Results

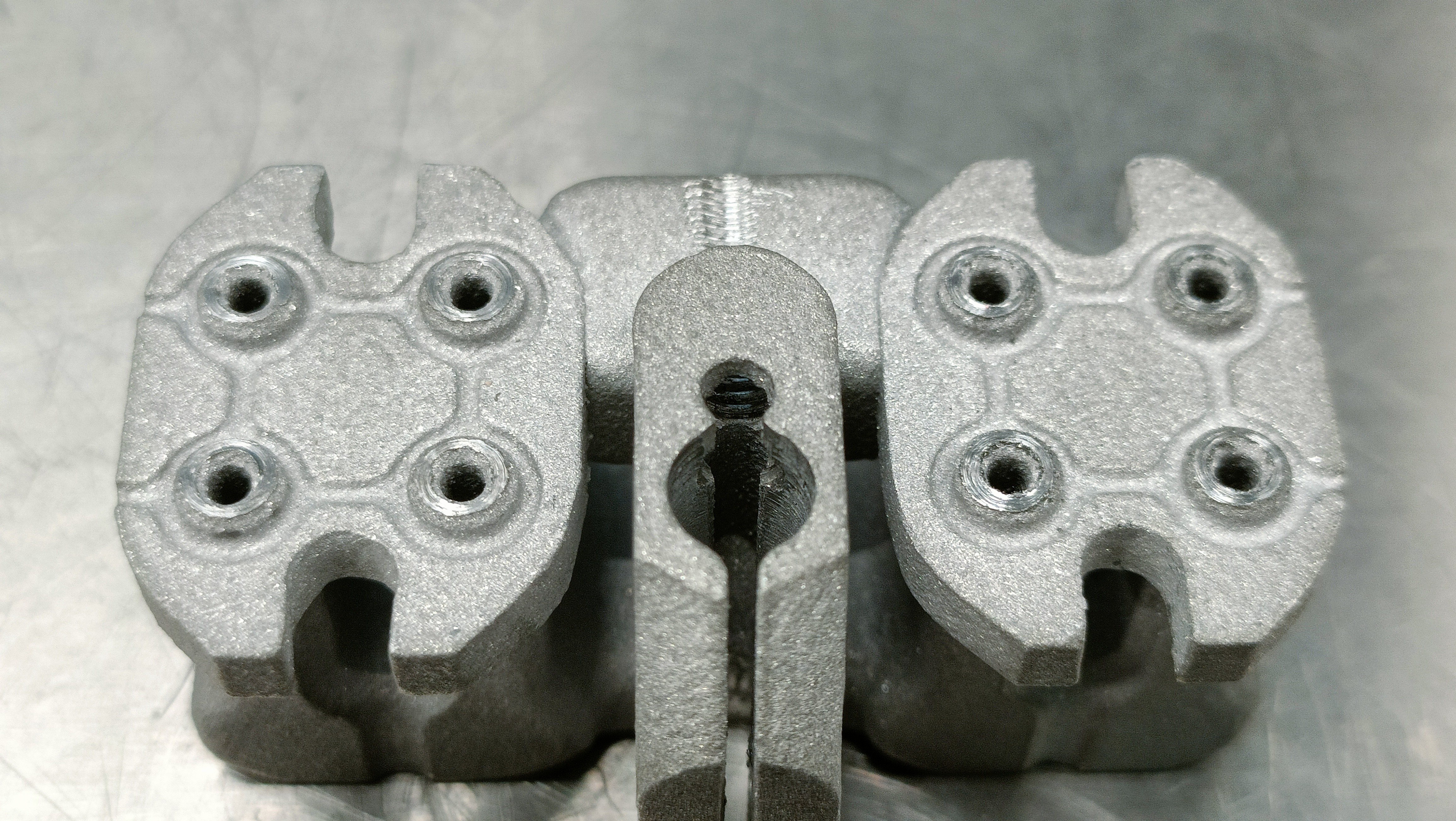

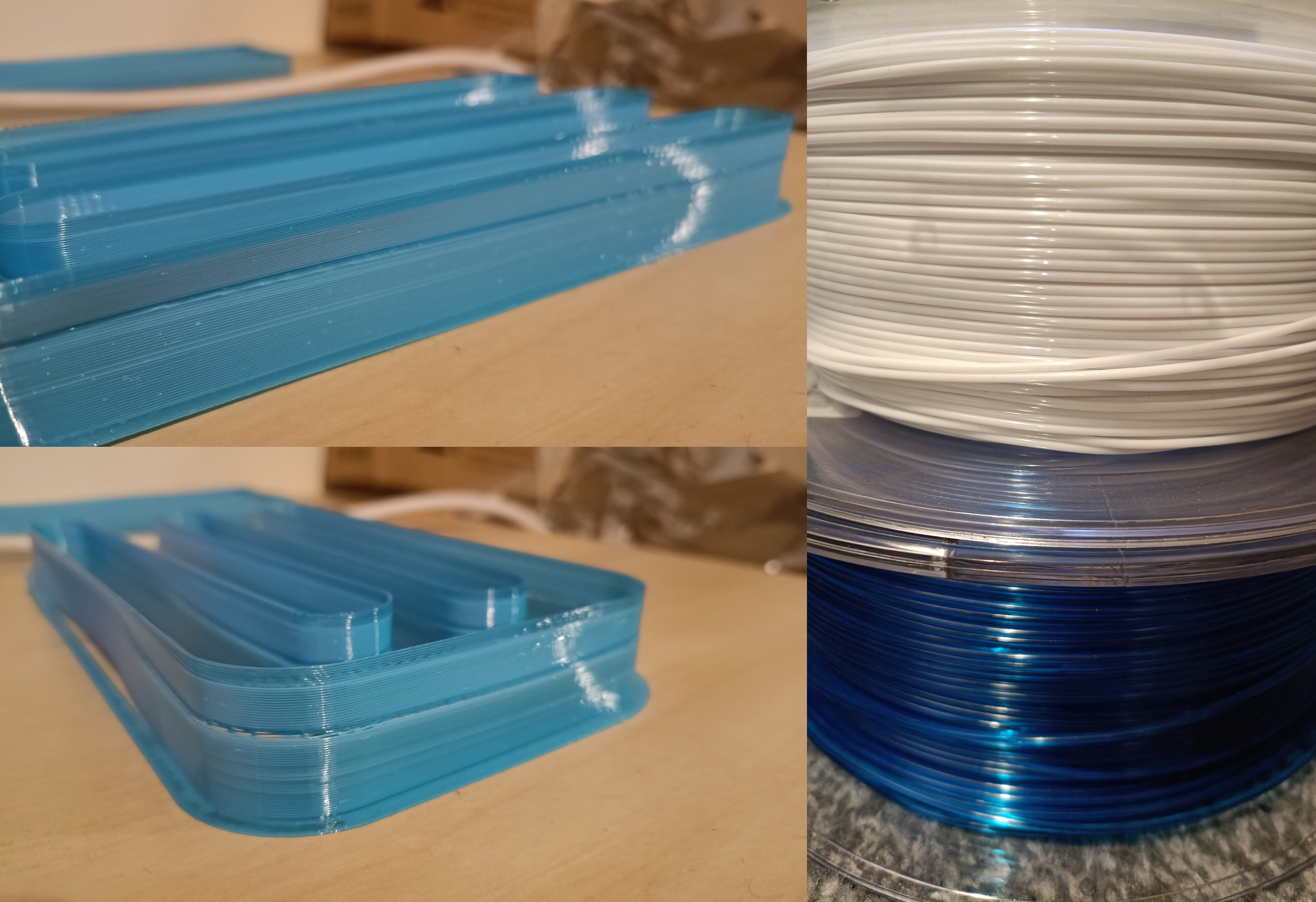

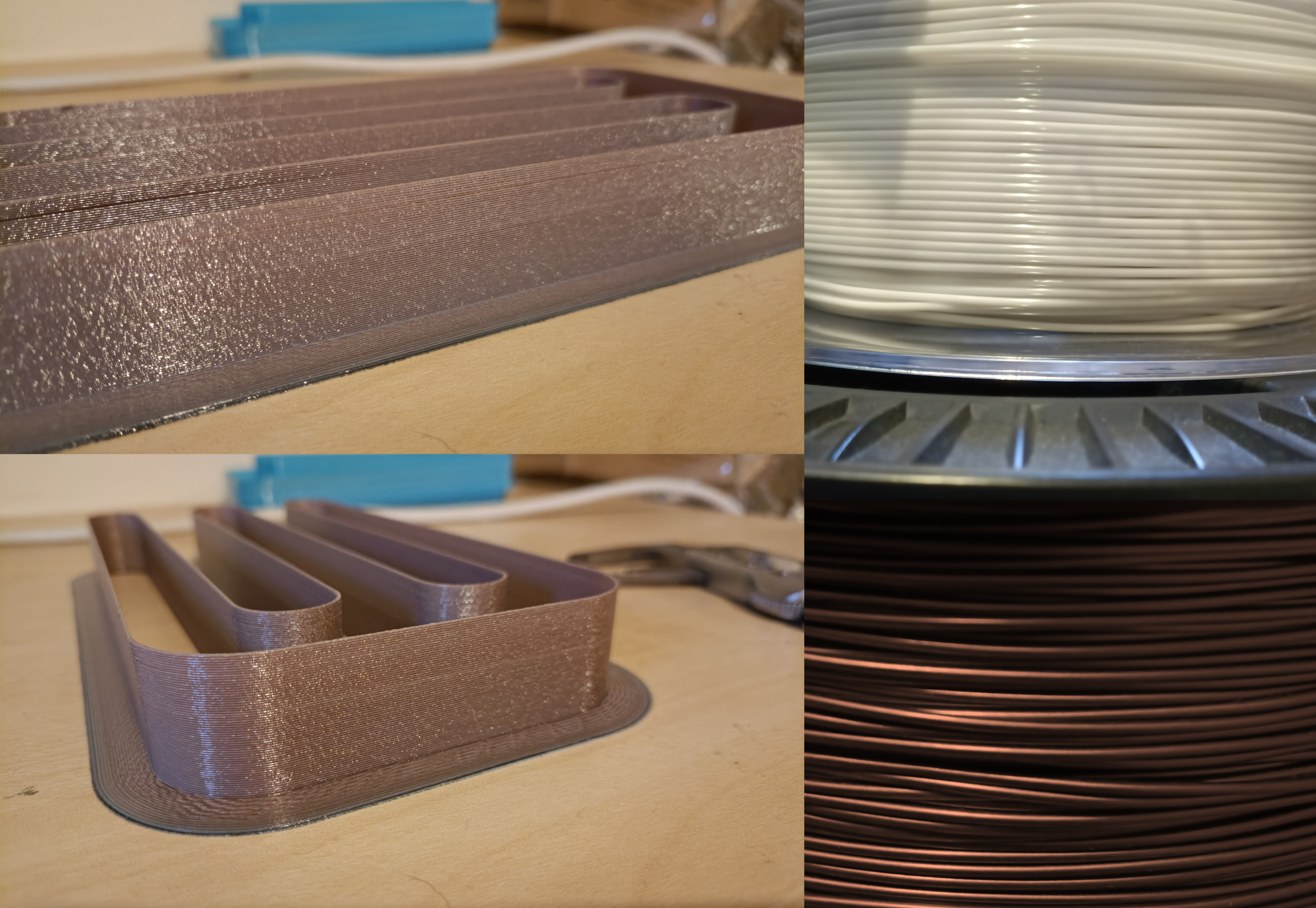

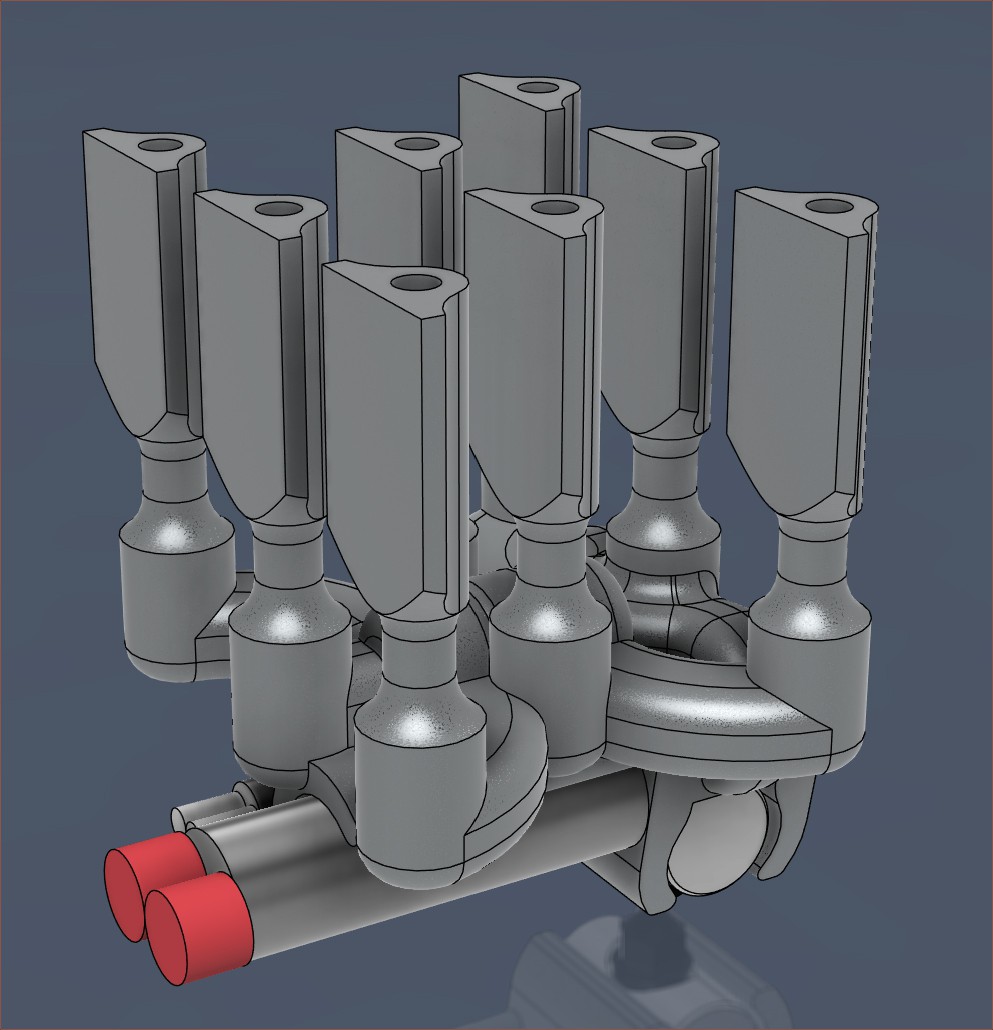

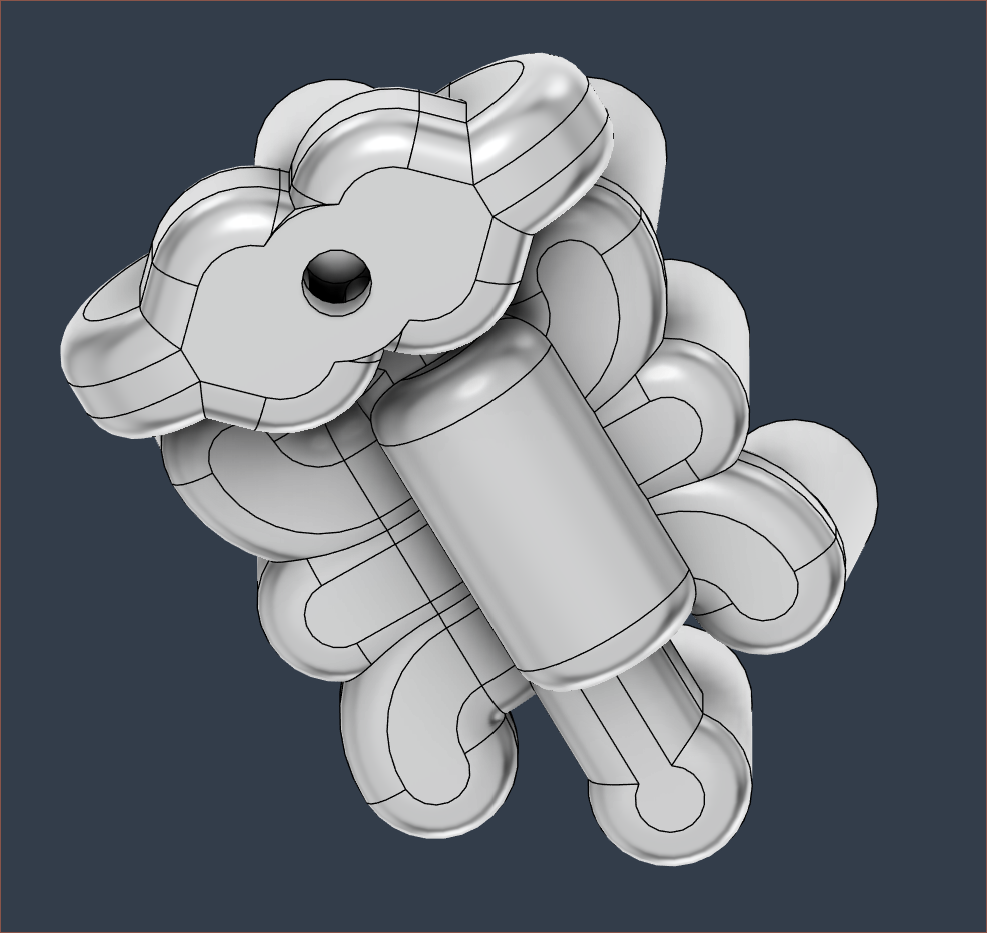

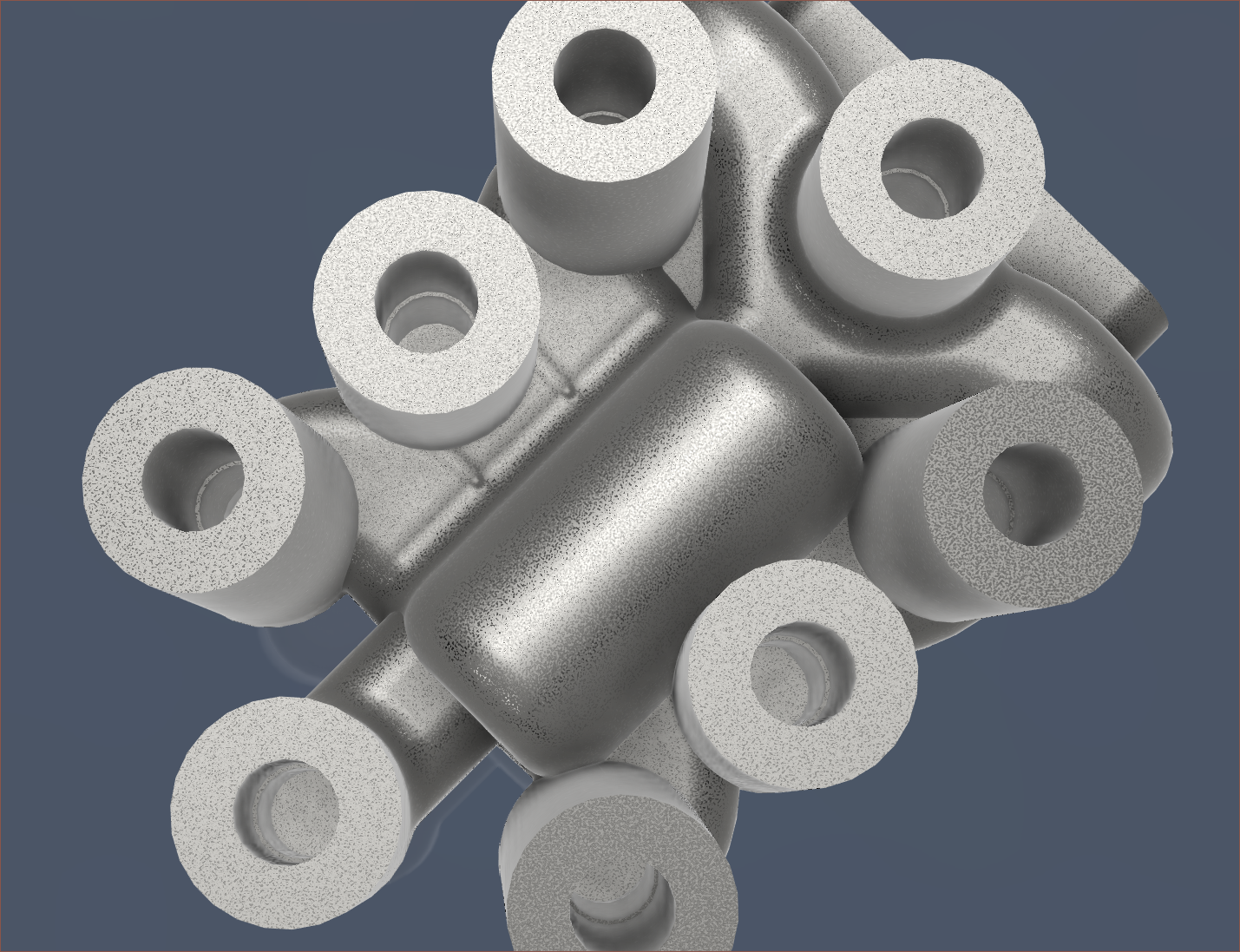

