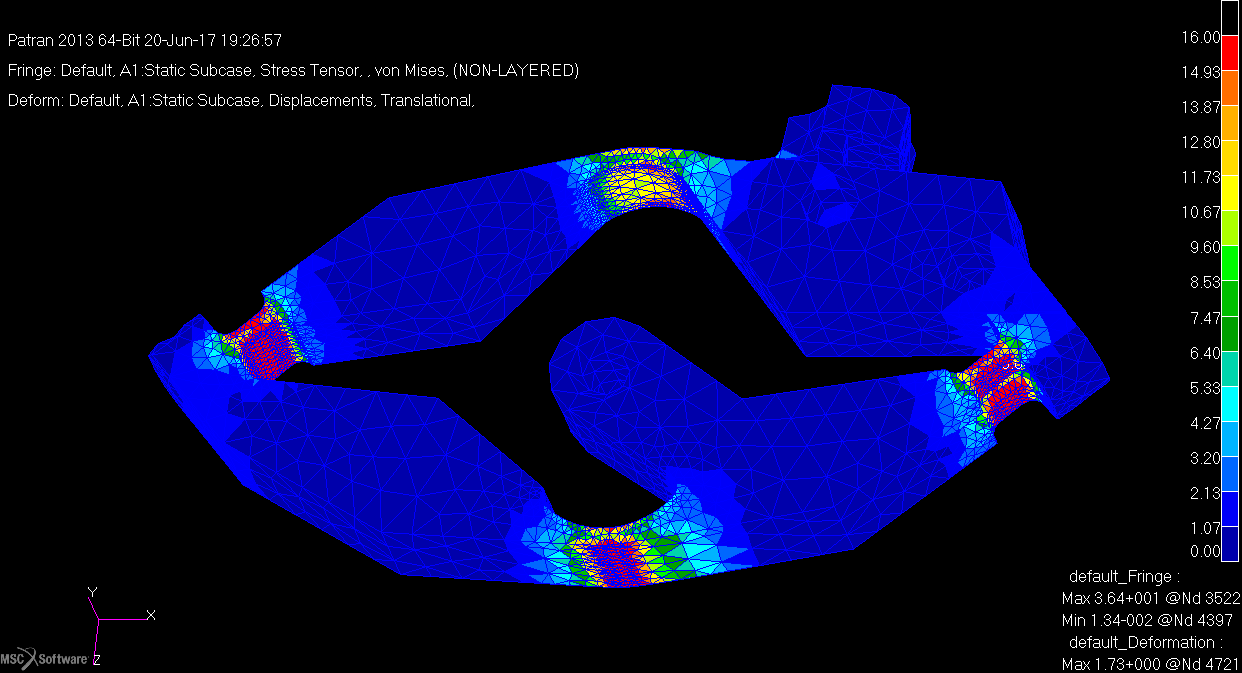

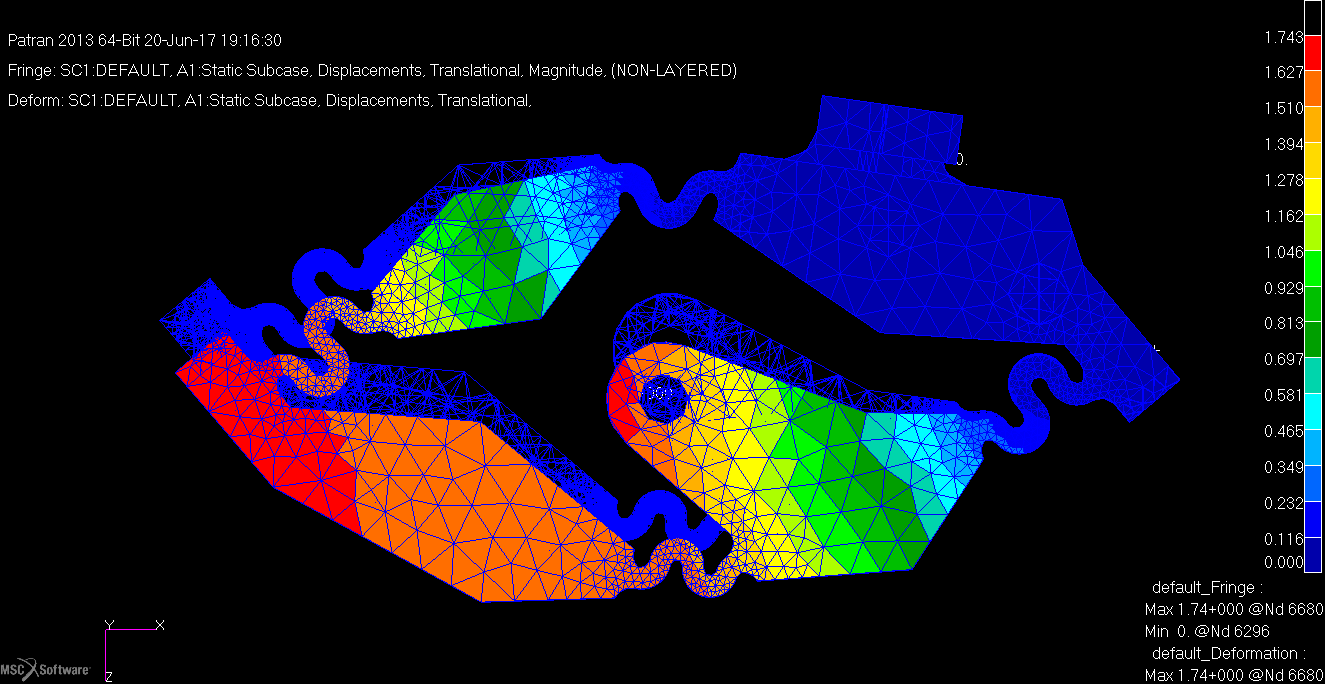

The design followed an itterative process from the initial design, extending the length of the thin hinge material. Initially simply, but when I found the fatigue data a more radical solution was needed to get the stress below 18MPa for a 1.5mm deflection. This necessitated meandering the thin hinge material to fit the length between the attachement points.The stress analysis was carried out using MSC Patran as this is what i've been using for the last ten years at work. The model was held at the motor attachement point and the pin displaced by 1.5mm.

Below are plots of the stages of development to the final design.

![]()

Figure: Von Mises stress plot (MPa / N/mm2) clipped at 16N/mm2 showing the stress in the part. Initial design first run.

![]()

Figure: Stress plot (MPa / N/mm2) clipped at 16N/mm2 showing the stress in the part. Prior to re-design for fatigue stress limit. Investigating the behaviour of the stress and flexure to extension of the hinge length.

![]()

Figure: Stress plot (MPa / N/mm2) clipped at 16N/mm2 showing the stress in the part well below the 10^6 cycle stress of 18N/mm2.

![]()

Figure: Displacement (mm), because of the constraints the movement looks a little odd, but is correct.

![]()

Figure: Allowable minimum thickness plot from shapeways web page, areas in red are below the minimum 0.6mm. I'm not worried by the limited areas and it passes their automated checks.

6-Axis Micro Manipulator

Micron level manipulator, using printed and low cost components

David Brown

David Brown Figure; Laser pointer mounted to the platform (test rotations)

Figure; Laser pointer mounted to the platform (test rotations) Figure; one end of the laser pointer supported (test translations)

Figure; one end of the laser pointer supported (test translations) The print of the frame took 15 hours and i was pleased with the quality, given that this was using the $150 printer with all stock nozzle, etc. I'll post up the models for the parts shortly. More after break below;