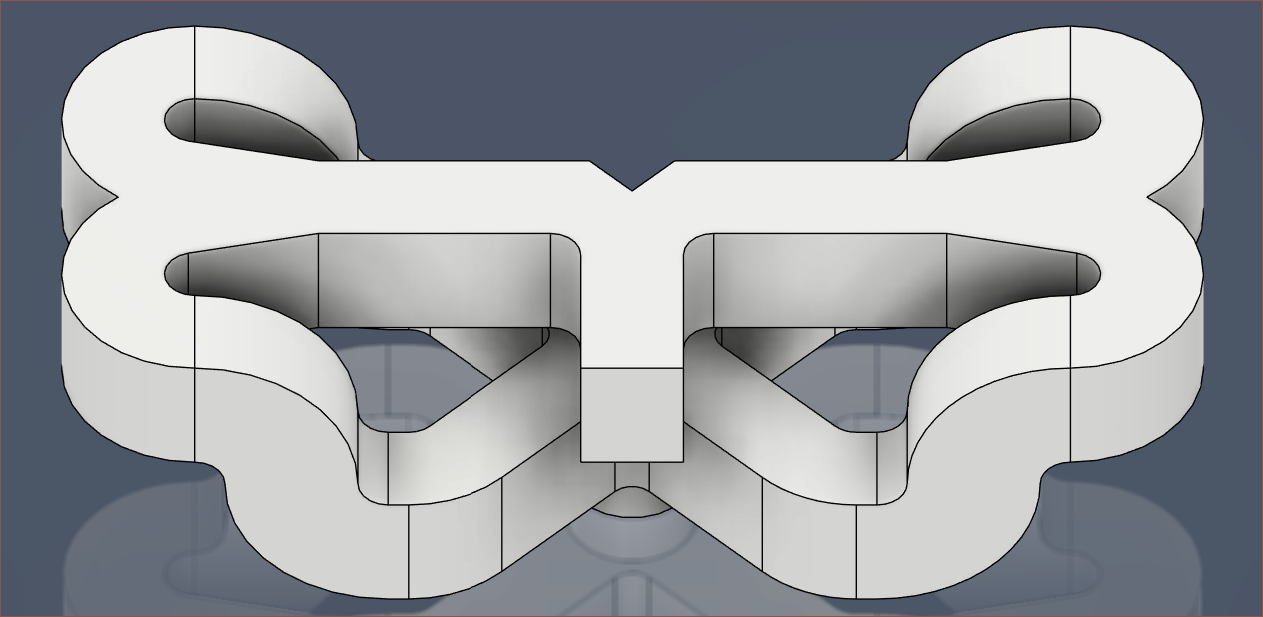

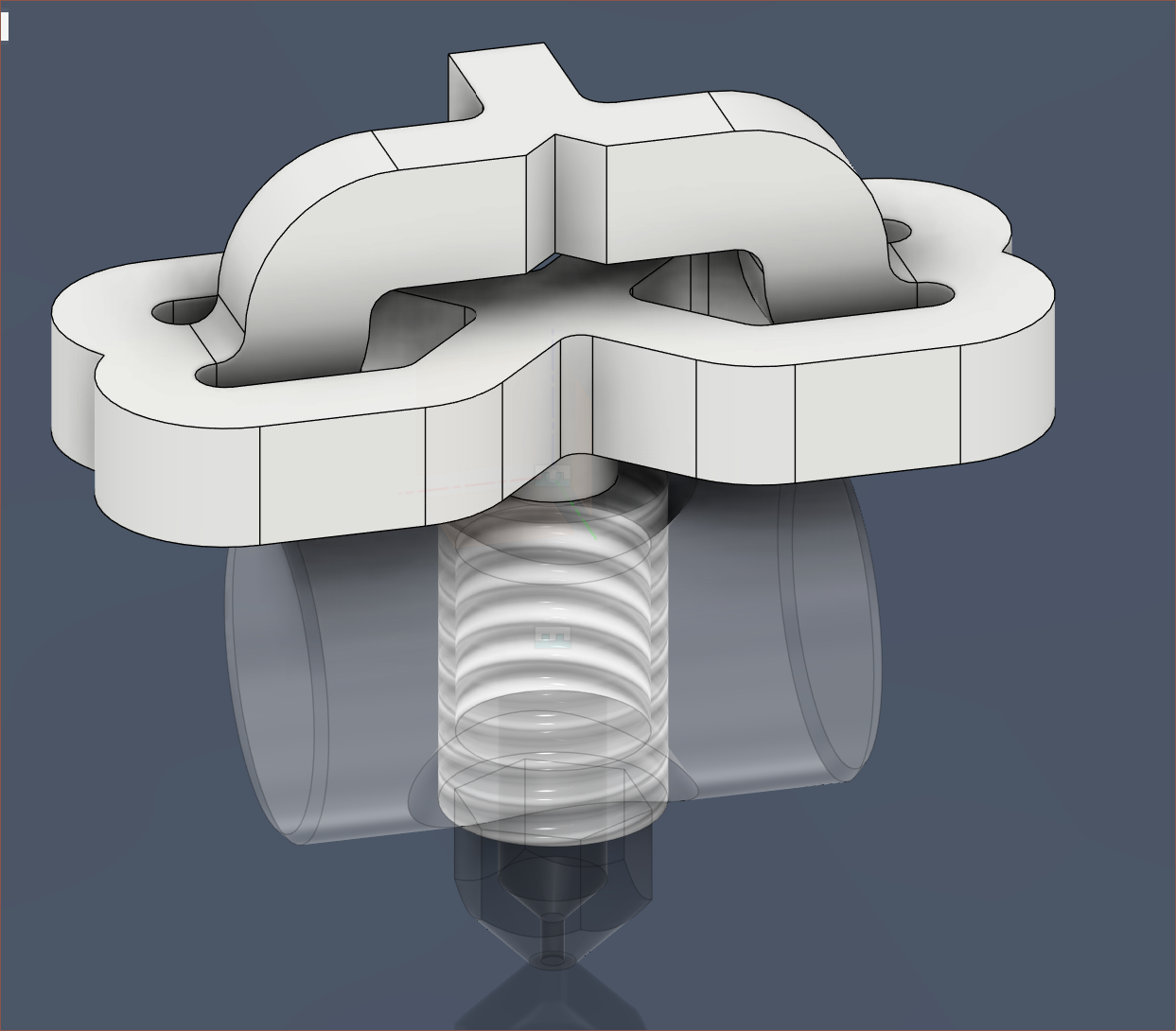

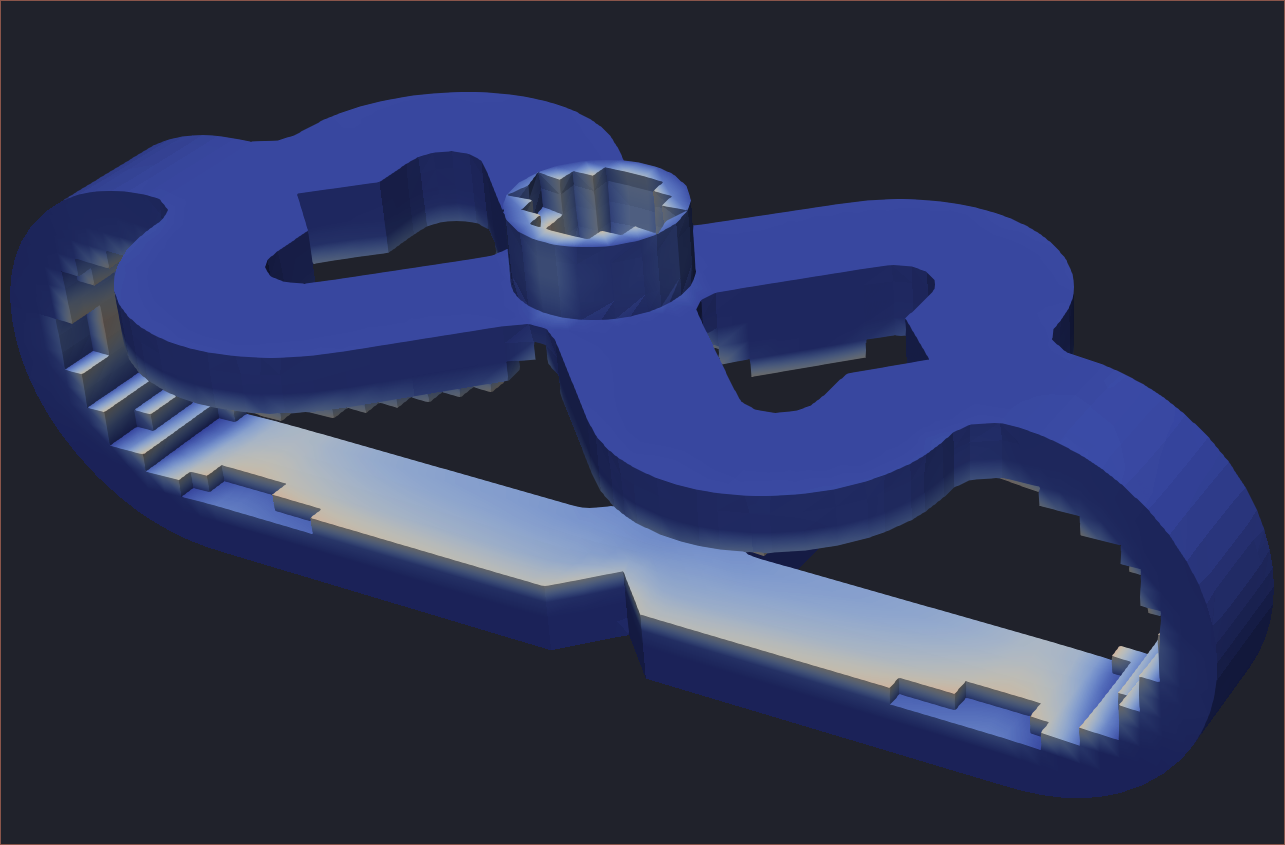

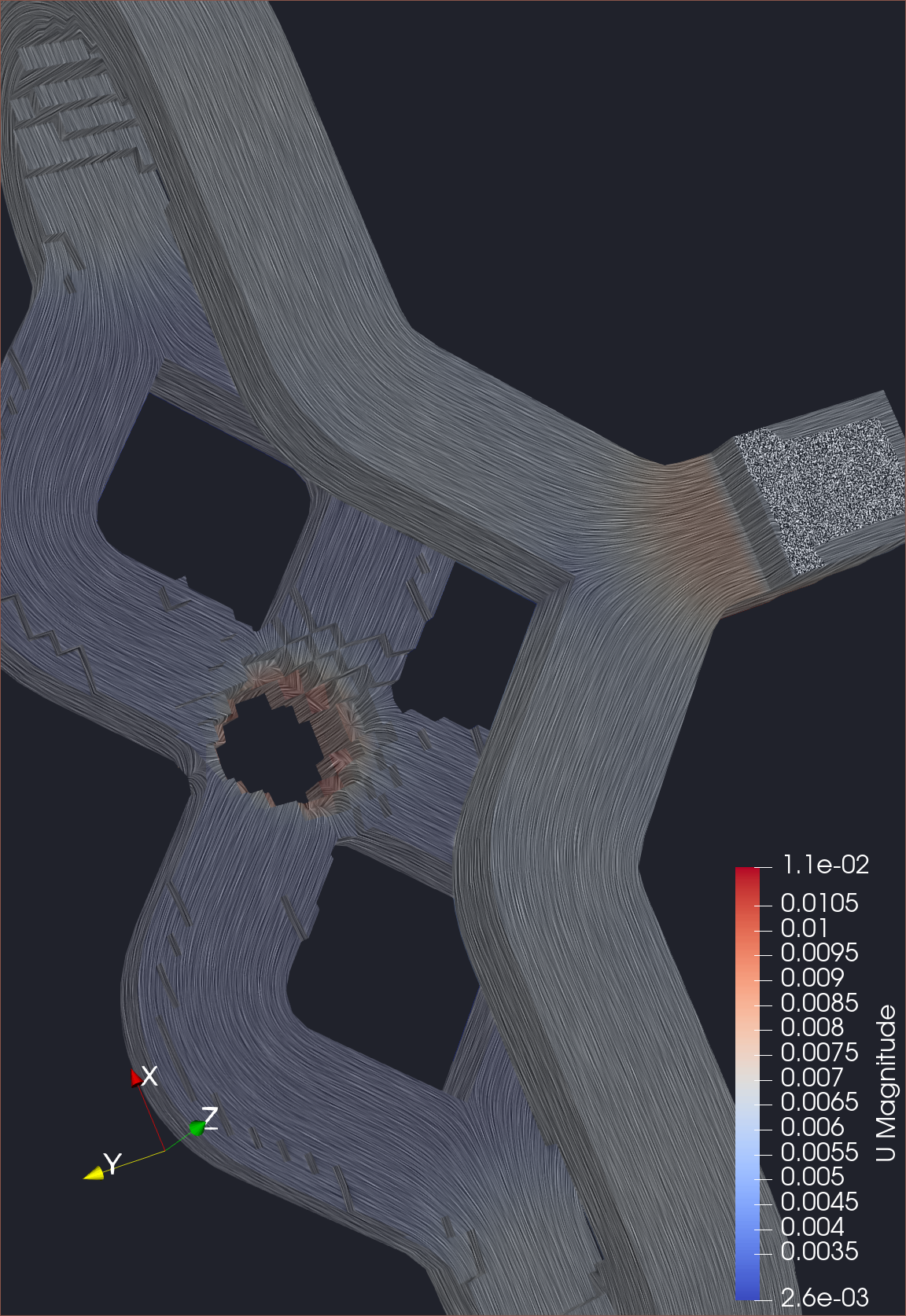

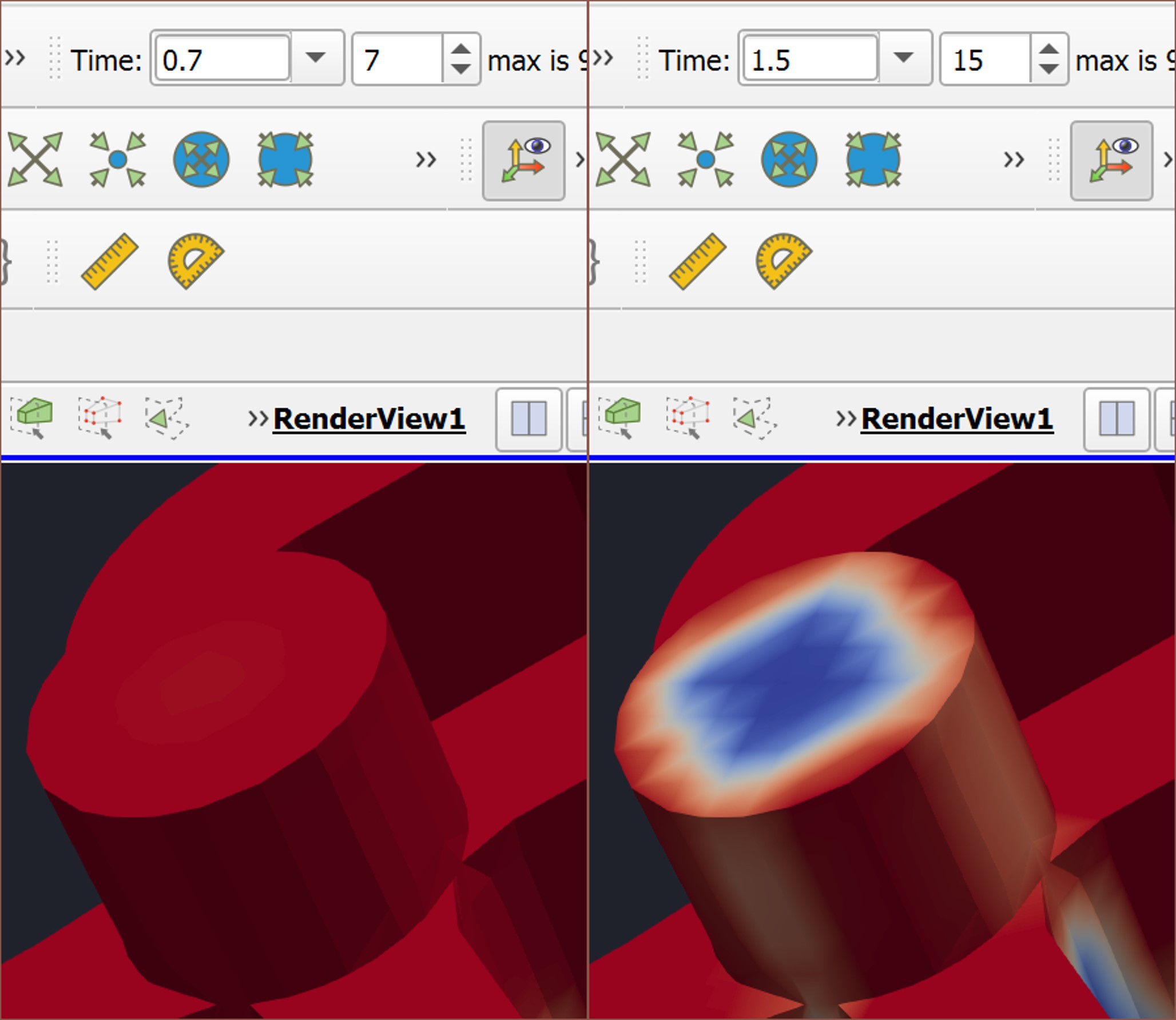

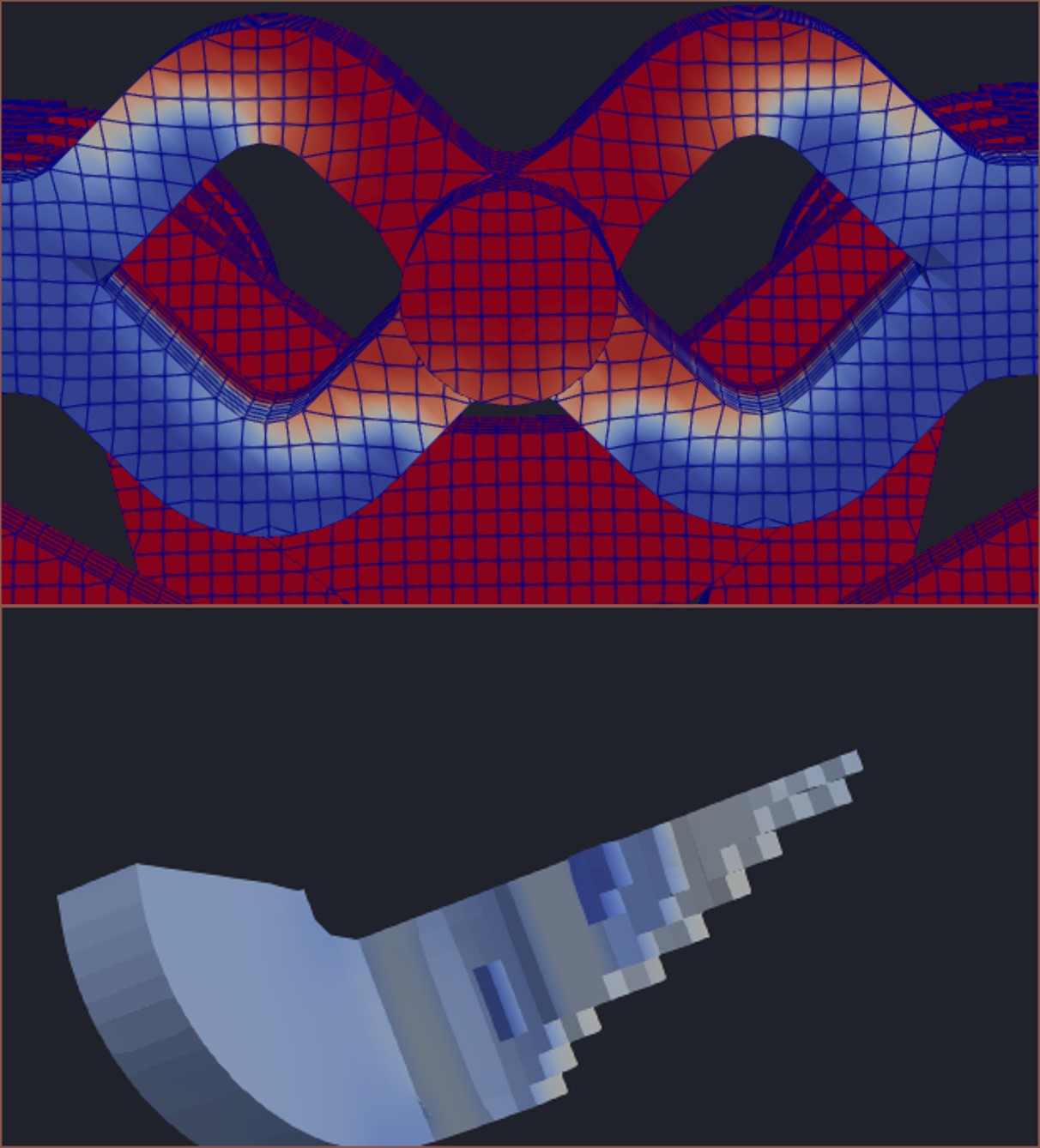