The print of the frame took 15 hours and i was pleased with the quality, given that this was using the $150 printer with all stock nozzle, etc. I'll post up the models for the parts shortly. More after break below;  By using the printer the cost was probably $5 of filament and 15hrs of time, versus $68 if i had used shapeways. So the printer will pay for itself in short order.

By using the printer the cost was probably $5 of filament and 15hrs of time, versus $68 if i had used shapeways. So the printer will pay for itself in short order. You can see the PCB in the base with the end stop switches that allow the lever arms to be set to a known position.

You can see the PCB in the base with the end stop switches that allow the lever arms to be set to a known position.  The platform end is also SLS printed nylon and I drilled out the doles for the wire cables using a 1mm drill bit.

The platform end is also SLS printed nylon and I drilled out the doles for the wire cables using a 1mm drill bit.  units = mm

units = mm

This has been designed for both the LB1935FA and LB1848MC bipolar motor control ICs, as i've still got a few pieces of the now obselete

This has been designed for both the LB1935FA and LB1848MC bipolar motor control ICs, as i've still got a few pieces of the now obselete

The design followed an itterative process from the initial design, extending the length of the thin hinge material. Initially simply, but when I found the fatigue data a more radical solution was needed to get the stress below 18MPa for a 1.5mm deflection. This necessitated meandering the thin hinge material to fit the length between the attachement points.

The design followed an itterative process from the initial design, extending the length of the thin hinge material. Initially simply, but when I found the fatigue data a more radical solution was needed to get the stress below 18MPa for a 1.5mm deflection. This necessitated meandering the thin hinge material to fit the length between the attachement points.