Coaxial8or R3

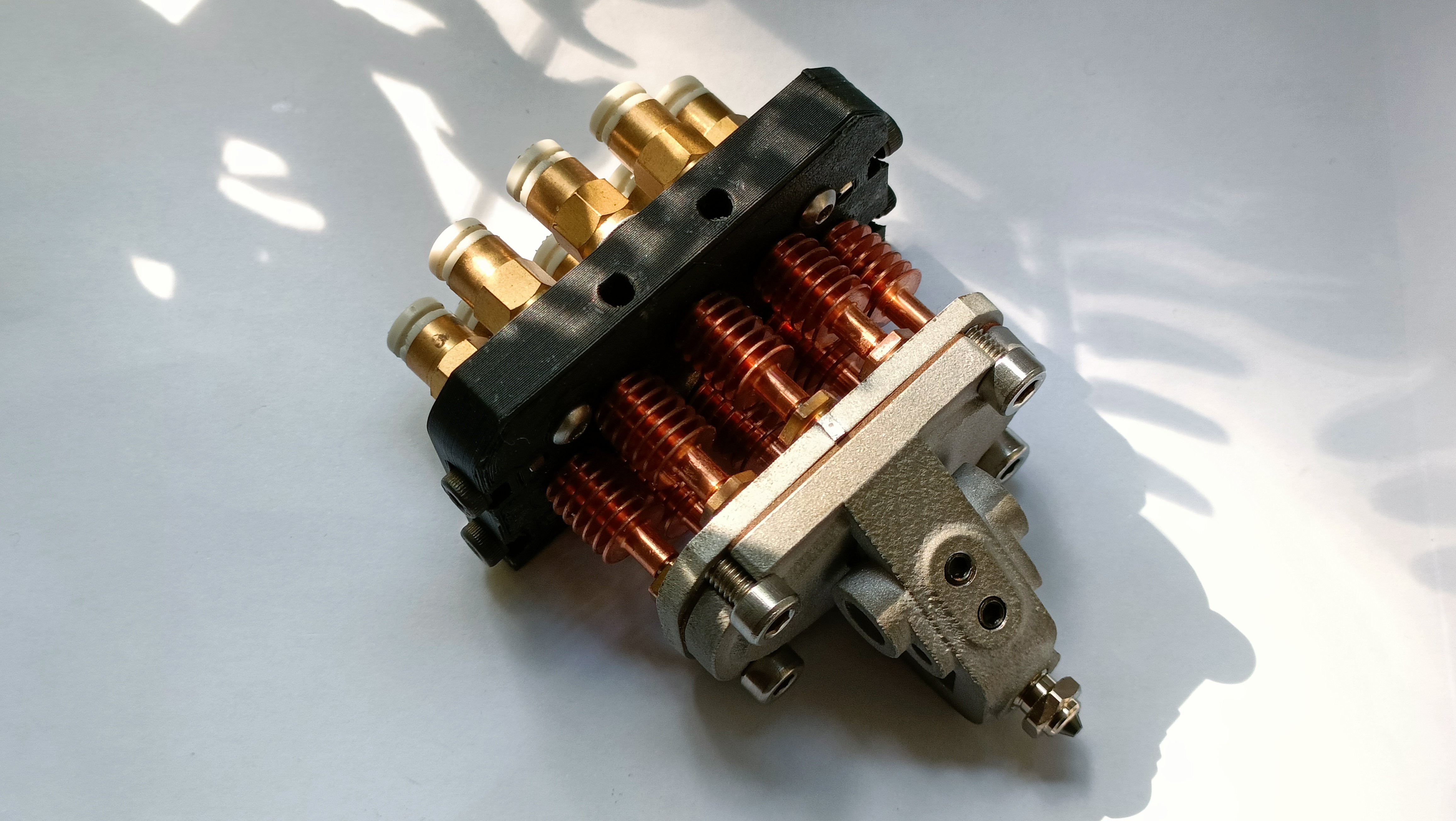

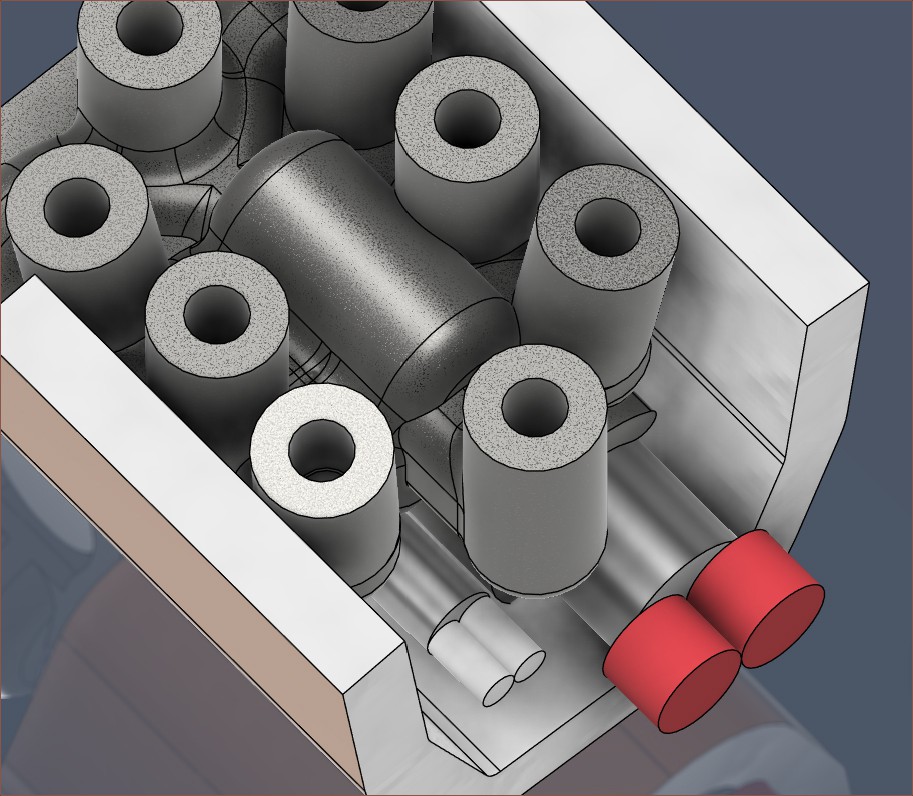

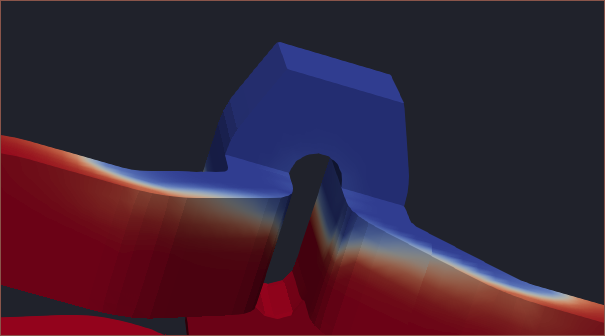

Coaxial8or R2

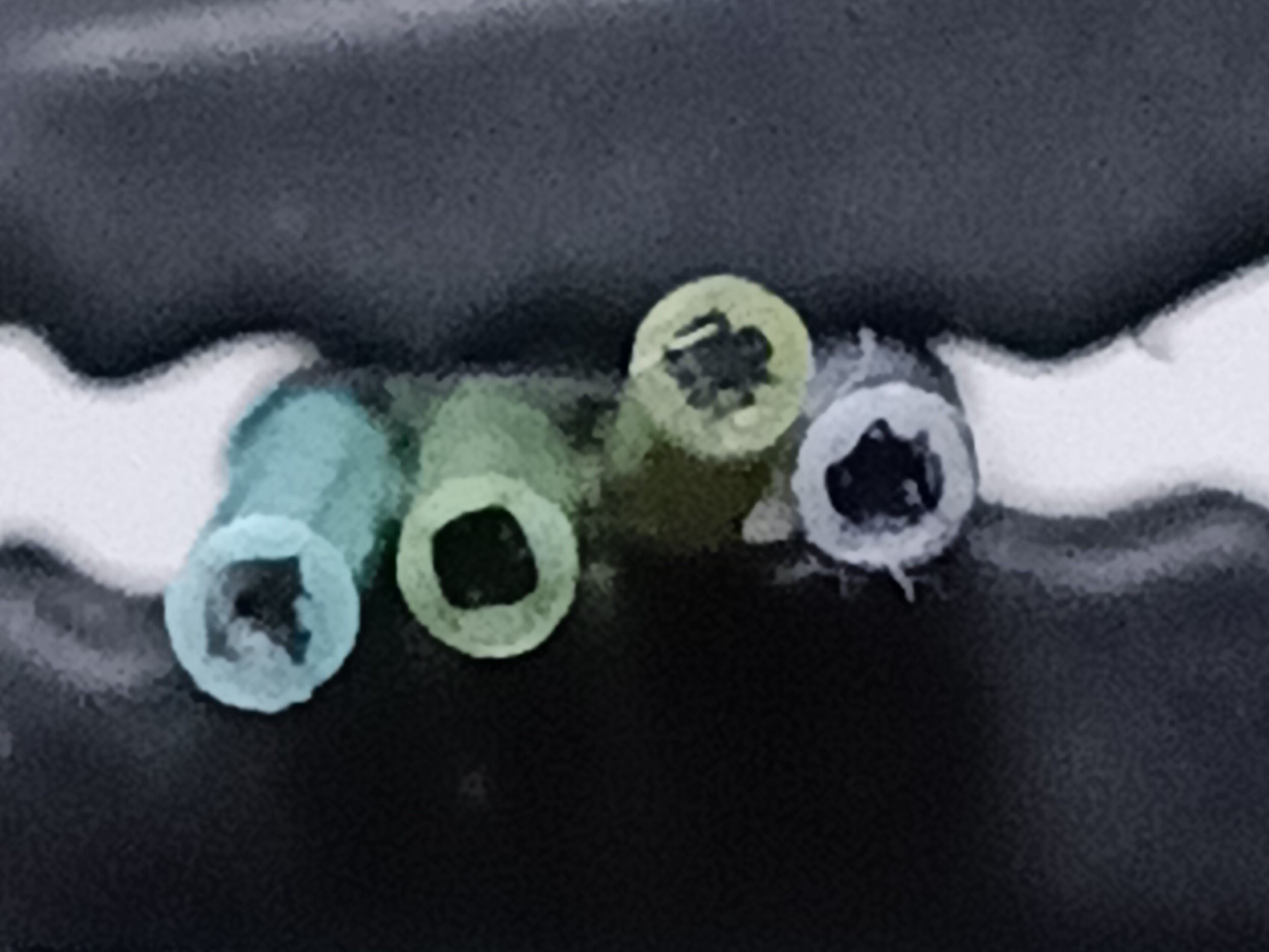

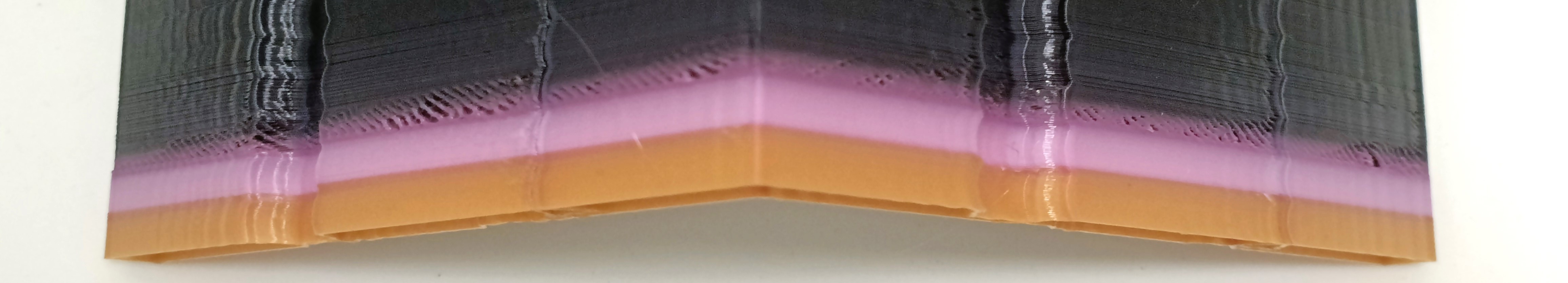

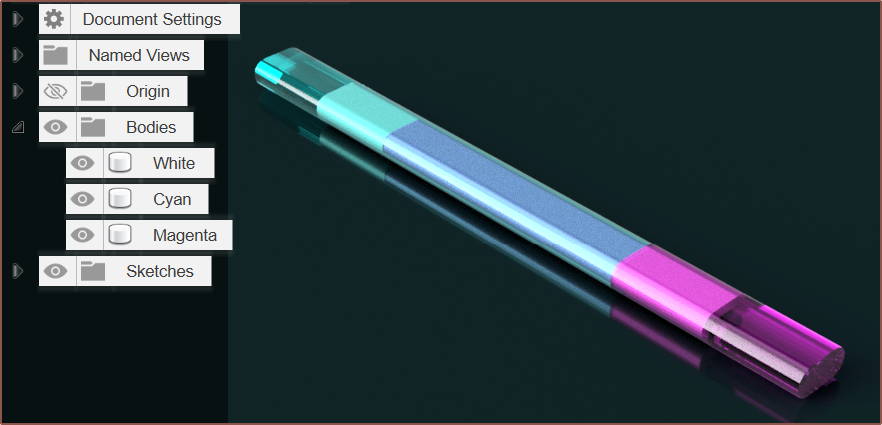

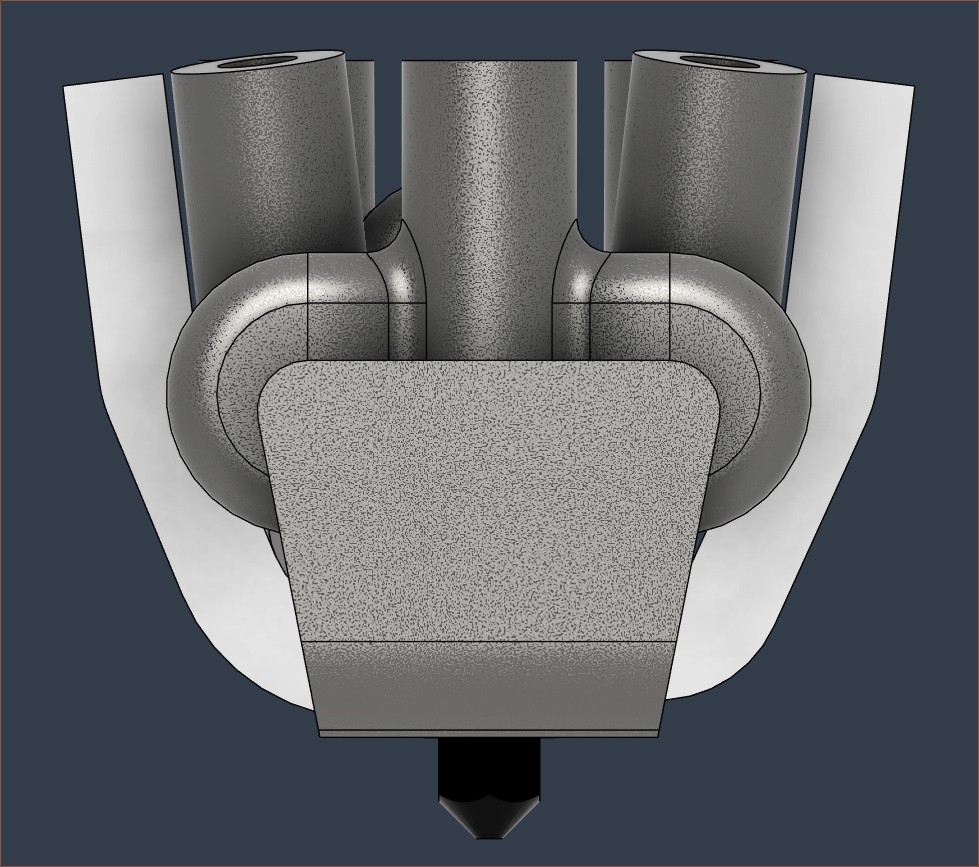

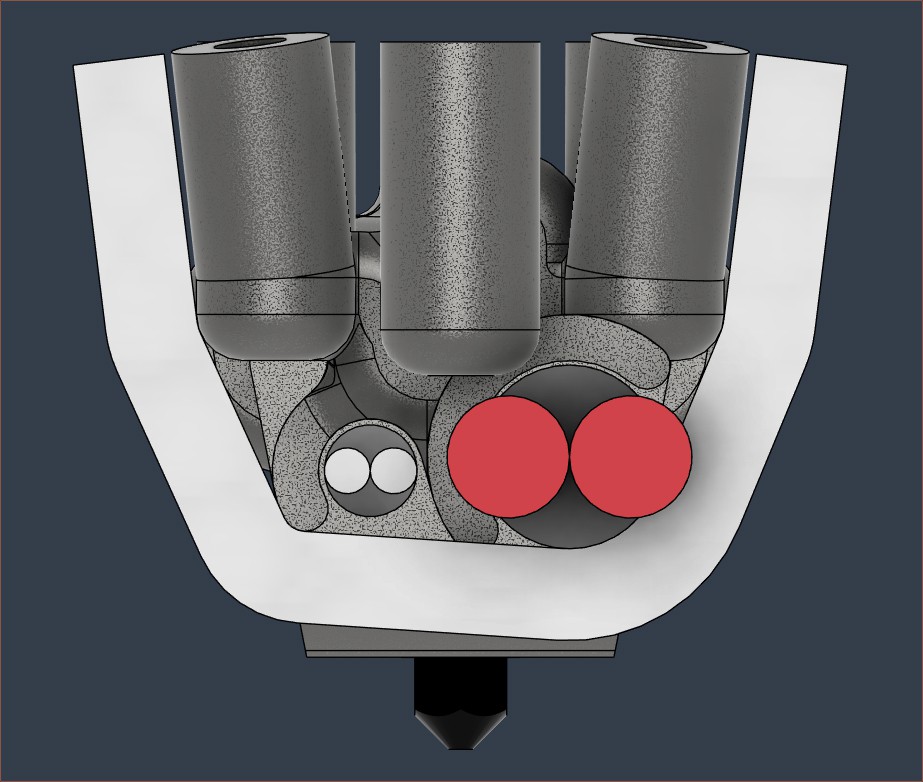

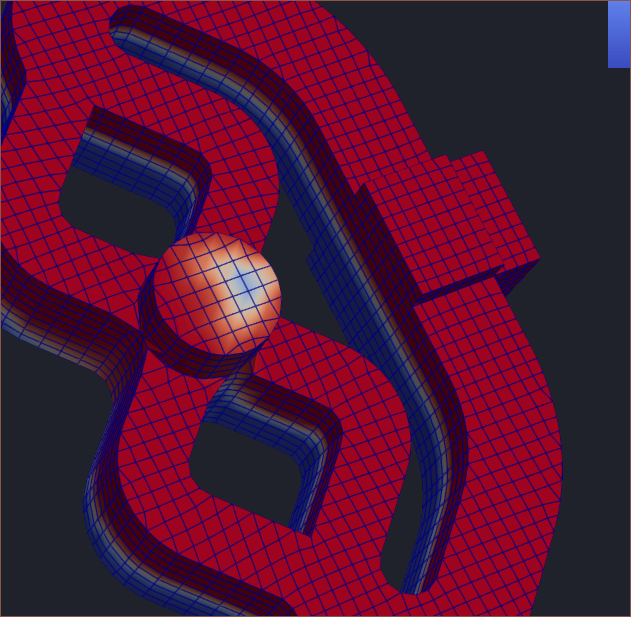

Middle: White around magenta

Bottom: Yellow around magenta

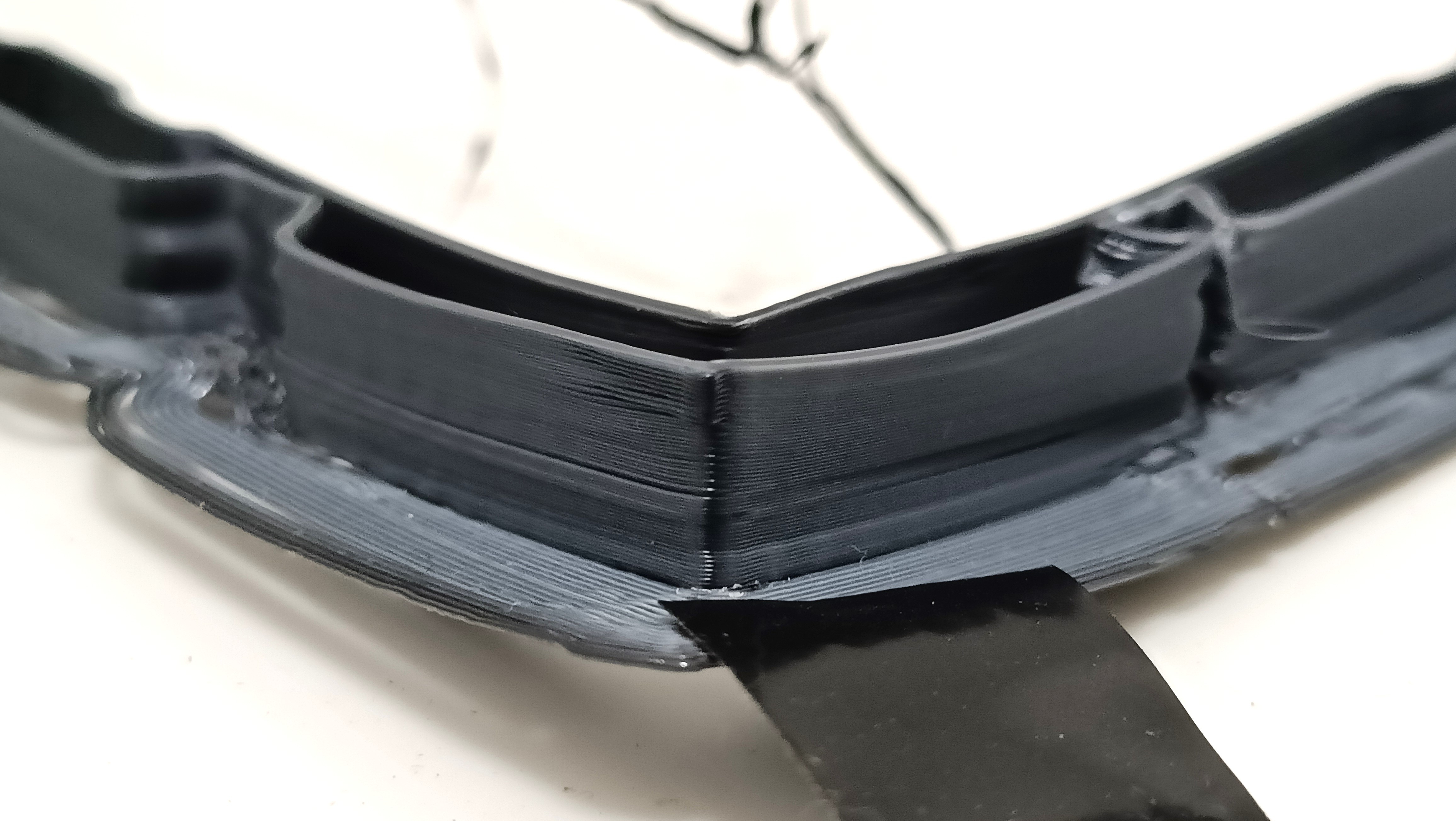

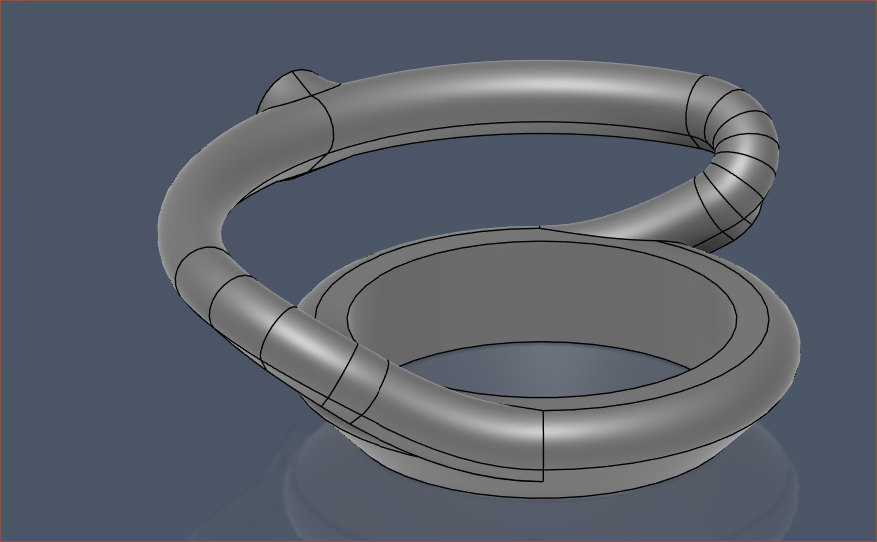

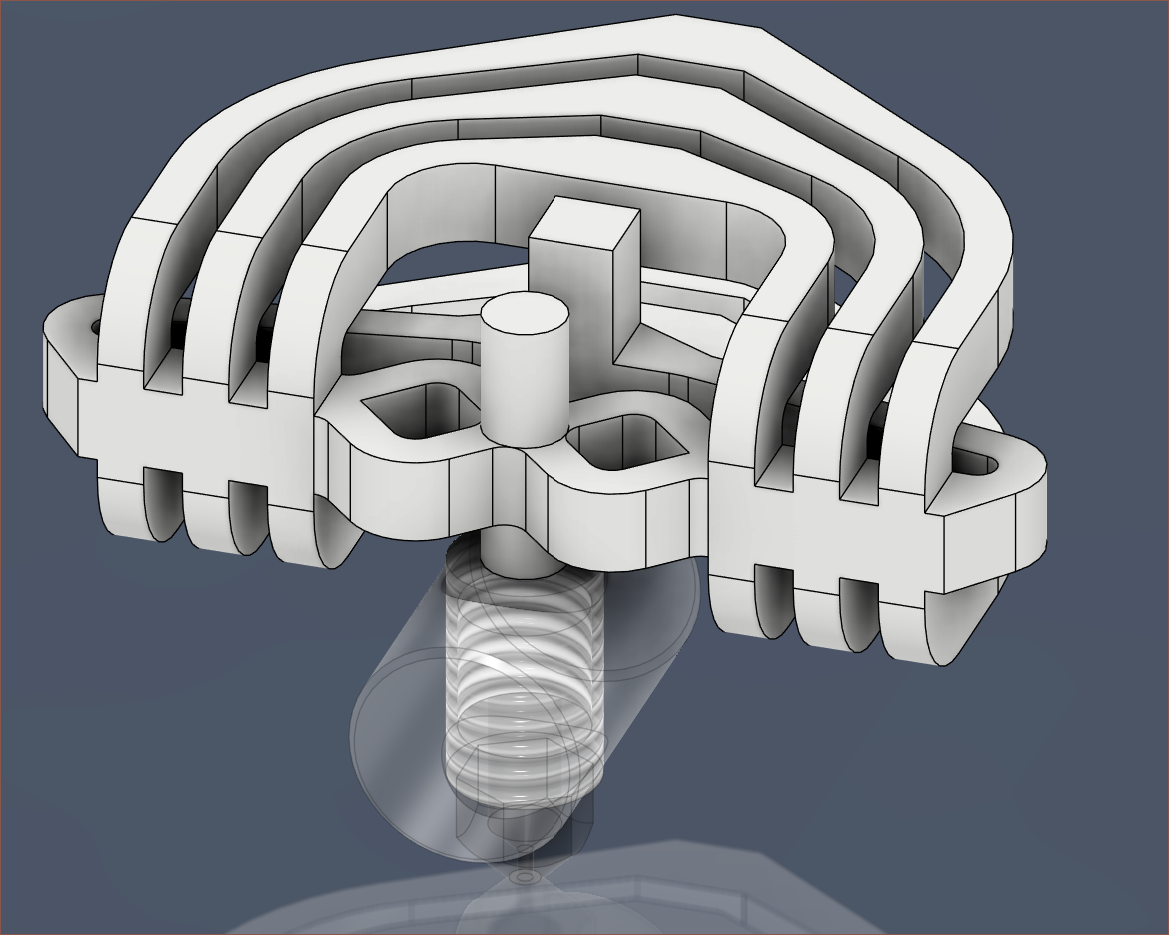

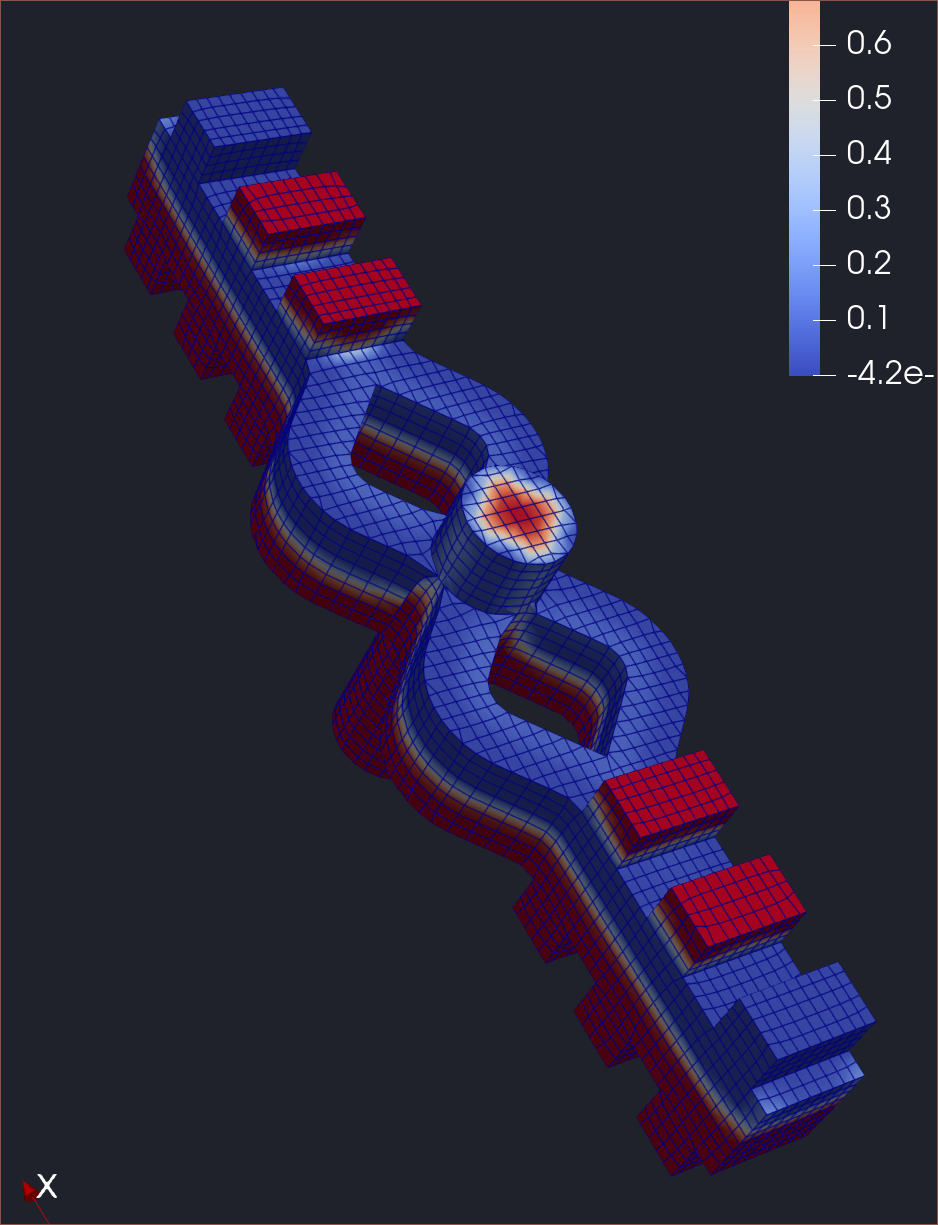

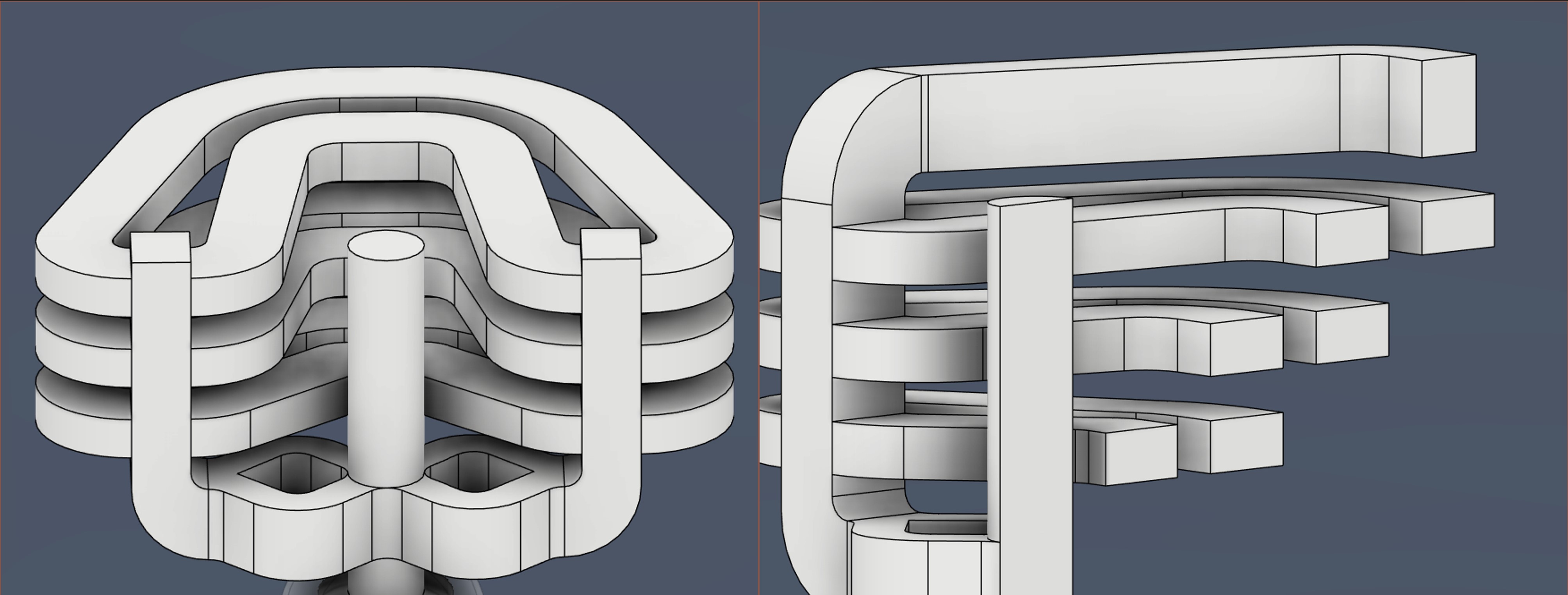

Coaxial8or R0

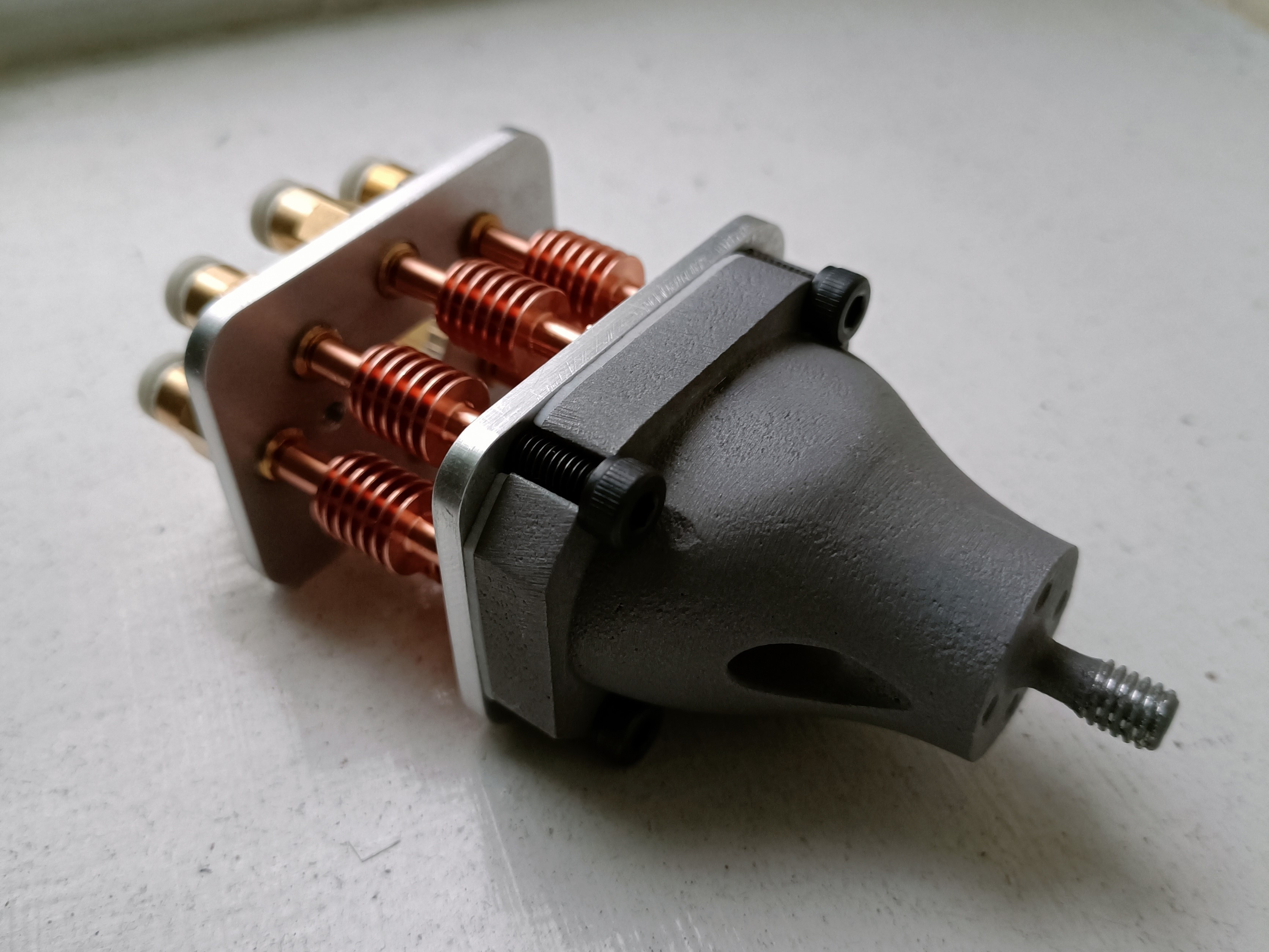

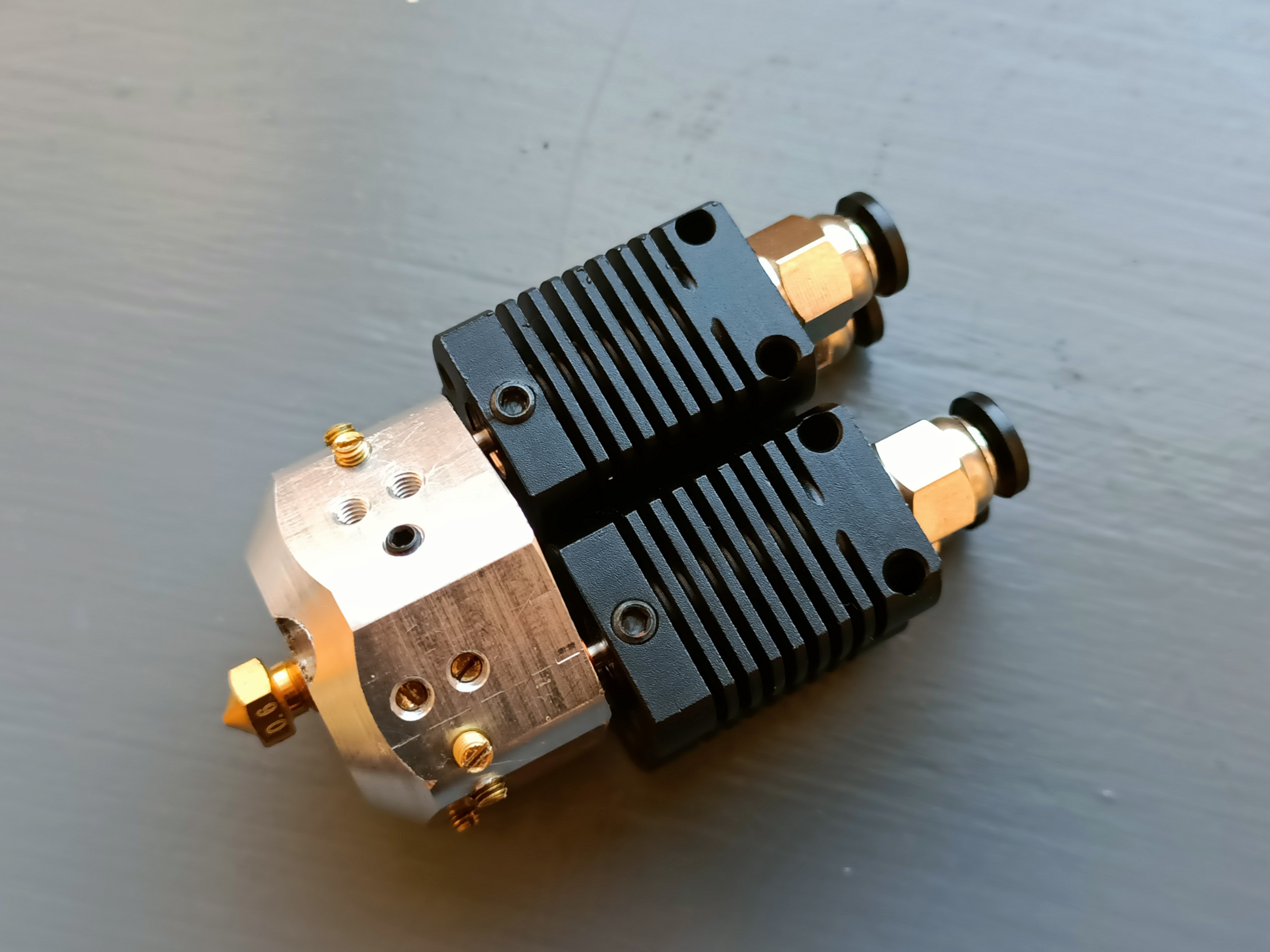

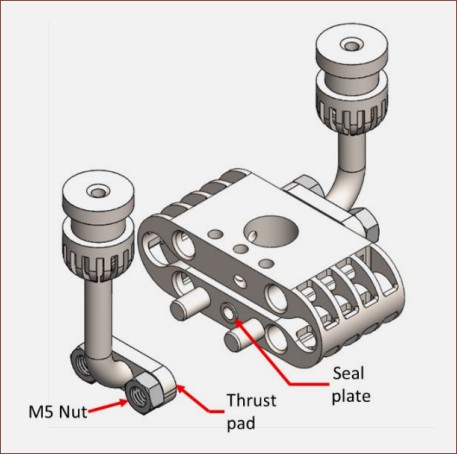

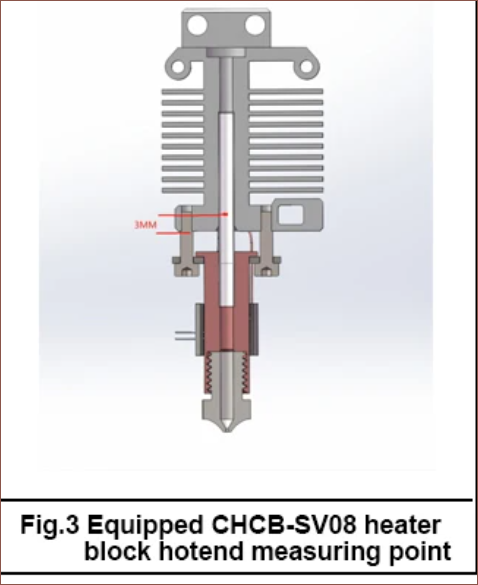

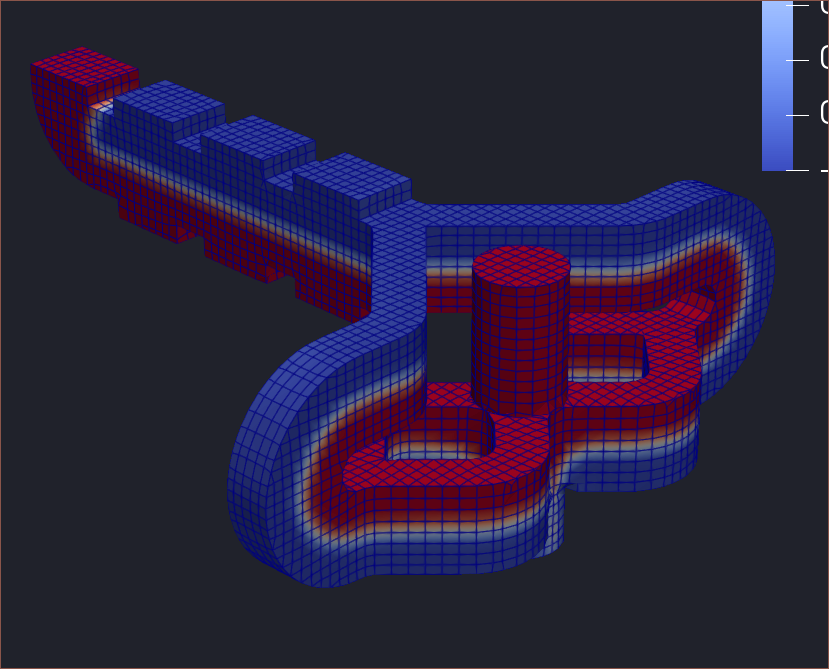

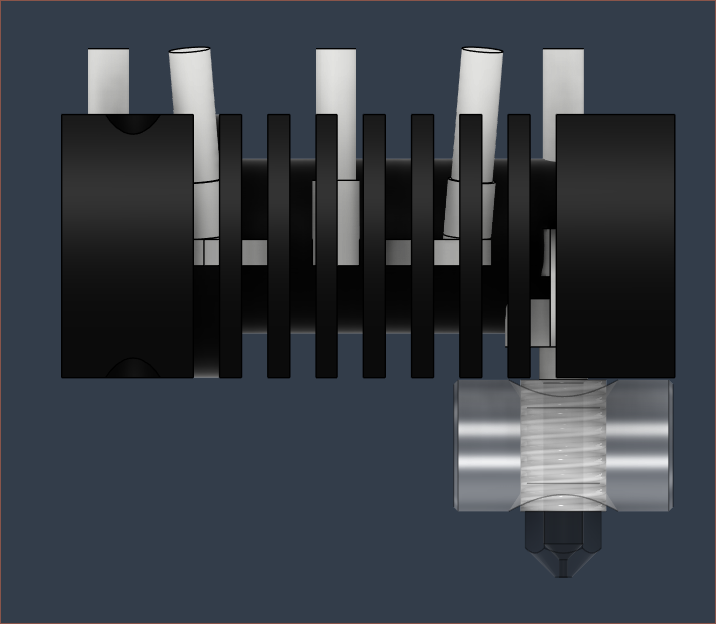

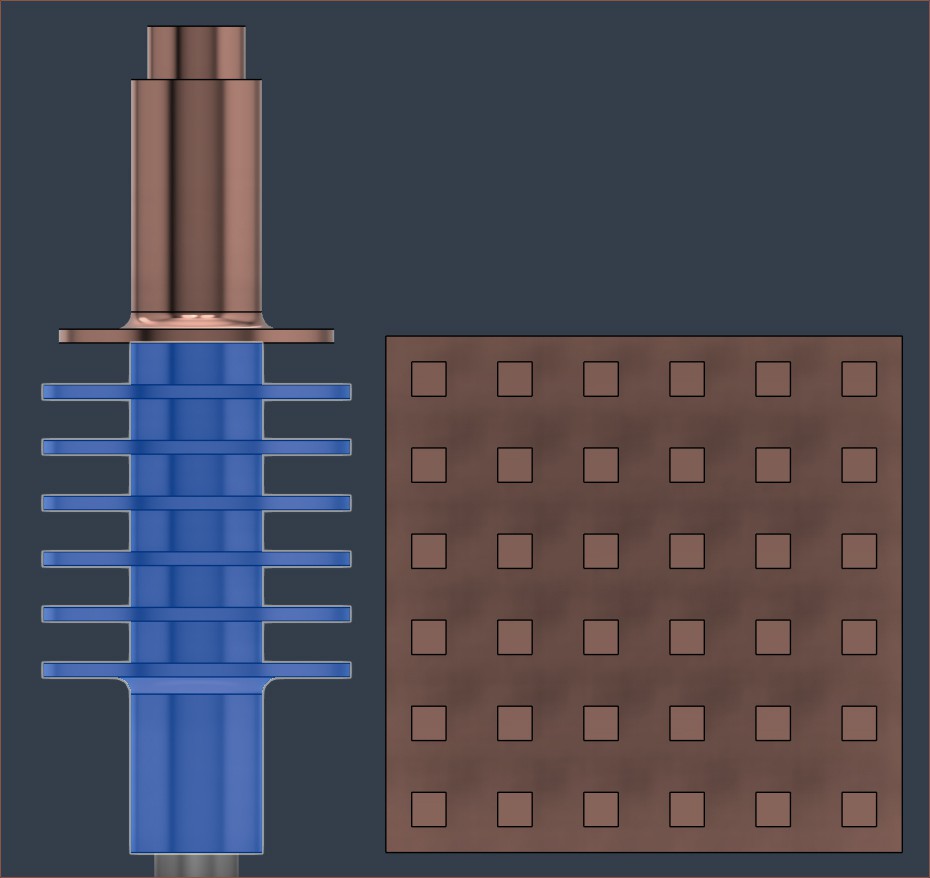

4-in-1-out Coaxial Hotend

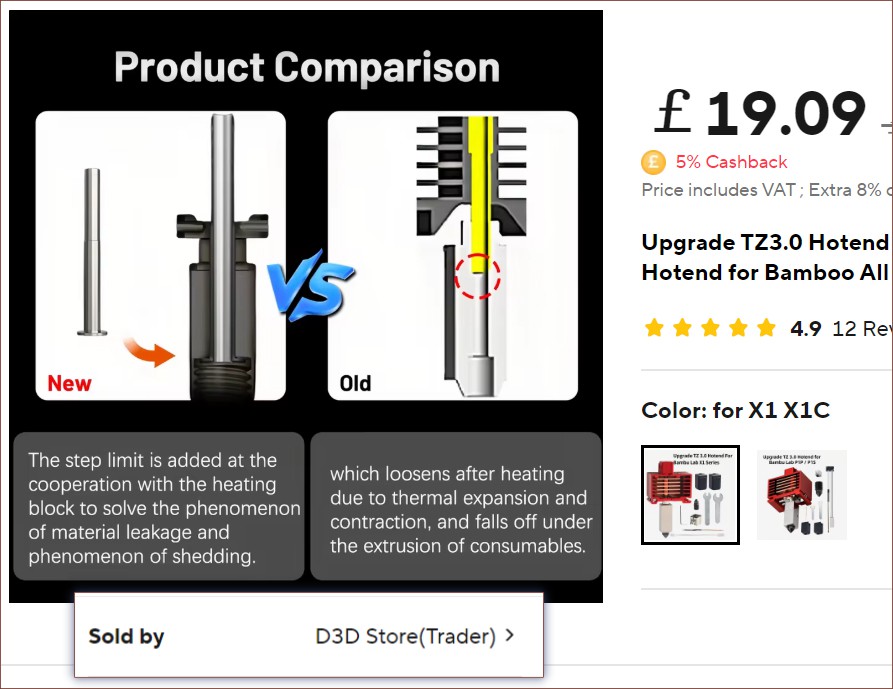

Inspiration and/or examples of working principle

Navigation

The title tag system is explained here, and the table is updated when a change occurs. Notable logs have bold L# text.

Read more » kelvinA

kelvinA

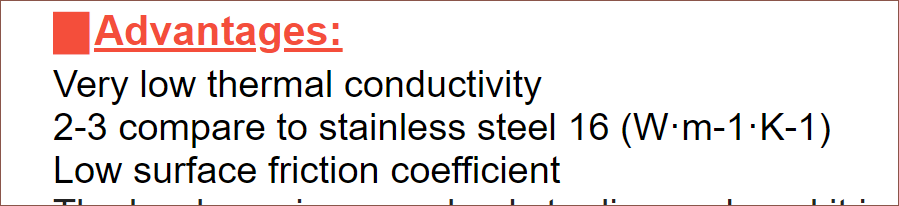

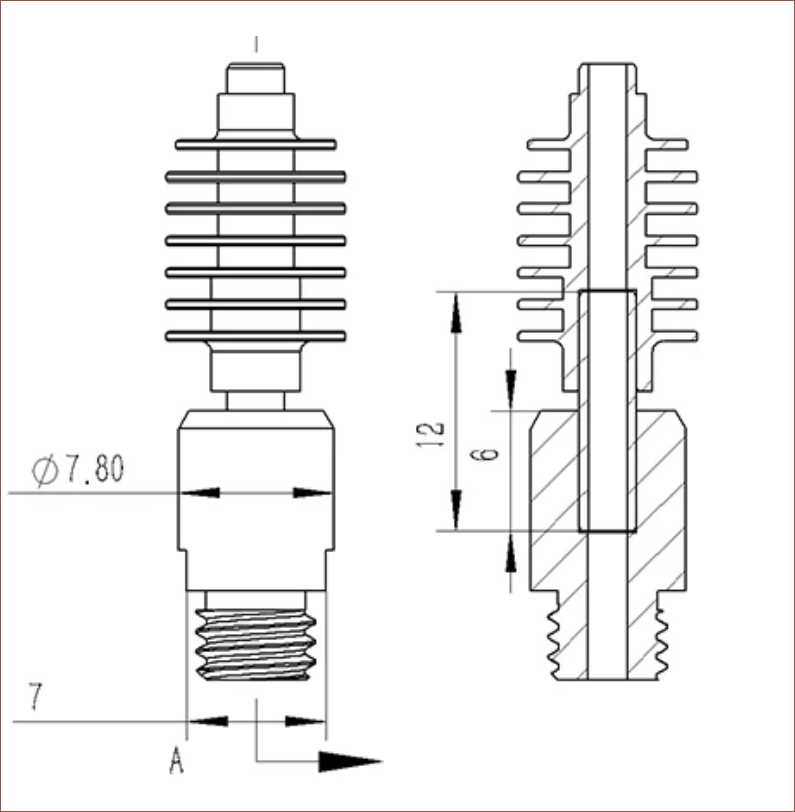

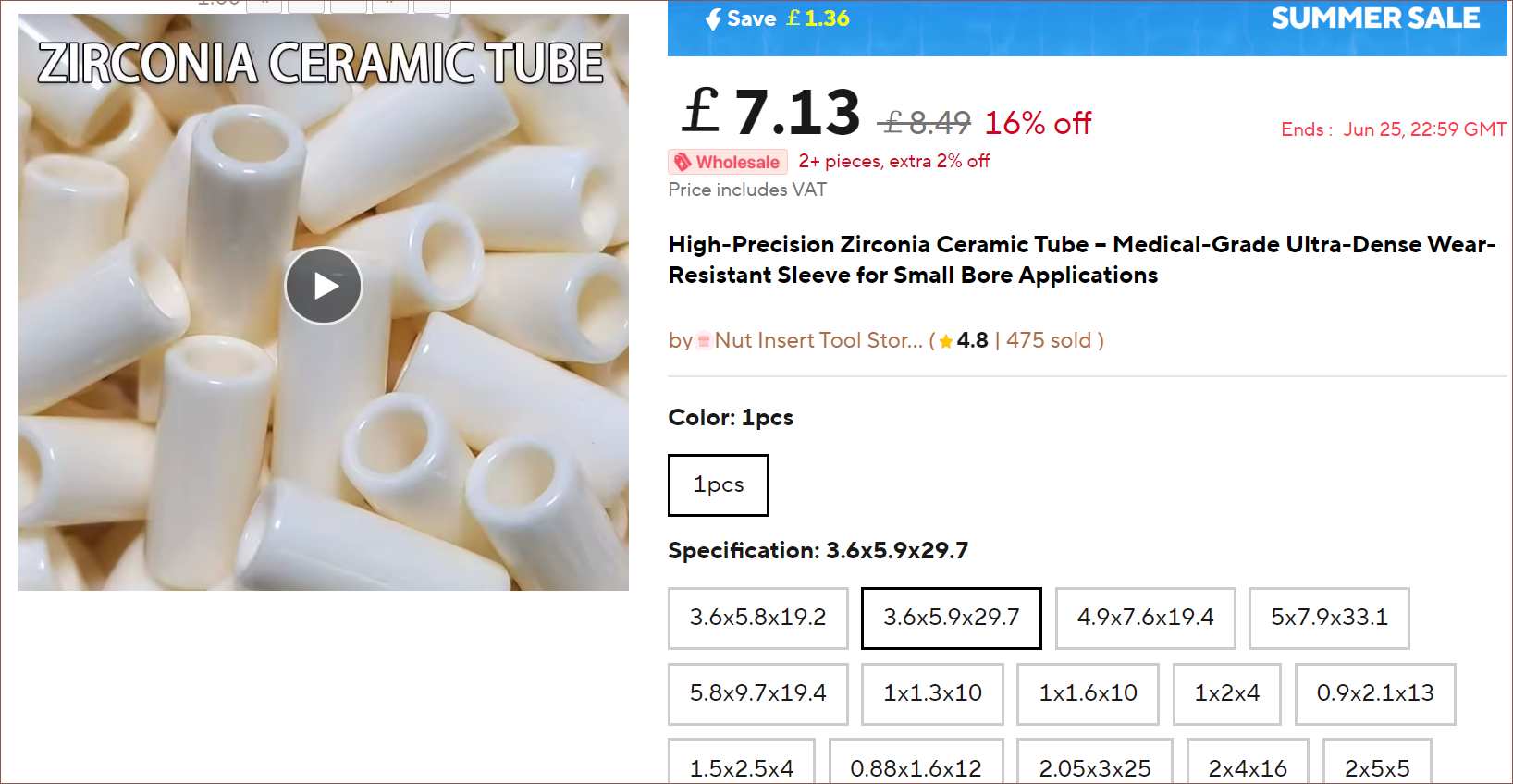

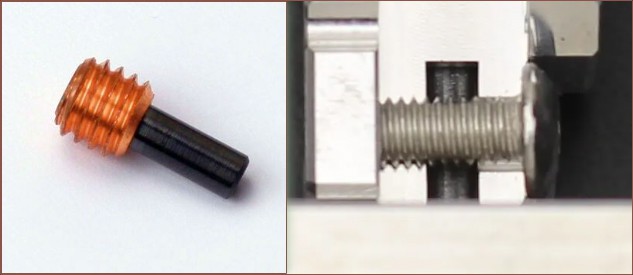

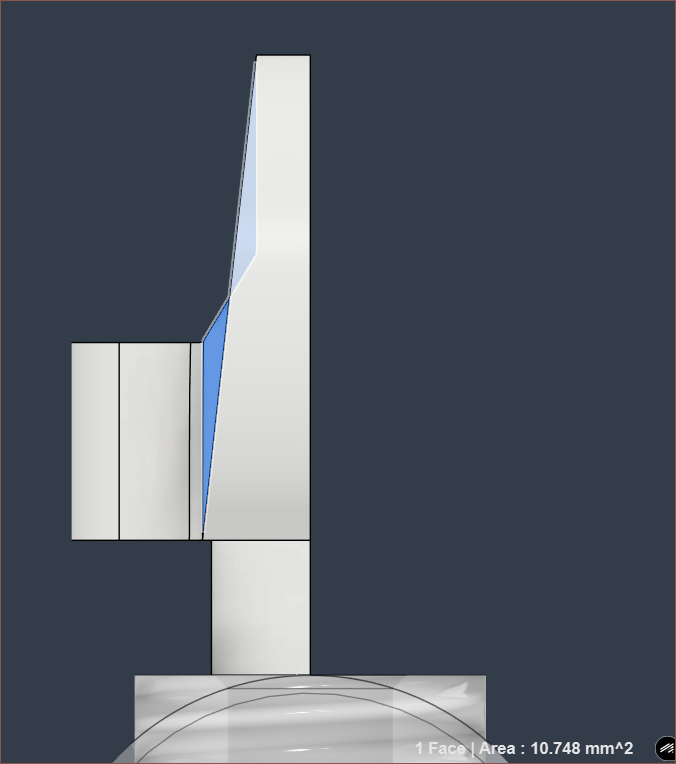

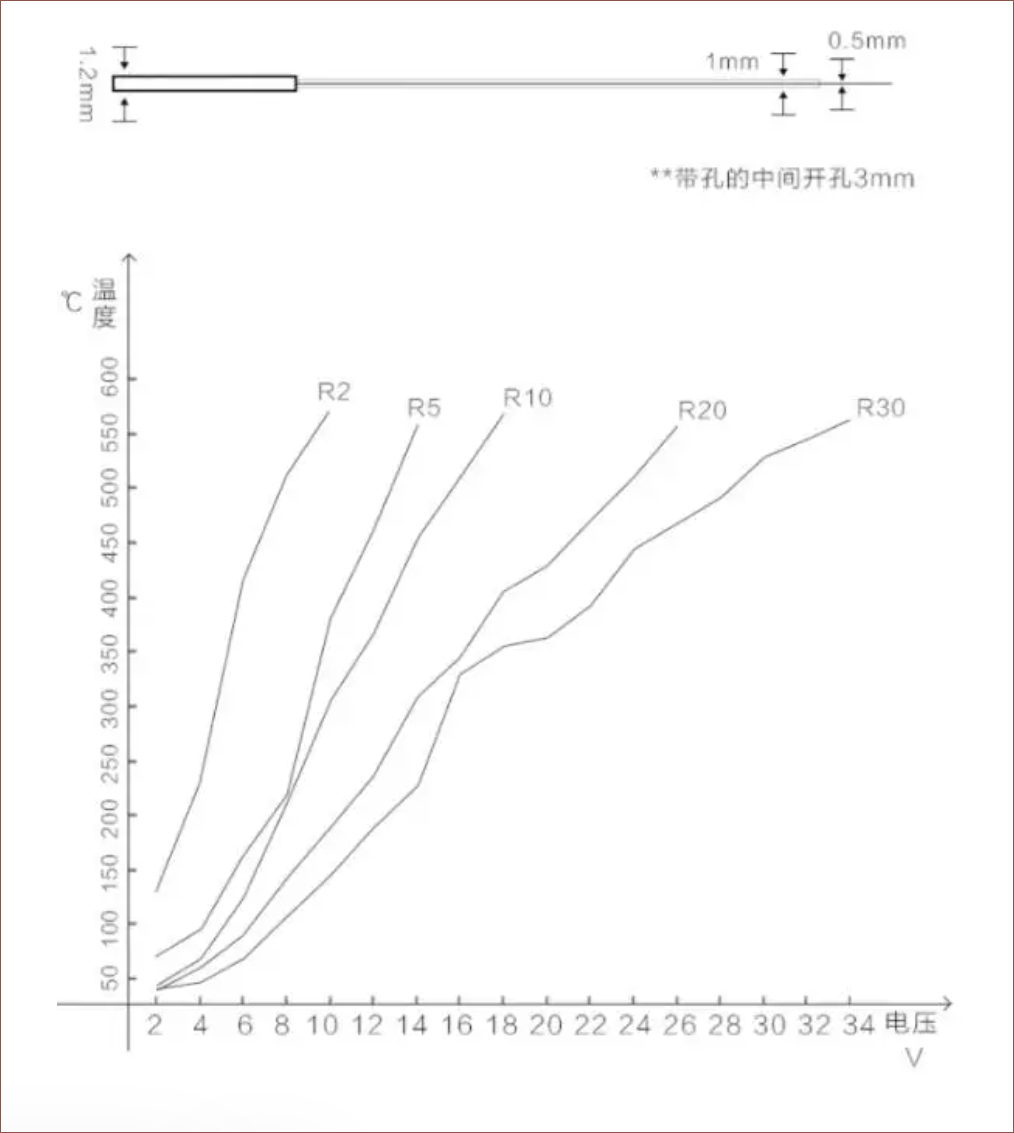

Currently, I've modelled 1.8mm ID 2.8mm OD tubes to try and balance powder removal, ease of drilling and lack of heat conduction.

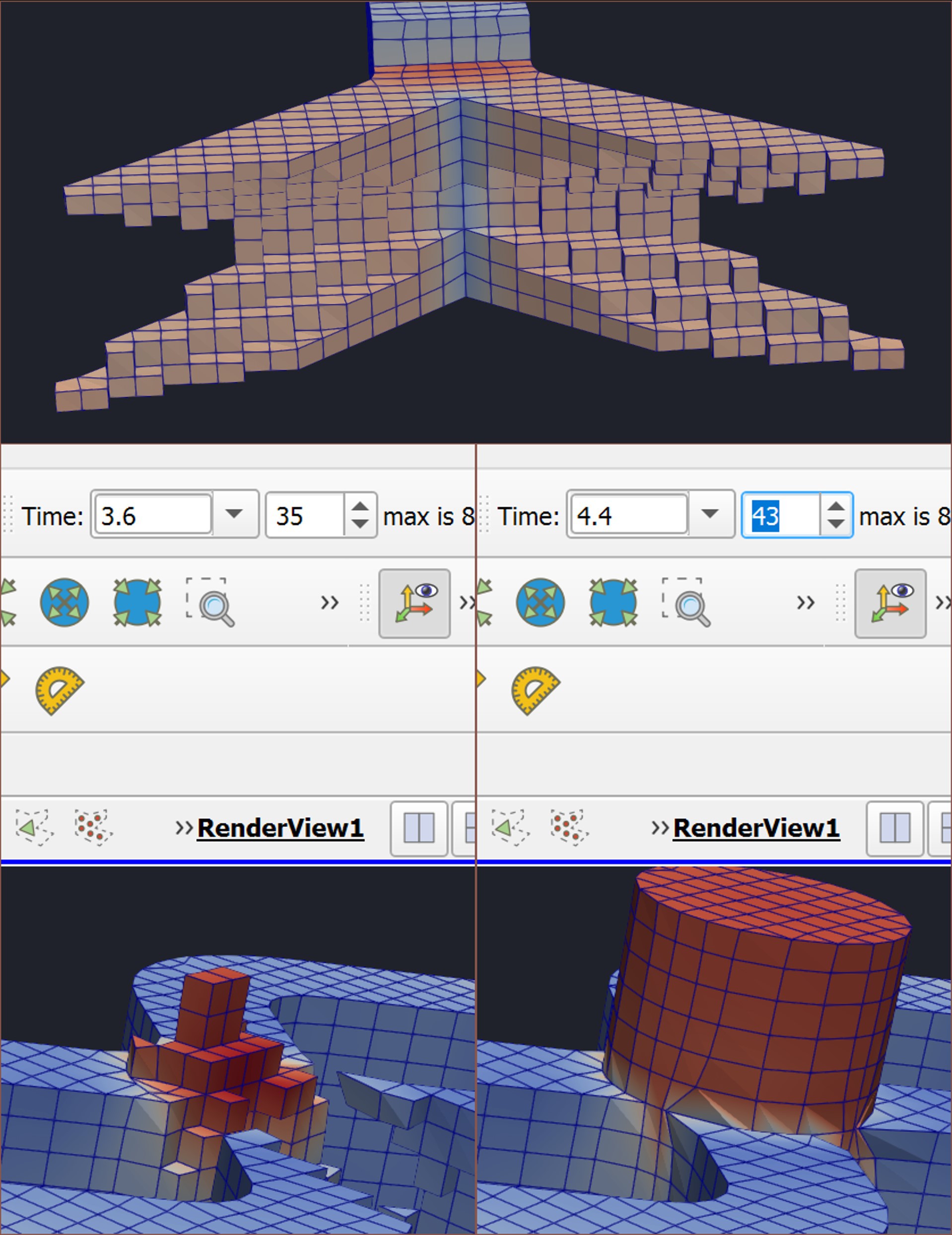

Currently, I've modelled 1.8mm ID 2.8mm OD tubes to try and balance powder removal, ease of drilling and lack of heat conduction. I'm not sure how far I'll get before all the additional manufacturing complexity nudges me over the edge to essentially say "Well, it was a good run, but that

I'm not sure how far I'll get before all the additional manufacturing complexity nudges me over the edge to essentially say "Well, it was a good run, but that

MasterOfNull

MasterOfNull

Tim Wilkinson

Tim Wilkinson

P

P

I have been following this project for months, and it's my go to morning reading when I clock into work, haha